ASTM D2824-94

(Specification)Standard Specification for Aluminum-Pigmented Asphalt Roof Coatings, Nonfibered, Asbestos Fibered, and Fibered without Asbestos

Standard Specification for Aluminum-Pigmented Asphalt Roof Coatings, Nonfibered, Asbestos Fibered, and Fibered without Asbestos

SCOPE

1.1 This specification covers asphalt-based, aluminum roof coatings suitable for application to roofing or masonry surfaces by brush or spray.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2824 – 94

Standard Specification for

Aluminum-Pigmented Asphalt Roof Coatings, Non-Fibered,

Asbestos Fibered, and Fibered without Asbestos

This standard is issued under the fixed designation D 2824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2 Type II—Fibered, containing asbestos fiber.

3.3 Type III—Fibered, containing no asbestos fiber.

1.1 This specification covers asphalt-based, aluminum roof

coatings suitable for application to roofing or masonry surfaces

4. Materials and Manufacture

by brush or spray.

4.1 Asphalt-based, aluminum roof coatings shall consist of

1.2 The values stated in inch-pound units are to be regarded

an asphalt base, volatile petroleum solvents, and a leafing-type

as the standard.

of aluminum pigment conforming to the requirements of

1.3 The following precautionary caveat pertains only to the

Specification D 962, with or without fiber added. They shall be

test method portion, Section 8, of this specification: This

mixed to a smooth, uniform consistency suitable for applica-

standard does not purport to address all of the safety concerns,

tion by brush, roller, or by spraying.

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

5. Composition

practices and determine the applicability of regulatory limita-

5.1 Asphalt-based, aluminum roof coatings complying with

tions prior to use.

this specification shall conform to the following composition

2. Referenced Documents limits:

Type I Type II or

2.1 ASTM Standards:

Type III

D 4 Test Method for Bitumen Content

Water, max, % 0.3 0.3

D 95 Test Method for Water in Petroleum Products and Nonvolatile matter (NVM), min, % 40 40

Insoluble in CS , max, % of NVM 40 50

Bituminous Materials by Distillation

Metallic aluminum, min, % 11 9

D 140 Practice for Sampling Bituminous Materials

D 562 Test Method for Consistency of Paints Using the

6. Physical Requirements

Stormer Viscometer

6.1 Uniformity—After a thoroughly stirred sample has

D 962 Specification for Aluminum Powder and Paste Pig-

stood for 72 h at room temperature 73.4 6° F (23 6 2°C) in a

ments for Paints

closed container, it shall show no separation of solvent or

D 2823 Specification for Asphalt Roof Coatings

settling that can not be overcome by moderate stirring.

D 3279 Test Method for n-Heptane Insolubles

6.2 Consistency—The roof coating shall be of a consistency

E 200 Practice for Preparation, Standardization, and Stor-

that will spread readily and permit application by brush, roller,

age of Standard Solutions for Chemical Analysis

or spray to produce a film in which the aluminum pigment leafs

to form a bright reflective surface on prepared roofing, satu-

3. Classification

rated felt, and metal surfaces at ambient temperatures above

3.1 Type I—Nonfibered, containing no fiber.

50°F (10°C).

6.2.1 Type I—Consistency at 77°F (25°C) shall be between

This specification is under the jurisdiction of ASTM Committee D-8 on 20 and 30 Stormer s/100 revolutions of the paddle-type rotor

Roofing, Waterproofing, and Bituminous Materials and is the direct responsibility of

with a 100-g load in addition to the standardizing load.

Subcommittee D08.05 on Solvent-Bearing Bituminous Compounds for Roofing and

6.2.2 Type II—Consistency at 77°F (25°C) shall be be-

Waterproofing.

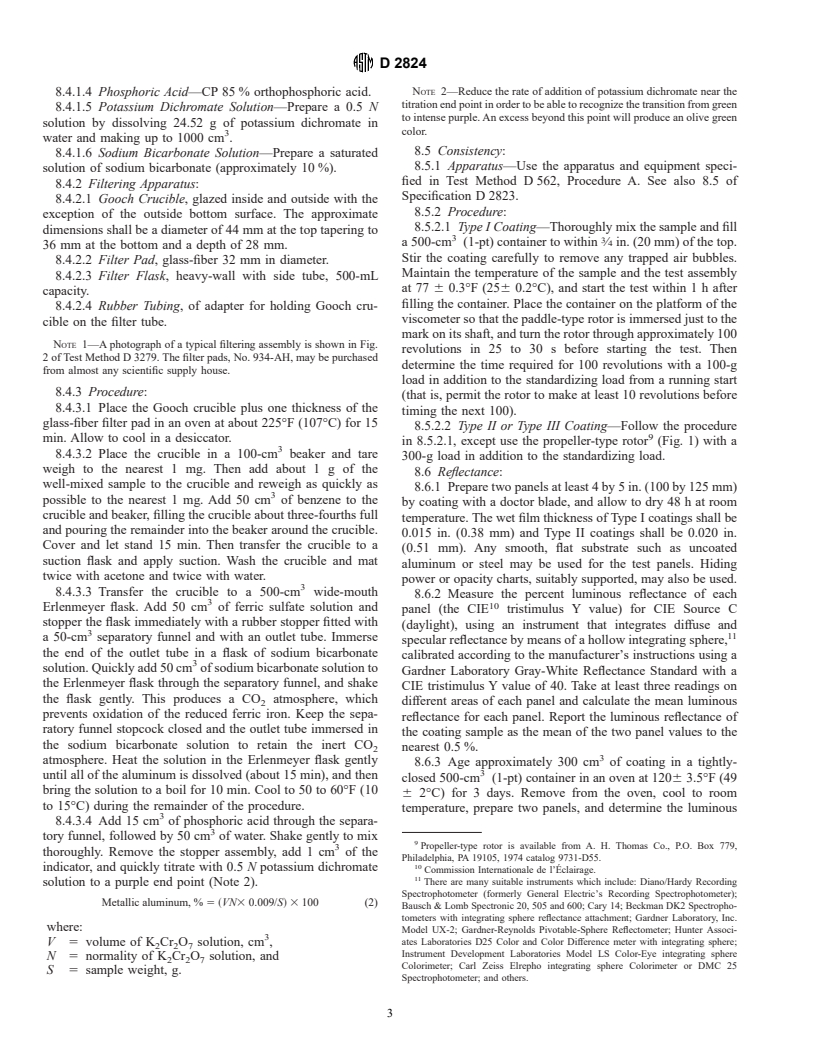

tween 15 and 90 Stormer s/100 revolutions of the propeller-

Current edition approved May 15, 1994. Published July 1994. Originally

published as D 2824 – 69. Last previous edition D 2824 – 85.

type rotor (Fig. 1) with a 300-g load in addition to the

Annual Book of ASTM Standards, Vol 04.04.

standardizing load.

Annual Book of ASTM Standards, Vol 05.01.

4 6.3 Reflectance—The percent luminous reflectance of coat-

Annual Book of ASTM Standards, Vol 04.03.

Annual Book of ASTM Standards, Vol 06.01. ings, determined on samples before and after high temperature

Annual Book of ASTM Standards, Vol 06.03.

shelf aging, shall be not less than 50 %.

Annual Book of ASTM Standards, Vol 15.05.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2824

Note—All dimensions are subject to a tolerance of 60.1 mm (60.004 in.) Material: nickel-plated brass or stainless steel.

FIG. 1 Propeller Rotor for Use with Stormer Viscometer

7. Sampling

S 5 mass of original sample, g.

7.1 Sample the material from the original containers imme- Record the average of the two separate determinations.

8.3 Insoluble in CS —Test Method D 4. Trichloroethylene

diately after stirring to a uniform consistency in accordance

with Practice D 140. Restir the samples to ensure uniformity may be used in place of carbon disulfide, if desired.

8.4 Metallic Aluminum:

immediately before withdrawing portions for individual tests.

8.4.1 Reagents—Reagent grade chemicals or equivalent,

8. Test Methods

prepared in conformance with Practice E 200, shall be used in

the determination of metallic aluminum.

8.1 Water—Test Method D 95.

8.4.1.1 Water—Use only distilled or deionized water.

8.2 Nonvolatile Matter—Weigh 10 6 1 g of coating to the

8.4.1.2 Ferric Sulfate Solution—Dissolve 330 g of ferric

nearest 0.01 g into each of two tared, flat-bottom dishes having

3 3

sulfate [Fe (SO ) ·9H O] in 750 cm of water and 75 cm of

a diameter of approximately 2.5 in. (64 mm) and walls ⁄8 in.

2 4 3 2

concentrated sulfuric acid (sp gr 1.84). Heat the solution and let

(16 mm) high. Heat the dish and contents in an oven at 320 to

stand 2 days to dissolve the ferric sulfate completely. Then add

330°F (160 to 166°C) until the residue shows a loss of not

water to make up a total volume of 1000 cm .

more than 0.05 g on successive hourly weighings. Make each

8.4.1.3 Indicator (Diphenylamine Sulfonate Solution) —

weighing after cooling in a desiccator. Calculate the percent

Dissolve 0.32 g of the barium salt of diphenylamine sulfonic

nonvolatile matter from the mass of the residue and the mass of

acid in 100 cm of water. Then add 0.5 g of sodium sulfate and

the original sample as follows:

filter off the precipitate of barium sulfate.

Nonvolatile matter, % 5 ~R /S! 3 100 (1)

e

where:

Diphenylamine sulfonate can be purchased from Sargent and Co., Distillation

R 5 mass of residue from evaporation, g, and

e

Products Industries, Division of Eastman Kodak Co., and possibly other firms.

D 2824

NOTE 2—Reduce the rate of addition of potassium dichromate near the

8.4.1.4 Phosphoric Acid—CP 85 % orthophosphoric acid.

titration end point in order to be able to recognize the transition from green

8.4.1.5 Potassium Dichromate Solution—Prepare a 0.5 N

to intense purple. An excess beyond this point will produce an olive green

solution by dissolving 24.52 g of potassium dichromate in

color.

water and making up to 1000 cm .

8.5 Consistency:

8.4.1.6 Sodium Bicarbonate Solution—Prepare a saturated

8.5.1 Apparatus—Use the apparatus and equipment speci-

solution of sodium bicarbonate (approximately 10 %).

fied in Test Method D 562, Procedure A. See also 8.5 of

8.4.2 Filtering Apparatus:

Specification D 2823.

8.4.2.1 Gooch Crucible, glazed inside and outside with the

8.5.2 Procedure:

exception of the outside bottom surface. The approximate

8.5.2.1 Type I Coating—Thoroughly mix the sample and fill

dimensions shall be a diameter of 44 mm at the top tapering to

a 500-cm (1-pt) container to within ⁄4 in. (20 mm) of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.