ASTM A512-96(2005)

(Specification)Standard Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing

Standard Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing

SCOPE

1.1 This specification covers cold-drawn buttweld carbon steel tubes for use as mechanical tubing.

1.2 This specification covers round, square, rectangular, and special shape mechanical tubing.

1.3 Round tube size ranges covered are outside diameters up to 3 1/2 in. (88.9 mm) and wall thickness from 0.035 to 0.500 in. (0.89 to 12.70 mm).

1.4 Optional supplementary requirements are provided and, when desired, shall be so stated in the order.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: A 512 – 96 (Reapproved 2005)

Standard Specification for

Cold-Drawn Buttweld Carbon Steel Mechanical Tubing

This standard is issued under the fixed designation A512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 Quantity(feet,weight(Note1),ornumberoflengths),

1.1 This specification covers cold-drawn buttweld carbon

NOTE 1—The term “weight” is temporarily used in this specification

steel tubes for use as mechanical tubing. becauseofestablishedtradeusage.Thewordisusedtomeanboth“force”

and “mass,” and care must be taken to determine which is meant in each

1.2 Thisspecificationcoversround,square,rectangular,and

case (SI unit for force = newton and for mass = kilogram).

special shape mechanical tubing.

1.3 Roundtubesizerangescoveredareoutsidediametersup

3.1.2 Name of material (buttweld carbon steel mechanical

to 3 ⁄2 in. (88.9 mm) and wall thickness from 0.035 to 0.500

tubing),

in. (0.89 to 12.70 mm).

3.1.3 Form (round, square, rectangular, special shape),

1.4 Optional supplementary requirements are provided and,

3.1.4 Condition, description and code letters (Section 5),

when desired, shall be so stated in the order.

3.1.5 Grade, if required (Section 6),

1.5 Thevaluesstatedininch-poundunitsaretoberegarded

3.1.6 Dimensions (round, Section 9 or square and rectangu-

as standard. The values given in parentheses are mathematical

lar, Section 10),

conversions to SI units that are provided for information only

3.1.7 Length (round length, 9.2; square and rectangular

and are not considered standard.

length, 10.5),

3.1.8 Burr removal (Section 11),

2. Referenced Documents

3.1.9 Report of chemical analysis and products analysis, if

2.1 ASTM Standards:

required,

A370 TestMethodsandDefinitionsforMechanicalTesting

3.1.10 Individual supplementary requirements if required

of Steel Products

(S1 through S5),

E59 PracticeforSamplingSteelandIronforDetermination

3.1.11 Special requirements,

of Chemical Composition

3.1.12 End use,

2.2 Military Standards:

3.1.13 Specification designation,

MIL-STD-129 Marking for Shipment and Storage

3.1.14 Special marking (Section 15), and

MIL-STD-163 Steel Mill Products Preparation for Ship-

3.1.15 Special packaging (Section 16).

ment and Storage

4. Materials and Manufacture

2.3 Federal Standard:

Fed. Std. No. 123 Marking for Shipments (CivilAgencies)

4.1 The steel shall be made by any process.

4.2 Ifaspecifictypeofmeltingisrequiredbythepurchaser,

3. Ordering Information

it shall be as stated on the purchase order.

3.1 Orders for material under this specification should

4.3 The primary melting may incorporate separate degas-

include the following, as required, to describe the required

sing or refining, and may be followed by secondary melting,

material adequately:

such as electroslag or vacuum-arc remelting. If secondary

melting is employed, the heat shall be defined as all of the

ingots remelted from a single primary heat.

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

4.4 Steel may be cast in ingots or may be strand cast.When

StainlessSteel,andRelatedAlloys,andisthedirectresponsibilityofSubcommittee

steel of different grades is sequentially strand cast, identifica-

A01.09 on Carbon Steel Tubular Products.

Current edition approved Oct. 1, 2005. Published November 2005. Originally

tion of the resultant transition material is required. The

approved in 1964. Last previous edition approved in 2001 as A512–96 (2001).

producer shall remove the transition material by an established

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

procedure that positively separates the grades.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 4.5 Tubes shall be made by the furnace buttweld process.

the ASTM website.

4.6 Tubes shall be cold finished, either externally only

Withdrawn.

(sunk) or externally and internally (mandrel drawn).

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 512 – 96 (2005)

A

TABLE 2 Chemical Requirements for Other Carbon Grades

5. Condition

Grade Chemical Composition Limits, %

5.1 The purchaser shall specify in the order one of the

Desig-

Phospho-

following conditions: B

nation Carbon Manganese Sulfur, max

rus, max

MD (Mandrel Drawn)—No final thermal treatment

1008 0.10 max 0.50 max 0.040 0.045

SD (Sink Drawn)—No final thermal treatment

1010 0.08–0.13 0.30–0.60 0.040 0.045

MDSR—Mandrel Drawn and Stress Relieved

1012 0.10–0.15 0.30–0.60 0.040 0.045

SDSR—Sink Drawn and Stress Relieved 1015 0.12–0.18 0.30–0.60 0.040 0.045

1016 0.12–0.18 0.60–0.90 0.040 0.045

MDSA—MandrelDrawnandSoftAnnealedornormalized

1018 0.14–0.20 0.60–0.90 0.040 0.045

SDSA—Sink Drawn and Soft Annealed or normalized

1019 0.14–0.20 0.70–1.00 0.040 0.045

1020 0.17–0.23 0.30–0.60 0.040 0.045

NORM-MD-SR—Normalized,MandrelDrawn,andStress

1021 0.17–0.23 0.60–0.90 0.040 0.045

Relieved

1025 0.22–0.28 0.30–0.60 0.040 0.045

NORM-SD-SR—Normalized, Sink Drawn, and Stress Re-

1026 0.22–0.28 0.60–0.90 0.040 0.045

lieved 1030 0.27–0.34 0.60–0.90 0.040 0.045

1035 0.31–0.38 0.60–0.90 0.040 0.045

C

1110 0.08–0.15 0.30–0.60 0.040 0.130

6. Chemical Composition

C

1115 0.13–0.20 0.60–0.90 0.040 0.130

C

1117 0.14–0.20 1.00–1.30 0.040 0.130

6.1 The steel shall conform to the requirements as to

A

Rimmed or capped steels which may be used for the above grades are

chemical composition prescribed in Table 1 or Table 2 and

characterized by a lack of uniformity in their chemical composition, and for this

Table 3.

reason product analysis is not technologically appropriate unless misapplication is

6.2 When a grade is ordered under this specification, sup-

clearly indicated.

B

Other analyses are available.

plying an alloy grade that specifically requires the addition of

C

Grades 1110, 1115, and 1117 shall contain 0.08 min % sulfur.

any element other than those listed for the ordered grade in

Table 1 or Table 2 is not permitted.

TABLE 3 Tolerances for Product Analysis for Steels Shown in

Table 1

7. Heat Analysis

Limit, or Maximum Variation, Over Maximum Limit or

Element

7.1 An analysis of each heat of steel shall be made by the

of Specified Under Minimum Limit

Range, %

steel manufacturer to determine the percentages of the ele-

Under min, % Over max, %

ments specified; if secondary melting processes are used, the

Carbon To 0.15, incl 0.02 0.03

heat analysis shall be obtained from one remelted ingot or the

Over 01.5 0.03 0.04

Manganeses To 0.60, incl 0.03 0.03

product of one remelted ingot of each primary melt. The heat

Over 0.60 0.04 0.04

analysis shall conform to the requirements specified, except

Phosphorus . . 0.01

that where the heat identity has not been maintained or where

Sulfur . . 0.01

the analysis is not sufficiently complete to permit conformance

tobedetermined,thechemicalcompositiondeterminedfroma

product analysis made by the tubular manufacturer shall

8.2 The product analysis limits shown for carbon are not

conform to the requirements specified for heat analysis. When

normally applicable to the MT grades.

requested in the order or contract, a report of such analyses

8.3 The number and source of samples for such product

shall be furnished to the purchaser.

analysis shall be based on the individual heat or lot identity of

7.2 A report of this analysis shall be furnished only when

one of the following forms of material.

requested on the order.

8.3.1 Heat Identity Maintained—One product analysis per

heat on either a billet, a length of flat rolled stock, or a tube.

8. Product Analysis

8.3.2 Heat Identity Not Maintained—One product analysis

8.1 When requested on the purchase order, a product analy-

from one tube per 2000 ft (610 m) or less for sizes over 3 in.

sis shall be made by the manufacturer. The chemical compo-

(76.2 mm), or one product analysis from one tube per 5000 ft

sition thus determined shall conform to the requirements

(1524 m) or less for sizes under 3 in. (76.2 mm).

prescribed in Table 1 or Table 2 as modified by Table 3.

8.4 If the original test for product analysis fails, retests of 2

additional billets, 2 lengths of flat rolled stock, or 2 tubes shall

be made. Both retests for the elements in question shall meet

A

TABLE 1 Chemical Requirements

the requirements of this specification; otherwise all remaining

Chemical Composition Limits, %

material in the heat or lot shall be rejected, or at the option of

Grade

Phospho-

Designation the producer, each billet, length, flat rolled stock, or tube may

Carbon Manganese Sulfur, max

rus, max

be individually tested for acceptance.

MT 1010 0.05–0.15 0.30–0.60 0.04 0.045

8.5 Samples for product analysis, except for spectrochemi-

MT 1015 0.10–0.20 0.30–0.60 0.04 0.045

cal analysis, shall be taken in accordance with PracticeE59,

MT X 1015 0.10–0.20 0.60–0.90 0.04 0.045

MT 1020 0.15–0.25 0.30–0.60 0.04 0.045

and the composition thus determined shall correspond to the

MT X 1020 0.15–0.25 0.70–1.00 0.04 0.045

requirements in applicable section or table.

A

Rimmed or capped steels which may be used for the above grades are

characterized by a lack of uniformity in their chemical composition, and for this

9. Permissible Variations in Dimensions of Round Tubing

reason product analysis is not technologically appropriate unless misapplication is

clearly indicated. 9.1 Diameter and Wall Thickness:

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 512 – 96 (2005)

TABLE 5 Permissible Variations in Length—Round Tubing

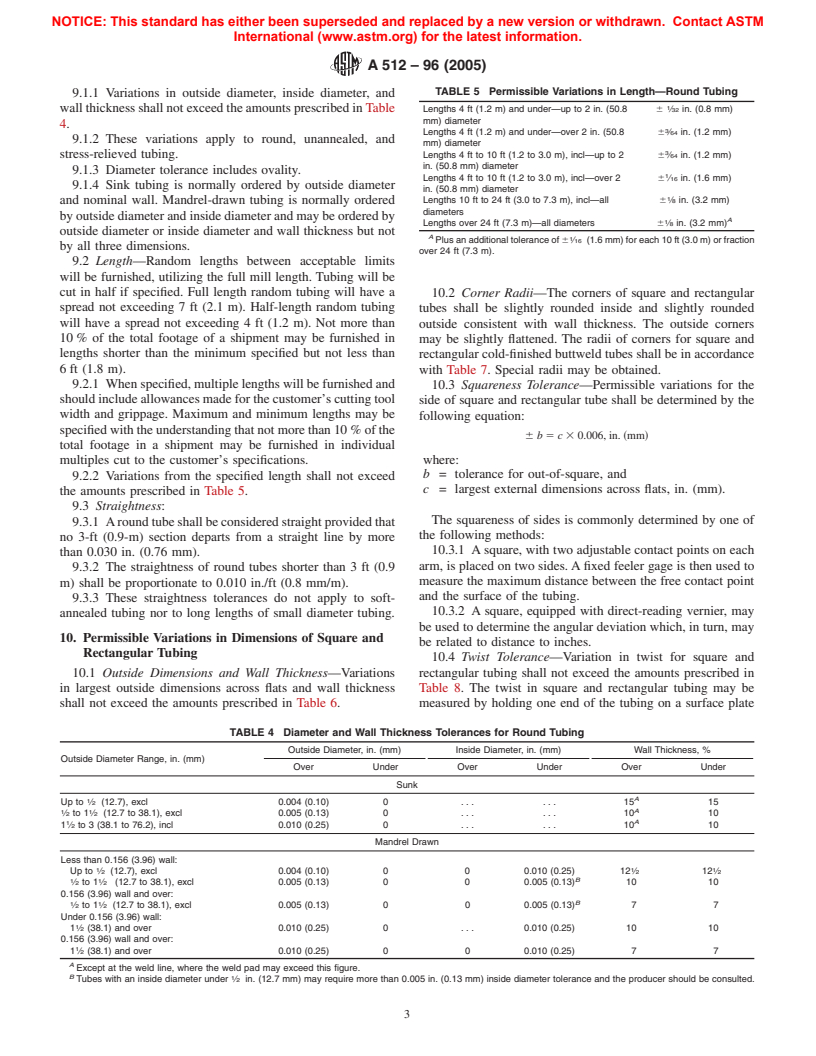

9.1.1 Variations in outside diameter, inside diameter, and

wallthicknessshallnotexceedtheamountsprescribedinTable Lengths 4 ft (1.2 m) and under—up to 2 in. (50.8 6 ⁄32 in. (0.8 mm)

mm) diameter

4.

Lengths 4 ft (1.2 m) and under—over 2 in. (50.8 6 ⁄64 in. (1.2 mm)

9.1.2 These variations apply to round, unannealed, and

mm) diameter

stress-relieved tubing. Lengths 4 ft to 10 ft (1.2 to 3.0 m), incl—up to 2 6 ⁄64 in. (1.2 mm)

in. (50.8 mm) diameter

9.1.3 Diameter tolerance includes ovality.

Lengths 4 ft to 10 ft (1.2 to 3.0 m), incl—over 2 6 ⁄16 in. (1.6 mm)

9.1.4 Sink tubing is normally ordered by outside diameter

in. (50.8 mm) diameter

Lengths 10 ft to 24 ft (3.0 to 7.3 m), incl—all 6 ⁄8 in. (3.2 mm)

and nominal wall. Mandrel-drawn tubing is normally ordered

diameters

byoutsidediameterandinsidediameterandmaybeorderedby

A

Lengths over 24 ft (7.3 m)—all diameters 6 ⁄8 in. (3.2 mm)

outside diameter or inside diameter and wall thickness but not

A

Plus an additional tolerance of 6 ⁄16 (1.6 mm) for each 10 ft (3.0 m) or fraction

by all three dimensions.

over 24 ft (7.3 m).

9.2 Length—Random lengths between acceptable limits

will be furnished, utilizing the full mill length. Tubing will be

cut in half if specified. Full length random tubing will have a 10.2 Corner Radii—The corners of square and rectangular

spread not exceeding 7 ft (2.1 m). Half-length random tubing

tubes shall be slightly rounded inside and slightly rounded

will have a spread not exceeding 4 ft (1.2 m). Not more than

outside consistent with wall thickness. The outside corners

10% of the total footage of a shipment may be furnished in

may be slightly flattened. The radii of corners for square and

lengths shorter than the minimum specified but not less than

rectangularcold-finishedbuttweldtubesshallbeinaccordance

6ft (1.8 m).

with Table 7. Special radii may be obtained.

9.2.1 Whenspecified,multiplelengthswillbefurnishedand

10.3 Squareness Tolerance—Permissible variations for the

shouldincludeallowancesmadeforthecustomer’scuttingtool

side of square and rectangular tube shall be determined by the

width and grippage. Maximum and minimum lengths may be

following equation:

specifiedwiththeunderstandingthatnotmorethan10%ofthe

6b 5c 30.006,in. ~mm!

total footage in a shipment may be furnished in individual

multiples cut to the customer’s specifications. where:

b = tolerance for out-of-square, and

9.2.2 Variations from the specified length shall not exceed

c = largest external dimensions across flats, in. (mm).

the amounts prescribed in Table 5.

9.3 Straightness:

The squareness of sides is commonly determined by one of

9.3.1 Aroundtubeshallbeconsideredstraightprovidedthat

the following methods:

no 3-ft (0.9-m) section departs from a straight line by more

10.3.1 Asquare, with two adjustable contact points on each

than 0.030 in. (0.76 mm).

arm, is placed on two sides.Afixed feeler gage is then used to

9.3.2 The straightness of round tubes shorter than 3 ft (0.9

measure the maximum distance between the free contact point

m) shall be proportionate to 0.010 in./ft (0.8 mm/m).

and the surface of the tubing.

9.3.3 These straightness tolerances do not apply to soft-

10.3.2 A square, equipped with direct-reading vernier, may

annealed tubing nor to long lengths of small diameter tubing.

be used to determine the angular deviation which, in turn, may

10. Permissible Variations in Dimensions of Square and

be related to distance to inches.

Rectangular Tubing

10.4 Twist Tolerance—Variation in twist for square and

10.1 Outside Dimensions and Wall Thickness—Variations rectangular tubing shall not exceed the amounts prescribed in

Table 8. The twist in square and rectangular tubing may be

in largest outside dimensions across flats and wall thickness

shall not exceed the amounts prescribed in Table 6. measured by holding one end of the tubing on a surface plate

TABLE 4 Diameter and Wall Thickness Tolerances for Round Tubing

Outside Diameter, in. (mm) Inside Diameter, in. (mm) Wall Thickness, %

Outside Diameter Range, in. (mm)

Over Under Over Under Over Under

Sunk

1 A

Up to ⁄2 (12.7), excl 0.004 (0.10) 0 . . . . . . 15 15

A

1 1

⁄2 to 1 ⁄2 (12.7 to 38.1), excl 0.005 (0.13) 0 . . . . . . 10 10

A

1 ⁄2 to 3 (38.1 to 76.2), incl 0.010 (0.25) 0 . . . . . . 10 10

Mandrel Drawn

Less than 0.156 (3.96) wall:

1 1 1

Up to ⁄2 (12.7), excl 0.004 (0.10) 0 0 0.010 (0.25) 12 ⁄2 12 ⁄2

B

1 1

⁄2 to 1 ⁄2 (12.7 to 38.1), excl 0.005 (0.13) 0 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.