ASTM D4537-04a

(Guide)Standard Guide for Establishing Procedures to Qualify and Certify Personnel Performing Coating Work Inspection in Nuclear Facilities

Standard Guide for Establishing Procedures to Qualify and Certify Personnel Performing Coating Work Inspection in Nuclear Facilities

SIGNIFICANCE AND USE

The requirements of this guide apply to personnel who perform coating work inspection during (1) fabrication, (2) receipt of items at the construction site, (3) construction, (4) pre-operational and startup testing, and (5) operational phases of nuclear facilities.

It is the responsibility of each organization participating in the project to ensure that only those personnel within their respective organizations who meet the requirements of this guide are permitted to perform coating work inspection activities covered by this guide.

The organization(s) responsible for establishing the applicable requirements for activities covered by this guide shall be identified, and the scope of their responsibility shall be documented. Delegation of this responsibility to other qualified organizations is permitted and shall be documented.

It is the responsibility of the organization performing these activities to specify the detailed methods and procedures for meeting the requirements of this guide, unless they are otherwise specified in the contract documents.

In the event of conflict, users of this guide must recognize that the licensee’plant-specific quality assurance program and licensing commitments shall prevail with respect to the process of qualifying personnel performing inspection of coating work.

SCOPE

1.1 This guide delineates the requirements for development of procedures for the qualification of personnel who perform inspection of coating work. These activities are accomplished to verify conformance to specified requirements for nuclear facility coating work whose satisfactory performance is required in order not to compromise safety-related coating systems.

1.2 This guide provides a uniform interpretation of the intent of the requirements in ANSI/ASME N45.2.6 for the inspection of coating work in nuclear facilities.

1.3 This guide meets the intent of ANSI/ASME NQA-1.

1.4 It is the intent of this guide to provide a recommended basis for qualification, not to mandate a singular basis for all qualifications. Variations or simplifications of the qualifications described in this guide may be appropriate for special coating work other than safety-related coating systems. Similarly, the qualification and certification process might be abbreviated for work of minor scope such as touch-up.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4537 – 04a

Standard Guide for

Establishing Procedures to Qualify and Certify Personnel

1

Performing Coating Work Inspection in Nuclear Facilities

This standard is issued under the fixed designation D4537; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ANSI/ASME NQA-1 Quality Assurance Program Require-

ments for Nuclear Facilities

1.1 This guide delineates the requirements for development

of procedures for the qualification of personnel who perform

3. Terminology

inspection of coating work. These activities are accomplished

3.1 Definitions of Terms Specific to This Standard:

to verify conformance to specified requirements for nuclear

3.1.1 certification, n—written documentation of qualifica-

facility coating work whose satisfactory performance is re-

tion.

quired in order not to compromise safety-related coating

3.1.2 coating work inspection, n—a phase of quality control

systems.

that, by means of examination, observation, or measurement,

1.2 The intent of this guide is to provide a uniform inter-

determines the conformance of safety-related coating system

pretation of the requirements in ANSI/ASME N45.2.6 and

applications to predetermined quality requirements. The term

NQA-1 for the inspection of coating work in nuclear facilities.

inspection as used in this standard shall be understood to mean

1.3 It is the intent of this guide to provide a recommended

coating work inspection.

basis for qualification, not to mandate a singular basis for all

3.1.3 Level I, II, and III inspection, n—indicative of the

qualifications.Variationsorsimplificationsofthequalifications

time in grade classification for personnel who perform coating

described in this guide may be appropriate for special coating

workinspection.Eachlevelreflectsprogressiveexperienceand

work other than safety-related coating systems. Similarly, the

responsibility. This term is separate from and differs distinctly

qualification and certification process might be abbreviated for

from Coating Service Levels. The latter term reflects differing

work of minor scope such as touch-up.

locations throughout a nuclear plant where safety-related and

1.4 This standard does not purport to address all of the

other coatings are found. (See Terminology section of Guide

safety concerns, if any, associated with its use. It is the

D5144 for definitions of Coating Service Levels I, II, and III.)

responsibility of whoever uses this standard to consult and

3.1.4 personnel performing coating work inspection,

establish appropriate safety and health practices and deter-

n—individuals whose job functions include but are not neces-

mine the applicability of regulatory limitations prior to use.

sarily limited to coating work inspection.

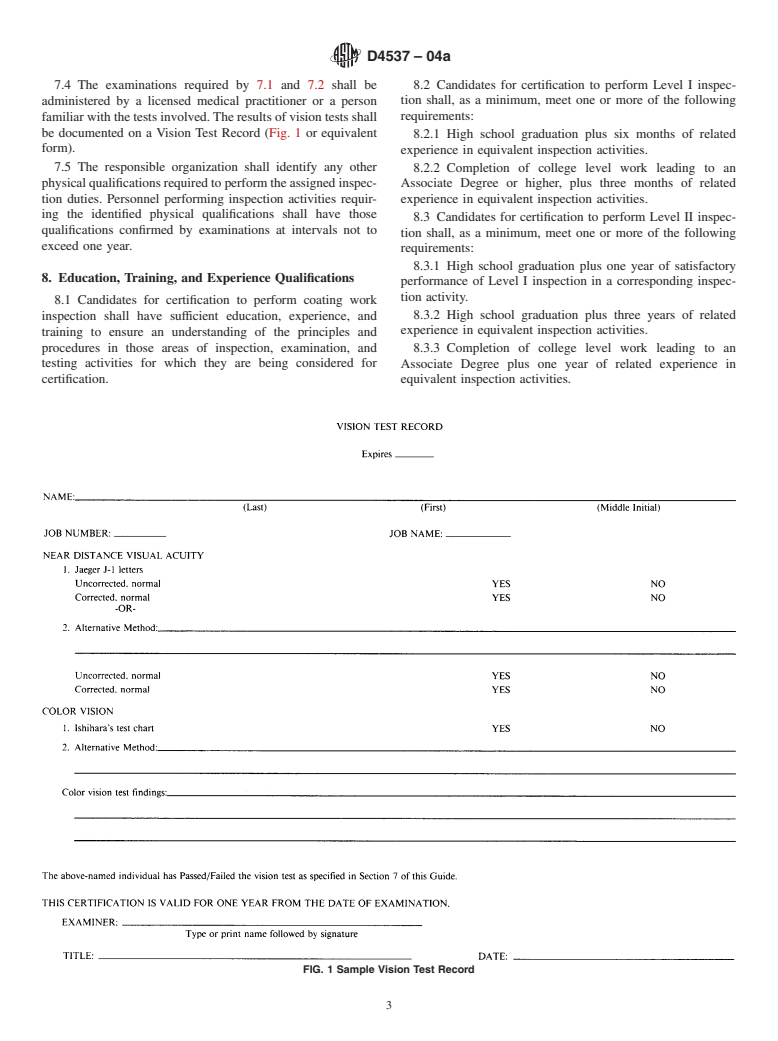

2. Referenced Documents 3.1.5 qualifications, n—skills, training, and experience re-

2 quiredforpersonneltoperformproperlythedutiesandexecute

2.1 ASTM Standards:

the responsibilities of the appropriate certification level.

D5144 Guide for Use of Protective Coating Standards in

3.1.6 safety-related coating system, n—a coating system

Nuclear Power Plants

3

used inside or outside of the reactor containment, the detach-

2.2 ANSI/ASME Standards:

ment of which could adversely affect the safety function of

ANSI/ASME N45.2.6 Qualifications of Inspection, Exami-

safety-related structures, systems, or components (SSC).

nation, and Testing Personnel for Nuclear Power Plants

3.1.7 training, n—the program developed to ensure that

personnel receive the knowledge and skills necessary for

1

This guide is under the jurisdiction of ASTM Committee D33 on Protective

qualification.

Coating and Lining Work for Power Generation Facilities and is the direct

responsibility of Subcommittee D33.04 on Quality Systems and Inspection.

4. Significance and Use

Current edition approved Aug. 1, 2004. Published September 2004. Originally

approved in 1986. Last previous edition approved in 2004 as D4537 – 04. DOI: 4.1 The requirements of this guide apply to personnel who

10.1520/D4537-04A.

perform coating work inspection during (1) fabrication, (2)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

receipt of items at the construction site, (3) construction, (4)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pre-operational and startup testing, and (5) operational phases

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

of nuclear facilities.

3

Available fromAmerican National Standards Institute, 11 W. 42nd Street, 13th

Floor, New York, NY 10036.

Copyright © ASTM International,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.