ASTM D1212-91(2013)

(Test Method)Standard Test Methods for Measurement of Wet Film Thickness of Organic Coatings

Standard Test Methods for Measurement of Wet Film Thickness of Organic Coatings

SIGNIFICANCE AND USE

4.1 Wet film thickness measurements aid in the prediction of dry film thickness. In instances where dry film thickness cannot be measured nondestructively, wet film thickness is frequently specified. Also, the ability to determine wet film thickness during application can provide the opportunity to correct the application procedures.

SCOPE

1.1 These test methods cover the determination of wet film thickness of organic coatings such as paint, varnish, and lacquer. Two methods are described as follows:

1.1.1 In Test Method A, the Wet Film Thickness Gage (English or Metric graduation (see 5.1)) is used to measure wet film thicknesses up to 60 mils on the English scale series, and up to 700 μm on the metric scale series (Sections 5-8).

1.1.2 In Test Method B, the Pfund Gage is used to measure wet film thicknesses up to 14.2 mils (360 μm) (Sections 9-13).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1212 − 91 (Reapproved 2013)

Standard Test Methods for

Measurement of Wet Film Thickness of Organic Coatings

This standard is issued under the fixed designation D1212; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

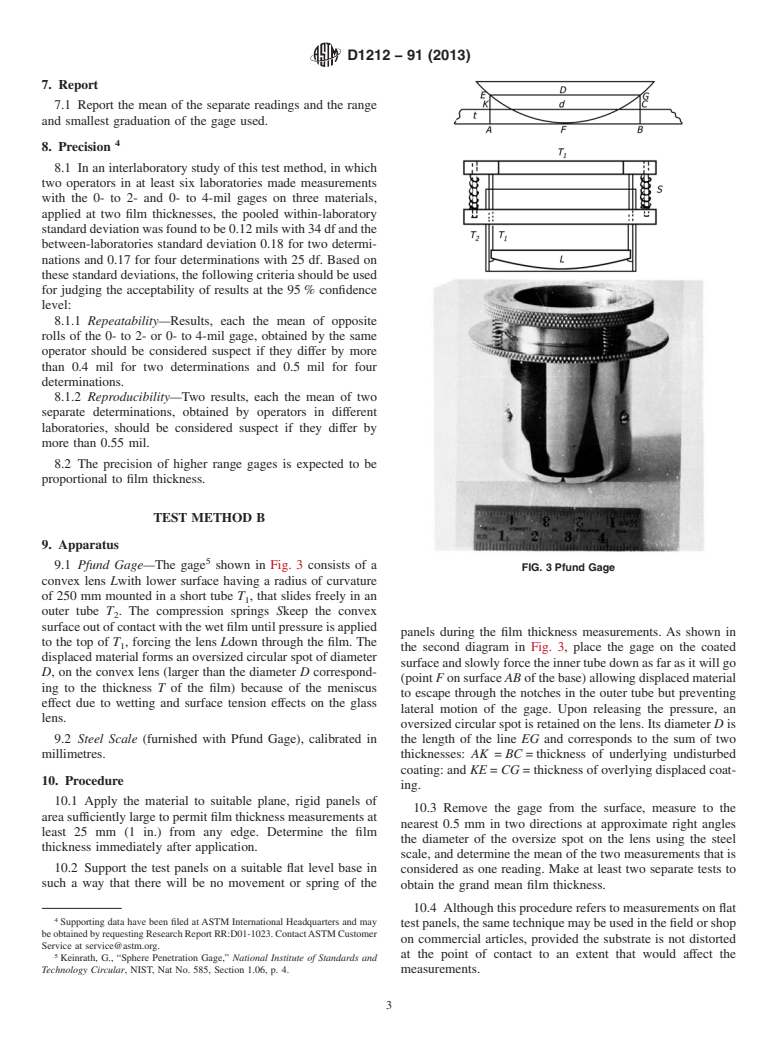

1. Scope 3.3 InTest Method B, a gage with a convex lower surface is

pushed into the wet film until the center touches the substrate.

1.1 These test methods cover the determination of wet film

The diameter of the spot of wet coating left on the convex

thickness of organic coatings such as paint, varnish, and

surface is measured and the film thickness calculated from the

lacquer. Two methods are described as follows:

diameter of the spot and the radius of curvature.

1.1.1 In Test Method A, the Wet Film Thickness Gage

(English or Metric graduation (see 5.1)) is used to measure wet

4. Significance and Use

film thicknesses up to 60 mils on the English scale series, and

4.1 Wet film thickness measurements aid in the prediction

up to 700 µm on the metric scale series (Sections5–8).

of dry film thickness. In instances where dry film thickness

1.1.2 In Test Method B, the Pfund Gage is used to measure

cannot be measured nondestructively, wet film thickness is

wet film thicknesses up to 14.2 mils (360 µm) (Sections9–

frequently specified. Also, the ability to determine wet film

13).

thickness during application can provide the opportunity to

1.2 The values stated in SI units are to be regarded as the

correct the application procedures.

standard. The values given in parentheses are for information

only.

TEST METHOD A

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Apparatus

responsibility of the user of this standard to establish appro-

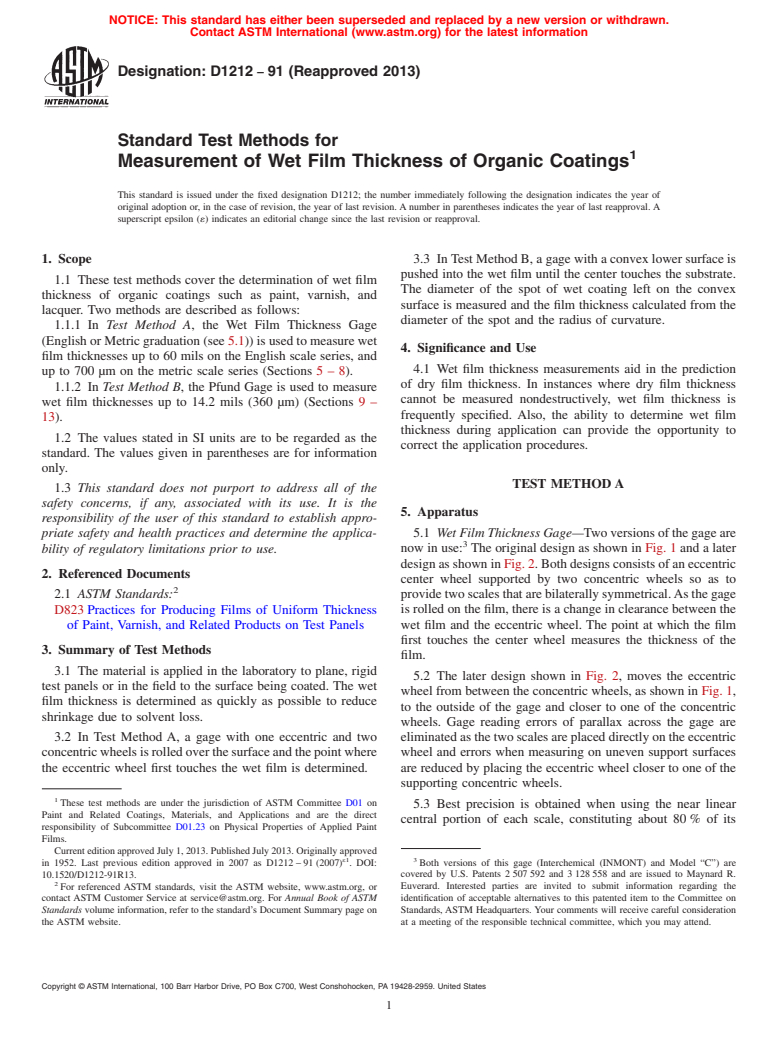

priate safety and health practices and determine the applica- 5.1 WetFilmThicknessGage—Twoversionsofthegageare

now in use: The original design as shown in Fig. 1 and a later

bility of regulatory limitations prior to use.

designasshowninFig.2.Bothdesignsconsistsofaneccentric

2. Referenced Documents

center wheel supported by two concentric wheels so as to

2.1 ASTM Standards: providetwoscalesthatarebilaterallysymmetrical.Asthegage

D823 Practices for Producing Films of Uniform Thickness is rolled on the film, there is a change in clearance between the

of Paint, Varnish, and Related Products on Test Panels wet film and the eccentric wheel. The point at which the film

first touches the center wheel measures the thickness of the

3. Summary of Test Methods

film.

3.1 The material is applied in the laboratory to plane, rigid

5.2 The later design shown in Fig. 2, moves the eccentric

test panels or in the field to the surface being coated. The wet

wheel from between the concentric wheels, as shown in Fig. 1,

film thickness is determined as quickly as possible to reduce

to the outside of the gage and closer to one of the concentric

shrinkage due to solvent loss.

wheels. Gage reading errors of parallax across the gage are

3.2 In Test Method A, a gage with one eccentric and two eliminatedasthetwoscalesareplaceddirectlyontheeccentric

concentricwheelsisrolledoverthesurfaceandthepointwhere wheel and errors when measuring on uneven support surfaces

the eccentric wheel first touches the wet film is determined. are reduced by placing the eccentric wheel closer to one of the

supporting concentric wheels.

These test methods are under the jurisdiction of ASTM Committee D01 on

5.3 Best precision is obtained when using the near linear

Paint and Related Coatings, Materials, and Applications and are the direct

central portion of each scale, constituting about 80 % of its

responsibility of Subcommittee D01.23 on Physical Properties of Applied Paint

Films.

Current edition approved July 1, 2013. Published July 2013. Originally approved

ε1

in 1952. Last previous edition approved in 2007 as D1212 – 91 (2007) . DOI: Both versions of this gage (Interchemical (INMONT) and Model “C”) are

10.1520/D1212-91R13. covered by U.S. Patents 2 507 592 and 3 128 558 and are issued to Maynard R.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Euverard. Interested parties are invited to submit information regarding the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM identification of acceptable alternatives to this patented item to the Committee on

Standards volume information, refer to the standard’s Document Summary page on Standards, ASTM Headquarters. Your comments will receive careful consideration

the ASTM website. at a meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1212 − 91 (2013)

FIG. 1 Interchemical Wet Film Thickness Gages

FIG. 2 Model “C” Wet Film Thickness Gages

total range as shown in the diagram in Fig. 1 and Fig. 2. film thickness measurements at least 25 mm (1 in.) from any

Therefore, the range of the particular gage selected for use edge. Determine the film thickness immediately after applica-

should be such that the measured film thickness falls within,

tion.

and preferably toward the center of the middle 80 % of each

6.2 Support the test panels on a suitable level base in such

scale. Gages are available covering the following ranges in

a way that there will be no movement or spring of the panels

mils and microns:

during the film thickness measurements. Place the gage on the

Smallest

Range, mils

wet film so that the minimum marking is at the top and the

Graduation, mils

0to2 0.1

greatest clearance between the eccentric wheel and the film is

0to4 0.2

directly over the wet film. Roll the gage over the film one-half

2to12 0.5

10 to 30 1.0 revolution in one direction toward the minimum marking on

20 to 60 2.0

the gage and repeat in the opposite direction. Read the points

Smallest

Range, µm at which the coating first makes contact with the eccentric

Graduation, µm

wheel and determine the mean which is considered as one

0to40 2.0

0 to 100 5.00

reading.

50 to 250 10.00

200 to 700 25.00

6.3 If the coating contains a solvent that evaporates rapidly

or if the solids content is low, make at least a second separate

6. Procedure

reading on a freshly applied film and calculate the mean of the

6.1 ApplythematerialinaccordancewithPracticesD823to

separate readings.

suitable plane rigid panels of area sufficiently large to permit

D1212 − 91 (2013)

7. Report

7.1 Report the mean of the separate readings and the range

and smallest graduation of the gage used.

8. Precision

8.1 In an interlaboratory study of this test method, in which

two operators in at least six laboratories made measurements

with the 0- to 2- and 0- to 4-mil gages on three materials,

applied at two film thicknesses, the pooled within-laboratory

standarddeviationwasfoundtobe0.12milswith34dfandthe

between-laboratori

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.