ASTM E928-03

(Test Method)Standard Test Method for Determination of Purity by Differential Scanning Calorimetry

Standard Test Method for Determination of Purity by Differential Scanning Calorimetry

SCOPE

1.1 This method describes the determination of purity of materials greater than 98.5 mole percent purity using differential scanning calorimetry and the van't Hoff equation.

1.2 This test method is applicable to thermally stable compounds with well-defined melting temperatures.

1.3 Determination of purity by this test method is only applicable when the impurity dissolves in the melt and is insoluble in the crystal.

1.4 Computer- or electronic-based instruments, techniques, or data treatments equivalent to this test method may also be used.

Note 1—Since all data treatments are not equivalent, it is the responsibility of the user to verify equivalency prior to use.

1.5 SI values are the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 There is no ISO method equivalent to this method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E928–03

Standard Test Method for

1

Purity by Differential Scanning Calorimetry

This standard is issued under the fixed designation E928; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This method describes the determination of purity of 3.1 Definitions—Thedefinitionsrelatingtothermalanalysis

materials greater than 98.5 mole percent purity using differen- appearinginTerminologyE473shallbeconsideredapplicable

tial scanning calorimetry and the van’t Hoff equation. to this method.

1.2 This test method is applicable to thermally stable

4. Summary of Method

compounds with well-defined melting temperatures.

3

4.1 This method is based upon the van’t Hoff equation :

1.3 Determination of purity by this test method is only

applicable when the impurity dissolves in the melt and is

2

T 5 T 2 ~RT x!/ ~HF! (1)

s o o

insoluble in the crystal.

1.4 Computer- or electronic-based instruments, techniques,

where:

T = specimen temperature, K

or data treatments equivalent to this test method may also be

s

T = melting temperature of 100% pure material, K

used.

o

−1 −1

R = gas constant (= 8.314 J mol K ),

NOTE 1—Since all data treatments are not equivalent, it is the respon-

x = mole fraction of impurity,

sibility of the user to verify equivalency prior to use. −1

H = heat of fusion, J mol , and

1.5 SI values are the standard. F = fraction melted.

1.6 This standard does not purport to address all of the

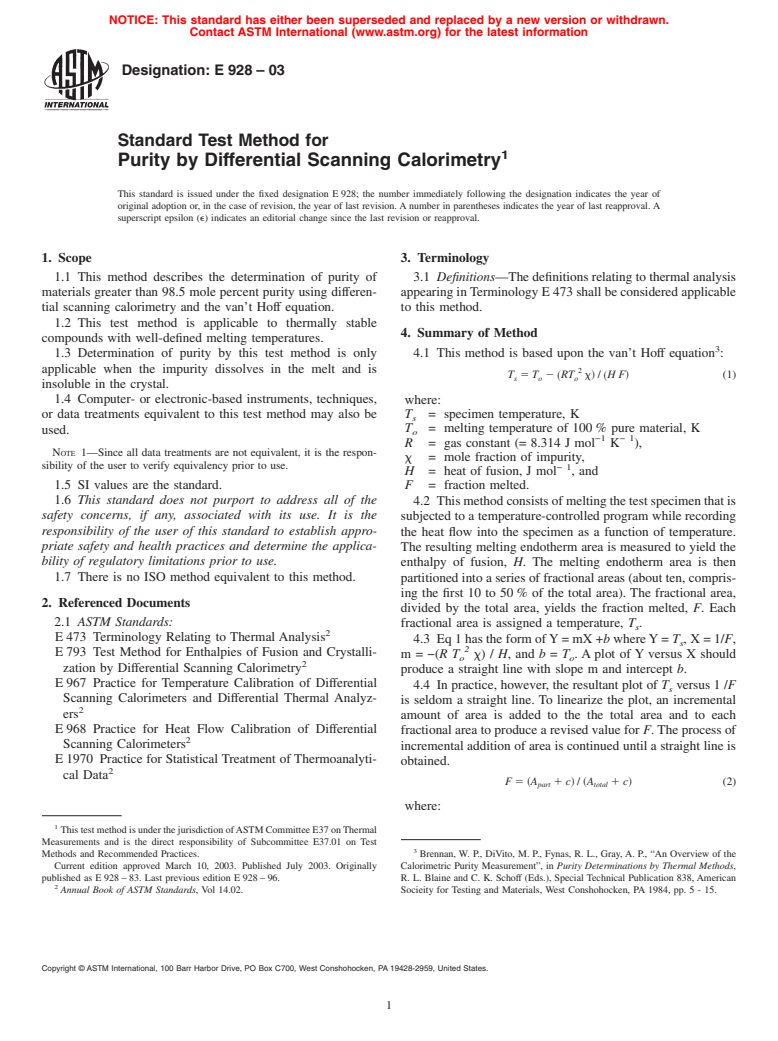

4.2 Thismethodconsistsofmeltingthetestspecimenthatis

safety concerns, if any, associated with its use. It is the subjected to a temperature-controlled program while recording

responsibility of the user of this standard to establish appro-

the heat flow into the specimen as a function of temperature.

priate safety and health practices and determine the applica- The resulting melting endotherm area is measured to yield the

bility of regulatory limitations prior to use.

enthalpy of fusion, H. The melting endotherm area is then

1.7 There is no ISO method equivalent to this method.

partitionedintoaseriesoffractionalareas(aboutten,compris-

ing the first 10 to 50% of the total area). The fractional area,

2. Referenced Documents

divided by the total area, yields the fraction melted, F. Each

2.1 ASTM Standards:

fractional area is assigned a temperature, T .

s

2

E473 Terminology Relating to Thermal Analysis

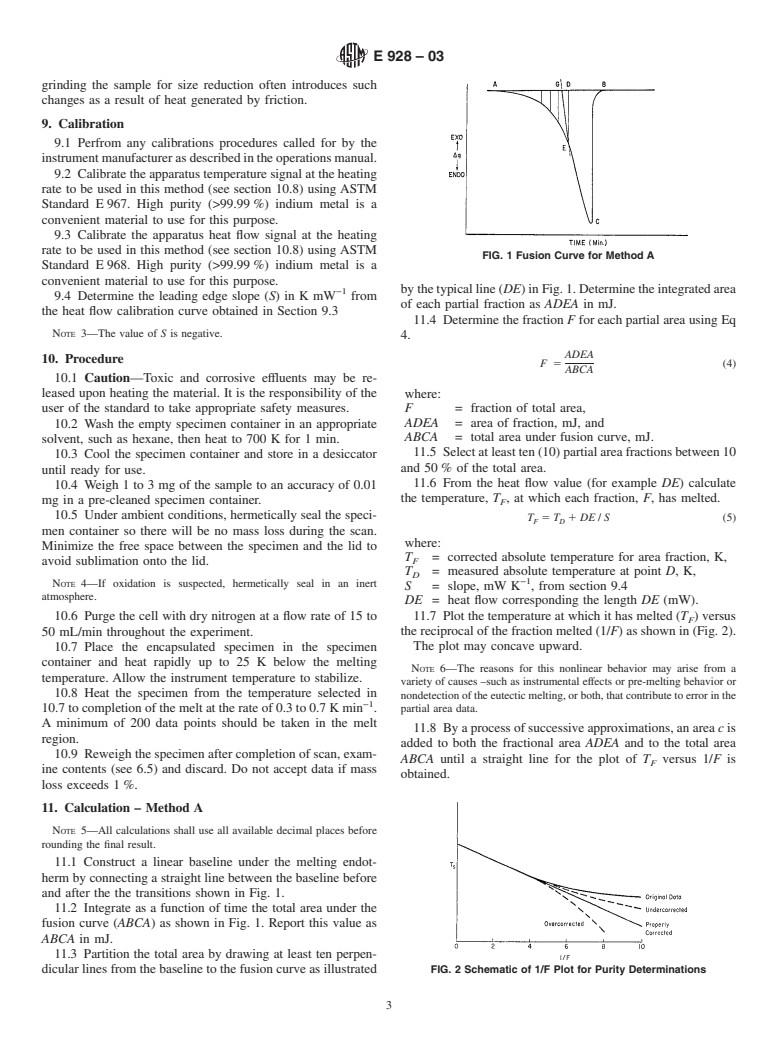

4.3 Eq1hastheformofY=mX+bwhereY= T,X=1/F,

s

2

E793 Test Method for Enthalpies of Fusion and Crystalli-

m=−(RT x)/ H, and b = T . A plot of Y versus X should

o o

2

zation by Differential Scanning Calorimetry

produce a straight line with slope m and intercept b.

E967 Practice for Temperature Calibration of Differential

4.4 In practice, however, the resultant plot of T versus 1 /F

s

Scanning Calorimeters and Differential Thermal Analyz-

is seldom a straight line. To linearize the plot, an incremental

2

ers

amount of area is added to the the total area and to each

E968 Practice for Heat Flow Calibration of Differential

fractionalareatoproducearevisedvaluefor F.Theprocessof

2

Scanning Calorimeters

incremental addition of area is continued until a straight line is

E1970 Practice for Statistical Treatment of Thermoanalyti-

obtained.

2

cal Data

F 5 ~A 1 c!/ ~A 1 c! (2)

part total

where:

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE37onThermal

Measurements and is the direct responsibility of Subcommittee E37.01 on Test

3

Methods and Recommended Practices. Brennan, W. P., DiVito, M. P., Fynas, R. L., Gray,A. P., “An Overview of the

Current edition approved March 10, 2003. Published July 2003. Originally Calorimetric Purity Measurement”, in Purity Determinations by Thermal Methods,

published as E928–83. Last previous edition E928–96. R. L. Blaine and C. K. Schoff (Eds.), Special Technical Publication 838,American

2

Annual Book of ASTM Standards, Vol 14.02. Socieity for Testing and Materials, West Conshohocken, PA 1984, pp.5-15.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E928–03

6.2.3 The major constituent displays a single well-defined

A = area of fraction melted, mJ

part

meltingendotherminthetemperaturerangeofinterest.Micro-

A = total area, mJ and

total

scopic investigations of the melt and the solid may help to

c = incremental area, mJ.

establish whether or not solid or liquid solutions have been

NOTE 2—The best fit straight line may be determined by the least

formed.

squares method. See Practice E1970.)

6.2.4 The solute and solvent are close in molecular size.

4.5 The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.