ASTM D4491-99a(2004)e1

(Test Method)Standard Test Methods for Water Permeability of Geotextiles by Permittivity

Standard Test Methods for Water Permeability of Geotextiles by Permittivity

SCOPE

1.1 These test methods cover procedures for determining the hydraulic conductivity (water permeability) of geotextiles in terms of permittivity under standard testing conditions, in the uncompressed state. Included are two procedures: the constant head method and the falling head method.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound units stated in parentheses are provided for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation:D4491–99a (Reapproved 2004)

Standard Test Methods for

Water Permeability of Geotextiles by Permittivity

This standard is issued under the fixed designation D4491; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Adjunct references were corrected editorially in June 2006.

1. Scope 3. Terminology

1.1 These test methods cover procedures for determining 3.1 Definitions:

the hydraulic conductivity (water permeability) of geotextiles 3.1.1 geotechnics, n—the application of scientific methods

in terms of permittivity under standard testing conditions, in and engineering principles to the acquisition, interpretation,

the uncompressed state. Included are two procedures: the and use of knowledge of materials of the earth’s crust to the

constant head method and the falling head method. solution of engineering problems.

1.2 The values stated in SI units are to be regarded as the 3.1.1.1 Discussion—Geotechnicsembracesthefieldsofsoil

standard. The inch-pound units stated in parentheses are mechanics, rock mechanics, and many of the engineering

provided for information only. aspects of geology, geophysics, hydrology, and related sci-

1.3 This standard does not purport to address all of the ences.

safety concerns, if any, associated with its use. It is the 3.1.2 geotextile, n—a permeable geosynthetic comprised

responsibility of the user of this standard to establish appro- solely of textiles.

priate safety and health practices and determine the applica- 3.1.3 permeability, n—the rate of flow of a liquid under a

bility of regulatory limitations prior to use. differential pressure through a material.

3.1.3.1 Discussion—The nominal thickness is used as it is

2. Referenced Documents

difficult to evaluate the pressure on the geotextile during the

2.1 ASTM Standards:

test, thereby making it difficult to determine the thickness of

D123 Terminology Relating to Textiles the fabric under these test conditions.

D653 Terminology Relating to Soil, Rock, and Contained 3.1.4 permeability, n—of geotextiles, hydraulic conductiv-

Fluids

ity.

D4439 Terminology for Geosynthetics 3.1.5 permittivity, (c), (T−1), n—of geotextiles, the volu-

D5199 Test Method for Measuring the Nominal Thickness

metric flow rate of water per unit cross sectional area per unit

of Geosynthetics head under laminar flow conditions, in the normal direction

E691 Practice for Conducting an Interlaboratory Study to

through a geotextile.

Determine the Precision of a Test Method 3.1.6 For the definitions of other terms relating to geotex-

2.2 ASTM Adjuncts:

tiles, refer toTerminology D4439. For the definitions of textile

Detailed Drawing and Materials List for Construction, 10 terms, refer to Terminology D123. For the definition of

Drawings

coefficient of permeability, refer to Terminology D653.

4. Summary of Test Methods

These test methods are under the jurisdiction of ASTM Committee D35 on

4.1 These test methods describe procedures for determining

Geosynthetics and are the direct responsibility of Subcommittee D35.03 on

the permittivity of geotextiles using constant head or falling

Permeability and Filtration.

Current edition approved April 7, 2006. Published March 2000. Originally

head test procedures, as follows:

apporoved in 1985. Last previous edition approved in 1999 as D4491–99a. DOI:

4.1.1 ConstantHeadTest—Aheadof50mm(2in.)ofwater

10.1520/D4491-99AR04E01.

is maintained on the geotextile throughout the test. The

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM quantity of flow is measured versus time. The constant head

Standards volume information, refer to the standard’s Document Summary page on

test is used when the flow rate of water through the geotextile

the ASTM website.

is so large that it is difficult to obtain readings of head change

Detailed drawings and a materials list for construction are available from

versus time in the falling head test.

ASTM Headquarters. Request adjunct No. ADJD4491.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D4491–99a (2004)

NOTE 1—Data has shown agreement between the falling and constant

6.1.1 The apparatus must be capable of maintaining a

head methods of determining permittivity of geotextiles. Selection of the

constant head of water on the geotextile being tested, or

test method, that is, constant or falling head, is left to the technician

6.1.2 Theapparatusmustbecapableofbeingusedasfalling

performing the test.

head apparatus.

4.1.2 Falling Head Test—A column of water is allowed to

6.2 In addition, the apparatus must not be the controlling

flow through the geotextile and readings of head changes

agent for flow during the test. It will be necessary to establish

versus time are taken. The flow rate of water through the

a calibration curve of volumetric flow rate versus head for the

geotextile must be slow enough to obtain accurate readings.

apparatus alone in order to establish compliance with this

requirement (see 11.7).

5. Significance and Use

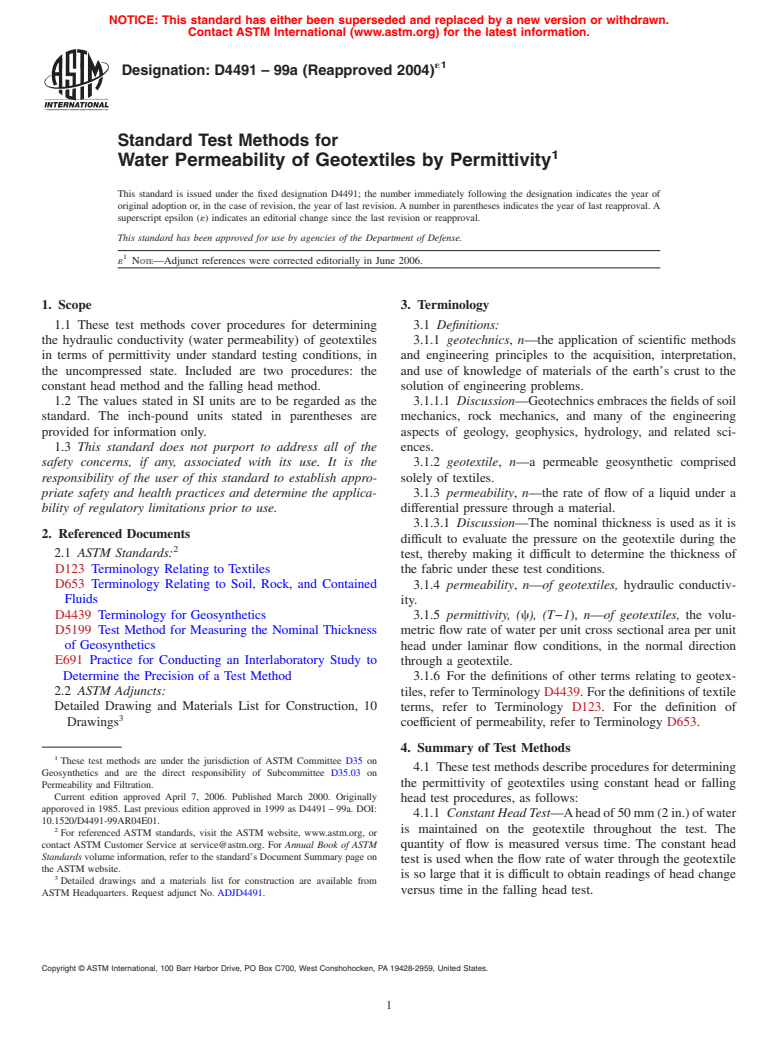

6.3 Refer to Fig. 1 for a schematic drawing of a device that

5.1 These test methods are considered satisfactory for ac-

conforms to all of the above requirements.The device consists

ceptance testing of commercial shipments of geotextiles since

of an upper and lower unit, which fasten together. The

the methods have been used extensively in the trade for

geotextile specimen is positioned in the bottom of the upper

acceptance testing.

unit. There is a standpipe for measuring the constant head

5.1.1 In case of a dispute arising from differences in

value. The rotating discharge pipe allows adjustment of the

reported test results when using these test methods for accep- 3

head of water at the bottom of the specimen. SeeADJD4491.

tance testing of commercial shipments, the purchaser and the

NOTE 3—The location of the manometer for measuring the headloss in

suppliershouldconductcomparativeteststodetermineifthere

either the constant head or falling head method shall be located directly

is a statistical bias between their laboratories. Competent

beneath the specimen. For the device shown in Fig. 1, this may be

statistical assistance is recommended for the investigation of

accomplished by drilling a small (3mm; ⁄8 in) diameter hole in the top

bias.Asaminimum,thetwopartiesshouldtakeagroupoftest

plate of the bottom reservoir tank directly beneath the specimen, and

specimens that are as homogeneous as possible and that are

attaching the manometer to this plate.

from a lot of material of the type in question. The test

specimens should then be randomly assigned in numbers to 7. Sampling

each laboratory for testing. The average results from the two

7.1 Lot Sample—As a lot sample for acceptance testing,

laboratories should be compared using Student’s t-test for

take at random the number of rolls of geotextile directed in an

unpaireddataandanacceptableprobabilitylevelchosenbythe

applicable material specification or other agreement between

two parties before the start of testing. If a bias is found, either

the purchaser and the supplier. Consider rolls of geotextile to

itscausemustbefoundandcorrected,orthepurchaserandthe

be the primary sampling units. If the specification requires

suppliermustagreetointerpretfuturetestresultsinlightofthe

samplingduringmanufacture,selecttherollsforthelotsample

known bias.

at uniformly spaced time intervals throughout the production

5.1.2 Permittivity is an indicator of the quantity of water

period.

that can pass through a geotextile in an isolated condition.

NOTE 4—An adequate specification or other agreement between the

5.1.3 As there are many applications and environmental

purchaser and the supplier requires taking into account the variability

conditions under which a geotextile may be used, care should

between rolls of geotextile and between specimens from a swatch from a

be taken when attempting to apply the results of these test

roll of geotextile so as to provide a sampling plan with a meaningful

methods to the field performance of a geotextile.

producer’s risk, consumer’s risk, acceptable quality level, and limiting

5.2 Sincetherearegeotextilesofvariousthicknessesinuse,

quality level.

evaluation in terms of their Darcy coefficient of permeabilities

7.2 Laboratory Sample—Take for the laboratory sample a

can be misleading. In many instances, it is more significant to

full roll width sample extending a minimum of 1 m along the

evaluate the quantity of water that would pass through a

selvage from each sample roll such that the requirements of

geotextile under a given head over a particular cross-sectional

Section 9 can be met.Take a sample that will exclude material

area; this is expressed as permittivity.

from the outer wrap of the roll or the inner wrap around the

5.3 If the permeability of an individual geotextile is of

core unless the sample is taken at the production site, at which

importance, a nominal coefficient of permeability, as related to

point inner and outer wrap material may be used.

geotechnical engineering, may be computed. By multiplying

permittivity times the nominal thickness of the geotextile, as

8. Test Water Preparation

determined by Test Method D5199, the nominal coefficient of

permeability is obtained. 8.1 To provide reproducible test results, the test water shall

be de-aired under a vacuum of 710 mm (28 in.) of mercury

NOTE 2—The nominal thickness is used as it is difficult to evaluate the

(Hg)foraperiodoftimetobringthedissolvedoxygencontent

pressure on the geotextile during the test, thereby making it difficult to

down to a maximum of six parts per million. The dissolved

determine the thickness of the fabric under these test conditions.

oxygen content may be determined by either commercially

6. Apparatus

available chemical kits or by a dissolved oxygen meter.

6.1 The apparatus shall conform to one of the following

NOTE 5—The de-airing system may be either a commercially available

arrangements:

system or one consisting of a vacuum pump capable of removing a

minimumof150L/minofairinconnectionwithanon-collapsiblestorage

tankwithalargeenoughstoragecapacityforthetestseries,oratleastone

Data available from ASTM Headquarters. Request RR: D-35-1007. specimen at a time.

´1

D4491–99a (2004)

FIG. 1 Constant and Falling Head Permeability Apparatus

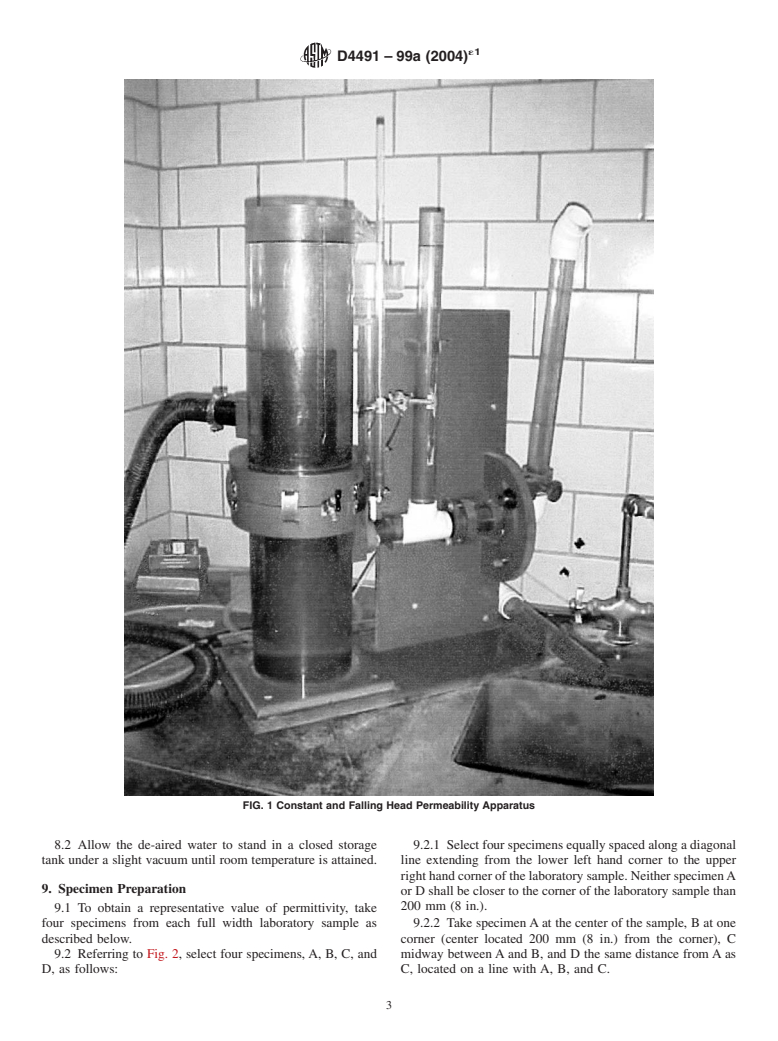

8.2 Allow the de-aired water to stand in a closed storage 9.2.1 Selectfourspecimensequallyspacedalongadiagonal

tank under a slight vacuum until room temperature is attained. line extending from the lower left hand corner to the upper

righthandcornerofthelaboratorysample.NeitherspecimenA

9. Specimen Preparation

or D shall be closer to the corner of the laboratory sample than

200 mm (8 in.).

9.1 To obtain a representative value of permittivity, take

four specimens from each full width laboratory sample as 9.2.2 Take specimenAat the center of the sample, B at one

described below. corner (center located 200 mm (8 in.) from the corner), C

9.2 Referring to Fig. 2, select four specimens,A, B, C, and midway betweenAand B, and D the same distance fromAas

D, as follows: C, located on a line with A, B, and C.

´1

D4491–99a (2004)

FIG. 2 Specimen Locations

9.2.3 Cut specimens shall fit the testing apparatus, for water on the geotextile. This is the head (h) under which the

example,73mm(2.87in.)indiameterforthedeviceillustrated test will be performed initially.

in Fig. 1. 11.5 Submergeatubeattachedtoasourceofvacuumtojust

9.3 Conditionthespecimenbysoakinginaclosedcontainer above (10 mm (0.5 in.)) the surface of the geotextile, moving

of de-aired water, at room conditions, for a period of 2 h. The thetubegentlyoverthesurfacewhileapplyingaslightvacuum

minimum specimen diameter is to be 50 mm (2 in.). in order to remove any trapped air that may be in or on the

specimen.Ifnecessary,readjusttheheadto50mm(2in.)after

NOTE 6—If the illustrated device is used, the specimens are attached to

removing the vacuum.

the specimen ring by contact cement.

11.6 Record the values of time (t), quantity of flow (Q)as

10. Operator Process Control

collected from the discharge pipe, and water temperature (T),

holding the head at 50 mm (2 in.). Make at least five readings

10.1 Prepare four specimens of Standard U.S. Mesh Sieve

per specimen and determine an average value of permittivity

to fit the test apparatus.

for the specimen.

10.2 Following Section 11 or Section 13, depending on the

methodtobeusedforthegeotextilespecimens,performtesting

NOTE 8—The quantity of flow may be measured in millilitres and then

on each mesh specimen.

converted to cubic millimetres for the computation of permittivity (1

10.3 Based on an interlaboratory test, involving seven mL=1000 mm ).

laboratories, the permittivity of No 200 Standard US Mesh

11.7 Afterthefirstspecimenhasbeentestedundera50-mm

−1

Sieve material has been determined to be 5.00 s , with a

(2-in.) head, using the same specimen, start with a 10-mm

standard deviation of 0.65. 3

( ⁄8-in.) head and repeat the procedure. Increase the head by 5

10.3.1 New operator process control shall be performed 3

mm ( ⁄16 in.) after every five readings. Increase the head until

until it is demonstrated that the operator is proficient in test

a75-mm(3-in.)headisreached.Usethisdatatodeterminethe

performance as demonstrated by obtaining the value of per-

region of laminar flow. Plot volumetric flow rate, v, (where v

mittivity stated in 10.3, plus or minus two standard deviations.

equals Q/At, values defined in 12.1) versus head. The quantity

10.3.2 Following initial proficiency testing, the operator

of flow (Q) should be corrected to 20°C (68°F). The initial

shall perform process control testing on a semi-annual basis.

straight line portion of the plot defines the region of laminar

flow. If the 50-mm head is outside the region of laminar flow,

CONSTANT HEAD TEST

repeat the test procedure using the head of water in the

mid-region of laminar flow.

11. Procedure

11.7.1 Compare the data from 11.7 with the apparatus

11.1 Assemble the apparatus with the specimen in place.

calibration curve referred to in 6.2. The apparatus calibration

11.2 Open the bleed valve and backfill the system through

plotofvolumetricflowrateversusheadshouldplotwellabove

the standpipe or discharge pipe, with de-aired water. Backfill-

t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.