ASTM D5178-98(2008)

(Test Method)Standard Test Method for Mar Resistance of Organic Coatings

Standard Test Method for Mar Resistance of Organic Coatings

SIGNIFICANCE AND USE

In some situations, marring of coatings applied to substrates under typical use conditions is unacceptable. This test method has been found useful in differentiating the degree of marring of coatings on substrates. It is most useful in providing relative ratings for a series of coated panels exhibiting significant differences in marring.

In a limited laboratory study, meaningful mar results were impossible when powder coatings were tested. The mar marking, that is, scratches, became less perceptible with time. Therefore, powder coatings may not be applicable coatings for this test method.

SCOPE

1.1 This test method covers the determination of the mar resistance on smooth, flat surfaces. Results are expressed in terms of force-to-mar films of organic coatings such as paint, varnish, and lacquer when applied to smooth, flat planar panel surfaces.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5178 − 98 (Reapproved2008)

Standard Test Method for

Mar Resistance of Organic Coatings

This standard is issued under the fixed designation D5178; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2691 Method for Microscopical Measurement of Dry Film

Thickness of Coatings on Wood Products (Withdrawn

1.1 This test method covers the determination of the mar

1992)

resistance on smooth, flat surfaces. Results are expressed in

terms of force-to-mar films of organic coatings such as paint,

3. Terminology

varnish, and lacquer when applied to smooth, flat planar panel

3.1 Definitions:

surfaces.

3.1.1 mar resistance, n—the ability of a coating to resist

1.2 The values stated in inch-pound units are to be regarded

damage caused by light abrasion. As just defined, it is a

as standard. The values given in parentheses are mathematical

resistance of the surface of the coating to permanent

conversions to SI units that are provided for information only

deformation, resulting from the application of a dynamic

and are not considered standard.

mechanical force.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 Thematerialsundertestareappliedatuniformthickness

priate safety and health practices and determine the applica-

to flat panels of uniform surface texture. After drying/curing,

bility of regulatory limitations prior to use.

the mar resistance is determined by pushing the panels beneath

a rounded stylus or loop that is loaded in increasing amounts

2. Referenced Documents

until the coating is marred.

2.1 ASTM Standards:

5. Significance and Use

D609 Practice for Preparation of Cold-Rolled Steel Panels

5.1 In some situations, marring of coatings applied to

for Testing Paint, Varnish, Conversion Coatings, and

substrates under typical use conditions is unacceptable. This

Related Coating Products

test method has been found useful in differentiating the degree

D823 Practices for Producing Films of Uniform Thickness

of marring of coatings on substrates. It is most useful in

of Paint, Varnish, and Related Products on Test Panels

providing relative ratings for a series of coated panels exhib-

D1005 Test Method for Measurement of Dry-Film Thick-

iting significant differences in marring.

ness of Organic Coatings Using Micrometers

D1186 Test Methods for Nondestructive Measurement of

5.2 In a limited laboratory study, meaningful mar results

Dry Film Thickness of Nonmagnetic Coatings Applied to

were impossible when powder coatings were tested. The mar

a Ferrous Base (Withdrawn 2006)

marking, that is, scratches, became less perceptible with time.

D1400 Test Method for Nondestructive Measurement of Dry

Therefore, powder coatings may not be applicable coatings for

Film Thickness of Nonconductive Coatings Applied to a

this test method.

Nonferrous Metal Base (Withdrawn 2006)

6. Apparatus

6.1 Application Equipment, as described in Practices D823.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6.2 Film-Thickness Measuring Apparatus, as described in

and Related Coatings, Materials, andApplications and is the direct responsibility of

Test Methods D1005, D1186, D1400,or D2691.

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

Current edition approved July 1, 2008. Published July 2008. Originally approved

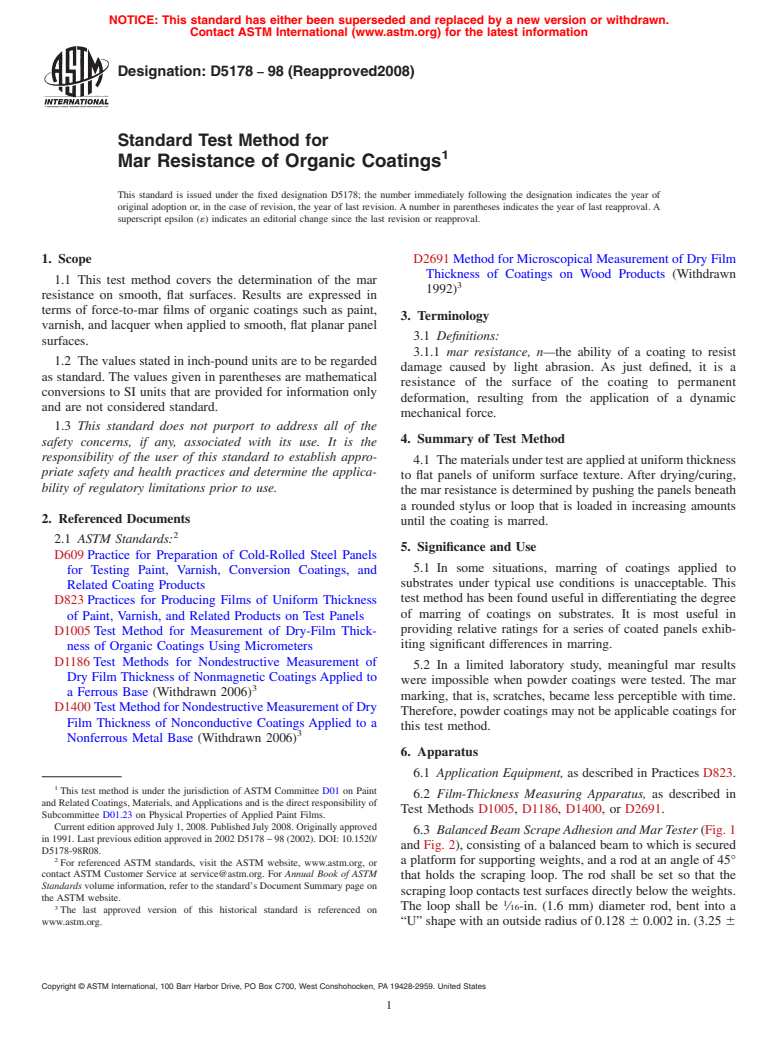

6.3 Balanced Beam Scrape Adhesion and Mar Tester (Fig. 1

in 1991. Last previous edition approved in 2002 D5178 – 98 (2002). DOI: 10.1520/

and Fig. 2), consisting of a balanced beam to which is secured

D5178-98R08.

a platform for supporting weights, and a rod at an angle of 45°

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

that holds the scraping loop. The rod shall be set so that the

Standards volume information, refer to the standard’s Document Summary page on

scraping loop contacts test surfaces directly below the weights.

the ASTM website.

The loop shall be ⁄16-in. (1.6 mm) diameter rod, bent into a

The last approved version of this historical standard is referenced on

www.astm.org. “U” shape with an outside radius of 0.128 6 0.002 in. (3.25 6

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5178 − 98 (2008)

same environment, or immediately on removal therefrom,

unless otherwise specified or agreed upon by the seller and the

purchaser. Test at least two replicate specimens of each

material.

9. Procedure

9.1 In preparation for using the apparatus, ensure that it is

reasonablylevelandplaceitsothattheweightholderistoward

the operator. This places the beam release on the operator’s

right and allows freedom to move the test specimen manually

under the weighted scraping element (loop). Insert the loop

FIG. 1 Balanced Beam Scrape Adhesion and Mar Tester

into the holder as far as it will go and tighten the clamping

screw. Adjust the main bearing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.