ASTM D2172-01e1

(Test Method)Standard Test Methods for Quantitative Extraction of Bitumen From Bituminous Paving Mixtures

Standard Test Methods for Quantitative Extraction of Bitumen From Bituminous Paving Mixtures

SCOPE

1.1 These test methods cover the quantitative determination of bitumen in hot-mixed paving mixtures and pavement samples. Aggregate obtained by these test methods may be used for sieve analysis using Test Method C 117 and Test Method C 136.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards are given in Section 7.

Note 1—The results obtained by these test methods may be affected by the age of the material tested, with older samples tending to yield slightly lower bitumen content. Best quantitative results are obtained when the test is made on mixtures and pavements shortly after their preparation. It is difficult to remove all the asphalt when some aggregates are used and some chlorides may remain within the mineral matter affecting the measured asphalt content.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D2172–01

Standard Test Methods for

Quantitative Extraction of Bitumen From Bituminous Paving

1

Mixtures

This standard is issued under the fixed designation D 2172; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—The word 81, 1, 1–trichloroethane’ was editorially changed to 8normal Propyl Bromide’ throughout. The address in

paragraph 7.1 was editorially corrected. All corrections applied March 2002.

2

1. Scope for Test Methods for Construction Materials

D 70 Test Method for Specific Gravity and Density of

1.1 These test methods cover the quantitative determination

3

Semi-Solid Bituminous Materials (Pycnometer Method)

of bitumen in hot-mixed paving mixtures and pavement

4

D 604 Specification for Diatomaceous Silica Pigment

samples. Aggregate obtained by these test methods may be

3

D 979 Practice for Sampling Bituminous Paving Mixtures

used for sieve analysis using Test Method C 117 and Test

D 1461 Test Method for Moisture or Volatile Distillates in

Method C 136.

3

Bituminous Paving Mixtures

1.2 The values stated in inch-pound units are to be regarded

D 1856 Test Method for Recovery ofAsphalt from Solution

as the standard. The values given in parentheses are for

3

by Abson Method

information only.

D 2111 Test Methods for Specific Gravity of Halogenated

1.3 This standard does not purport to address all of the

5

Organic Solvents and Their Admixtures

safety concerns, if any, associated with its use. It is the

D 6368 Specification forVapor-Degreasing Grade and Gen-

responsibility of the user of this standard to establish appro-

5

eral Grade normal–Propyl Bromide

priate safety and health practices and determine the applica-

2.2 Federal Specifications:

bilityofregulatorylimitationspriortouse.Specifichazardsare

6

O-T-634 (latest) normal Propyl Bromide, Technical

given in Section 7.

NOTE 1—The results obtained by these test methods may be affected by 3. Summary of Test Methods

the age of the material tested, with older samples tending to yield slightly

3.1 The paving mixture is extracted with trichloroethylene,

lowerbitumencontent.Bestquantitativeresultsareobtainedwhenthetest

normal Propyl Bromide, or methylene chloride using the

is made on mixtures and pavements shortly after their preparation. It is

extraction equipment applicable to the particular method. The

difficult to remove all the asphalt when some aggregates are used and

bitumen content is calculated by difference from the mass of

some chlorides may remain within the mineral matter affecting the

measured asphalt content. the extracted aggregate, moisture content, and mineral matter

in the extract. The bitumen content is expressed as mass

2. Referenced Documents

percent of moisture-free mixtures.

2.1 ASTM Standards:

4. Significance and Use

C 117 Test Method for Materials Finer than 75-µm (No.

2

200) Sieve in Mineral Aggregates by Washing

4.1 All of these test methods can be used for quantitative

C 128 Test Method for Density, Relative Density (Specific

determinations of bitumen in hot-mixed paving mixtures and

2

Gravity), and Absorption of Fine Aggregate

pavement samples for specification acceptance, service evalu-

C 136 Test Method for Sieve Analysis of Fine and Coarse

ation, control, and research. Each method prescribes the

2

Aggregates

solvent or solvents and any other reagents that can be used in

C 670 Practice for Preparing Precision and Bias Statements

thetestmethod.TestMethodD 1856requiresthatMethodAbe

used when asphalt is recovered from solution.

1

These test methods are under the jurisdiction of ASTM Committee D04 on

3

Road and Paving Materials and are the direct responsibilities of Subcommittee Annual Book of ASTM Standards, Vol 04.03.

4

D04.25 on Analysis of Bituminous Mixtures. Annual Book of ASTM Standards, Vol 06.03.

5

Current edition approved Dec. 10, 2001. Published February 2002. Originally Annual Book of ASTM Standards, Vol 15.05.

6

published as D 2172 – 63 T. Last previous edition D 2172 – 95. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

2

Annual Book of ASTM Standards, Vol 04.02. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

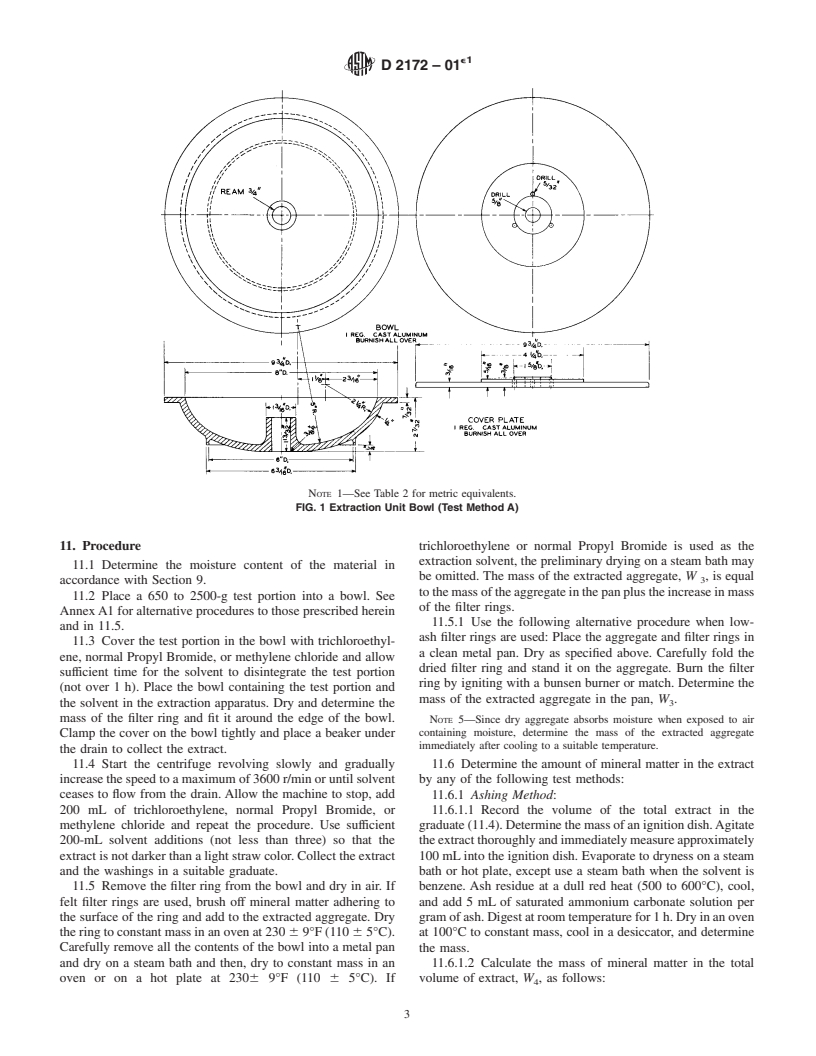

e1

D2172–01

5. Apparatus 8.2.2 The size of the test sample shall be governed by the

nominal maximum aggregate size of the mixture and shall

5.1 Oven, capable of maintaining the temperature at 230 6

conform to t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.