ASTM D4138-07a

(Test Method)Standard Practices for Measurement of Dry Film Thickness of Protective Coating Systems by Destructive, Cross-Sectioning Means

Standard Practices for Measurement of Dry Film Thickness of Protective Coating Systems by Destructive, Cross-Sectioning Means

SIGNIFICANCE AND USE

Many coating properties are markedly affected by the film thickness of the dry film such as adhesion, flexibility, and harness. To be able to compare results obtained by different operators, it is essential to measure film thickness carefully.

Most protective and high performance coatings are applied to meet a requirement or a specification for the dry-film thickness of each coat, or for the complete system, or both. Coatings must be applied within a certain minimum and maximum thickness tolerances in order that they can fulfill their intended function.

SCOPE

1.1 This practice describes the measurement of dry film thickness of coating films by microscopic observation of precision angular cuts in the coating film. Use of these procedures may require repair of the coating film. This practice is intended to supplement the manufacturers' instructions for the manual operation of the gages and is not intended to replace them. It includes definitions of key terms, reference documents, the significance and use of the practice, and the advantages and limitations of the instruments.

1.2 Three procedures are provided for measuring dry film thickness of protective coating systems:

1.2.1 Procedure A - Using groove cutting instruments.

1.2.2 Procedure B - Using grinding instruments.

1.2.3 Procedure C - Using drill bit instruments.

1.3 These procedures are not applicable for soft or ductile substrates that may deform under the test gage cutting tip. The substrate should be sufficiently rigid to prevent deformation of the coating during the cutting process. The surface may be flat or moderately curved. Pipes as small as 25 mm (1 in.) in diameter may be measured in the axial direction.

1.4 Individual coats in a multicoat system where there is a discernible visual difference between coats or the overall thickness of a coating system can be measured by these procedures.

1.5 The range of thickness measurement is typically 2 to 2000 microns (0.1 to 80 mils) and depends upon the cutting angle of the blade.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4138 − 07a

StandardPractices for

Measurement of Dry Film Thickness of Protective Coating

1

Systems by Destructive, Cross-Sectioning Means

This standard is issued under the fixed designation D4138; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This practice describes the measurement of dry film

thickness of coating films by microscopic observation of

2. Referenced Documents

precision angular cuts in the coating film. Use of these

2

proceduresmayrequirerepairofthecoatingfilm.Thispractice 2.1 ASTM Standards:

is intended to supplement the manufacturers’ instructions for

D823Practices for Producing Films of Uniform Thickness

themanualoperationofthegagesandisnotintendedtoreplace of Paint, Varnish, and Related Products on Test Panels

them. It includes definitions of key terms, reference

D1005Test Method for Measurement of Dry-Film Thick-

documents, the significance and use of the practice, and the ness of Organic Coatings Using Micrometers

advantages and limitations of the instruments.

D7091Practice for Nondestructive Measurement of Dry

Film Thickness of Nonmagnetic Coatings Applied to

1.2 Three procedures are provided for measuring dry film

Ferrous Metals and Nonmagnetic, Nonconductive Coat-

thickness of protective coating systems:

ings Applied to Non-Ferrous Metals

1.2.1 Procedure A—Using groove cutting instruments.

1.2.2 Procedure B—Using grinding instruments.

3. Terminology

1.2.3 Procedure C—Using drill bit instruments.

3.1 Definitions of Terms:

1.3 These procedures are not applicable for soft or ductile

3.1.1 accuracy, n—the measure of the magnitude of error

substrates that may deform under the test gage cutting tip. The

between the result of a measurement and the true thickness of

substrate should be sufficiently rigid to prevent deformation of

the item being measured.

the coating during the cutting process. The surface may be flat

or moderately curved. Pipes as small as 25 mm (1 in.) in 3.1.2 dry film thickness, n—the thickness of a coating (or

diameter may be measured in the axial direction. coating layers) as measured from the surface of the substrate.

3.1.3 micrometre (micron), n—one one-thousandths of a

1.4 Individual coats in a multicoat system where there is a

millimetre (0.001 mm); 25.4 microns = 1 mil.

discernible visual difference between coats or the overall

thickness of a coating system can be measured by these

3.1.4 mil, n—an imperial unit of measure; one one-

procedures.

thousandths of an inch (0.001 in.); 1 mil = 25.4 microns.

1.5 The range of thickness measurement is typically 2 to

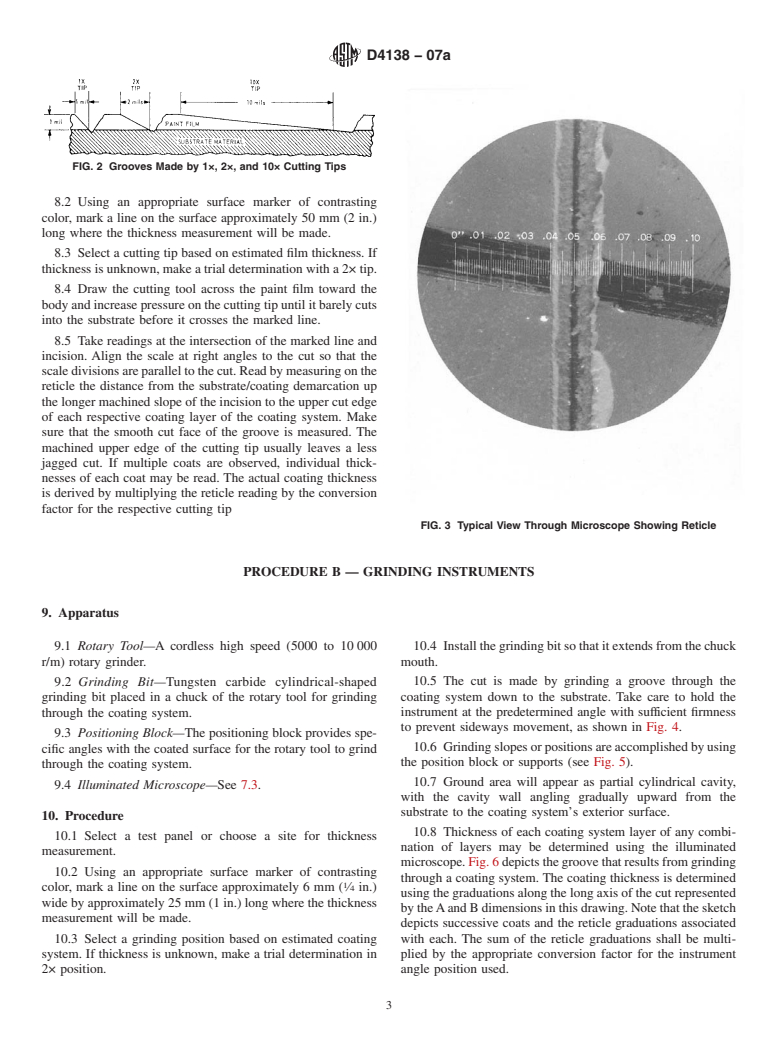

3.1.5 reticle, n—a scale on transparent material fitted at the

2000 microns (0.1 to 80 mils) and depends upon the cutting

focal plane of the eyepiece of the microscope for the purpose

angle of the blade.

of measuring the width of a feature within the image.

1.6 The values stated in SI units are to be regarded as the

4. Summary of Practice

standard. The values given in parentheses are for information

only.

4.1 The three procedures are based on measurement of dry

filmthicknessbyobservationofthewidthofangularcutsinthe

1.7 This standard does not purport to address all of the

coating through a microscope having a built-in reticle with a

safety concerns, if any, associated with its use. It is the

scale. Each procedure employs different instruments to make

responsibility of the user of this standard to establish appro-

the cut in the coating.

1

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

2

Subcommittee D01.23 on Physical Properties of Applied Paint Films. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJuly1,2007.PublishedJuly2007.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1982. Last previous edition approved in 2007 as D4138–07. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D4138-07A. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4138 − 07a

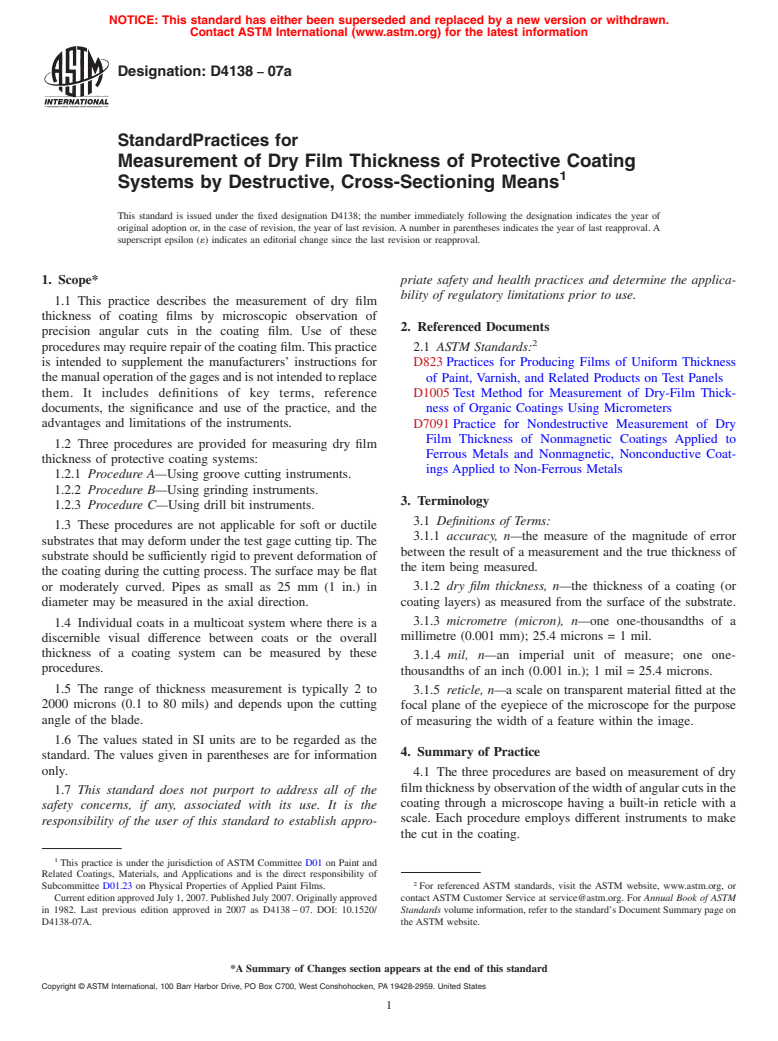

4.2 Procedure A—Usesacarbideorcarbide-tippedwedgeto good cutting characteristics. With some coatings, improved

cutagrooveinthecoating.Thegrooveiscutatapreciseangle cuts can be achieved by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.