ASTM C957/C957M-17

(Specification)Standard Specification for High-Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane With Integral Wearing Surface

Standard Specification for High-Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane With Integral Wearing Surface

ABSTRACT

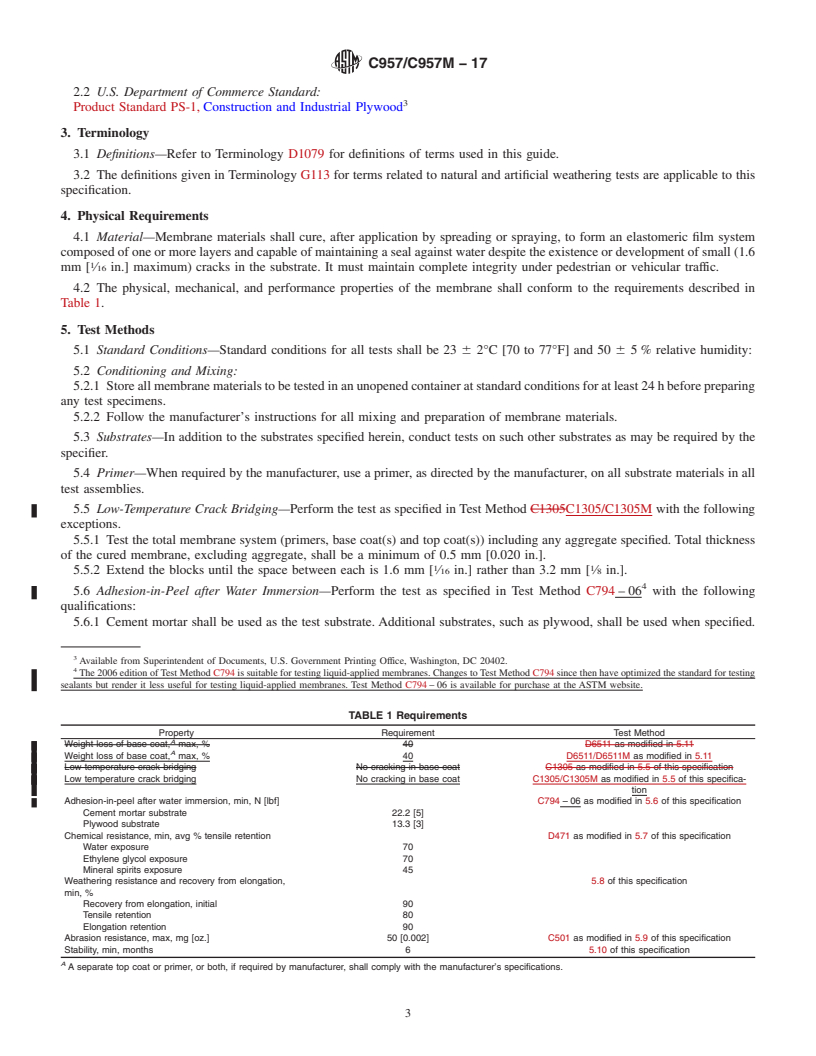

This specification describes the required properties and test methods for high-solids content, cold liquid-applied elastomeric membrane with integral wearing surface for waterproofing building decks not subject to hydrostatic pressure. This specification does not include specific requirements for skid resistance or fire retardance, although both may be important in specific uses. The properties to which the materials will be tested upon for conformance are as follows: weight loss of base coat; low temperature crack bridging; adhesion-in-peel to cement mortar and plywood substrates after water immersion; chemical resistance after water, ethylene glycol, and mineral spirits exposure; weathering resistance, recovery from elongation, tensile retention, and elongation retention; abrasion resistance; and stability.

SCOPE

1.1 This specification describes the required properties and test methods for a cold liquid-applied elastomeric membrane for waterproofing building decks not subject to hydrostatic pressure. The specification applies only to a membrane system that has an integral wearing surface. This specification does not include specific requirements for skid resistance or fire retardance, although both may be important in specific uses.

1.2 The type of membrane system described in this specification is used for pedestrian and vehicular traffic and in high-abrasion applications. The membrane may be single- or multi-component, and may consist of one or more coats (for example base coat, top coat, etc.). The coat(s) may be built to the desired thickness in one or more applications. One coat (base coat) provides the primary waterproofing function and normally comprises the major amount of organic material in the membrane. The function of the top coat(s) is to resist wear and weather. Aggregate may be used as a component of the membrane system, as all or part of a course, to increase wear and skid resistance.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.4 Test methods in this specification require a minimum 0.5-mm [0.020-in.] base coat dry film thickness. Actual thickness required for a particular application and the use of aggregate in topcoats shall be established by the membrane manufacturer.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 The following safety hazards caveat pertains only to the test method portion, Section 5, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C957/C957M −17

Standard Specification for

High-Solids Content, Cold Liquid-Applied Elastomeric

1

Waterproofing Membrane With Integral Wearing Surface

This standard is issued under the fixed designation C957/C957M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The following safety hazards caveat pertains only to the

test method portion, Section 5, of this specification: This

1.1 This specification describes the required properties and

standard does not purport to address all of the safety problems,

test methods for a cold liquid-applied elastomeric membrane

if any, associated with its use. It is the responsibility of the user

for waterproofing building decks not subject to hydrostatic

of this standard to establish appropriate safety, health, and

pressure. The specification applies only to a membrane system

environmental practices and determine the applicability of

thathasanintegralwearingsurface.Thisspecificationdoesnot

regulatory limitations prior to use.

include specific requirements for skid resistance or fire

1.7 This international standard was developed in accor-

retardance, although both may be important in specific uses.

dance with internationally recognized principles on standard-

1.2 The type of membrane system described in this speci-

ization established in the Decision on Principles for the

fication is used for pedestrian and vehicular traffic and in

Development of International Standards, Guides and Recom-

high-abrasion applications. The membrane may be single- or

mendations issued by the World Trade Organization Technical

multi-component, and may consist of one or more coats (for

Barriers to Trade (TBT) Committee.

example base coat, top coat, etc.). The coat(s) may be built to

the desired thickness in one or more applications. One coat

2. Referenced Documents

(base coat) provides the primary waterproofing function and

2

2.1 ASTM Standards:

normally comprises the major amount of organic material in

C501 Test Method for Relative Resistance to Wear of

the membrane. The function of the top coat(s) is to resist wear

Unglazed Ceramic Tile by the Taber Abraser

and weather. Aggregate may be used as a component of the

C794 – 06 Test Method forAdhesion-in-Peel of Elastomeric

membrane system, as all or part of a course, to increase wear

Joint Sealants

and skid resistance.

C1305/C1305M Test Method for Crack Bridging Ability of

1.3 Thecommitteewithjurisdictionoverthisstandardisnot

Liquid-Applied Waterproofing Membrane

aware of any comparable standards published by other orga-

C1442 Practice for Conducting Tests on Sealants Using

nizations.

Artificial Weathering Apparatus

D412 Test Methods forVulcanized Rubber andThermoplas-

1.4 Test methods in this specification require a minimum

0.5-mm [0.020-in.] base coat dry film thickness. Actual thick- tic Elastomers—Tension

D471 Test Method for Rubber Property—Effect of Liquids

ness required for a particular application and the use of

aggregate in topcoats shall be established by the membrane D609 Practice for Preparation of Cold-Rolled Steel Panels

for Testing Paint, Varnish, Conversion Coatings, and

manufacturer.

Related Coating Products

1.5 The values stated in either SI units or inch-pound units

D1079 Terminology Relating to Roofing and Waterproofing

are to be regarded separately as standard. The values stated in

D1133 Test Method for Kauri-Butanol Value of Hydrocar-

each system may not be exact equivalents; therefore, each

bon Solvents

system shall be used independently of the other. Combining

D2370 Test Method for Tensile Properties of Organic Coat-

values from the two systems may result in non-conformance

ings

with the standard.

D6511/D6511M Test Methods for Solvent Bearing Bitumi-

nous Compounds

1

This specification is under the jurisdiction of ASTM Committee D08 on

Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.25

on Liquid Applied Polymeric Materials Used for Roofing and Waterproofing

2

Membranes that are Directly Exposed to the Weather. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2017. Published October 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1981. Last previous edition approved in 2015 as C957/C957M – 15. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C0957_C0957M-17. the ASTM website.

Copyr

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C957/C957M − 15 C957/C957M − 17

Standard Specification for

High-Solids Content, Cold Liquid-Applied Elastomeric

1

Waterproofing Membrane With Integral Wearing Surface

This standard is issued under the fixed designation C957/C957M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification describes the required properties and test methods for a cold liquid-applied elastomeric membrane for

waterproofing building decks not subject to hydrostatic pressure. The specification applies only to a membrane system that has an

integral wearing surface. This specification does not include specific requirements for skid resistance or fire retardance, although

both may be important in specific uses.

1.2 The type of membrane system described in this specification is used for pedestrian and vehicular traffic and in high-abrasion

applications. The membrane may be single- or multi-component, and may consist of one or more coats (for example base coat,

top coat, etc.). The coat(s) may be built to the desired thickness in one or more applications. One coat (base coat) provides the

primary waterproofing function and normally comprises the major amount of organic material in the membrane. The function of

the top coat(s) is to resist wear and weather. Aggregate may be used as a component of the membrane system, as all or part of a

course, to increase wear and skid resistance.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other

organizations.

1.4 Test methods in this specification require a minimum 0.5-mm [0.020-in.] base coat dry film thickness. Actual thickness

required for a particular application and the use of aggregate in topcoats shall be established by the membrane manufacturer.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.6 The following safety hazards caveat pertains only to the test method portion, Section 5, of this specification:This standard

does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of

regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C501 Test Method for Relative Resistance to Wear of Unglazed Ceramic Tile by the Taber Abraser

C794C794 – 06 Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants

C1305C1305/C1305M Test Method for Crack Bridging Ability of Liquid-Applied Waterproofing Membrane

C1442 Practice for Conducting Tests on Sealants Using Artificial Weathering Apparatus

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D471 Test Method for Rubber Property—Effect of Liquids

1

This specification is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.25 on Liquid

Applied Polymeric Materials Used for Roofing and Waterproofing Membranes that are Directly Exposed to the Weather.

Current edition approved Jan. 1, 2015Oct. 1, 2017. Published January 2015October 2017. Originally approved in 1981. Last previous edition approved in 20142015 as

C957/C957M – 14.C957/C957M – 15. DOI: 10.1520/C0957_C0957M-15.10.1520/C0957_C0957M-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 --------

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C957/C957M − 17

Standard Specification for

High-Solids Content, Cold Liquid-Applied Elastomeric

1

Waterproofing Membrane With Integral Wearing Surface

This standard is issued under the fixed designation C957/C957M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The following safety hazards caveat pertains only to the

test method portion, Section 5, of this specification: This

1.1 This specification describes the required properties and

standard does not purport to address all of the safety problems,

test methods for a cold liquid-applied elastomeric membrane

if any, associated with its use. It is the responsibility of the user

for waterproofing building decks not subject to hydrostatic

of this standard to establish appropriate safety, health, and

pressure. The specification applies only to a membrane system

environmental practices and determine the applicability of

that has an integral wearing surface. This specification does not

regulatory limitations prior to use.

include specific requirements for skid resistance or fire

1.7 This international standard was developed in accor-

retardance, although both may be important in specific uses.

dance with internationally recognized principles on standard-

1.2 The type of membrane system described in this speci-

ization established in the Decision on Principles for the

fication is used for pedestrian and vehicular traffic and in

Development of International Standards, Guides and Recom-

high-abrasion applications. The membrane may be single- or

mendations issued by the World Trade Organization Technical

multi-component, and may consist of one or more coats (for

Barriers to Trade (TBT) Committee.

example base coat, top coat, etc.). The coat(s) may be built to

the desired thickness in one or more applications. One coat

2. Referenced Documents

(base coat) provides the primary waterproofing function and

2

2.1 ASTM Standards:

normally comprises the major amount of organic material in

C501 Test Method for Relative Resistance to Wear of

the membrane. The function of the top coat(s) is to resist wear

Unglazed Ceramic Tile by the Taber Abraser

and weather. Aggregate may be used as a component of the

C794 – 06 Test Method for Adhesion-in-Peel of Elastomeric

membrane system, as all or part of a course, to increase wear

Joint Sealants

and skid resistance.

C1305/C1305M Test Method for Crack Bridging Ability of

1.3 The committee with jurisdiction over this standard is not

Liquid-Applied Waterproofing Membrane

aware of any comparable standards published by other orga-

C1442 Practice for Conducting Tests on Sealants Using

nizations.

Artificial Weathering Apparatus

1.4 Test methods in this specification require a minimum D412 Test Methods for Vulcanized Rubber and Thermoplas-

tic Elastomers—Tension

0.5-mm [0.020-in.] base coat dry film thickness. Actual thick-

ness required for a particular application and the use of D471 Test Method for Rubber Property—Effect of Liquids

D609 Practice for Preparation of Cold-Rolled Steel Panels

aggregate in topcoats shall be established by the membrane

manufacturer. for Testing Paint, Varnish, Conversion Coatings, and

Related Coating Products

1.5 The values stated in either SI units or inch-pound units

D1079 Terminology Relating to Roofing and Waterproofing

are to be regarded separately as standard. The values stated in

D1133 Test Method for Kauri-Butanol Value of Hydrocar-

each system may not be exact equivalents; therefore, each

bon Solvents

system shall be used independently of the other. Combining

D2370 Test Method for Tensile Properties of Organic Coat-

values from the two systems may result in non-conformance

ings

with the standard.

D6511/D6511M Test Methods for Solvent Bearing Bitumi-

nous Compounds

1

This specification is under the jurisdiction of ASTM Committee D08 on

Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.25

on Liquid Applied Polymeric Materials Used for Roofing and Waterproofing

2

Membranes that are Directly Exposed to the Weather. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2017. Published October 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1981. Last previous edition approved in 2015 as C957/C957M – 15. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/C0957_C0957M-17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.