ASTM A795-00

(Specification)Standard Specification for Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire Protection Use

Standard Specification for Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire Protection Use

SCOPE

1.1 This specification covers black and hot-dipped galvanized welded and seamless steel pipe in sizes NPS 1/2 (Note 1) to NPS 10 inclusive, with wall thicknesses as given in Table 1 and Table 2. Pipe having other wall thicknesses may be furnished provided such pipe complies with all other requirements of this specification and the outside diameter is as given in Table 2. Pipe ordered under this specification is intended for use in fire protection systems. The pipe may be bent, but it is not intended for bending made at ambient temperature wherein the inside diameter of the bend is less than twelve times the outside diameter of the pipe being bent (Note 2).

Note 1--The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter," "size," and "nominal size."

Note 2--Successful bending of pipe is a function of equipment and technique as well as pipe properties.

1.2 This pipe is suitable for joining by the following methods:

1.2.1 Light-Weight Fire Protection Pipe-- Rolled groove, welding, and fittings for plain end pipe. See Table 1 for dimensions.

1.2.2 Standard-Weight Fire Protection Pipe-- Cut or rolled groove, threading, welding, and fittings for plain end pipe. See Table 2 for dimensions.

1.2.3 For pipe having dimensions other than those of Table 1 and Table 2, the joining method must be compatible with the pipe dimensions. A complete listing of standard light weight dimensions appears in ASME B36.10 and B36.19.

1.3 The following precautionary caveat pertains only to the test method portion, Sections 8, 9, and 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: A 795 – 00

Standard Specification for

Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and

Seamless Steel Pipe for Fire Protection Use

This standard is issued under the fixed designation A 795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 The values stated in inch-pound units are to be regarded

as the standard. The SI equivalents may be approximate.

1.1 This specification covers black and hot-dipped galva-

nized welded and seamless steel pipe in sizes NPS 1/2 (Note 1)

2. Referenced Documents

to NPS 10 inclusive, with wall thicknesses as given in Table 1

2.1 ASTM Standards:

and Table 2. Pipe having other wall thicknesses may be

A90 TestMethodforWeight(Mass)ofCoatingonIronand

furnished provided such pipe complies with all other require-

Steel Articles with Zinc or Zinc-Alloy Coatings

ments of this specification and the outside diameter is as given

A 700 Practices for Packaging, Marking, and Loading

in Table 2. Pipe ordered under this specification is intended for

Methods for Steel Products for Domestic Shipment

use in fire protection systems. The pipe may be bent, but it is

A 751 Test Methods, Practices, and Terminology for

not intended for bending made at ambient temperature wherein

Chemical Analysis of Steel Products

the inside diameter of the bend is less than twelve times the

A 865 Specification for Threaded Couplings, Steel, Black

outside diameter of the pipe being bent (Note 2).

or Zinc-Coated (Galvanized) Welded or Seamless, for Use

NOTE 1—The dimensionless designator NPS (nominal pipe size) has

in Steel Pipe Joints

been substituted in this standard for such traditional terms as “nominal 6

B6 Specification for Zinc

diameter,” “size,” and “nominal size.”

E 213 Practice for Ultrasonic Examination of Metal Pipe

NOTE 2—Successful bending of pipe is a function of equipment and

and Tubing

technique as well as pipe properties.

E 309 Practice for Eddy-Current Examination of Steel Tu-

1.2 This pipe is suitable for joining by the following

bular Products Using Magnetic Saturation

methods:

2.2 ASME Standards:

1.2.1 Light-Weight Fire Protection Pipe— Rolled groove,

B1.20.1 Pipe Threads, General Purpose, Inch

welding, and fittings for plain end pipe. See Table 1 for

B36.10 Welded and Seamless Wrought Steel Pipe

dimensions.

B36.19 Stainless Steel Pipe

1.2.2 Standard-Weight Fire Protection Pipe—Cut or rolled

2.3 Federal Standard:

groove, threading, welding, and fittings for plain end pipe. See

Fed. Std. No. 123 Marking for Shipments (CivilAgencies)

Table 2 for dimensions.

2.4 Military Standards:

1.2.3 For pipe having dimensions other than those of Table

MIL-STD-129 Marking for Shipment and Storage

1 and Table 2, the joining method must be compatible with the

MIL-STD-163 Steel Mill Products, Preparation for Ship-

pipe dimensions. A complete listing of standard light weight

ment and Storage

dimensions appears in ASME B36.10 and B36.19.

1.3 The following precautionary caveat pertains only to the

3. Terminology

test method portion, Sections 8, 9, and 10, of this specification:

3.1 Definitions of Terms Specific to This Standard:

This standard does not purport to address all of the safety

concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and

Annual Book of ASTM Standards, Vol 01.06.

health practices and determine the applicability of regulatory

Annual Book of ASTM Standards, Vol 01.05.

limitations prior to use.

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.01.

Annual Book of ASTM Standards, Vol 02.04.

1 7

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Annual Book of ASTM Standards, Vol 03.03.

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee Available from ASME International, Three Park Avenue, New York, NY

A01.09 on Steel Pipe. 10016–5990.

Current edition approved Sept. 10, 2000. Published November 2000. Originally AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

e1

published as A 795 – 82. Last previous edition A 795 – 97 . Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A795–00

A

TABLE 1 Dimensions, Weights, and Test Pressure For Light-Weight Fire Protection Pipe—Schedule 10

Test Pressure

Outside Diameter Nominal Wall Thickness Weight Plain End

NPS Seamless and Electric-

Furnace-Welded

Designator Resistance-Welded

in. mm in. mm lb/ft kg/m psi MPa psi MPa

⁄4 1.050 (26.7) 0.083 (2.11) 0.86 (1.28) 500 (3.45) 700 (4.83)

1 1.315 (33.4) 0.109 (2.77) 1.41 (2.09) 500 (3.45) 700 (4.83)

1 ⁄4 1.660 (42.2) 0.109 (2.77) 1.81 (2.69) 500 (3.45) 1000 (6.89)

1 ⁄2 1.900 (48.3) 0.109 (2.77) 2.09 (3.11) 500 (3.45) 1000 (6.89)

2 2.375 (60.3) 0.109 (2.77) 2.64 (3.93) 500 (3.45) 1000 (6.89)

2 ⁄2 2.875 (73.0) 0.120 (3.05) 3.53 (5.26) 500 (3.45) 1000 (6.89)

3 3.500 (88.9) 0.120 (3.05) 4.34 (6.46) 500 (3.45) 1000 (6.89)

3 ⁄2 4.000 (101.6) 0.120 (3.05) 4.98 (7.41) 500 (3.45) 1200 (8.27)

4 4.500 (114.3) 0.120 (3.05) 5.62 (8.37) 500 (3.45) 1200 (8.27)

BB

5 5.563 (141.3) 0.134 (3.40) 7.78 (11.58) 1200 (8.27)

BB

6 6.625 (168.3) 0.134 (3.40) 9.30 (13.85) 1000 (6.89)

C BB

8 8.625 (219.1) 0.188 (4.78) 16.96 (25.26) 800 (5.51)

C BB

10 10.750 (273.1) 0.188 (4.78) 21.23 (31.62) 700 (4.83)

A

Schedule 10 corresponds to Schedule 10S as listed in ANSI B 36.19 for NPS ⁄4 through 6 only.

B

Furnace-welded pipe is not made in sizes larger than NPS 4.

C

Not Schedule 10.

TABLE 2 Dimensions, Weights, Test Pressures For Standard-Weight Fire Protection Pipe—Schedule 30 and Schedule 40

Test Pressure

Nominal Wall Weight Thread And

Outside Diameter Weight Plain End

A B

NPS Seamless and Electric-

Thickness Couplings

Furnace-Welded

Designator Resistance-Welded

in. mm in. mm lb/ft kg/m lb/ft kg/m psi MPa psi MPa

⁄2 0.840 (21.3) 0.109 (2.77) 0.85 (1.27) 0.85 (1.27) 700 (4.83) 700 (4.83)

⁄4 1.050 (26.7) 0.113 (2.87) 1.13 (1.69) 1.13 (1.68) 700 (4.83) 700 (4.83)

1 1.315 (33.4) 0.133 (3.38) 1.68 (2.50) 1.68 (2.50) 700 (4.83) 700 (4.83)

1 ⁄4 1.660 (42.2) 0.140 (3.56) 2.27 (3.39) 2.28 (3.40) 1000 (6.89) 1000 (6.89)

1 ⁄2 1.900 (48.3) 0.145 (3.68) 2.72 (4.05) 2.73 (4.07) 1000 (6.89) 1000 (6.89)

2 2.375 (60.3) 0.154 (3.91) 3.66 (5.45) 3.69 (5.50) 1000 (6.89) 1000 (6.89)

2 ⁄2 2.875 (73.0) 0.203 (5.16) 5.80 (8.64) 5.83 (8.68) 1000 (6.89) 1000 (6.89)

3 3.500 (88.9) 0.216 (5.49) 7.58 (11.29) 7.62 (11.35) 1000 (6.89) 1000 (6.89)

3 ⁄2 4.000 (101.6) 0.226 (5.74) 9.12 (13.58) 9.21 (13.71) 1200 (8.27) 1200 (8.27)

4 4.500 (114.3) 0.237 (6.02) 10.80 (16.09) 10.91 (16.25) 1200 (8.27) 1200 (8.27)

CC

5 5.563 (141.3) 0.258 (6.55) 14.63 (21.79) 14.82 (22.07) 1200 (8.27)

CC

6 6.625 (168.3) 0.280 (7.11) 18.99 (28.29) 19.20 (28.60) 1200 (8.27)

A CC

8 8.625 (219.1) 0.277 (7.04) 24.72 (36.82) 25.57 (38.09) 1200 (8.27)

A CC

10 10.750 (273.1) 0.307 (7.80) 34.27 (51.05) 35.78 (53.29) 1000 (6.89)

A

NPS ⁄2 through 6—Schedule 40; NPS 8 and 10—Schedule 30.

B

Based on 20-ft (6.1-m) lengths.

C

Furnace-welded pipe is not made in sizes larger than NPS 4.

3.1.1 imperfection—any discontinuity or irregularity found 5.1.4 Grade (seamless and electric-resistance-welded only),

in the pipe.

5.1.5 Size (NPS designator and weight class; standard

3.1.2 defect—an imperfection of sufficient size or magni-

weight or light weight; or outside diameter and nominal wall)

tude to be cause for rejection.

and wall thickness (Table 1 and Table 2),

5.1.6 Finish (black, galvanized, or other type of coating as

4. Classification

specified by the purchaser),

4.1 Pipe may be furnished in the following types (Note 3):

5.1.7 Length (specific or random),

4.1.1 Type F—Furnace-butt welded, continuous welded,

5.1.7.1 Grade for Type E and Type S,

4.1.2 Type E—Electric-resistance-welded, or

5.1.8 End finish,

4.1.3 Type S—Seamless.

5.1.8.1 Plain end, square cut,

NOTE 3—See Annex A1 for definitions of the types of pipe.

5.1.8.2 Plain end, beveled,

5.1.8.3 Cut groove (Note 4),

5. Ordering Information

5.1.8.4 Rolled groove (Note 4),

5.1 Orders for material under this specification should

5.1.8.5 Threads only,

include the following, as required, to describe the desired

5.1.8.6 Threaded and coupled, and

material adequately:

5.1.8.7 Couplings power tight.

5.1.1 Quantity (feet or number of lengths),

5.1.2 Name of material (steel pipe),

NOTE 4—Type of groove specified by the purchaser.

5.1.3 Type (seamless, electric-resistance-welded, or

furnace-welded), 5.1.9 ASTM designation.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A795–00

6. Materials and Manufacture electric test in accordance with Practice E 213 or Practice

E 309. It is the intent of this test to reject pipe containing

6.1 The steel for both welded and seamless pipe shall be

defects.

made by one or more of the following processes: open-hearth,

9.2 The following information is for the benefit of the user

electric-furnace, or basic-oxygen.

of this specification:

6.2 Welded pipe NPS 4 and under may be furnace-welded

9.2.1 The ultrasonic examination referred to in this specifi-

or electric-resistance welded. Welded pipe over NPS 4 shall be

cation is intended to detect longitudinal discontinuities having

electric-resistance–welded.

a reflective area similar to or larger than the reference notch.

6.3 The weld seam of electric-resistance-welded pipe in

The examination may not detect circumferentially oriented

Grade B shall be heat treated after welding to a minimum of

imperfections or short, deep defects.

1000°F (540°C) so that no untempered martensite remains, or

9.2.2 The eddy-current examination referenced in this

otherwise processed in such a manner that no untempered

specification has the capability of detecting significant discon-

martensite remains.

tinuities, especially of the short, abrupt type.

9.2.3 The hydrostatic test referred to in Section 8 is a test

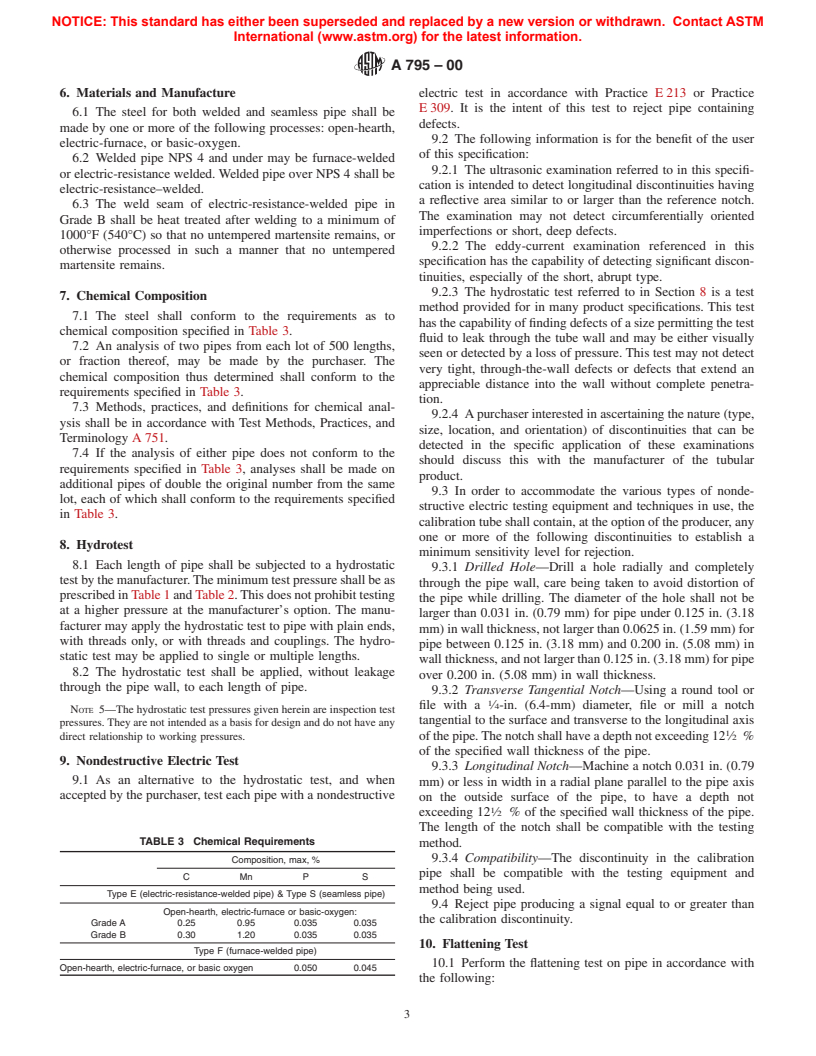

7. Chemical Composition

method provided for in many product specifications. This test

7.1 The steel shall conform to the requirements as to

hasthecapabilityoffindingdefectsofasizepermittingthetest

chemical composition specified in Table 3.

fluid to leak through the tube wall and may be either visually

7.2 An analysis of two pipes from each lot of 500 lengths,

seen or detected by a loss of pressure. This test may not detect

or fraction thereof, may be made by the purchaser. The

very tight, through-the-wall defects or defects that extend an

chemical composition thus determined shall conform to the

appreciable distance into the wall without complete penetra-

requirements specified in Table 3.

tion.

7.3 Methods, practices, and definitions for chemical anal-

9.2.4 Apurchaser interested in ascertaining the nature (type,

ysis shall be in accordance with Test Methods, Practices, and

size, location, and orientation) of discontinuities that can be

Terminology A 751.

detected in the specific application of these examinations

7.4 If the analysis of either pipe does not conform to the

should discuss this with the manufacturer of the tubular

requirements specified in Table 3, analyses shall be made on

product.

additional pipes of double the original number from the same

9.3 In order to accommodate the various types of nonde-

lot, each of which shall conform to the requirements specified

structive electric testing equipment and techniques in use, the

in Table 3.

calibrationtubeshallcontain,attheoptionoftheproducer,any

one or more of the following discontinuities to establish a

8. Hydrotest

minimum sensitivity level for rejection.

8.1 Each length of pipe shall be subjected to a hydrostatic

9.3.1 Drilled Hole—Drill a hole radially and completely

testbythemanufacturer.Theminimumtestpressureshallbeas

through the pipe wall, care being taken to avoid distortion of

prescribedinTable1andTable2.Thisdoesnotprohibittesting

the pipe while drilling. The diameter of the hole shall not be

at a higher pressure at the manufacturer’s option. The manu-

larger than 0.031 in. (0.79 mm) for pipe under 0.125 in. (3.18

facturer may apply the hydrostatic test to pipe with plain ends,

mm) in wall thickness, not larger than 0.0625 in. (1.59 mm) for

with threads only, or with threads and couplings. The hydro-

pipe between 0.125 in. (3.18 mm) and 0.200 in. (5.08 mm) in

static test may be applied to single or multiple lengths.

wall thickness, and not larger than 0.125 in. (3.18 mm) for pipe

8.2 The hydrostatic test shall be applied, without leakage

over 0.200 in. (5.08 mm) in wall thickness.

through the pipe wall, to each length of pipe.

9.3.2 Transverse Tangential Notch—Using a round tool or

file with a ⁄4-in. (6.4-mm) diameter, file or mill a notch

NOTE 5—The hydrostatic test pressures given herein are inspection test

tangential to the surface and transverse to the longitudinal axis

pressures. They are not intended as a basis for design and do not have any

direct relationship to working pressures. ofthepipe.Thenotchshallhaveadepthnotexceeding12 ⁄2 %

of the specified wall thickness of the pipe.

9. Nondestructive Electric Test

9.3.3 Longitudinal Notch—Machine a notch 0.031 in. (0.79

9.1 As an alternative to the hydrostatic test, and when

mm) or less in width in a radial plane parallel to the pipe axis

accepted by the purchaser, test each pipe with a nondestructive

on the outside surface of the pipe, to have a depth not

exceeding 12 ⁄2 % of the specified wall thickness of the pipe.

The length of the notch shall be compatible with the testing

TABLE 3 Chemical Requirements

method.

Composition, max, % 9.3.4 Compatibility—The discontinuity in the calibration

pipe shall be compatible with the testing equipment and

CMn P S

method being used.

Type E (electric-resistance-welded pipe) & Type S (seamless pipe)

9.4 Reject pipe producing a signal equal to or greater than

Open-hearth, electric-furnace or basic-oxygen:

the calibration discontinuity.

Grade A 0.25 0.95 0.035 0.035

Grade B 0.30 1.20 0.035 0.035

10. Flattening Test

Type F (furnace-welded pipe)

10.1 Perform the flattening test on pipe in accordance with

Open-hearth, electric-furnace, or basic oxygen 0.050 0.045

the following:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.