ASTM D7460-10

(Test Method)Standard Test Method for Determining Fatigue Failure of Compacted Asphalt Concrete Subjected to Repeated Flexural Bending (Withdrawn 2019)

Standard Test Method for Determining Fatigue Failure of Compacted Asphalt Concrete Subjected to Repeated Flexural Bending (Withdrawn 2019)

SIGNIFICANCE AND USE

The laboratory fatigue life determined by this standard for beam specimens have been used to estimate the fatigue life of asphalt concrete pavement layers under repeated traffic loading. Although the field performance of asphalt concrete is impacted by many factors (traffic variation, speed, and wander; climate variation; rest periods between loads; aging; etc.), it has been more accurately predicted when laboratory properties are known along with an estimate of the strain level induced at the layer depth by the traffic wheel load traveling over the pavement.

Note 1—The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely assure reliable results. Reliable results depend on many factors; following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 This test method provides procedures for determining a unique failure point for estimating the fatigue life of 380 mm (14.96 in.) long by 50 mm (1.97 in.) thick by 63 mm (2.48 in.) wide asphalt concrete beam specimens sawed from laboratory or field compacted asphalt concrete, which are subjected to repeated flexural bending.

1.2 The between-laboratory reproducibility of this test method is being determined and will be available on or before June 2013. Therefore, this test method should not be used for acceptance or rejection of a material for purchasing purposes.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 Units—The values stated in SI units are to be regarded as standard. Other units of measurement included in this standard are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method provided procedures for determining a unique failure point for estimating the fatigue life of 380 mm (14.96 in.) long by 50 mm (1.97 in.) thick by 63 mm (2.48 in.) wide asphalt concrete beam specimens sawed from laboratory or field compacted asphalt concrete, which are subjected to repeated flexural bending.

Formerly under the jurisdiction of Committee D04 on Road and Paving Materials, this test method was withdrawn in June 2019 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7460 − 10

Standard Test Method for

Determining Fatigue Failure of Compacted Asphalt Concrete

1

Subjected to Repeated Flexural Bending

This standard is issued under the fixed designation D7460; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3203Test Method for Percent Air Voids in Compacted

Dense and Open Bituminous Paving Mixtures

1.1 This test method provides procedures for determining a

D3549Test Method for Thickness or Height of Compacted

unique failure point for estimating the fatigue life of 380 mm

Bituminous Paving Mixture Specimens

(14.96 in.) long by 50 mm (1.97 in.) thick by 63 mm (2.48 in.)

D3666Specification for Minimum Requirements for Agen-

wide asphalt concrete beam specimens sawed from laboratory

cies Testing and Inspecting Road and Paving Materials

or field compacted asphalt concrete, which are subjected to

D5361Practice for Sampling Compacted Bituminous Mix-

repeated flexural bending.

tures for Laboratory Testing

1.2 The between-laboratory reproducibility of this test

E29Practice for Using Significant Digits in Test Data to

method is being determined and will be available on or before

Determine Conformance with Specifications

June 2013. Therefore, this test method should not be used for 3

2.2 AASHTO Standards:

acceptance or rejection of a material for purchasing purposes.

T 321Standard Method of Test for Determining the Fatigue

1.3 The text of this standard references notes and footnotes Life of Compacted Hot-MixAsphalt (HMA) Subjected to

Repeated Flexural Bending

which provide explanatory material.These notes and footnotes

(excluding those in tables and figures) shall not be considered PP 3Preparing Hot-Mix Asphalt (HMA) Specimens by

Means of the Rolling Wheel Compactor

as requirements of the standard.

R30StandardPracticeforMixtureConditioningofHot-Mix

1.4 Units—The values stated in SI units are to be regarded

Asphalt (HMA)

as standard. Other units of measurement included in this

standard are for information only.

3. Terminology

1.5 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 beam modulus—Flexural Beam Stiffness, as deter-

responsibility of the user of this standard to establish appro-

mined in 10.1.3.

priate safety and health practices and determine the applica-

3.1.2 failure point—the number of cycles to failure, N,

f

bility of regulatory limitations prior to use.

which corresponds to the maximum or peak Normalized

Modulus × Cycles (Fig. 13) when plotted versus Number of

2. Referenced Documents

Cycles.

2

2.1 ASTM Standards:

3.1.3 initial beam modulus—Flexural Beam Stiffness deter-

D75Practice for Sampling Aggregates

mined at approximately 50 load cycles.

D140Practice for Sampling Bituminous Materials

3.1.4 normalized modulus × cycles—see Rowe and Bouldin

D979Practice for Sampling Bituminous Paving Mixtures

4

(1):

D2041Test Method for Theoretical Maximum Specific

Gravity and Density of Bituminous Paving Mixtures

BeamStiffness 3CycleNumber

~ !

~InitialBeamModulus 3CycleofInitialBeamModulus!

4. Summary of Test Method

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.26 on

4.1 The four-point flexural bending test method is con-

Fundamental/Mechanistic Tests.

ducted on compacted beam specimens to evaluate the fatigue

CurrenteditionapprovedJune1,2010.PublishedJuly2010.Originallyapproved

in 2008. Last previous edition approved in 2008 as D7640–08. DOI: 10.1520/

3

D7460-10. Available from American Association of State Highway and Transportation

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM http://www.transportation.org.

4

Standards volume information, refer to the standard’s Document Summary page on Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7460 − 10

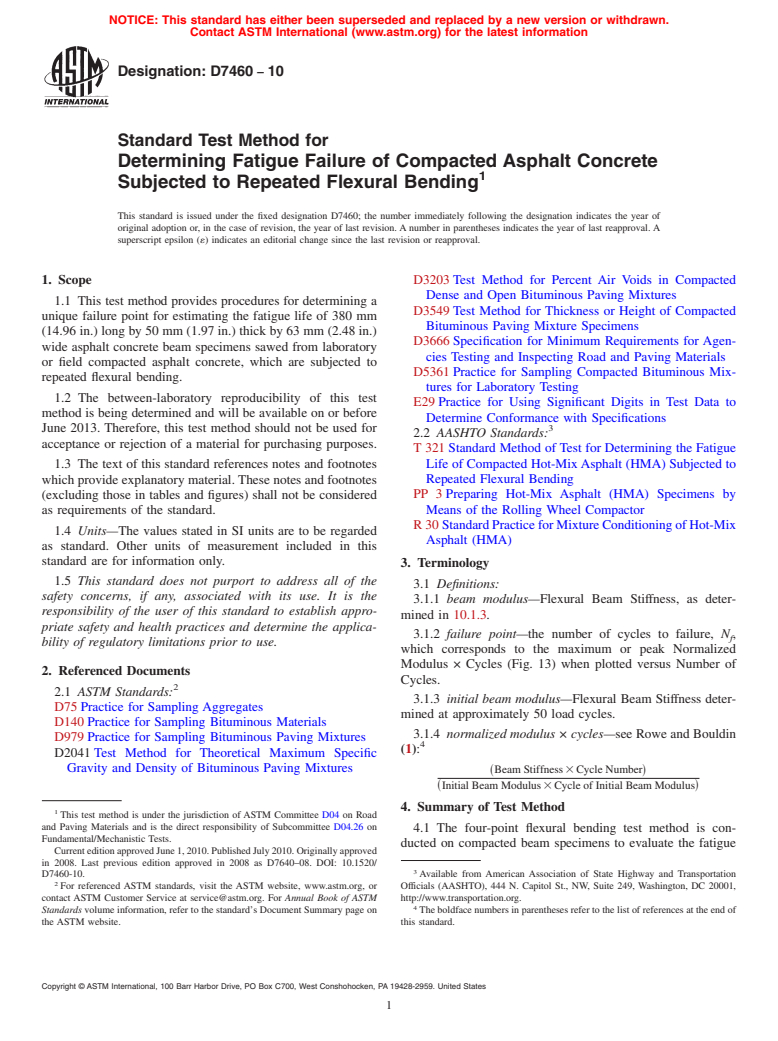

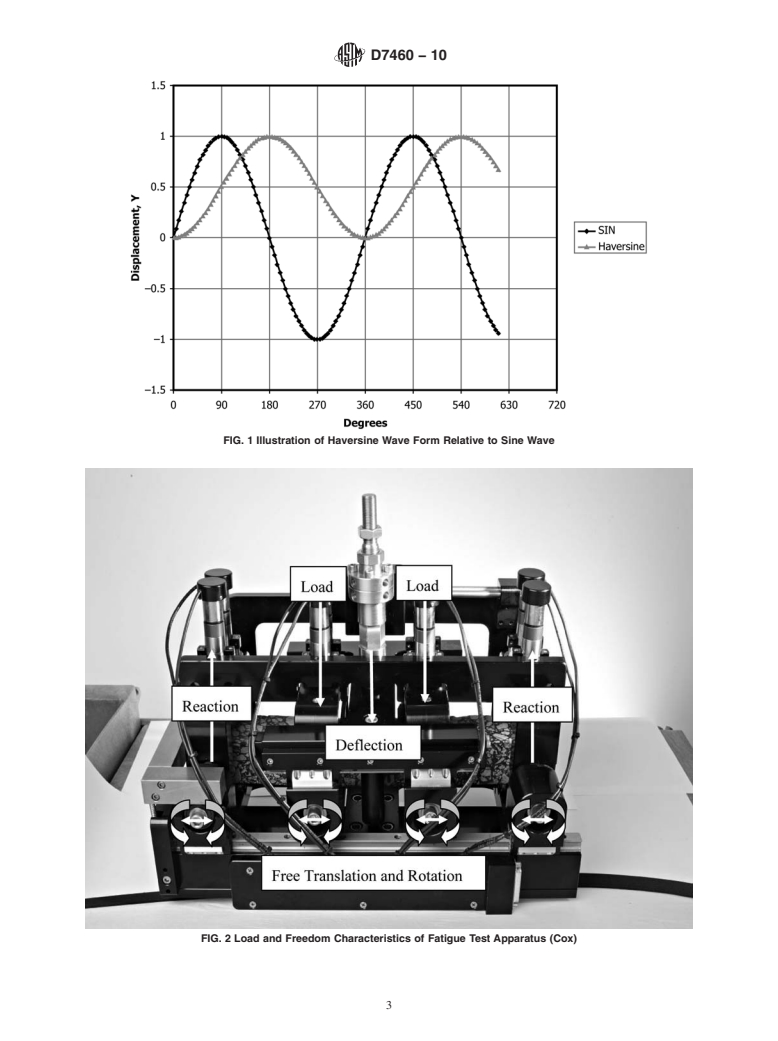

properties of an asphalt concrete mixture. A cyclic haversine Table1.Thisstandardspecificallydescribesthesystemsoftwo

(displaced sine wave with full amplitude on tension side of primary suppliers (Cox and Sons, Inc. [Cox] and Industrial

zero) displacement is applied at the central H-frame third Process Controls, Ltd. [IPC]); however,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.