ASTM F2847-10

(Practice)Standard Practice for Reporting and Assessment of Residues on Single Use Implants

Standard Practice for Reporting and Assessment of Residues on Single Use Implants

SIGNIFICANCE AND USE

The quality and consequently the clinical performance of implants may be affected by residues. Residues may induce no tissue response, minor tissue irritations, or they may lead to local inflammation of tissues surrounding the implant which may lead to failure in short-term or long-term use. Residues may also cause harm at locations away from the implant. Residues may originate from manufacturing materials used in the course of processing, or may be the result of handling and packaging (1-3).

This practice shall be used to report the results of testing for residue. All residues cannot necessarily be detected. It suggests standard techniques that may be applied for analysis, and provides suggestions for how limit values may be set.

Residues may be of inorganic, organic, or biological nature. They may exhibit as surface bound substance, or as an adsorbate (for example, electrostatically held), an efflorescence, or a mechanically held substance. Residues may be soluble in aqueous media, soluble in organic solvents, or may be insoluble particulates.

Data generated in validation processes, that is, cleaning validation or sterility validation may be used as results or as basis for setting acceptance criteria in the report.

SCOPE

1.1 The purpose of this practice is to describe how the cleanliness of single use implants as manufactured shall be reported. This practice proposes how to approach the identification of critical compounds and suggests different analytical methods.

1.2 The practice does not address substances which are intrinsic to the implant properties or design. In particular, it does not address substances released during implant resorption, implant coatings, or leachables by design.

1.3 This practice does not address the cleanliness of implants which are re-processed, re-cleaned after unpacking for re-use in the hospital or by the manufacturer.

1.4 This practice does not establish limit values for residues.

1.5 This practice suggests appropriate test methods for the general specification of residues and residue requirements of implants. This practice may also be used to characterize semi-finished components for implants.

1.6 The test methods suggested and described herein refer to established analytical methods and to existing standard methods for chemical, biochemical, or biological analysis.

1.7 This practice is intended solely to provide guidance regarding suitable test methods and reporting conventions for residues, which may or may not affect implant biocompatibility. This practice does not suggest or recommend test methods for biocompatibility, which may be found in Practice F748 or in ISO 10993-1.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2847 − 10

Standard Practice for

Reporting and Assessment of Residues on Single Use

Implants

This standard is issued under the fixed designation F2847; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 The purpose of this practice is to describe how the

E996 Practice for Reporting Data in Auger Electron Spec-

cleanliness of single use implants as manufactured shall be

troscopy and X-ray Photoelectron Spectroscopy

reported. This practice proposes how to approach the identifi-

E1078 Guide for Specimen Preparation and Mounting in

cation of critical compounds and suggests different analytical

Surface Analysis

methods.

E1504 PracticeforReportingMassSpectralDatainSecond-

1.2 The practice does not address substances which are

ary Ion Mass Spectrometry (SIMS)

intrinsic to the implant properties or design. In particular, it

E1635 Practice for Reporting Imaging Data in Secondary

doesnotaddresssubstancesreleasedduringimplantresorption,

Ion Mass Spectrometry (SIMS)

implant coatings, or leachables by design.

E1829 Guide for Handling Specimens Prior to Surface

Analysis

1.3 This practice does not address the cleanliness of im-

F561 Practice for Retrieval and Analysis of Medical

plants which are re-processed, re-cleaned after unpacking for

Devices, and Associated Tissues and Fluids

re-use in the hospital or by the manufacturer.

F748 PracticeforSelectingGenericBiologicalTestMethods

1.4 Thispracticedoesnotestablishlimitvaluesforresidues.

for Materials and Devices

F1251 Terminology Relating to Polymeric Biomaterials in

1.5 This practice suggests appropriate test methods for the

Medical and Surgical Devices (Withdrawn 2012)

general specification of residues and residue requirements of

F1877 Practice for Characterization of Particles

implants. This practice may also be used to characterize

F2459 Test Method for Extracting Residue from Metallic

semi-finished components for implants.

Medical Components and Quantifying via Gravimetric

1.6 Thetestmethodssuggestedanddescribedhereinreferto Analysis

F2809 Terminology Relating to Medical and Surgical Mate-

established analytical methods and to existing standard meth-

ods for chemical, biochemical, or biological analysis. rials and Devices

G121 Practice for Preparation of Contaminated Test Cou-

1.7 This practice is intended solely to provide guidance

pons for the Evaluation of Cleaning Agents

regarding suitable test methods and reporting conventions for

G131 PracticeforCleaningofMaterialsandComponentsby

residues, which may or may not affect implant biocompatibil-

Ultrasonic Techniques

ity. This practice does not suggest or recommend test methods

G136 Practice for Determination of Soluble Residual Con-

for biocompatibility, which may be found in Practice F748 or

taminants in Materials by Ultrasonic Extraction

in ISO 10993-1.

2.2 ISO Standards:

1.8 This standard does not purport to address all of the

ISO 10993-1 Biological Evaluation of Medical Devices—

safety concerns, if any, associated with its use. It is the

Part 1: Evaluation and Testing

responsibility of the user of this standard to establish appro-

ISO 10993-17 Biological Evaluation of Medical Devices—

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

ThispracticeisunderthejurisdictionofASTMCommitteeF04onMedicaland the ASTM website.

Surgical Materials and Devices and is the direct responsibility of Subcommittee The last approved version of this historical standard is referenced on

F04.15 on Material Test Methods. www.astm.org.

Current edition approved Dec. 1, 2010. Published January 2011. DOI: 10.1520/ Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

F2847–10. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2847 − 10

Part 17: Establishment ofAllowable Limits for Leachable 3.2.2 exhaustive extraction, n—extraction until the cumula-

Substances tive residue change is analytically insignificant or less than

ISO 10993-18 Biological Evaluation of Medical Devices— 10 % of the initial extract.

Part 18: Chemical Characterization of Materials

3.2.3 limit value, n—the maximum allowable amount(s) of

ISO 11737-1 Sterilization of Medical Devices—

substance(s) at the surface of an implant not yet found to be

Microbiological Methods—Part 1: Determination of a

harmful for the surrounding tissues and organs. Its value is

Population of Microorganisms on Products

established and defined by the manufacturer.

2.3 United States Pharmacopeia (USP) Document:

3.2.4 model residue, n—a single substance or a mixture of

<85> Bacterial Endotoxin Test

substances that reflect the process materials likely to be

encountered and used during the manufacturing of the device.

2.4 European Pharmacopoeia (PhEUR) Documents:

2.2.23 Atomic Absorption Spectrometry

3.2.5 residue, n—a substance present at the surface of an

2.2.24 Absorption Spectrophotometry, Infrared

implant or embedded therein that is not explicitly recognized

2.2.25 Absorption Spectrophotometry, Ultraviolet and Vis-

and defined as part of the implant specification (special

ible

definition for residue analysis of surfaces). It includes process-

2.2.28 Gas Chromatography

based residues as well as contamination by environmental

2.2.29 Liquid Chromatography

factors (adsorbates).

2.2.43 Mass Spectrometry

3.2.6 single use implant, n—a medical device which in-

2.2.44 Total Organic Carbon in Water for Pharmaceutical

tended use is to be implanted permanently and that is not

Use

re-cleaned or re-worked for a second implantation after even-

2.2.48 Raman Spectrometry

tual removal.

2.2.55 Peptide Mapping

3.2.7 soiling, n—procedureofapplyingknownamountsofa

2.2.57 Inductively Coupled Plasma-Atomic Emission Spec-

substance onto a medical device for determination of process

trometry

capability, that is, cleaning efficiency and extraction yields.

2.2.58 Inductively Coupled Plasma-Mass Spectrometry

3.2.8 spiking, n—procedureofapplyingexactquantitiesofa

2.5 Association for the Advancement of Medical Instrumen-

substance to an analyte for instrumental calibration and deter-

tation (AAMI) Document:

mination reaction yield.

AAMI ST72 Bacterial Endotoxins—Test Methodologies,

3.2.9 surface area, n—the projected surface area of a part.

Routine Monitoring, and Alternatives to Batch Testing

This area does not include the internal porosity of parts with

2.6 Other References:

cancellous, porous, or wire structure. It does include factors

FDA Guideline on Validation of the Limulus Amebocyte

that correct for the estimated surface roughness.

Lysate Test as an End-Product Endotoxin Test for Human

and Animal Parenteral Drugs, Biological Products, and

4. Summary of Practice

Medical Device, 1987

4.1 This practice describes how to report residues on im-

200.7 EPA Methodologies for ICP

plant surfaces and indicates useful and typical applicable

8270C EPA Methodologies for GC-MS

analytical methods.

4.2 Application of the test methods contained within this

3. Terminology

practice does not guarantee clinical success of a finished

3.1 Unless provided otherwise in 3.2, terminology shall be

implant,butitwillhelptoensureconsistencyinitscleanliness.

in conformance with Terminology F1251 and with Terminol-

ogy F2809.

5. Significance and Use

3.2 Definitions:

5.1 The quality and consequently the clinical performance

3.2.1 action value, n—the amount(s) of substance(s) toler-

of implants may be affected by residues. Residues may induce

ated at the surface of an implant by the manufacturer before it

no tissue response, minor tissue irritations, or they may lead to

will interfere with the manufacturing process.

local inflammation of tissues surrounding the implant which

may lead to failure in short-term or long-term use. Residues

may also cause harm at locations away from the implant.

Residues may originate from manufacturing materials used in

Available from U.S. Pharmacopeia (USP), 12601Twinbrook Pkwy., Rockville,

MD 20852-1790, http://www.usp.org.

the course of processing, or may be the result of handling and

Available from European Directorate for the Quality of Medicines and

packaging (1-3).

HealthCare (EDQM), 7 allee Kastner, CS 30026, F67081, Strasbourg, France,

http://www.edqm.eu/en/News-and-General-Information-43.html.

5.2 Thispracticeshallbeusedtoreporttheresultsoftesting

Available from Association for the Advancement of Medical Instrumentation

for residue. All residues cannot necessarily be detected. It

(AAMI), 4301 North Fairfax Drive, Suite 301, Arlington, VA 22203, http://

suggests standard techniques that may be applied for analysis,

www.aami.org.

and provides suggestions for how limit values may be set.

Available from Food and Drug Administration (FDA), 5600 Fishers Ln.,

Rockville, MD 20857, http://www.fda.gov.

Available from United States Environmental Protection Agency (EPA), Ariel

Rios Bldg., 1200 Pennsylvania Ave., NW, Washington, DC 20460, http:// The boldface numbers in parentheses refer to the list of references at the end

www.epa.gov. of this standard.

F2847 − 10

5.3 Residues may be of inorganic, organic, or biological 6.2.3.1 In this practice, microbiologic residues are to be

nature. They may exhibit as surface bound substance, or as an listedseparatelyanddifferentiatedasbioburdenandendotoxin.

adsorbate (for example, electrostatically held), an It should be noted that for medical devices sold sterile,

efflorescence, or a mechanically held substance. Residues may bioburden testing is often part of sterilization validation and is

be soluble in aqueous media, soluble in organic solvents, or

monitoredonapredeterminedscheduleforthepurposeofdose

may be insoluble particulates. audits or process control.

6.2.4 In this practice, particulate residues are referred to as

5.4 Data generated in validation processes, that is, cleaning

material insoluble in aqueous media or organic solvent, which

validation or sterility validation may be used as results or as

can be removed from the surface of an implant by physical-

basis for setting acceptance criteria in the report.

chemical means without interfering with the integrity of the

implant surface. Even though particulates shall be reported

6. Reporting of Residues on Implants

separately, they belong to one of the chemical classes men-

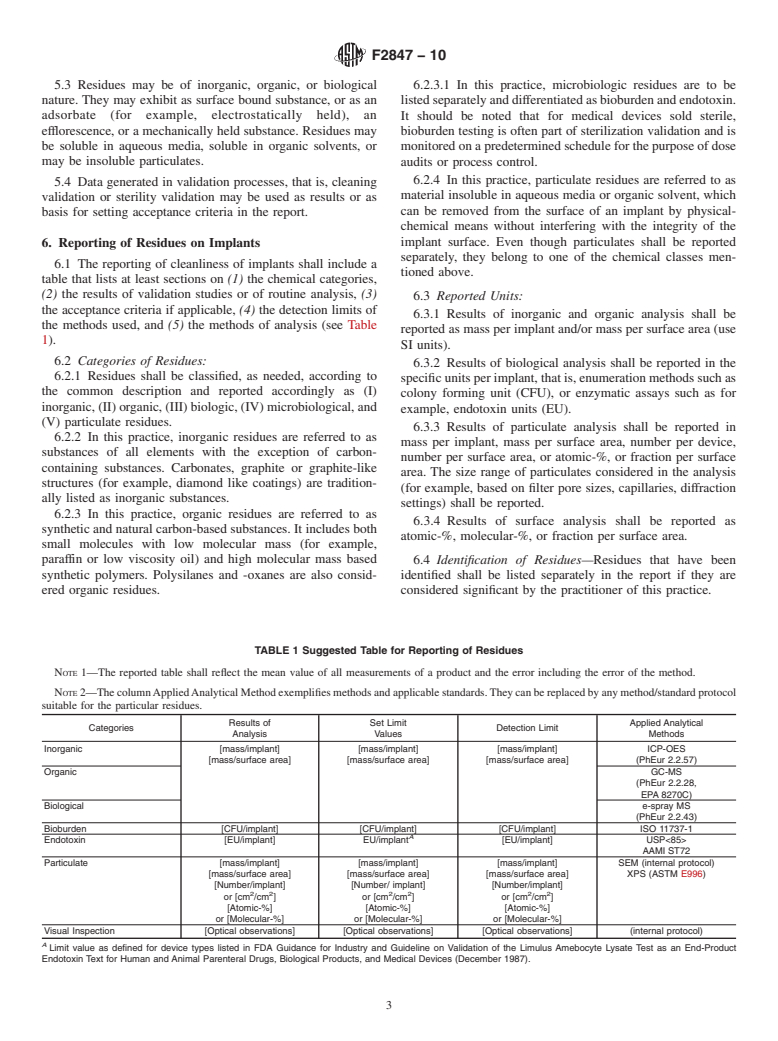

6.1 The reporting of cleanliness of implants shall include a

tioned above.

table that lists at least sections on (1) the chemical categories,

(2) the results of validation studies or of routine analysis, (3)

6.3 Reported Units:

the acceptance criteria if applicable, (4) the detection limits of

6.3.1 Results of inorganic and organic analysis shall be

the methods used, and (5) the methods of analysis (see Table

reported as mass per implant and/or mass per surface area (use

1).

SI units).

6.2 Categories of Residues:

6.3.2 Results of biological analysis shall be reported in the

6.2.1 Residues shall be classified, as needed, according to

specificunitsperimplant,thatis,enumerationmethodssuchas

the common description and reported accordingly as (I)

colony forming unit (CFU), or enzymatic assays such as for

inorganic,(II)organic,(III)biologic,(IV)microbiological,and

example, endotoxin units (EU).

(V) particulate residues.

6.3.3 Results of particulate analysis shall be reported in

6.2.2 In this practice, inorganic residues are referred to as

mass per implant, mass per surface area, number per device,

substances of all elements with the exception of carbon-

number per surface area, or atomic-%, or fraction per surface

containing substances. Carbonates, graphite or graphite-like

area. The size range of particulates considered in the analysis

structures (for example, diamond like coatings) are tradition-

(for example, based on filter pore sizes, capillaries, diffraction

ally listed as inorganic substances.

settings) shall be reported.

6.2.3 In this practice, organic residues are referred to as

6.3.4 Results of surface analysis shall be reported as

synthetic and natural carbon-based substances. It includes both

atomic-%, molecular-%, or fraction per surface area.

small molecules with low molecular mass (for example,

paraffin or low viscosity oil) and high molecular mass based 6.4 Identification of Residues—Residues that have been

synthetic polymers. Polysilanes and -oxanes are also consid- identified shall be listed separately in the report if they are

ered organic residues. considered significant by the practitioner of this practice.

TABLE 1 Suggested Table for Reporting of Residues

NOTE 1—The reported table shall reflect the mean value of all measurements of a product and the error including the error of the method.

NOTE2—ThecolumnAppliedAnalyticalMethodexemplifiesmethodsandapplicablestandards.Theycanbereplacedbyanymethod/standardprotocol

suitable for the particular residues.

Results of Set Limit Applied Analytical

Categories Detection Limit

Analysis Values Methods

Inorganic [mass/implant] [mass/implant] [mass/implant] ICP-OES

[mass/surface area] [mass/surface area] [mass/surface area] (PhEur 2.2.57)

Organic GC-MS

(PhEur 2.2.28,

EPA 8270C)

Biological e-spray MS

(PhEur 2.2.43)

Bioburden [CFU/implant] [CFU/implant] [CFU/implant] ISO 11737-1

A

Endotoxin [EU/implant] EU/implant [EU/implant] USP<85>

AAMI ST72

Particulate [mass/implant] [mass/implant] [mass/implant] SEM (internal protocol)

[mass/surface area] [mass/surface area] [mass/surface area] XPS (ASTM E996)

[Number/implant] [Number/ implant] [Number/implant]

2 2 2 2 2 2

or [cm /cm ] or [cm /cm ] or [cm /cm ]

[Atomic-%] [Atomic-%] [Atomic-%]

or [Molecular-%] or [Molecular-%] or [Molecular-%]

Visual Inspection [Optical observations] [Optical observations] [Optical observations] (internal protocol)

A

Limit value as defined for device types listed in FDA Guidance for Industry and Guideline on Validation of the Limulus Amebocyte Lysate Test as an End-Product

Endotoxin Text for Human and Animal Parenteral Drugs, Biological Products, and Medical Devices (December 1987).

F2847 − 10

7. Quality Assurance 7.6 Each method of analysis shall be establishe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.