ASTM F3169-16

(Test Method)Standard Test Method for Leak Detection in Blister Packaging by Vacuum Deflection Method by Laser Measurement

Standard Test Method for Leak Detection in Blister Packaging by Vacuum Deflection Method by Laser Measurement

SIGNIFICANCE AND USE

5.1 Leaks in blister packs may affect product quality and such defects can arise from imperfections in the packaging material or bond between the sealed surfaces.

5.2 This method of leak testing is a useful tool as it allows non-destructive and non-subjective leak testing of blister packs. It allows the operator to evaluate how different packaging materials and packaging machine conditions affect the integrity of the packaging. It can also provide indication of unwanted changes in the packaging conditions.

5.3 This type of testing is typically used in pharmaceutical packaging production, during stability trials and for package research and development operations because of its non-destructive nature, cleanliness, and speed.

SCOPE

1.1 Test Packages—This test method can be applied to non-porous blister packs sealed with flexible films such as those used in pharmaceutical packaging. Such blister packs typically consist of thermoformed polymer or cold formed aluminum trays that contain a number of individual blister pockets into which tablets or capsules are placed. The trays are then sealed with a polymer, paper-backed or foil-based flexible laminate lidding material.

1.2 Leaks Detected—This test method detects leaks in blister packs by measuring the deflection of the blister pack surface in response to an applied vacuum. This deflection of the blister pack surface results from the difference in pressure between the gas inside the blister pack and the applied vacuum. Air loss from within a blister pocket as a result of a leak will alter this pressure differential causing a measureable variation in blister pocket deflection. This test method requires that the blister packs are held in appropriate tooling inside a suitable test chamber.

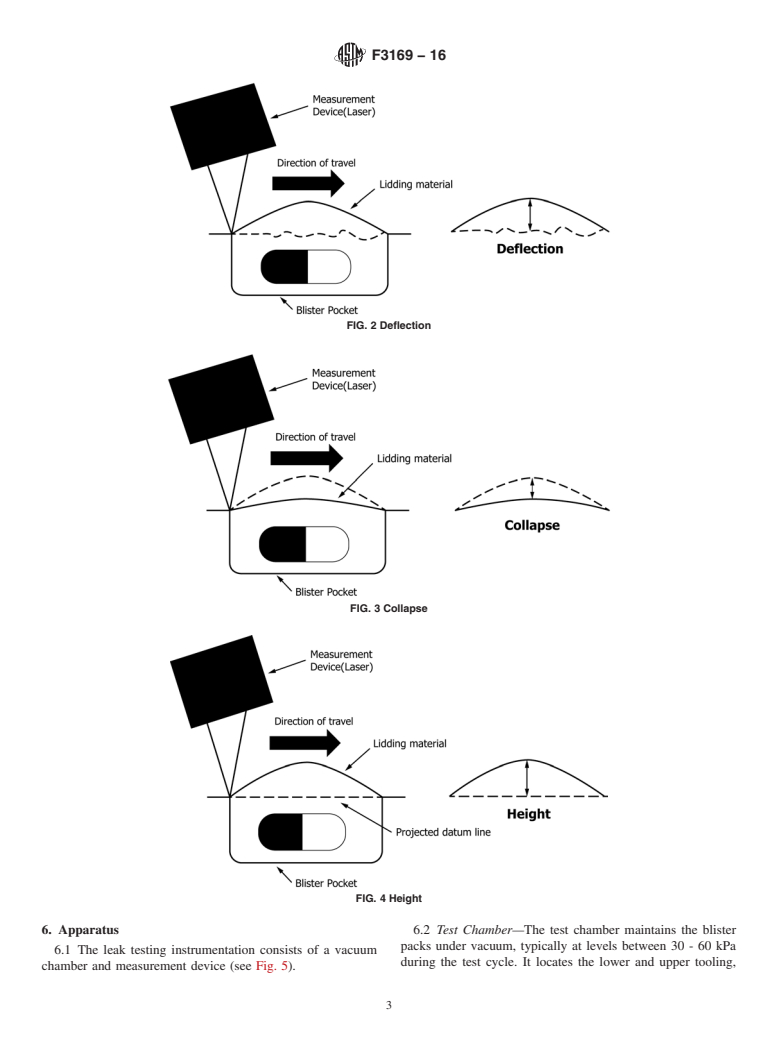

1.3 Test Results—Test results are reported qualitatively (pass/fail). Appropriate acceptance criteria for deflection, height, and collapse values are established by comparing non-leaking packs with those containing defects of a known size. Suitably sized defects in the laminate, tray material, and seal can be detected using this test method. The sensitivity of this test method depends upon a range of factors including blister pocket headspace, blister pocket size, lidding material type, lidding material thickness, lidding material tension, printing, surface texture, test conditions, and the values selected for the pass/fail acceptance criteria. The ability of the test to detect 15 µm, 50 µm, and catastrophic sized holes in four blister pack designs was demonstrated in a study.

1.4 The values stated in SI units are to be regarded as standard and no other units of measurement are included in this test method.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F3169 −16

Standard Test Method for

Leak Detection in Blister Packaging by Vacuum Deflection

1

Method by Laser Measurement

This standard is issued under the fixed designation F3169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 Test Packages—This test method can be applied to

responsibility of the user of this standard to establish appro-

non-porous blister packs sealed with flexible films such as

priate safety and health practices and determine the applica-

those used in pharmaceutical packaging. Such blister packs

bility of regulatory limitations prior to use.

typically consist of thermoformed polymer or cold formed

aluminum trays that contain a number of individual blister

2. Referenced Documents

pockets into which tablets or capsules are placed. The trays are

2

2.1 ASTM Standards:

then sealed with a polymer, paper-backed or foil-based flexible

D996 Terminology of Packaging and Distribution Environ-

laminate lidding material.

ments

1.2 Leaks Detected—This test method detects leaks in

F17 Terminology Relating to Flexible Barrier Packaging

blister packs by measuring the deflection of the blister pack

surfaceinresponsetoanappliedvacuum.Thisdeflectionofthe

3. Terminology

blister pack surface results from the difference in pressure

3.1 For definitions used in this test method, see Terminolo-

betweenthegasinsidetheblisterpackandtheappliedvacuum.

gies D996 and F17.

Air loss from within a blister pocket as a result of a leak will

3.2 Definitions of Terms Specific to This Standard:

alter this pressure differential causing a measureable variation

3.2.1 blister pack, n—forming material, encapsulated

in blister pocket deflection. This test method requires that the

product, and sealed lidding material.

blister packs are held in appropriate tooling inside a suitable

test chamber.

3.2.2 blister pocket, n—sealed cavity in the forming mate-

rial that contains product.

1.3 Test Results—Test results are reported qualitatively

(pass/fail). Appropriate acceptance criteria for deflection, 3.2.3 collapse, n—difference in height of the blister pocket

height, and collapse values are established by comparing

profile in one plane before and after the reduced vacuum has

non-leaking packs with those containing defects of a known been applied.

size. Suitably sized defects in the laminate, tray material, and

3.2.4 deflection, n—difference in height of the blister pocket

seal can be detected using this test method. The sensitivity of

profileinoneplanebeforeandaftertheinitialvacuumhasbeen

this test method depends upon a range of factors including

applied.

blister pocket headspace, blister pocket size, lidding material

3.2.5 height, n—difference in height of the blister pocket

type, lidding material thickness, lidding material tension,

profile in one plane after initial vacuum when compared

printing, surface texture, test conditions, and the values se-

against blister pack surface height.

lected for the pass/fail acceptance criteria. The ability of the

3.2.6 profile, n—surface of the lidding material measured at

testtodetect15µm,50µm,andcatastrophicsizedholesinfour

regular intervals across the blister pocket.

blister pack designs was demonstrated in a study.

1.4 The values stated in SI units are to be regarded as

4. Summary of Test Method

standard and no other units of measurement are included in this

4.1 The test blister packs are located in the test chamber in

test method.

appropriate tooling to prevent them from moving under

vacuum. The chamber is then sealed and the profile of every

1

This test method is under the jurisdiction ofASTM Committee F02 on Primary

2

Barrier Packaging and is the direct responsibility of Subcommittee F02.40 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Package Integrity. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 1, 2016. Published January 2017. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F3169-16 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3169−16

blister pocket is measured using an appropriate measurement by comparing the deflection an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.