ASTM D4213-96e1

(Test Method)Standard Test Method for Scrub Resistance of Paints by Abrasion Weight Loss

Standard Test Method for Scrub Resistance of Paints by Abrasion Weight Loss

SCOPE

1.1 This test method covers an accelerated procedure for determining the resistance of paints to erosion caused by scrubbing. (note: The term wet abrasion is sometimes used for scrubbing and wet abrasion resistance or scrubbability for scrub resistance). Although scrub resistance tests are intended primarily for interior coatings, they are sometimes used with exterior coatings as an additional measure of film performance.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

Designation:D4213–96

Standard Test Method for

Scrub Resistance of Paints by Abrasion Weight Loss

This standard is issued under the fixed designation D 4213; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes made throughout in November 1996.

1. Scope E70 Test Method for pH of Aqueous Solutions with the

Glass Electrode

1.1 This test method covers an accelerated procedure for

E 180 Practice for Determining the Precision of ASTM

determining the resistance of paints to erosion caused by

Methods forAnalysis and Testing of Industrial Chemicals

scrubbing. (Note:The term wet abrasion is sometimes used for

E 691 Practice for Conducting an Interlaboratory Study to

scrubbing, and wet abrasion resistance or scrubbability for

Determine Precision

scrub resistance.) Although scrub resistance tests are intended

primarily for interior coatings, they are sometimes used with

3. Summary of Test Method

exterior coatings as an additional measure of film performance.

3.1 Thematerialundertestisappliedtoablackplasticscrub

1.2 The values stated in inch-pound units are to be regarded

test panel, and after drying one week, a section of the test panel

as the standard. The values given in parentheses are for

is placed in a straight-line abrasion tester, adjacent to a similar

information only.

section of a standard calibration panel. The two sections are

1.3 This standard does not purport to address all of the

scrubbed simultaneously to produce essentially identical abra-

safety concerns, if any, associated with its use. It is the

sion experiences and the amount of erosion loss in each section

responsibility of the user of this standard to establish appro-

determined from the panel weights before and after scrubbing.

priate safety and health practices and determine the applica-

3.2 The scrub resistance on a dry-film basis is calculated as

bility of regulatory limitations prior to use.

the percent ratio of the weight loss of the calibration panel to

2. Referenced Documents that of the test panel. From that value, scrub resistance is

calculated on the basis of both dry- and wet-film volume.

2.1 ASTM Standards:

D 562 Test Method for Consistency of Paints Using the

4. Significance and Use

Stormer Viscometer

3 4.1 Interior paint films often become soiled, especially near

D 1193 Specification for Reagent Water

doorways, windows, and play areas, and frequently need to be

D 1475 Test Method for Density of Paint, Varnish, Lacquer

2 cleaned by scrubbing. This test method covers the determina-

and Related Products

tion of the relative resistance of paints to erosion when

D 2486 Test Method for Scrub Resistance of Interior Latex

4 scrubbed.

Flat Wall Paints

4.2 The precision of scrub resistance measurements in

D 3450 Test Method for Washability Properties of Interior

4 absolute physical values, such as Test Method D 2486 cycles-

Architectural Coatings

to-failureorthistestmethod,microlitresper100cycles,ispoor

D 3980 Practice for Interlaboratory Testing of Paint and

2 due to the relatively large effect of subtle and difficult-to-

Related Materials

control variables in test conditions. The test method described

D 4828 Test Methods for Practical Washability of Organic

herein minimizes this problem by using a standard calibration

Coatings

panel as an integral part of each scrubbing operation and

relating its weight loss to that of the paint film under test to

establish the latter’s scrub resistance.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

NOTE 1—The numerical scrub resistance values obtained by this test

Subcommittee D01.42 on Architectural Finishes.

method are of significance only in relation to the specific calibration panel

Current edition approved June 10, 1996. Published August 1996. Originally

published as D 4213 – 83. Last previous edition D 4213 – 95.

Annual Book of ASTM Standards, Vol 06.01.

3 5

Annual Book of ASTM Standards, Vol 11.01. Annual Book of ASTM Standards, Vol 15.05.

4 6

Annual Book of ASTM Standards, Vol 06.02. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D4213–96

types with which the value is obtained. Thus, for example, a scrub

5.7 Drawdown Plate, ⁄4-in. (6-mm) thick, clear float glass,

resistance value of 83 with a Type X calibration panel would be reported

size adequate to be used as a base for drawdowns on the

as 83X.

specified scrub test panels.

4.3 Results obtained by this test method do not necessarily

5.8 Non-Abrasive Scrub Medium, standard wetting liquid.

, ,

11 12 13

represent the scrub resistance that might be determined if the Formula and preparation instructions are as follows:

test film is allowed to dry before testing appreciably longer

Formula—Parts by Weight

A

Water, reagent, Specification D 1193, Type IV 89.6

than the seven-day period specified herein.

Hydroxyethyl cellulose 2.0

4.4 Results obtained by this test method do not necessarily

Detergent 4.0

relate to ease of soil or stain removal (also referred to as

Trisodium phosphate, anhydrous 4.0

B

Acetic acid glacial 0.3

“cleanability” or “cleansability”). To test for those character-

Preservative 0.1

istics use Test Methods D 3450 and D 4828.

100.0

A

Vary to achieve a final consistency of 165 to 220 g (75 to 85 Krebs Units) with

a Stormer viscometer in accordance with Test Method D 562.

B

Vary to achieve a final pH from 9.5 to 10.0 in accordance with Test Method

E70.

5.8.1 Slowly add the hydroxyethyl cellulose to the water

while stirring mechanically. Stir until uniform and then slowly

add 2 to 3 drops of 28 % ammonium hydroxide solution while

mixing, and continue mixing until the solution turns clear. In

the order shown, add the other ingredients separately, stirring

continuously. Be sure each item is uniformly dispersed before

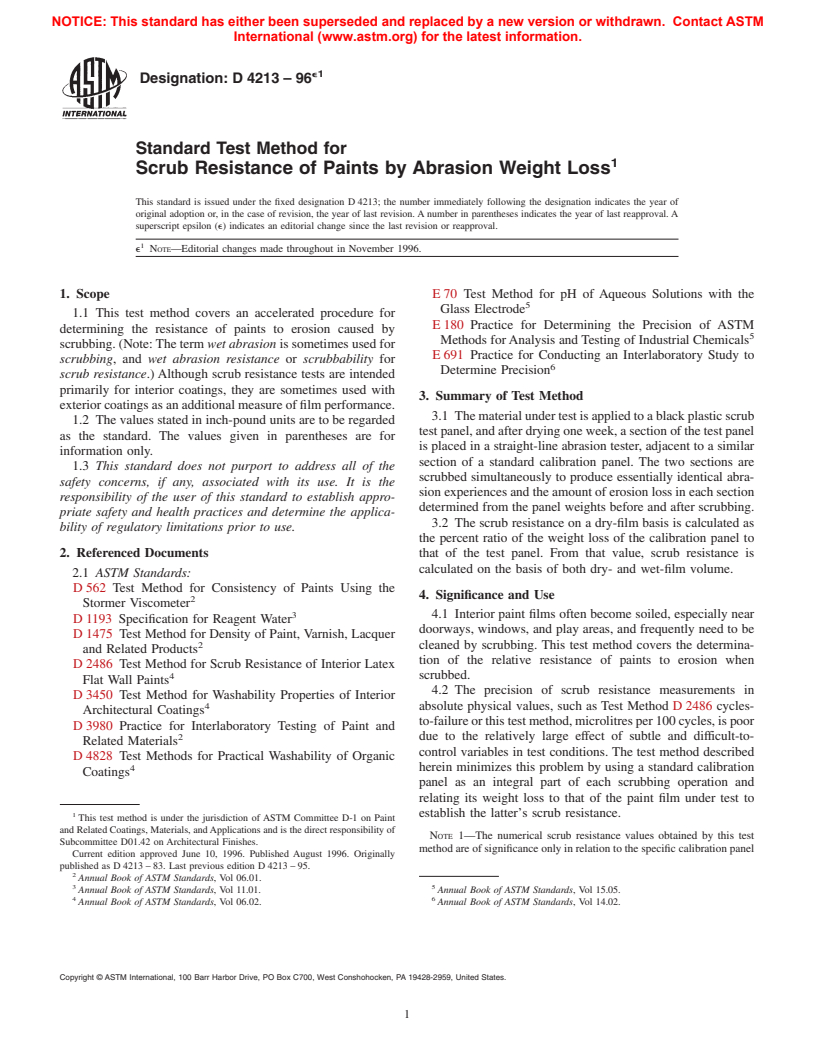

FIG. 1 Alignment of Panels for Scrubbing

addingthenextone.Finally,addthepreservativeandadjustthe

pH with glacial acetic acid.

5. Apparatus and Materials

5.1 Straight-line Scrub Tester, set for 37 6 1 cycles per NOTE 3—When a referee test is made the medium should be freshly

prepared, or from a previously unopened container that is no more than

minute,havingaminimumintrinsicstrokelengthof10in.(255

1-year old.

mm), counter for recording the number of scrub cycles, base

pan, glass support plate, “Lilly” frame, and C-clamps to hold 5.9 Analytical Balance With Windshield Enclosure, reading

down the entire test assembly. to 0.1 mg and accurate to 1 mg.

1 1

5.2 Sponge Holder, stainless steel construction, weight: 450 5.10 Static Shield, a thin gage metal plate, size 4 ⁄4 by 6 ⁄2

7 3

6 10 g, approximate inside dimensions: ⁄8by3by3 ⁄4 in. (22 in. (110 by 165 mm), to be placed on the balance pan when

by 75 by 95 mm). weighing. A satisfactory shield can be made from 7 to 12 mil

5.3 Polyurethane Sponges, skin free, open-cell formation, (175 to 300 mm) thick aluminum or tinplate.

3 3

density 2 to 2.5 lb/ft (0.032 to 0.040 g/cm ), compression 5.11 Oven, adjusted to 120 to 130°F (50 to 55°C).

(25 % deflection) 0.7 psi (4.8 kPa), width and length 0.08 in. (2 5.12 Calibration Panels, prepared in advance using paints

mm) larger than the sponge holder with which it is to be used, of suitable scrub resistance.

thickness such that when inserted into the sponge holder it

NOTE 4—The procedure for preparing calibration panels is the same as

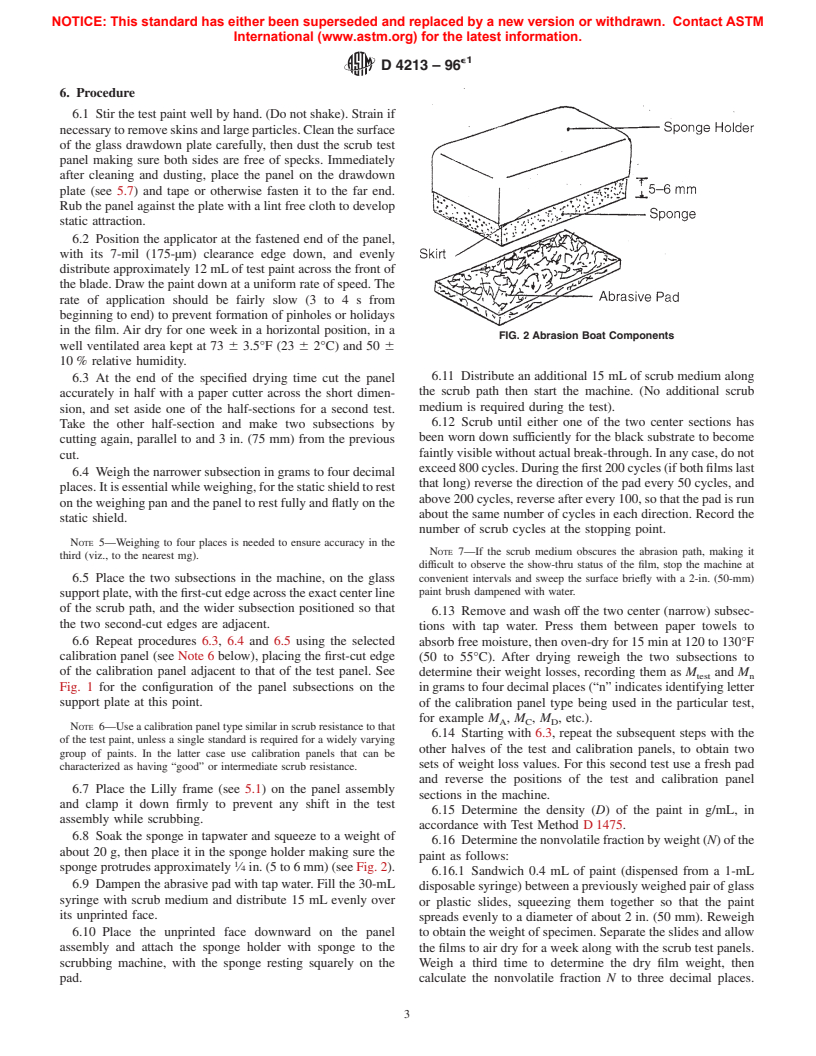

protrudes about 0.25 in. (5 to 6 mm) beyond the skirt (see Fig.

described in 6.1 and 6.2 for regular test panels, except that the panels shall

1).

beagedsufficientlybeforeusetoensurethattheeffectofadditionalageing

5.4 Abrasive Pad, ⁄4-in. (6-mm) thick, cut to same size as on their scrub resistance is negligible. A period of 6 months has been

found adequate. Earlier use requires that in a given test series all

the sponge with which it is to be used.

calibration panels be the same age.

5.5 Film Caster, with horse shoe frame, clearance 7 mils

(175 µm), film width approximately 5 ⁄4 in. (135 mm).

5.13 Pycnometer, for example, “weight-per-gallon” cup.

5.6 Black Plastic Panels, dimensions: 0.01 6 10 % by 6.5

by 17 in. (0.25 6 10 % by 165 by 430 mm). Level and uniform

dull black surface, impervious to and unaffected by water or

Non-Abrasive Scrub Medium—Catalog Item SC-1 available from The Leneta

aliphatic solvents, plasticizer-free, density 1.33 6 0.05 g/cm .

Company is made in accordance with these requirements.

Hydroxyethyl cellulose having a molar substitution (MS) value from 1.8 to 2.5

NOTE 2—With dark colored paints use white panels. These should be

and a 2 % solution viscosity in the range of 4400 to 6500 cps.

the same as the black except for color, and density: 1.41 6 0.05 g/cm .

Iso-octylphenoxy polyethoxyethanol detergent, such as Triton X-100 has been

found satisfactory for this purpose.

1,3,5-triethyl hexahydro-sym-triazine (Vancide TH), obtainable from R. T.

Sponges, available from suppliers of scrub testers, cut to precise size for their Vanderbilt Co., 30 Winfield St., Norwalk, CT 06855, has been found satisfactory.

respective holders. Calibration panels may be prepared by individual laboratories for internal use

Abrasive pad—Scotch-Brite #7448 manufactured by 3M Company, 3M Center and for relating their results to those of associated laboratories. Suitably aged and

Bldg., St. Paul, MN 55144-1000 has been found satisfactory. Pads cut to the correct standardized calibration panels, having“ poor,” “good,” and “very good” scrub

size are available from suppliers of scrub testers. resistance are available commercially from the Leneta Company. These are

Scrub Test Panels—Black: Form P121-10N and White: Form P122-10N, identified asTypeA, C, and D respectively.The scrub resistance ofTypeAhas been

available from The Leneta Co., 15 Whitney Rd., Mahwah, NJ 07430, have been foundtobeapproximately35 %ofTypeC,andTypeCapproximately50 %ofType

found satisfactory and are in compliance with requirements stated in 5.6. D.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D4213–96

6. Procedure

6.1 Stir the test paint well by hand. (Do not shake). Strain if

necessarytoremoveskinsandlargeparticles.Cleanthesurface

of the glass drawdown plate carefully, then dust the scrub test

panel making sure both sides are free of specks. Immediately

after cleaning and dusting, place the panel on the drawdown

plate (see 5.7) and tape or otherwise fasten it to the far end.

Rub the panel against the plate with a lint free cloth to develop

static attraction.

6.2 Position the applicator at the fastened end of the panel,

with its 7-mil (175-µm) clearance edge down, and evenly

distribute approximately 12 mLof test paint across the front of

the blade. Draw the paint down at a uniform rate of speed. The

rate of application should be fairly slow (3 to 4 s from

beginning to end) to prevent formation of pinholes or holidays

in the film. Air dry for one week in a horizontal position, in a

FIG. 2 Abrasion Boat Components

well ventilated area kept at 73 6 3.5°F (23 6 2°C) and 50 6

10 % relative humidity.

6.11 Distribute an additional 15 mL of scrub medium along

6.3 At the end of the specified drying time cut the panel

the scrub path then start the machine. (No additional scrub

accurately in half with a paper cutter across the short dimen-

medium is required during the test).

sion, and set aside one of the half-sections for a second test.

6.12 Scrub until either one of the two center sections has

Take the other half-section and make two subsections by

been worn down sufficiently for the black substrate to become

cutting again, parallel to and 3 in. (75 mm) from the previous

faintlyvisiblewithoutactualbreak-through.Inanycase,donot

cut.

exceed800cycles.Duringthefirst200cycles(ifbothfilmslast

6.4 Weigh the narrower subsection in grams to four decimal

that long) reverse the direction of the pad every 50 cycles, and

places.Itisessentialwhileweighing,forthestaticshieldtorest

above 200 cycles, reverse after every 100, so that the pad is run

on the weighing pan and the panel to rest fully and flatly on the

about the same number of cycles in each direction. Record the

static shield.

number of scrub cycles at the stopping point.

NOTE 5—Weighing to four places is needed to ensure accuracy in the

NOTE 7—If the scrub medium obscures the abrasion path, making it

third (viz., to the nearest mg).

difficult to observe the show-thru status of the film, stop the machine at

6.5 Place the two subsections in the machine, on the glass convenient intervals and sweep the surface briefly with a 2-in. (50-mm)

paint brush dampened with water.

supportplate,withthefirst-cutedgeacrosstheexactcenterline

of the scrub path, and the wider subsection positioned so that

6.13 Remove and wash off the two center (narrow) subsec-

the two second-cut edges are adjacent.

tions with tap water. Press them between paper towels to

6.6 Repeat procedures 6.3, 6.4 and 6.5 using the selected

absorb free moisture, then oven-dry for 15 min at 120 to 130°F

calibration panel (see Note 6 below), placing the first-cut edge (50 to 55°C). After drying reweigh the two subsections to

of the calibration panel adjacent to that of the test panel. See

determine their weight losses, recording them as M and M

test n

Fig. 1 for the configuration of the panel subsections on the in grams to four decimal places (“n” indicates identifying letter

support plate at this point.

of the calibration panel type being used in the particular test,

for example M , M , M , etc.).

A C D

NOTE 6—Use a calibration panel type similar in scrub resistance to that

6.14 Starting with 6.3, repeat the subsequent steps with the

of the test paint, unless a single standard is required for a widely varying

other halves of the test and calibration panels, to obtain two

group of paints. In the latter case use calibration panels that can be

sets of weight loss values. For this second test use a fresh pad

characterized as having “good” or intermediate scrub resistance.

and reverse the positions of the test and calibration panel

6.7 Place the Lilly frame (see 5.1) on the panel a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.