ASTM C1221-10(2018)

(Test Method)Standard Test Method for Nondestructive Analysis of Special Nuclear Materials in Homogeneous Solutions by Gamma-Ray Spectrometry

Standard Test Method for Nondestructive Analysis of Special Nuclear Materials in Homogeneous Solutions by Gamma-Ray Spectrometry

SIGNIFICANCE AND USE

5.1 This test method is a nondestructive means of determining the nuclide concentration of a solution for special nuclear material accountancy, nuclear safety, and process control.

5.2 It is assumed that the nuclide to be analyzed is in a homogeneous solution (Practice C1168).

5.3 The transmission correction makes the test method independent of matrix (solution elemental composition and density) and useful over several orders of magnitude of nuclide concentrations. However, a typical configuration will normally span only two to three orders of magnitude because of detector dynamic range.

5.4 The test method assumes that the solution-detector geometry is the same for all measured items. This can be accomplished by requiring that the liquid height in the sidelooking geometry exceeds the detector field of view defined by the collimator. For the upward-looking geometry, a fixed solution fill height must be maintained and vials of identical radii must be used unless the vial radius exceeds the field of view defined by the collimator.

5.5 Since gamma-ray systems can be automated, the test method can be rapid, reliable, and not labor intensive.

5.6 This test method may be applicable to in-line or off-line situations.

SCOPE

1.1 This test method covers the determination of the concentration of gamma-ray emitting special nuclear materials dissolved in homogeneous solutions. The test method corrects for gamma-ray attenuation by the solution and its container by measurement of the transmission of a beam of gamma rays from an external source (Refs. (1), (2), and (3)).2

1.2 Two solution geometries, slab and cylinder, are considered. The solution container that determines the geometry may be either a removable or a fixed geometry container. This test method is limited to solution containers having walls or a top and bottom of equal transmission through which the gamma rays from the external transmission correction source must pass.

1.3 This test method is typically applied to radionuclide concentrations ranging from a few milligrams per litre to several hundred grams per litre. The assay range will be a function of the specific activity of the nuclide of interest, the physical characteristics of the solution container, counting equipment considerations, assay gamma-ray energies, solution matrix, gamma-ray branching ratios, and interferences.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazards, see Section 9.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C1221 −10 (Reapproved 2018)

Standard Test Method for

Nondestructive Analysis of Special Nuclear Materials in

Homogeneous Solutions by Gamma-Ray Spectrometry

This standard is issued under the fixed designation C1221; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of the con-

2.1 ASTM Standards:

centration of gamma-ray emitting special nuclear materials

C1133/C1133MTest Method for Nondestructive Assay of

dissolved in homogeneous solutions. The test method corrects

SpecialNuclearMaterialinLow-DensityScrapandWaste

for gamma-ray attenuation by the solution and its container by

by Segmented Passive Gamma-Ray Scanning

measurement of the transmission of a beam of gamma rays

C1168PracticeforPreparationandDissolutionofPlutonium

from an external source (Refs. (1), (2), and (3)).

Materials for Analysis

1.2 Two solution geometries, slab and cylinder, are consid- C1490GuidefortheSelection,TrainingandQualificationof

ered.The solution container that determines the geometry may Nondestructive Assay (NDA) Personnel

be either a removable or a fixed geometry container. This test

C1592/C1592MGuide for Making Quality Nondestructive

method is limited to solution containers having walls or a top

Assay Measurements (Withdrawn 2018)

and bottom of equal transmission through which the gamma

C1673Terminology of C26.10 NondestructiveAssay Meth-

rays from the external transmission correction source must

ods

pass.

E181Test Methods for Detector Calibration andAnalysis of

Radionuclides

1.3 This test method is typically applied to radionuclide

concentrations ranging from a few milligrams per litre to

2.2 ANSI Standards:

several hundred grams per litre. The assay range will be a

ANSI N15.20Guide to Calibrating Nondestructive Assay

function of the specific activity of the nuclide of interest, the

Systems

physical characteristics of the solution container, counting

ANSI N15.35Guide to Preparing Calibration Material for

equipment considerations, assay gamma-ray energies, solution

NondestructiveAssaySystemsthatCountPassiveGamma

matrix, gamma-ray branching ratios, and interferences.

Rays

1.4 This standard does not purport to address all of the ANSI N15.37Guide to the Automation of Nondestructive

safety concerns, if any, associated with its use. It is the

Assay Systems for Nuclear Material Control

responsibility of the user of this standard to establish appro-

ANSI N42.14American National Standard for Calibration

priate safety, health, and environmental practices and deter-

and Use of Germanium Spectrometers for the Measure-

mine the applicability of regulatory limitations prior to use.

ment of Gamma-Ray Emission Rates of Radionuclides

For specific hazards, see Section 9.

ANSI/IEEE 645Test Procedures for High-Purity Germa-

1.5 This international standard was developed in accor-

nium Detectors for Ionizing Radiation

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3. Terminology

Development of International Standards, Guides and Recom-

3.1 Fordefinitionsoftermsusedinthistestmethod,referto

mendations issued by the World Trade Organization Technical

Committee C26.10’s Terminology standard, C1673.

Barriers to Trade (TBT) Committee.

1 3

ThistestmethodisunderthejurisdictionofASTMCommitteeC26onNuclear For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fuel Cycle and is the direct responsibility of Subcommittee C26.10 on Non contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Destructive Assay. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2018. Published April 2018. Originally the ASTM website.

approved in 1992. Last previous edition approved in 2010 as C1221–10. DOI: The last approved version of this historical standard is referenced on

10.1520/C1221-10R18. www.astm.org.

2 5

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

this test method. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1221−10 (2018)

4. Summary of Test Method

4.1 Manynuclearmaterialsspontaneouslyemitgammarays

with energies and intensities characteristic of the decaying

nuclide. The analysis for these nuclear materials is accom-

plished by selecting appropriate gamma rays and measuring

their intensity to identify and quantify the nuclide.

4.1.1 The gamma-ray spectrum of a portion of solution is

obtained with a collimated, high resolution gamma-ray detec-

tor.

4.1.2 Count-rate-dependent losses are determined and cor-

rections are made for these losses.

4.1.3 A correction factor for gamma-ray attenuation in the

solution and its container is determined from the measurement

of the transmitted intensity of an external gamma-ray source.

The gamma rays from the external source have energies close

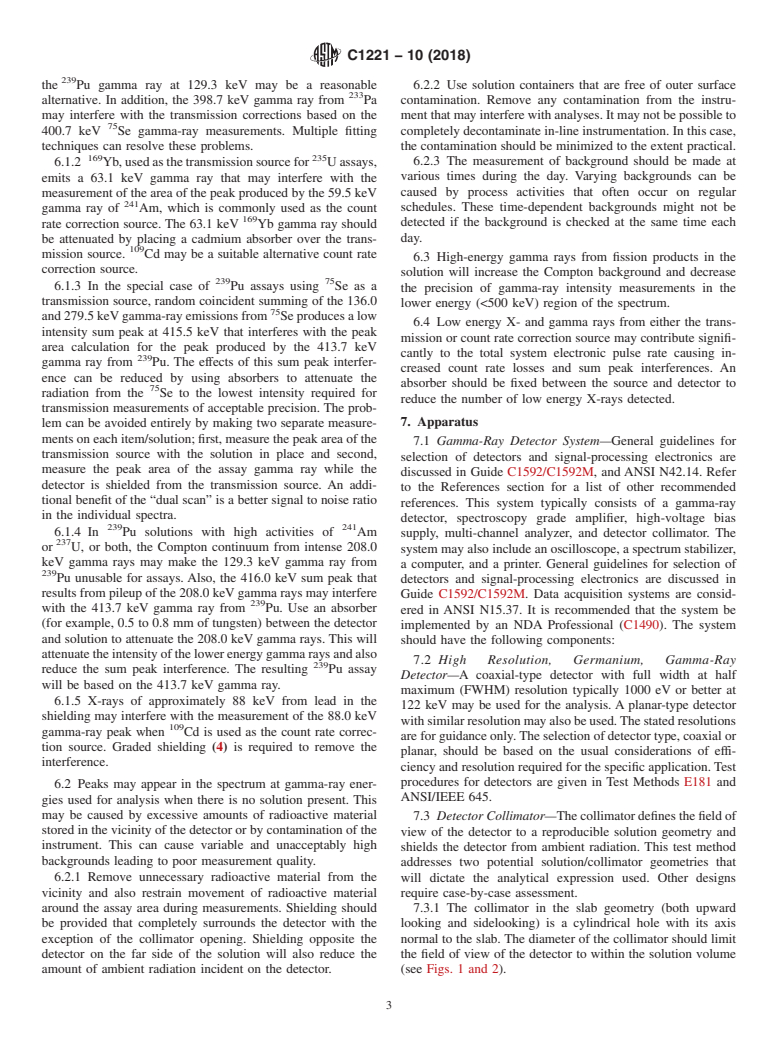

NOTE 1—The sample geometry in this case is a slab. (Not to scale.)

to those of the assay gamma rays emitted from the solution.

FIG. 2Schematic of an Uplooking Configuration

Figs. 1 and 2 illustrate typical transmission source, solution,

and detector configurations. Gamma rays useful for assays of

TABLE 1 Suggested Nuclide/Source Combinations

235 239

U and Pu are listed in Table 1.

Count

Peak Peak Peak

Transmission Rate

4.1.4 The relationship between the measured gamma-ray

Nuclide Energy Energy Energy

Source Correction

intensity and the nuclide concentration (the calibration con- (keV) (keV) (keV)

Source

stant) is determined by use of appropriate standards (ANSI

235 169 241

U 185.7 Yb 177.2 Am 59.5

N15.20, ANSI N15.35, and Guide C1592/C1592M).

198.0

239 75 133

Pu 413.7 Se 400.1 Ba 356.3

4.2 In the event that the total element concentration is

239 57 109

Pu 129.3 Co 122.1 Cd 88.0

desired and only one isotope of an element is determined (for 136.5

example, Pu), the isotopic ratios must be measured or

estimated.

5.4 The test method assumes that the solution-detector

5. Significance and Use

geometry is the same for all measured items. This can be

5.1 Thistestmethodisanondestructivemeansofdetermin-

accomplished by requiring that the liquid height in the side-

ing the nuclide concentration of a solution for special nuclear

lookinggeometryexceedsthedetectorfieldofviewdefinedby

material accountancy, nuclear safety, and process control.

the collimator. For the upward-looking geometry, a fixed

solution fill height must be maintained and vials of identical

5.2 It is assumed that the nuclide to be analyzed is in a

radii must be used unless the vial radius exceeds the field of

homogeneous solution (Practice C1168).

view defined by the collimator.

5.3 The transmission correction makes the test method

5.5 Since gamma-ray systems can be automated, the test

independent of matrix (solution elemental composition and

method can be rapid, reliable, and not labor intensive.

density)andusefuloverseveralordersofmagnitudeofnuclide

concentrations. However, atypical configurationwill normally

5.6 This test method may be applicable to in-line or off-line

spanonlytwotothreeordersofmagnitudebecauseofdetector

situations.

dynamic range.

6. Interferences

6.1 Radionuclides may be present in the solution, which

produce gamma rays with energies that are the same or very

nearly the same as the gamma rays suggested for nuclide

measurement,countratecorrection,ortransmissioncorrection.

Thus,thecorrespondingpeaksinthegamma-rayspectrummay

be unresolved and their areas may not be easily determined

unless multiplet fitting techniques are used. In some cases, the

nuclideofinterestmayemitothergammaraysthatcanbeused

foranalysisoralternativetransmissionorcountratecorrection

sources may be used.

6.1.1 Occasionally,asignificantamountof Npisfoundin

237 233

a plutonium solution. The Np daughter, Pa, emits a

gamma ray at 415.8 keV as well as other gamma rays in the

300 to 400 keVregion.These Pa gamma rays may interfere

NOTE1—Thesamplegeometrymaybeeithercylindricaloraslab.(Not

with the analysis of Pu at 413.7 keV and at several other

to scale.)

FIG. 1Schematic of a Sidelooking Configuration normally useful Pu gamma-ray energies. In this case,

C1221−10 (2018)

the Pu gamma ray at 129.3 keV may be a reasonable 6.2.2 Use solution containers that are free of outer surface

alternative. In addition, the 398.7 keV gamma ray from Pa contamination. Remove any contamination from the instru-

may interfere with the transmission corrections based on the mentthatmayinterferewithanalyses.Itmaynotbepossibleto

400.7 keV Se gamma-ray measurements. Multiple fitting completelydecontaminatein-lineinstrumentation.Inthiscase,

techniques can resolve these problems. the contamination should be minimized to the extent practical.

169 235

6.2.3 The measurement of background should be made at

6.1.2 Yb,usedasthetransmissionsourcefor Uassays,

various times during the day. Varying backgrounds can be

emits a 63.1 keV gamma ray that may interfere with the

caused by process activities that often occur on regular

measurementoftheareaofthepeakproducedbythe59.5keV

schedules. These time-dependent backgrounds might not be

gamma ray of Am, which is commonly used as the count

detected if the background is checked at the same time each

rate correction source. The 63.1 keV Yb gamma ray should

day.

be attenuated by placing a cadmium absorber over the trans-

mission source. Cd may be a suitable alternative count rate

6.3 High-energy gamma rays from fission products in the

correction source.

solution will increase the Compton background and decrease

239 75

6.1.3 In the special case of Pu assays using Se as a

the precision of gamma-ray intensity measurements in the

transmission source, random coincident summing of the 136.0

lower energy (<500 keV) region of the spectrum.

and279.5keVgamma-rayemissionsfrom Seproducesalow

6.4 Low energy X- and gamma rays from either the trans-

intensity sum peak at 415.5 keV that interferes with the peak

mission or count rate correction source may contribute signifi-

area calculation for the peak produced by the 413.7 keV

cantly to the total system electronic pulse rate causing in-

gamma ray from Pu. The effects of this sum peak interfer-

creased count rate losses and sum peak interferences. An

ence can be reduced by using absorbers to attenuate the

absorber should be fixed between the source and detector to

radiation from the Se to the lowest intensity required for

reduce the number of low energy X-rays detected.

transmission measurements of acceptable precision. The prob-

7. Apparatus

lem can be avoided entirely by making two separate measure-

mentsoneachitem/solution;first,measurethepeakareaofthe

7.1 Gamma-Ray Detector System—General guidelines for

transmission source with the solution in place and second,

selection of detectors and signal-processing electronics are

measure the peak area of the assay gamma ray while the

discussed in Guide C1592/C1592M, and ANSI N42.14. Refer

detector is shielded from the transmission source. An addi-

to the References section for a list of other recommended

tional benefit of the “dual scan” is a better signal to noise ratio

references. This system typically consists of a gamma-ray

in the individual spectra.

detector, spectroscopy grade amplifier, high-voltage bias

239 241

6.1.4 In Pu solutions with high activities of Am

supply, multi-channel analyzer, and detector collimator. The

or U, or both, the Compton continuum from intense 208.0

systemmayalsoincludeanoscilloscope,aspectrumstabilizer,

keV gamma rays may make the 129.3 keV gamma ray from

a computer, and a printer. General guidelines for selection of

Pu unusable for assays. Also, the 416.0 keV sum peak that

detectors and signal-processing electronics are discussed in

resultsfrompileupofthe208.0keVgammaraysmayinterfere

Guide C1592/C1592M. Data acquisition systems are consid-

with the 413.7 keV gamma ray from Pu. Use an absorber

ered in ANSI N15.37. It is recommended that the system be

(for example, 0.5 to 0.8 mm of tungsten) between the detector

implemented by an NDA Professional (C1490). The system

and solution to attenuate the 208.0 keV gamma rays. This will

should have the following components:

attenuatetheintensityofthelowerenergygammaraysandalso

7.2 High Resolution, Germanium, Gamma-Ray

reduce the sum peak interference. The resulting Pu assay

Detector—A coaxial-type detector with full width at half

will be based on the 413.7 keV gamma ray.

maximum (FWHM) resolution typically 1000 eV or better at

6.1.5 X-rays of approximately 88 keV from lead in the

122 keV may be used for the analysis. A planar-type detector

shielding may interfere with the measurement of the 88.0 keV

withsimilarresolutionmayalsobeused.Thestatedresolutions

gamma-ray peak when Cd is used as the count rate correc-

areforguidanceonly.Theselectionofdetectortype,coaxialor

tion source. Graded shielding (4) is required to remove the

planar, should be based on the usual considerations of effi-

interference.

ciencyandresolutionrequiredforthespecificapplication.Test

procedures for detectors are given in Test Methods E181 and

6.2 Peaks may appear in the spectrum at gamma-ray ener-

ANSI/IEEE 645.

gies used for analysis when there is no solution present. This

may be caused by excessive amounts of radioactive material

7.3 DetectorCollimator—Thecollimatordefinesthefieldof

storedinthevicinityofthedetectororbycontaminationofthe

view of the detector to a reproducible solution geometry and

instrument. This can cause variable and unacceptably high

shields the detector from ambient radiation. This test method

backgrounds leading to poor measurement quality.

addresses two potential solution/collimator geometries that

6.2.1 Remove unnecessary radioactive material from the will dictate the analytical expression used. Other designs

vicinity and also restrain movement of radioactive material require case-by-case assessment.

around the assay area during measurements. Shielding should 7.3.1 The collimator in the slab geometry (both upward

be provided that completely surrounds the detector with the looking and sidelooking) is a cyl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.