ASTM D4158-92

(Guide)Standard Guide for Abrasion Resistance of Textile Fabrics (Uniform Abrasion)

Standard Guide for Abrasion Resistance of Textile Fabrics (Uniform Abrasion)

SCOPE

1.1 This guide covers the determination of the resistance to abrasion of a wide range of textile materials using the uniform abrasion testing instrument. Fabrics of all types including carpets, garments and nonwovens may be tested under this method.

Note 1-- Other procedures for measuring the abrasion resistance of textile fabrics are given in: Test Methods D3884, D3885, D3886, D4157, D4966, and AATCC Test Method 93.

1.1.1 Provisions are provided for testing specimens in dry and wet conditions. Four options for evaluation are included:

Option 1--Fabric RuptureOption 2--Mass LossOption 3-Thickness LossOption 4--Breaking Strength Loss

1.1.2 Provision is provided for testing specimens in the wet state.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This guide does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4158 – 92

Standard Test Method for

Abrasion Resistance of Textile Fabrics (Uniform Abrasion

Method)

This standard is issued under the fixed designation D 4158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope material by rubbing against another surface.

3.2 For definitions of other terms used in these methods,

1.1 This test method covers the determination of the resis-

refer to Terminology D 123.

tance to abrasion of a wide range of textile materials using the

uniform abrasion testing machine.

4. Summary of Test Method

NOTE 1—Other procedures for measuring the abrasion resistance of

4.1 Abrasive action is applied uniformly in all directions in

textile fabrics are given in: Test Methods D 3884, D 3885, D 3886,

the plane of the surface of the specimen about every point in it.

D 4157, and AATCC 93.

The settings of the machine, method of mounting specimens,

1.2 The values stated in SI units are to be regarded as

conditions of test (as, dry or wet), and criteria to be used in

standard; the values in English units are provided as informa-

evaluating abrasive wear in the test, depend upon the nature of

tion only and are not exact equivalents.

the specimen to be tested and the use to be made of the test

1.3 This standard does not purport to address all of the

results. Resistance to abrasion is evaluated by various means

safety problems, if any, associated with its use. It is the

which are described in Section 12, Evaluation of Abrasion.

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.1 The resistance to abrasion of textile materials is affected

by many factors in a very complex and as yet little understood

2. Referenced Documents

manner. The abrasion machine covered in this test method

2.1 ASTM Standards:

provides a very sensitive means for studying the influence of

D 123 Terminology Relating to Textiles

the involved factors. The machine should therefore be used

D 1776 Practice for Conditioning Textiles for Testing

primarily as a research instrument. The results may not only

D 3884 Test Method for Abrasion Resistance of Textile

shed much needed light on this complex problem but may also

Fabrics (Rotary Platform, Double Head Method)

provide information on the effects of mechanical and chemical

D 3885 Test Method for Abrasion Resistance of Textile

treatments on fibers, yarns, and fabrics, and on the influence of

Fabrics (Flexing and Abrasion Method)

variations in yarn and fabric construction on the properties of

D 3886 Test Method for Abrasion Resistance of Textile

the final textile product. The results of comparative tests of the

Fabrics (Inflated Diaphragm Method)

abrasion resistance of several fabrics of similar types are often

D 4157 Test Method for Abrasion Resistance of Textile

very useful in the evaluation of the serviceability of fabrics for

Fabrics (Oscillatory Cylinder Method)

a specific end use. In many instances, the relative results

2.2 Other Documents:

obtained with this machine on a series of fabrics agreed well

AATCC 93, Impeller Tumble Method

with those obtained by the supplier of the fabrics, based upon

performance in end use. The experimenter, however, should be

3. Terminology

constantly on the alert for anomalous results which can be

3.1 Definitions:

attributed in most instances to uncontrolled factors in manu-

3.1.1 abrasion, n—the wearing away of any part of a

facturing or other processes. Specific instances of this type

5,6

have been described. Others may be encountered as the

This method is under the jurisdiction of ASTM Committee D-13 on Textiles

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

Specific. Schiefer, H. F. and Krasny, J. F., “Note on the Disintegration of Wool in

Current edition approved June 15, 1992. Published August 1992. Originally Abrasion Tests,” Textile Research Journal, Vol 19, January 1950, pp. 802–809;

published as D 4158 – 82. Last previous edition D 4158 – 82. Journal of Research, Nat. Bureau Standards, Vol 44, January 1950, pp. 9–14

Annual Book of ASTM Standards, Vol 07.01. (Research Paper RP 2054).

3 6

Annual Book of ASTM Standards, Vol 07.02. Shiefer, H. F., Crean, L. E. and Krasny, J. F. “Improved Single-Unit Schiefer

Available from American Association of Textile Chemists and Colorists, P.O. Abrasion Testing Machine,” Journal of Research, Nat. Bureau Standards, Vol 42,

Box 12215, Research Triangle Park, NC 27709. May, 1949, pp. 259–269. ASTM Bulletin, No. 159, July 1949, pp. 73–78 (TP133).

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4158

machine is used more extensively and a greater variety of

textiles have been tested. These anomalous results are fre-

quently very fruitful in the attainment of more durable and

satisfactory fabrics. As a rule they are not attributable to a

faulty operation of the testing machine or carelessness of the

operator. These results should not be discarded but should be

studied very intensively, for an understanding of the factors

which cause such anomalous results adds immeasurably to a

better understanding to this complex problem and to its more

intelligent application.

5.2 Test Method D 4158 for the determination of the abra-

sion resistance of textile fabrics, uniform abrasion method,

may be used for the acceptance testing of commercial ship-

ments of textile fabrics but caution is advised since technicians

may fail to get good agreement between results on certain

fabrics. Comparative tests as directed in 5.2.1 may be desir-

able.

5.2.1 In case of a dispute arising from differences in

reported test results when using Test Method D 4158 for

acceptance testing of commercial shipments, the purchaser and

the supplier should conduct comparative tests to determine if

there is a statistical bias between their laboratories. Competent

statistical assistance is recommended for the investigation of

bias. As a minimum, the two parties should take a group of test

FIG. 1 Schematic Diagram of Uniform Abrasion Testing Machine

specimens which are as homogeneous as possible and which

mounting of thick, stiff materials. For the first, a plastic

are from a lot of material of the type in question. The test

1 1 1

pressure foot 12.7, 25.4, 31.3, 38.1, 50.8 mm ( ⁄2,1,1 ⁄4,1 ⁄2,

specimens should then be randomly assigned in equal numbers

or 2 in.) in diameter, as called for, shall be mounted at the upper

to each laboratory for testing. The average results from the two

end of the specimen shaft to fix the area of the specimen to be

laboratories should be compared using Student’s t-test and an

abraded. A conical clamp seat fitted to the shaft rotates with it

acceptable probability level chosen by the two parties before

but is free to move vertically on the shaft. A cam is provided

the testing began. If a bias is found, either its cause must be

for raising and lowering the clamp seat. The specimen clamp

found and corrected or the purchaser and the supplier must

shown unassembled in Fig. 3 fits on the seat (C, Fig. 3) and can

agree to interpret future test results in the light of the known

be fastened to it by merely rotating it slightly to engage the two

bias.

pins in the slots. The clamp and specimen assembly can be

6. Apparatus removed quickly for examining the specimen and measuring

the wear and returned to the machine without unclamping the

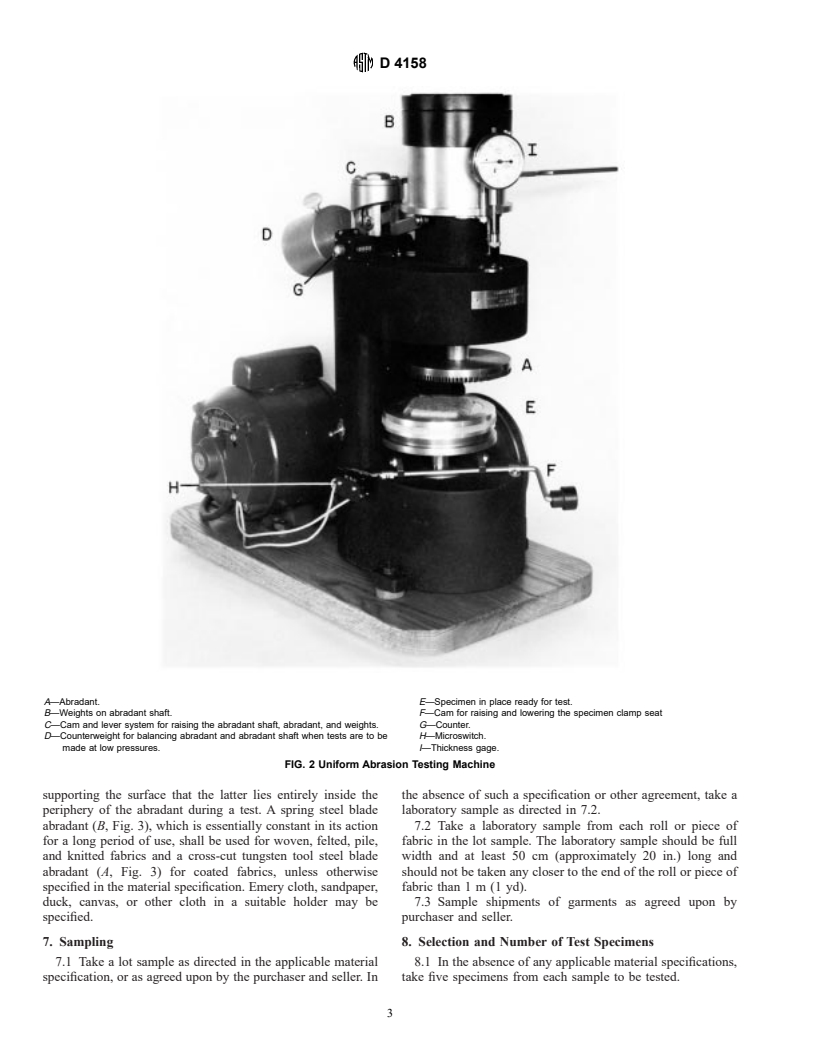

6.1 The machine, shown in Figs. 1 and 2, consists of an

specimen. When the clamp seat is lowered by turning the cam,

abrading mechanism, specimen supporting mechanism, and

the combined weight of the clamp seat and specimen clamp is

driving mechanism. Essentially, the surface of the abradant lies

suspended by the specimen over the presser foot. This places

in a plane parallel to the plane surface supporting the specimen

the specimen under constant tension throughout the test with

and presses upon the specimen. The abradant and specimen

take-up of any stretch in the specimen. Different tensions may

rotate in the same direction at very nearly but not quite the

be applied to the specimen by changing the weight of the clamp

same angular velocity (250 rpm) on noncoaxial axes which are

seat, for example, by adding auxiliary weights. For rigid

parallel to 0.0025 mm (0.0001 in.). The small difference in

mounting of thick, stiff cloths such as carpeting and felts, the

speed is to permit each part of the specimen to come in contact

specimen clamp and mounting aids shown in Fig. 4 shall be

with a different part of the abradant at each rotation.

used and the assembly screwed onto the specimen shaft in

6.1.1 The abrading mechanism consists of the abradant

place of the presser foot and specimen clamp seat (E, Fig. 2).

mounted at the lower end of a shaft, weights placed upon the

6.1.3 The driving mechanism consists of a motor-driven

upper end of the shaft to produce constant pressure between

auxiliary drive shaft connected to the abradant shaft and

abradant and specimen throughout the test, lever and cam for

specimen shaft by spur gears.

raising and lowering the abradant, shaft, and weights. A

6.1.4 The machine shall be equipped with a resettable

counterweight for balancing the abradant and abradant shaft is

counter (G, Fig. 2) to indicate the number of rotations in a test;

needed when tests are to be carried out at low pressure.

sensitive microswitch (H, Fig. 2) to stop the machine automati-

6.1.2 The specimen-supporting mechanism provides for

cally when a tension-suspended specimen is worn through;

tension mounting of thinner, more flexible materials and rigid

thickness gage (I, Fig. 2), when specified, for indicating

changes in thickness of the specimen during a test.

6.1.5 Abradant—The working surface of the abradant disk

The Schiefer machine meets these requirements and is manufactured by Frazier

Precision Co., Gaithersburg, Md. shall be sufficiently greater in diameter than the specimen

D 4158

A—Abradant.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.