ASTM F1890-04

(Test Method)Standard Test Method for Measuring Softball Bat Performance Factor

Standard Test Method for Measuring Softball Bat Performance Factor

SCOPE

1.1 This test method covers a method for determining bat performance by measuring the bat-ball coefficient of restitution (BBCOR), deriving the bat performance factor (BPF) and calculating a batted ball speed (BBS). It is applicable to softball bats of any construction or material. The method provides a quantitative measure of bat dynamic performance that may be used for comparison purposes.

1.2 The BBCOR, BPF, and BBS are each calculated from measurements taken in the laboratory on test equipment meeting the requirements defined in this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F1890–04

Standard Test Method for

1

Measuring Softball Bat Performance Factor

This standard is issued under the fixed designation F 1890; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 center of percussion (COP), n—also known as the

center of oscillation, the length of a simple pendulum with the

1.1 This test method covers a method for determining bat

same period as a physical pendulum, as in a bat oscillating on

performance by measuring the bat-ball coefficient of restitution

a pivot. Forces and impacts at this location will not induce

(BBCOR), deriving the bat performance factor (BPF) and

axial reactions at the pivot point.

calculating a batted ball speed (BBS). It is applicable to

3.1.5 coeffıcient of restitution (COR), n—measure of impact

softball bats of any construction or material. The method

efficiency calculated as the relative speed of the objects after

provides a quantitative measure of bat dynamic performance

impact divided by the relative speed of the objects before

that may be used for comparison purposes.

impact.

1.2 The BBCOR, BPF, and BBS are each calculated from

3.1.6 cycle—one complete performance of the oscillation of

measurements taken in the laboratory on test equipment

the bat, specifically, one full swing of the bat.

meeting the requirements defined in this specification.

3.1.7 moment of inertia (MOI), n—measure of mass distri-

1.3 The values stated in inch-pound units are to be regarded

bution relative to an axis of rotation. It is the product of the

as the standard.

mass multiplied by the square of the distance to the mass,

1.4 This standard does not purport to address all of the

summed over the entire bat.

safety concerns, if any, associated with its use. It is the

3.1.8 period, n—time required for a pendulum to oscillate

responsibility of the user of this standard to establish appro-

through one complete cycle.

priate safety and health practices and determine the applica-

bility of regulatory requirements prior to use.

4. Significance and Use

2. Referenced Documents 4.1 This test method offers a laboratory means to compare

2

the performance of a softball bat.

2.1 ASTM Standards:

4.2 Use of this test method can provide sports governing

F 1887 Test Method for Measuring the Coefficient of Res-

bodies a means to compare calculated BBS and other physical

titution (COR) of Baseballs and Softballs

properties of the bat for the purposes of controlling the game.

F 1888 Test Method for Compression-Displacement of

Baseballs and Softballs

5. Apparatus

3. Terminology 5.1 Bat COP Test Apparatus:

5.1.1 Ruler, suitable for measuring lengths up to 42 in.

3.1 Definitions of Terms Specific to This Standard:

(1067 mm) to the nearest 0.031 in. (0.79 mm).

3.1.1 balance point, n—distance to the center of mass of a

5.1.2 Weight Scale, suitable for measuring weight up to 48

bat when measured from the distal end of the bat knob.

oz (1360 g) to the nearest 0.0035 oz (0.1 g).

3.1.2 bat-ball coeffıcient of restitution (BBCOR), n—COR

5.1.3 Electronic Timer, suitable device for measuring time

of a specific ball colliding with a bat as defined in this test

to the nearest 1 µs (0.000001 s).

method. See coeffıcient of restitution (COR).

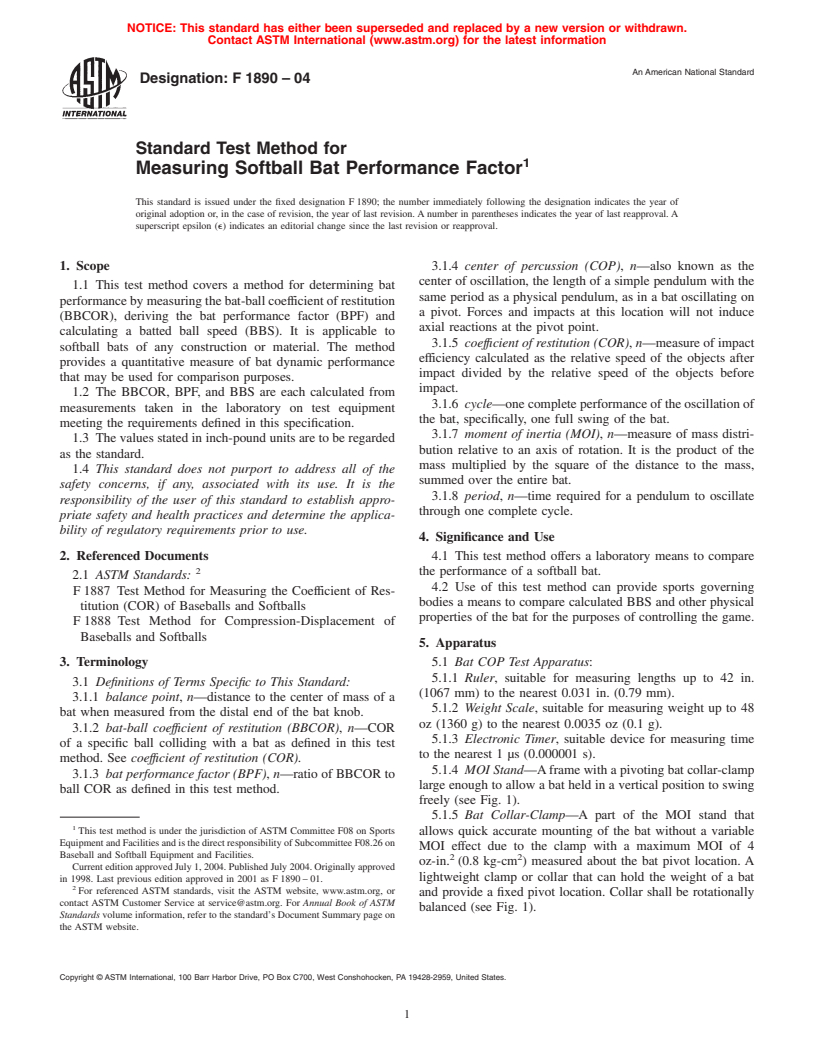

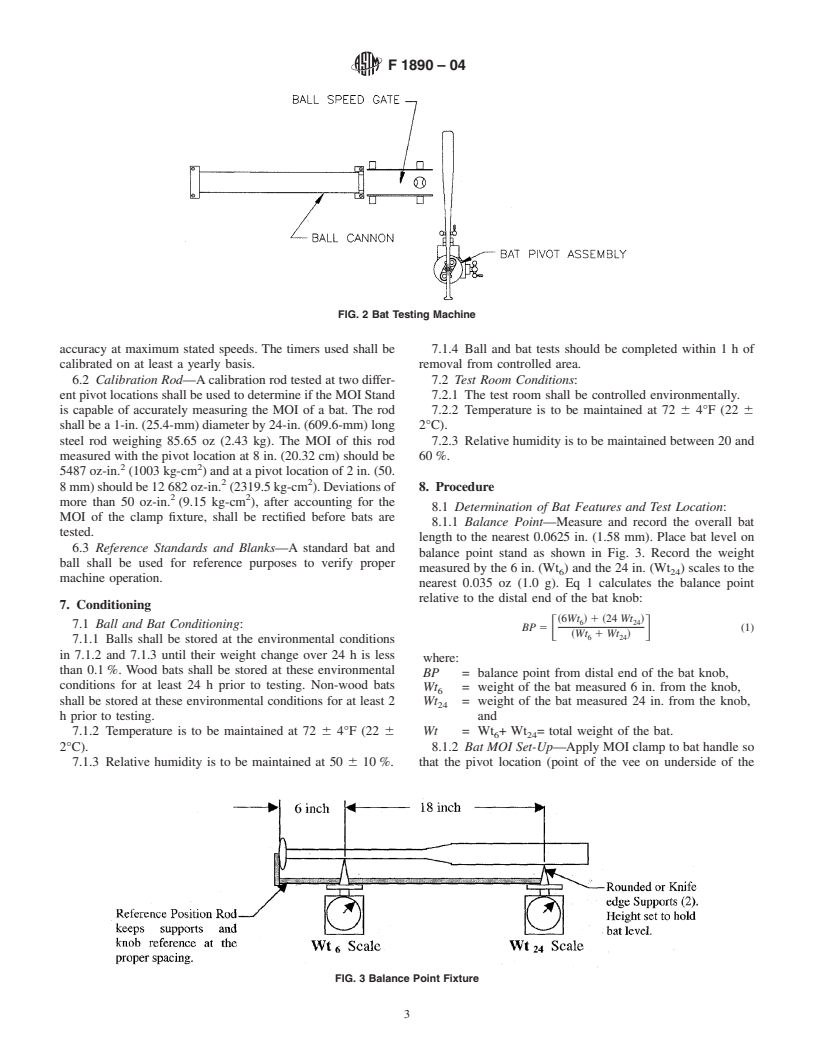

5.1.4 MOI Stand—Aframe with a pivoting bat collar-clamp

3.1.3 bat performance factor (BPF), n—ratio of BBCOR to

large enough to allow a bat held in a vertical position to swing

ball COR as defined in this test method.

freely (see Fig. 1).

5.1.5 Bat Collar-Clamp—A part of the MOI stand that

1

This test method is under the jurisdiction of ASTM Committee F08 on Sports

allows quick accurate mounting of the bat without a variable

Equipment and Facilities and is the direct responsibility of Subcommittee F08.26 on

MOI effect due to the clamp with a maximum MOI of 4

Baseball and Softball Equipment and Facilities.

2 2

oz-in. (0.8 kg-cm ) measured about the bat pivot location. A

Current edition approved July 1, 2004. Published July 2004. Originally approved

lightweight clamp or collar that can hold the weight of a bat

in 1998. Last previous edition approved in 2001 as F 1890 – 01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and provide a fixed pivot location. Collar shall be rotationally

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

balanced (see Fig. 1).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.