ASTM E928-96

(Test Method)Standard Test Method for Determination of Purity by Differential Scanning Calorimetry

Standard Test Method for Determination of Purity by Differential Scanning Calorimetry

SCOPE

1.1 This test method covers the determination of purity by use of differential scanning calorimetry and the evaluation of the results using the van't Hoff equation.

1.2 This test method is generally applicable to thermally stable compounds with well-defined melting temperatures.

1.3 Determination of purity by this test method is only applicable when the impurity dissolves in the melt and is insoluble in the crystal.

1.4 Computer- or electronic-based instruments, techniques, or data treatments equivalent to this test method may also be used.

Note 1--Since all data treatments are not equivalent, it is the responsibility of the user to verify equivalency prior to use.

1.5 SI values are the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 There is no ISO method equivalent to this method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 928 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determination of Purity by Differential Scanning

Calorimetry

This standard is issued under the fixed designation E 928; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

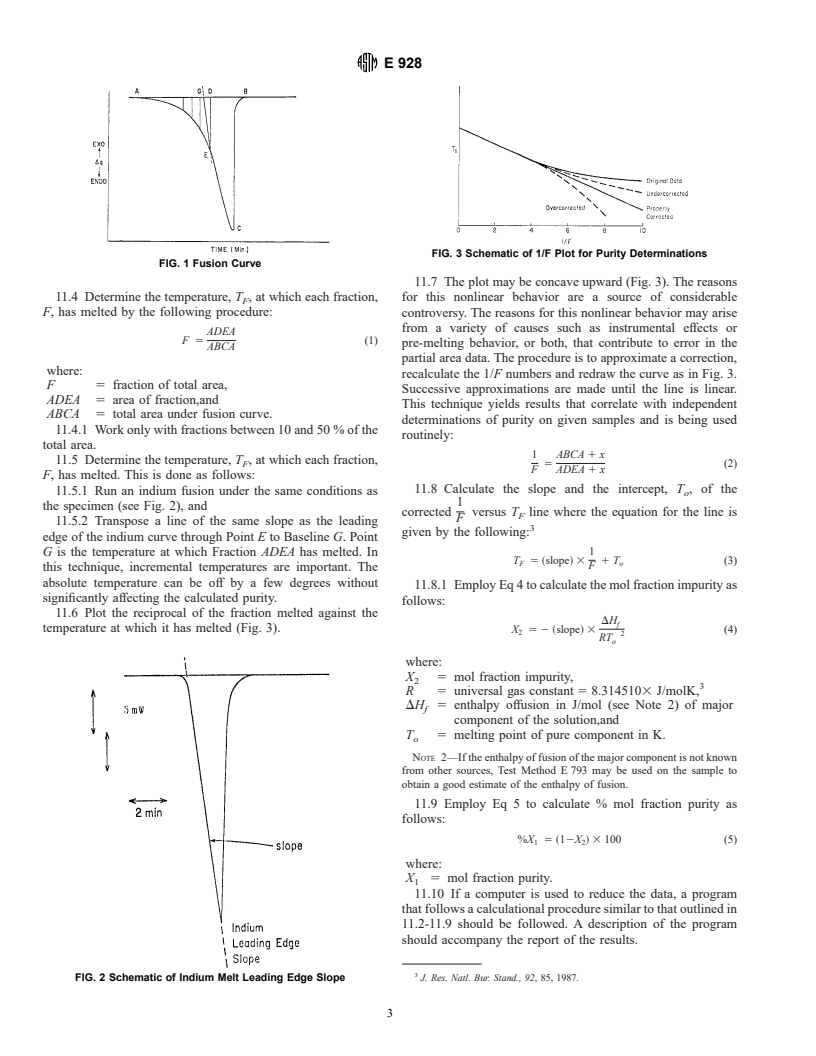

1.1 This test method covers the determination of purity by 4.1 This test method consists of melting the test specimen

use of differential scanning calorimetry and the evaluation of that is subjected to a temperature-controlled program while

the results using the van’t Hoff equation. recording the heat flow (power) into the specimen as a function

1.2 This test method is generally applicable to thermally of time. The resulting endotherm area is often measured to

stable compounds with well-defined melting temperatures. yield the enthalpy of fusion. The melting endotherm area is

1.3 Determination of purity by this test method is only then partitioned into a series of fractional areas (about ten,

applicable when the impurity dissolves in the melt and is comprising the first 10 to 50 % of the total area). Each

insoluble in the crystal. fractional area is assigned a temperature. A plot of the

1.4 Computer- or electronic-based instruments, techniques, reciprocal fractional areas and their corresponding tempera-

or data treatments equivalent to this test method may also be tures is then produced. The resulting plot is seldom a straight

used. Users of this test method are expressly advised that all line. To linearize the plot, an incremental amount is added to

such instruments or techniques may not be equivalent. It is the the enthalpy of fusion and the fractional areas recalculated and

responsibility of the user of this test method to determine the plotted. The purity level is then calculated from the slope of

necessary equivalency prior to use. this straight line.

1.5 The values stated in SI units are to be regarded as the

5. Significance and Use

standard.

1.6 This standard does not purport to address all of the 5.1 The melting temperature range of a compound broadens

as the impurity level rises. This phenomenon is described

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- approximately by the van’t Hoff equation for melting point

depressions. Measuring and recording the instantaneous heat

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. flow (power) into the specimen as a function of time or

temperature during such a melting process is a practical way

2. Referenced Documents

for the generation of data suitable for analysis by the van’t Hoff

2.1 ASTM Standards: equation.

E 473 Terminology for Thermal Analysis 5.2 The results obtained include: sample purity (expressed

E 793 Test Method for Enthalpies of Fusion and Crystalli- as mol percent); enthalpy of fusion (expressed as joules per

zation by Differential Scanning Calorimetry mol); and the melting temperature (expressed in Kelvin) of the

E 967 Practice for Temperature Calibration of Differential pure form of the major component.

Scanning Calorimeters and Differential Thermal Analyz- 5.3 Generally, the repeatability of this test method decreases

ers as the purity level decreases. This test method is ordinarily

E 968 Practice for Heat Flow Calibration of Differential considered unreliable when the purity level of the major

Scanning Calorimeters component of the mixture is less than 98.5 mol % or when the

incremental enthalpy correction (x) exceeds 20 % of the

3. Terminology

original detected enthalpy of fusion.

3.1 Definitions—The definitions relating to thermal analysis 5.4 This test method is used for quality control, specifica-

appearing in Terminology E 473 shall be considered applicable

tion acceptance, and research.

to this test method.

6. Interferences

6.1 This test method is nonspecific. Many impurities may

This test method is under the jurisdiction of ASTM Committee E-37 on

cause the melting temperature broadening. Thus, it is not useful

Thermal Measurements and is the direct responsibility of Subcommittee E37.01 on

Test Methods and Recommended Practices. in identifying the nature of the impurity or impurities but only

Current edition approved Dec. 10, 1996. Published April 1997. Originally

the total mol percent of impurity present.

published as E 928 – 83. Last previous edition E 928 – 85 (1989)e .

6.2 The van’t Hoff theory assumes the following:

Annual Book of ASTM Standards, Vol 14.02.

E 928

6.2.1 The impurities dissolve in the melt of the major Only 1 to 3 mg is required for each analysis.

constituent forming a solution approximately described by 8.2 Avoid any physical or mechanical treatment of the

ideal solution theory; material that will cause chemical changes. For example,

6.2.2 The solubility of the impurity in the solid of the major grinding the sample for size reduction often introduces such

constituent is negligible; and changes as a result of heat generated by friction.

6.2.3 The major constituent must display a single well-

9. Calibration

defined melting endotherm in the temperature range of interest.

9.1 Accurate calibration of the absolute temperature or

Microscopic investigations of the melt and the solid may help

enthalpy of fusion is not necessary to determine the mol

to establish whether or not solid or liquid solutions have been

percent purity. However, if the accurate melting temperature or

formed.

enthalpy of fusion of the pure compound is desired, calibrate

6.3 In some cases the sample may react with air during the

the instrument in accordance with Practice E 967 and E 968.

temperature cycle, causing an incorrect transition to be mea-

Perform calibrations at the heating rate used for the purity

sured. Where it has been shown that this effect is present,

determination (see 11.7) and in the temperature range of the

provision shall be made for sealing the specimen and running

melting temperature of the pure material.

the test under an inert gas blanket. Since some materials

9.2 When metals are used with aluminum specimen holders,

degrade near the melting region, carefully distinguish between

it is best to use a fresh sample each time as alloying of the

degradation and transition.

metallic standard with aluminum may result on reheating.

6.4 Since milligram quantities of sample are used, ensure

that samples are homogeneous and representative.

10. Procedure

6.5 Sublimation will lead to a different heat consumption

10.1 Caution—Toxic and corrosive effluents may be re-

and, perhaps, a change in composition of the specimen. The

leased upon heating the material. It is the responsibility of the

specimen holder should be examined after the measurement for

user of the standard to take appropriate safety measures.

crystals not part of the resolidified melt.

10.2 Wash the empty specimen container in an appropriate

solvent, such as hexane, then heat to 700 K for 1 min.

7. Apparatus

10.3 Cool the specimen container and store in a desiccator

7.1 The essential equipment required to provide the mini-

until ready for use.

mum instrument capability for this test method includes:

10.4 Weigh 1 to 3 mg of the sample to an accuracy of 0.01

7.1.1 Differential Scanning Calorimeter (DSC), consisting

mg in a pre-cleaned holder.

of:

10.5 Under ambient conditions, hermetically seal the speci-

7.1.1.1 DSC Test Chamber, composed of a furnace(s) to

men container so there will be no mass loss during the scan.

provide uniform controlled heating of a specimen and refer-

Minimize the free space between the specimen and the lid to

ence to a constant temperature or at a constant rate within the

avoid sublimation onto the lid

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.