ASTM D5146-98

(Guide)Standard Guide to Testing Solvent-Borne Architectural Coatings

Standard Guide to Testing Solvent-Borne Architectural Coatings

SCOPE

1.1 This guide covers the selection and use of procedures for testing solvent-borne coatings to be used on exterior, interior or both types of surfaces (see Note 1). The properties that can be examined or, in some cases, the relevant test procedures are listed in Tables 1 and 2. Note 1-The term "architectural coating" as used here combines the definition in Definitions D16 with that in the FSCT Paint/Coatings Dictionary, as follows: "Organic coatings intended for on-site application to interior or exterior surfaces of residential, commercial, institutional, or industrial buildings, in contrast to industrial coatings. They are protective and decorative finishes applied at ambient temperatures. Often called Trade Sales Coatings." (See 2.3.) Note 2-Architectural coatings that are designed to give better performance than most conventional coatings because they are tougher and more stain- and abrasion-resistant are covered by Guide D3730.

1.2 The types of organic coatings covered by this guide are as follows: (1) Type 1 Interior Low-Gloss Wall Finish, partly covered by Guide D3323, (2) Type 2 Interior Gloss and Semigloss Wall and Trim Enamels, partly covered by Guide D3425, (3) Type 3 Exterior House and Trim Coatings, now covered by Guide D2932, and (4) Type 4 Floor Enamel, Exterior and/or Interior, now covered by Guide D3383.

1.2.1 Each is intended for application by brushing, rolling, spraying, or other means to the materials appropriate for its type, which may include wood, plaster, wallboard, masonry, steel, previously painted surfaces, and other architectural substrates.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5146 – 98

Standard Guide to

Testing Solvent-Borne Architectural Coatings

This standard is issued under the fixed designation D 5146; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 93 Test Method for Flash Point by Pensky-Martens

Closed Tester

1.1 This guide covers the selection and use of procedures

D 154 Guide for Testing Varnishes

for testing solvent-borne coatings to be used on exterior,

D 185 Test Methods for Coarse Particles in Pigments,

interior or both types of surfaces (see Note 1). The properties

Pastes, and Paints

that can be examined or, in some cases, the relevant test

D 215 Practice for Chemical Analysis of White Linseed Oil

procedures are listed in Table 1 and Table 2.

Paints

NOTE 1—The term “architectural coating” as used here combines the

D 344 Test Method for Relative Hiding Power of Paints by

definition in Terminology D 16 with that in the FSCT Paint/Coatings

the Visual Evaluation of Brushouts

Dictionary, as follows: “Organic coatings intended for on-site application

D 358 Specification for Wood to be Used as Panels in

to interior or exterior surfaces of residential, commercial, institutional, or

Weathering Tests of Coatings

industrial buildings, in contrast to industrial coatings. They are protective

D 522 Test Method for Mandrel Bend Test of Attached

and decorative finishes applied at ambient temperatures. Often called

Trade Sales Coatings.” (See 2.3.)

Organic Coatings

NOTE 2—Architectural coatings that are designed to give better perfor-

D 523 Test Method for Specular Gloss

mance than most conventional coatings because they are tougher and more

D 562 Test Method for Consistency of Paints Using the

stain- and abrasion-resistant are covered by Guide D 3730.

Stormer Viscometer

1.2 The types of organic coatings covered by this guide are

D 658 Test Method for Abrasion Resistance of Organic

as follows:

Coatings by Air Blast Abrasive

(1) Type 1 Interior Low-Gloss Wall Finish,

D 660 Test Method for Evaluating Degree of Checking of

(2) Type 2 Interior Gloss and Semigloss Wall and Trim

Exterior Paints

Enamels,

D 661 Test Method for Evaluating Degree of Cracking of

(3) Type 3 Exterior House and Trim Coatings, and

Exterior Paints

(4) Type 4 Floor Enamel, Exterior and/or Interior.

D 662 Test Method for Evaluating Degree of Erosion of

1.2.1 Each is intended for application by brushing, rolling,

Exterior Paints

spraying, or other means to the materials appropriate for its

D 772 Test Method for Evaluating Degree of Flaking (Scal-

type, which may include wood, plaster, wallboard, masonry,

ing) of Exterior Paints

steel, previously painted surfaces, and other architectural

D 869 Test Method for Evaluating Degree of Settling of

substrates.

Paint

1.3 This standard does not purport to address all of the

D 968 Test Methods for Abrasion Resistance of Organic

safety concerns, if any, associated with its use. It is the

Coatings by Falling Abrasive

responsibility of the user of this standard to establish appro-

D 1006 Practice for Conducting Exterior Exposure Tests of

priate safety and health practices and determine the applica-

Paints on Wood

bility of regulatory limitations prior to use.

D 1014 Test Method for Conducting Exterior Exposure

Tests of Paints on Steel

2. Referenced Documents

D 1038 Terminology Relating to Veneer and Plywood

2.1 ASTM Standards:

D 1208 Test Methods for Common Properties of Certain

D 16 Terminology for Paint and Related Coatings, Materi-

Pigments

als, and Applications

D 1210 Test Method for Fineness of Dispersion of Pigment-

Vehicle Systems by Hegman-Type Gage

This guide is under the jurisdiction of ASTM Committee D-1 on Paint and

Related Coating, Materials, and Applications and is the direct responsibility of

Subcommittee D01.42 on Architectural Finishes. Annual Book of ASTM Standards, Vol 05.01.

Current edition approved June 10, 1998. Published September 1998. Originally Annual Book of ASTM Standards, Vol 06.03.

e1 5

published as D 5146-90. Last previous edition D 5146-90 . Annual Book of ASTM Standards, Vol 06.02.

2 6

Annual Book of ASTM Standards, Vol 06.01. Annual Book of ASTM Standards, Vol 04.10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5146–98

D 1296 Test Method for Odor of Volatile Solvents and D 3928 Test Method for Evaluation of Gloss or Sheen

7 5

Diluents Uniformity

D 1308 Test Method for Effect of Household Chemicals on D 4017 Test Method for Water in Paints and Paint Materials

5 2

Clear and Pigmented Organic Finishes by Karl Fischer Method

D 1475 Test Method for Density of Liquid Coatings, Inks, D 4060 Test Method for Abrasion Resistance of Organic

2 2

and Related Products Coating by the Taber Abraser

D 1543 Test Method for Color Permanence of White Archi- D 4062 Test Method for Leveling of Paints by Draw-Down

8 5

tectural Enamels Method

D 1554 Terminology Relating to Wood-Base Fiber and D 4213 Test Method for Scrub Resistance of Paints by

6 5

Particle Panel Materials Abrasion Weight Loss

D 1640 Test Methods for Drying, Curing or Film Formation D 4214 Test Methods for Evaluating Degree of Chalking of

2 2

of Organic Coatings at Room Temperature Exterior Paint Films

D 1729 Practice for Visual Evaluation of Color Differences D 4287 Test Method for High Shear Viscosity Using the ICI

2 2

of Opaque Materials Cone/Plate Viscometer

D 1849 Test Method for Package Stability of Paint D 4400 Test Methods for Sag Resistance of Paints Using a

D 2196 Test Methods for Rheological Properties of Non- Multinotch Applicator

Newtonian Materials by Rotational (Brookfield) Viscom- D 4585 Practice for Testing Water Resistance of Coatings

2 2

eter Using Controlled Condensation

D 2197 Test Method for Adhesion of Organic Coatings by D 4707 Test Method for Measuring Paint Spatter Resistance

2 5

Scrape Adhesion During Roller Application

D 2244 Test Method for Calculation of Color Differences D 4828 Test Method for Practical Washability of Organic

2 5

from Instrumentally Measured Color Coordinates Coatings

D 2245 Test Method for Identification of Oils and Oil Acids D 4958 Test Method for Comparison of the Brush Drag of

2 5

in Solvent-Reducible Paints Latex Paints

2 9

D 2369 Test Method for Volatile Content of Coatings E 105 Practice for Probability Sampling of Materials

D 2370 Test Method for Tensile Properties of Organic E 313 Practice for Calculating Yellowness and Whiteness

2 2

Coatings Indices from Instrumentally Measured Color Coordinates

D 2371 Test Method for Pigment Content of Solvent- E 1347 Test Method for Color and Color-Difference Mea-

2 2

Reducible Paints surement by Tristimulus (Filter) colorimetry

D 2372 Practice for Separation of Vehicle from Solvent- 2.2 U.S. Federal Standard:

2 10

Reducible Paints Federal Test Method Standard No. 141

D 2486 Test Method for Scrub Resistance of Interior Latex 2112 Application by Roller

Flat Wall Paints 2131 Application of Sprayed Films

D 2621 Test Method for Infrared Identification of Vehicle 2141 Application of Brushed Films

Solids from Solvent-Reducible Paints 3011 Condition in Container

D 2697 Test Method for Volume Nonvolatile Matter in 4203 Reducibility and Dilution Stability

Clear or Pigmented Coatings 4401 Odor Test

D 2698 Test Method for Determination of the Pigment 4421 Absorption Test

Content of Solvent-Reducible Paints by High Speed Cen- 4541 Working Properties and Appearance of Dried Film

trifuging 6132 Accelerated Yellowness

D 2805 Test Method for Hiding Power of Paints by Reflec- 2.3 Other Document:

tometry Paint/Coatings Dictionary of the Federation of Societies for

D 3278 Test Methods for Flash Point of Liquids by Small Coatings Technology

Scale Closed-Cup Apparatus

3. Terminology

D 3359 Test Methods for Measuring Adhesion by Tape

3.1 For definitions of terms in this guide refer to Terminol-

Test

D 3450 Test Method for Washability Properties of Interior ogy D 16, D 1554 and D 1038 and to the FSCT Paint/Coatings

Dictionary.

Architectural Coatings

D 3456 Practice for Determining by Exterior Exposure

4. Conditions Affecting Solvent-Reducible Coatings

Tests Susceptibility of Paint Films to Microbiological

4.1 Interior and Exterior Coatings:

Attack

4.1.1 Substrate Type—The substrate to be painted can affect

D 3730 Guide for Testing High-Performance Interior Archi-

not only the application properties of a coating, such as gloss

tectural Wall Coatings

D 3925 Practice for Sampling Liquid Paints and Related

Pigmented Coatings

Annual Book of ASTM Standards, Vol 14.02.

Standardization Documents Order Desk, Bldg. 4 Section D, 700 Robbins Ave.,

Philadelphia, PA 19111-5094.

7 11

Annual Book of ASTM Standards, Vol 06.04. Available from the Federation of Societies for Coatings Technology, 492

Discontinued; see 1990 Annual Book of ASTM Standards, Vol 06.01. Norristown Rd., Blue Bell, PA 19422.

D5146–98

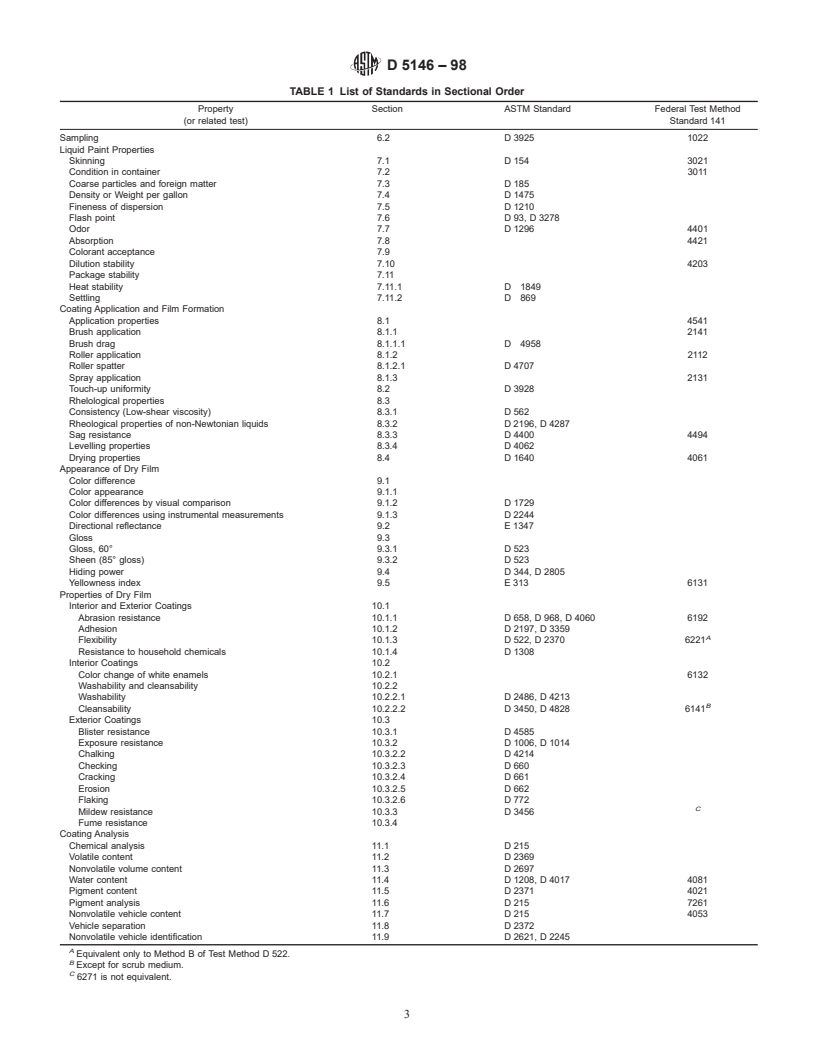

TABLE 1 List of Standards in Sectional Order

Property Section ASTM Standard Federal Test Method

(or related test) Standard 141

Sampling 6.2 D 3925 1022

Liquid Paint Properties

Skinning 7.1 D 154 3021

Condition in container 7.2 3011

Coarse particles and foreign matter 7.3 D 185

Density or Weight per gallon 7.4 D 1475

Fineness of dispersion 7.5 D 1210

Flash point 7.6 D 93, D 3278

Odor 7.7 D 1296 4401

Absorption 7.8 4421

Colorant acceptance 7.9

Dilution stability 7.10 4203

Package stability 7.11

Heat stability 7.11.1 D 1849

Settling 7.11.2 D 869

Coating Application and Film Formation

Application properties 8.1 4541

Brush application 8.1.1 2141

Brush drag 8.1.1.1 D 4958

Roller application 8.1.2 2112

Roller spatter 8.1.2.1 D 4707

Spray application 8.1.3 2131

Touch-up uniformity 8.2 D 3928

Rhelological properties 8.3

Consistency (Low-shear viscosity) 8.3.1 D 562

Rheological properties of non-Newtonian liquids 8.3.2 D 2196, D 4287

Sag resistance 8.3.3 D 4400 4494

Levelling properties 8.3.4 D 4062

Drying properties 8.4 D 1640 4061

Appearance of Dry Film

Color difference 9.1

Color appearance 9.1.1

Color differences by visual comparison 9.1.2 D 1729

Color differences using instrumental measurements 9.1.3 D 2244

Directional reflectance 9.2 E 1347

Gloss 9.3

Gloss, 60° 9.3.1 D 523

Sheen (85° gloss) 9.3.2 D 523

Hiding power 9.4 D 344, D 2805

Yellowness index 9.5 E 313 6131

Properties of Dry Film

Interior and Exterior Coatings 10.1

Abrasion resistance 10.1.1 D 658, D 968, D 4060 6192

Adhesion 10.1.2 D 2197, D 3359

A

Flexibility 10.1.3 D 522, D 2370 6221

Resistance to household chemicals 10.1.4 D 1308

Interior Coatings 10.2

Color change of white enamels 10.2.1 6132

Washability and cleansability 10.2.2

Washability 10.2.2.1 D 2486, D 4213

B

Cleansability 10.2.2.2 D 3450, D 4828 6141

Exterior Coatings 10.3

Blister resistance 10.3.1 D 4585

Exposure resistance 10.3.2 D 1006, D 1014

Chalking 10.3.2.2 D 4214

Checking 10.3.2.3 D 660

Cracking 10.3.2.4 D 661

Erosion 10.3.2.5 D 662

Flaking 10.3.2.6 D 772

C

Mildew resistance 10.3.3 D 3456

Fume resistance 10.3.4

Coating Analysis

Chemical analysis 11.1 D 215

Volatile content 11.2 D 2369

Nonvolatile volume content 11.3 D 2697

Water content 11.4 D 1208, D 4017 4081

Pigment content 11.5 D 2371 4021

Pigment analysis 11.6 D 215 7261

Nonvolatile vehicle content 11.7 D 215 4053

Vehicle separation 11.8 D 2372

Nonvolatile vehicle identification 11.9 D 2621, D 2245

A

Equivalent only to Method B of Test Method D 522.

B

Except for scrub medium.

C

6271 is not equivalent.

D5146–98

and uniformity, but is also a factor in determining the type of if others are to be accentuated. This balance of properties must

coating to use. For instance, low-gloss wall finishes do not be considered when selecting the tests and establishing the

have the abrasion resistance required on floors, whereas requirements. The significance of the tests and the normal

finishes intended only for interior service probably do not have range of values are presented in the different sections, in most

adequate resistance to weather factors. Other factors are the cases.

type and quality of metal, wood or wood composite (plywood, 5.3 This guide does not indicate relative importance of the

particle board or hardboard), the type, quality and alkalinity of various tests nor does it recommend specific test values

concrete, plaster and joint cement systems, and the type and because properties very important to one purchaser may be less

condition of any previous coatings. so to another.

4.1.2 Substrate Conditions—Conditions such as porosity,

6. Sampling

hardness or, in the case of unpainted concrete, alkalinity

6.1 Prior to sampling, the condition of the container should

determine the kind of coating that can be applied. The

be checked since damage to it may cause evaporation, skin-

condition of previously painted substrates, such as degree of

ning, or other undesirable effects on the coating.

chalk, presence of grease, dirt, and mold, film adhesion and

6.2 Sample in accordance with Practice D 3925. Determine

porosity, all influence the performance of coatings. Smoothness

of the substrate affects the spreading rate, final appearance, and the density in pounds per gallon (kilograms/litre) in accordance

with Test Method D 1475. Continue sampling and determining

texture.

4.1.3 Preparation of previously painted substrates including density until successive results agree within 0.1 lb (45 g) or as

agreed upon between the purchaser and seller. Then take

detergent cleaning, solvent cleaning, and sanding.

4.1.4 Type and quality of primer or undercoat and time of samples for testing.

6.3 Specify the amount required for a representative sample,

drying before topcoating.

4.1.5 Environmental conditions such as temperature and the package sizes, and an identification code. A 1-U.S. gal (or

4-L) sample is usually sufficient for the recommended tests, but

humidity at the time of coating application and during drying.

for guidance in selecting a sampling plan consult Practice

4.2 Exterior Finishes:

E 105.

4.2.1 Substrate Weathering—Weathering of wood before

painting will probably adversely affect the performance of

7. Liquid Coating Properties

exterior coatings. Some weathering of masonry surfaces may

7.1 Skinning—Coatings that contain a binder that dries by

have beneficial effects on the performance.

oxidation may be subject to skin formation in a partially-filled

4.2.2 Substrate Aspects of the Building— If construction

can. Since skins are insoluble in th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.