ASTM D8020-15

(Test Method)Standard Test Method for Freeze-Thaw Viscosity Stability of Water-Based Inks and Ink Vehicles

Standard Test Method for Freeze-Thaw Viscosity Stability of Water-Based Inks and Ink Vehicles

SIGNIFICANCE AND USE

4.1 When waterborne inks and ink vehicles are shipped during cold weather, these materials may experience cycles of freezing and thawing. This can damage the material rendering it unusable.

4.2 Cycles of freezing and thawing can cause more damage to waterborne inks or ink vehicles than when the inks or ink vehicles are subjected to steady freezing.

SCOPE

1.1 This test method covers a procedure for evaluating the effect of freeze-thaw cycling on the properties of water-based inks and ink vehicles.

1.2 This test is based on a similar standard test for coatings; Test Method D2243.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D8020 −15

Standard Test Method for

Freeze-Thaw Viscosity Stability of Water-Based Inks and Ink

1

Vehicles

This standard is issued under the fixed designation D8020; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope thawing. After cycling, the ink or ink vehicle is examined for

changes in viscosity and uniformity.

1.1 This test method covers a procedure for evaluating the

effect of freeze-thaw cycling on the properties of water-based

4. Significance and Use

inks and ink vehicles.

4.1 When waterborne inks and ink vehicles are shipped

1.2 This test is based on a similar standard test for coatings;

during cold weather, these materials may experience cycles of

Test Method D2243.

freezing and thawing. This can damage the material rendering

1.3 The values stated in SI units are to be regarded as the

it unusable.

standard. The values given in parentheses are for information

4.2 Cycles of freezing and thawing can cause more damage

only.

to waterborne inks or ink vehicles than when the inks or ink

1.4 This standard does not purport to address all of the

vehicles are subjected to steady freezing.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Apparatus

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5.1 Test Chamber, a suitable cabinet, room, or enclosure

space large enough to contain the specimens to be tested

2. Referenced Documents

permitting at least 25 mm (1 in.) of air space between the sides

2

of adjacent jars and capable of being maintained continuously

2.1 ASTM Standards:

at a temperature of –18°C (0°F).

D2243 Test Method for Freeze-Thaw Resistance of Water-

NOTE1—Althoughavariationofthetestchambertemperatureof 62°C

Borne Coatings

(3.5°F) is allowed, the test chamber temperature should be maintained as

D2196 Test Methods for Rheological Properties of Non-

near –18°C (0°F) as practicable and the amount of variation should be

Newtonian Materials by Rotational Viscometer

recorded and reported.

D4212 Test Method for Viscosity by Dip-Type Viscosity

5.2 Viscometer, a dip-type viscosity cup as described in Test

Cups

Method D4212 or a Brookfield type viscometer as described in

E177 Practice for Use of the Terms Precision and Bias in

Test Methods D2196.

ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to

5.3 Recirculating Water Bath, capable of maintaining a

Determine the Precision of a Test Method

temperature of 25 6 1°C (77 61.8°F).

5.4 Cylindrical Container, with a capacity of 0.5-L (1-pt),

3. Summary of Test Method

3

85 mm (3 ⁄8 in.) diameter to contain the test specimen during

3.1 The waterborne ink or ink vehicle is placed into two

testing.

237-mL plastic jars. One jar is stored at room temperature,

5.5 Spatula.

while the other jar is subjected to cycles of freezing and

6. Sampling and Test Specimens

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6.1 Ensure that the bulk sample from which the jars are

and Related Coatings, Materials, andApplications and is the direct responsibility of

filled is well stirred and uniform, the containers used are clean,

Subcommittee D01.37 on Ink Vehicles.

and the lids are applied promptly to the jars to prevent

Current edition approved Dec. 1, 2015. Published January 2016. DOI: 10.1520/

D8020-15.

evaporation losses. Prepare two specimens for testing by filling

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

0.5-L plastic jars with 400 mL of the ink or ink vehicle.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Identify one as the test specimen and the other as the control

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specimen.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8020−15

7. Procedure 9.1.3 The number of cycles passed by the test specimen.

7.1 Stir the specimen by hand and measure its viscosity in

3

10. Precision and Bias

accordance with Test Methods D4212 or D2196.

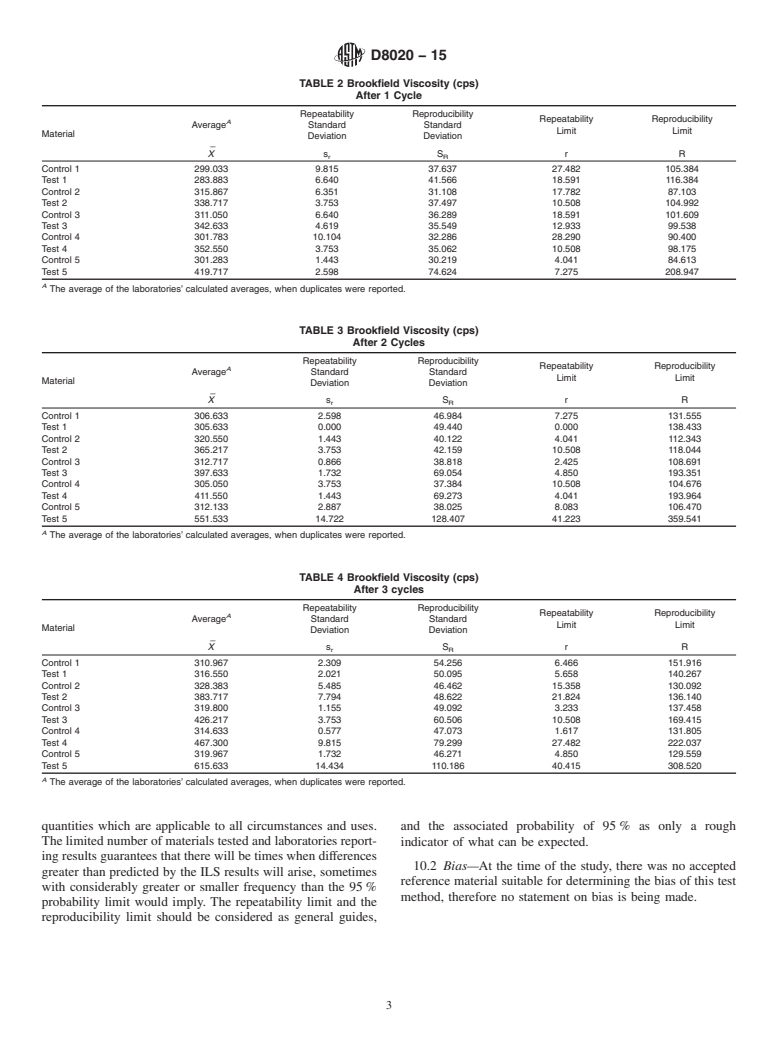

10.1 The precision of this test method is based on an

7.2 Store the control specimen at room temperature.

interlaboratory study of ASTM D8020, Test Method for

7.3 Place the test specimen in the chamber maintained at

Freeze-Thaw Viscosity Stability of Water-Based Inks and Ink

–18°C (0°F) in such a manner that it does not touch the walls

Vehicles, conducted in 2013. A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.