ASTM D4062-99

(Test Method)Standard Test Method for Leveling of Paints by Draw-Down Method

Standard Test Method for Leveling of Paints by Draw-Down Method

SCOPE

1.1 This test method covers the laboratory determination of the relative leveling of water and solvent-reducible architectural paints in white and light tints by comparing the ridges produced in a draw-down film to a series of plastic leveling standards.

1.2 Unpigmented, texture, and deep-tint coatings cannot be readily evaluated with the shadowing produced by oblique lighting employed in this test method. Such coatings may be rated by comparing them with the plastic standards at various angles of reflection. For this purpose ordinary room lighting is satisfactory.

1.3 Since other factors may influence the tendency of liquid paints to sag, this test method is not intended to measure sagging.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:D4062–99

Standard Test Method for

Leveling of Paints by Draw-Down Method

This standard is issued under the fixed designation D 4062; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and comparing the contrast of lightness and shadow caused by

2 the paint ridges to that of a series of plastic leveling standards

1.1 Thistestmethod coversthelaboratorydeterminationof

under the same lighting conditions.

the relative leveling of water and solvent-reducible architec-

tural paints in white and light tints by comparing the ridges

4. Significance and Use

produced in a draw-down film to a series of plastic leveling

4.1 Leveling can affect the hiding and appearance of

standards.

applied architectural coatings, the presence of brushmarks and

1.2 Unpigmented, texture, and deep-tint coatings cannot be

surface irregularities being more conspicuous with gloss and

readily evaluated with the shadowing produced by oblique

semi-gloss finishes than with flat finishes. Instrumental evalu-

lighting employed in this test method. Such coatings may be

ations of leveling by this test method have been shown to

rated by comparing them with the plastic standards at various

correlate with those made by brush application.

angles of reflection. For this purpose ordinary room lighting is

satisfactory.

5. Apparatus

1.3 Since other factors may influence the tendency of liquid

3,4

5.1 Leveling Test Blade —A grooved draw-down blade

paints to sag, this test method is not intended to measure

designed to lay down a wet film with parallel ridges (see Fig.

sagging.

1).

1.4 This standard does not purport to address all of the

5.2 Draw-Down Plate, with two parallel, smooth-faced

safety concerns, if any, associated with its use. It is the

straightedges to guide the blade during film application and

responsibility of the user of this standard to establish appro-

ensure that the ridges are straight.

priate safety and health practices and determine the applica-

5.3 Syringe and Needle—A 10-mL LuerLok syringe and

bility of regulatory limitations prior to use.

1 ⁄2-in. (38-mm) No. 15 gage needle for placing a fixed amount

2. Terminology of the paint in front of the blade while simultaneously

preshearing it (as during brushing) prior to drawing-down.

2.1 Definitions of Terms Specific to This Standard:

Either glass or disposable plastic syringes may be used with

2.1.1 leveling—of a paint, a measure of its ability to flow

water-reducible paints. Glass syringes only may be used with

out after application so as to obliterate any surface irregulari-

solvent-reducible paints due to swelling of disposable syringes

ties such as brush marks, orange peel, peaks, or craters that

by the solvent.

have been produced by the mechanical process of application.

3. Summary of Test Method

The Leneta Company, 15 Whitney Road, Mahwah, NJ 07430, is the sole

3.1 The material to be tested is presheared and then applied

manufacturer of the leveling test blade. This blade, the drawn-down plate, chart,

to a sealed chart by means of a special leveling test blade

light source, and levelness standards are all manufactured solely by the Leneta Co.,

and can be obtained from Leneta and most scientific supply houses.

designed to lay down a film with parallel ridges simulating

TheLenetaLevelingTestBladeusedinthistestmethodisamodificationofthe

brush marks. After allowing the completed draw-down to dry

threaded draw-down bar described in an article by Dodge, J. S. “Quantitative

in a horizontal position, leveling of the test paint is rated by

Measures of Leveling,” Journal of Paint Technology, Vol 44, No. 564, January

viewing the draw-down under a strong, oblique light source 1972.

A suitable draw-down plate may be constructed from the description given in

5.2 of this test method.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, andApplications, and is the direct responsibility of

Subcommittee D01.42 on Architectural Finishes.

Current edition approved May 10, 1999. Published July 1999. Originally

published as D 4062 – 81. Last previous edition D 4062 – 88 (1993).

This test method was essentially developed by the Leneta Company as outlined

in Leneta Catalog No. 3, pp. 26–7 (1976).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D4062

in. (ap- in. (ap-

Dimensions: mm Dimensions: mm

prox.) prox.)

A—Length 165 6.5 E—Major doctoring edge 1.25 0.05

B—Diameter 22 0.87 F—Minor clearance 0.10 0.004

C—Supporting edge 25 1.0 G—Clearance step 0.20 0.008

D—Minor doctoring edge 1.25 0.05 H—Major clearance 0.30 0.012

Note—This is actually a cylindrical rod, the term “blade” being employed as a conventional reference to film applicators. Auxillary plastic side arms not shown. See

Fig. 1 (b)and1(c).

FIG. 1 (a) Leneta Leveling Test Draw-Down Blade

Note—Plastic sidearms are for guidance to assure rectilinearity of blade move- Note—Illustration of use of draw-down plate and catch papers. Note that side-

ments. arms are attached to the test blade and parallel straightedge guides on draw-

down plate.

FIG. 1 (b) Photograph of the Leneta Leveling Test Draw-Down Blade FIG. 1 (c) Application With the Leneta Leveling Test Draw-Down Blade

6 7

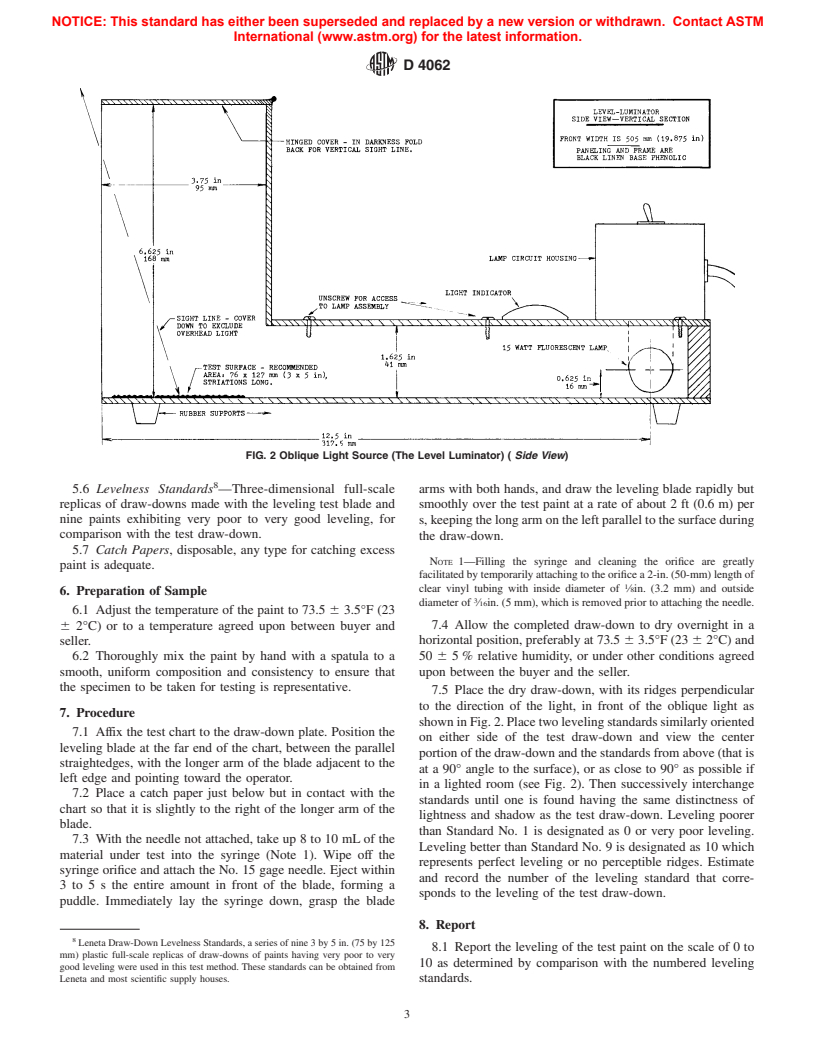

5.4 Test Chart, plain white (for white or light tints) or 5.5 Light Source, oblique,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.