ASTM D2010/D2010M-98(2004)

(Test Method)Standard Test Methods for Evaluation of Total Sulfation Activity in the Atmosphere by the Lead Dioxide Technique

Standard Test Methods for Evaluation of Total Sulfation Activity in the Atmosphere by the Lead Dioxide Technique

SIGNIFICANCE AND USE

Sulfur oxide gases are produced during the combustion of materials containing sulfur. These gases are precursors of atmospheric sulfuric acid, which has been shown to be injurious to living creatures and plants, as well as some inanimate materials such as metals, limestone and sandstone building materials.

Sulfur dioxide is moderately toxic and strongly phytotoxic to many species. Permissible ambient levels of SO2 have been established by law.

When it is necessary to establish whether ambient air concentrations of sulfuric acid precursors, such as sulfur oxides, are present and to comply with legal criteria, manual and automatic monitoring systems specific for the individual sulfur species are used. Likely locations for monitoring sites for the estimation of concentrations and concentration trends over long periods of time can be screened conveniently using the PbO 2 candles or sulfation plates.

Atmospheric corrosion of metallic materials is a function of many weather and atmospheric variables. The effect of specific corrodants, such as SO2, can accelerate the atmospheric corrosion of metals or structures significantly. The PbO2 candle and sulfation plate test methods provide simple techniques to monitor SO2 levels in the atmosphere independently to yield a weighted average result.

The results of these test methods are useful for characterizing atmospheric corrosion test sites regarding the effective average concentrations of SO2 in the atmosphere at these locations.

These test methods are useful for determining microclimatic seasonal and long-term variations in effective average SO2 concentrations.

The results of these test methods may be used in correlations of atmospheric corrosion rates with atmosphere data to determine the sensitivity of the corrosion rate to the SO2 level.

These test methods may also be used with other test methods to characterize the atmosphere at sites at which buildings or other construction are planned in order to determine t...

SCOPE

1.1 These test methods describe the evaluation of the total sulfation activity in the atmosphere. Because of its oxidizing power, lead dioxide (PbO2) converts not only sulfur dioxide (SO2), but other compounds, such as mercaptans and hydrogen sulfide, into sulfate. It fixes sulfur trioxide and sulfuric acid mist present in the atmosphere (see Note 0).

1.2 Test Method A describes the use of a PbO2 candle, and Test Method B describes that of a PbO2 sulfation plate.

1.3 These test methods provide a weighted average effective SO2 level for a 30-day interval.

1.4 The results of these test methods correlate approximately with volumetric SO2 concentrations, although the presence of dew or condensed moisture tends to enhance the capture of SO2 onto the candle or plate.

1.5 The values stated in SI units shall be regarded as the standard. The values given in brackets are for information only and may be approximate.Note 0

It has been shown that the rate constant of the chemical reaction between SO2 and PbO2 is independent of the concentration of SO2 up to levels of 1000 ppm(v), if 15 % or less of the PbO2 has been reduced (). 15 % of the PbO2 is equivalent to 11 to 12 mg of SO2/cm2 per day.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2010/D2010M–98 (Reapproved 2004)

Standard Test Methods for

Evaluation of Total Sulfation Activity in the Atmosphere by

the Lead Dioxide Technique

This standard is issued under the fixed designation D2010/D2010M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods describe the evaluation of the total 2.1 ASTM Standards:

sulfation activity in the atmosphere. Because of its oxidizing D516 Test Method for Sulfate Ion in Water

power, lead dioxide (PbO ) converts not only sulfur dioxide D1193 Specification for Reagent Water

(SO ),butothercompounds,suchasmercaptansandhydrogen D1356 Terminology Relating to Sampling and Analysis of

sulfide, into sulfate. It fixes sulfur trioxide and sulfuric acid Atmospheres

mist present in the atmosphere (see Note 1). D1357 Practice for Planning the Sampling of the Ambient

1.2 Test MethodAdescribes the use of a PbO candle, and Atmosphere

Test Method B describes that of a PbO sulfation plate. G91 Practice for Monitoring Atmospheric SO Using the

2 2

1.3 Thesetestmethodsprovideaweightedaverageeffective Sulfation Plate Technique

SO level for a 30-day interval.

3. Terminology

1.4 The results of these test methods correlate approxi-

3.1 Definitions—For definitions of terms used in these test

mately with volumetric SO concentrations, although the

presence of dew or condensed moisture tends to enhance the methods, refer to Terminology D1356.

3.2 Definitions of Terms Specific to This Standard:

capture of SO onto the candle or plate.

1.5 The values stated in SI units shall be regarded as the 3.2.1 sulfation—the process by which sulfur-containing

compounds are oxidized by the action of PbO .

standard.Thevaluesgiveninbracketsareforinformationonly

and may be approximate. 3.2.2 sulfation activity—the capture rate of sulfur-

containing compounds as they are oxidized by PbO under the

NOTE 1—It has been shown that the rate constant of the chemical

conditions of these test methods.

reaction between SO and PbO is independent of the concentration of

2 2

SO up to levels of 1000 ppm(v), if 15% or less of the PbO has been

2 2

4. Summary of Test Methods

3 2

reduced (1). 15% of the PbO is equivalent to 11 to 12 mg of SO /cm

2 2

per day. 4.1 Test Method A—Inert cylinders are coated with PbO

paste and exposed to the atmosphere for an extended period of

1.6 This standard does not purport to address all of the

time, usually one month. Sulfur oxides react chemically with

safety concerns, if any, associated with its use. It is the

the paste, forming lead sulfate (PbSO ) (1-5).

responsibility of the user of this standard to establish appro-

4.2 Test Method B—Sulfation plates consisting of a PbO

priate safety and health practices and determine the applica-

paste in an inverted dish are likewise exposed to the atmo-

bility of regulatory limitations prior to use. For specific

sphere (6).

precautionary statements, see Section 8.

4.3 Test Methods A and B—The cylinders or plates are

returned to a laboratory after the sampling period; the paste is

These test methods are under the jurisdiction of ASTM Committee D22 on

removed and suspended in hot sodium carbonate (Na CO )

2 3

Sampling andAnalysis ofAtmosphere and are the direct responsibility of Subcom-

solution to dissolve the PbSO and convert the sulfate to

mittee D22.03 on Ambient Atmospheres and Source Emissions.

soluble sodium sulfate (Na SO ). The Na SO solution is

CurrenteditionapprovedOctober1,2004.PublishedDecember2004.Originally 2 4 2 4

approved in 1962. Last previous edition approved in 1998 as D2010/D2010M-98.

DOI: 10.1520/D2010_D2010M-98R04.

Test Method B has been adapted from Test Method G91, which is under the

jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct For referenced ASTM standards, visit the ASTM website, www.astm.org, or

responsibility of Subcommittee G01.04 on Atmospheric Corrosion. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2010/D2010M–98 (2004)

separated from the PbO slurry by filtration. The sulfate is 6.1.2 Sampling Apparatus—This may be a louvered enclo-

determined by precipitation with barium chloride (BaCl ) (7). sure, such as a cylinder or a rectangular box. If cylindrical, it

shall be not less than 20-cm [8-in.] high and 18-cm [7-in.] in

4.4 The chemistry of the process is illustrated, for the case

of SO , in the following reactions: diameter;ifrectangular,itshallbenotlessthan20by20by20

cm [8 by 8 by 8 in.]. Position the louvers at an angle of p/4

PbO 1 SO → PbSO

2 2 4

(45°) to provide maximum protection from the rain. Construct

PbSO 1 Na CO → Na SO 1 PbCO

4 2 3 2 4 3

the enclosure of an inert material, such as plastic or wood. Do

Na SO 1 BaCl → BaSO ↓ 12 NaCl

2 4 2 4

not coat the enclosure with a lead based paint. The sampling

apparatus shall have provisions to hold the PbO candle in a

vertical position.

5. Significance and Use

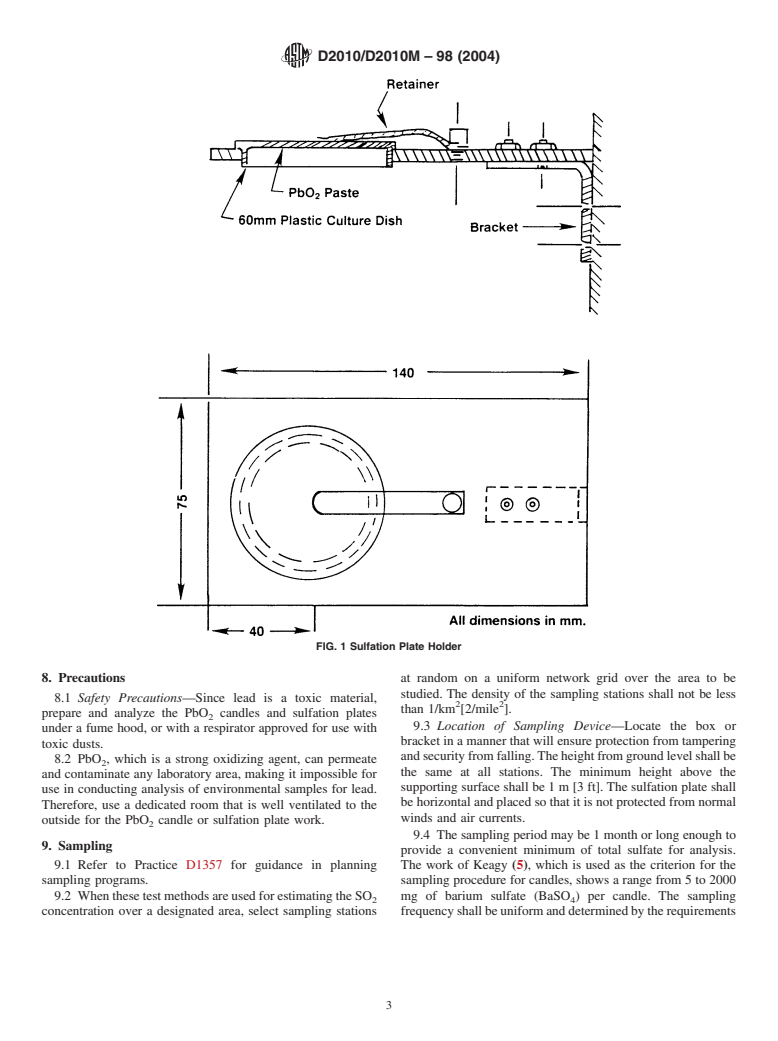

6.2 Test Method B:

5.1 Sulfur oxide gases are produced during the combustion 6.2.1 Sulfation Plate—A polystyrene or polycarbonate cul-

of materials containing sulfur. These gases are precursors of ture (petri) dish, 50 or 60 mm in diameter, containing a filter

atmospheric sulfuric acid, which has been shown to be injuri- paperdisc,coatedwithPbO paste.SeeX1.2forpreparationof

ous to living creatures and plants, as well as some inanimate the sulfation plate.

6.2.2 Bracket, to hold the plates securely in an inverted

materials such as metals, limestone and sandstone building

materials. positionsothatthePbO mixturefacesdownward.Thebracket

design shall include a retaining clip or other provision to hold

5.2 Sulfur dioxide is moderately toxic and strongly phyto-

theplateintheeventofstrongwinds.Theretainerclipmaybe

toxic to many species. Permissible ambient levels of SO have

made from stainless steel, spring bronze, hard aluminum alloy

been established by law.

(3003H19), or other alloys with sufficient strength and atmo-

5.3 When it is necessary to establish whether ambient air

spheric corrosion resistance.Atypical bracket design is shown

concentrations of sulfuric acid precursors, such as sulfur

in Fig. 1.

oxides, are present and to comply with legal criteria, manual

and automatic monitoring systems specific for the individual

7. Reagents and Materials

sulfur species are used. Likely locations for monitoring sites

for the estimation of concentrations and concentration trends

7.1 Purity of Reagents—Reagent grade chemicals shall be

over long periods of time can be screened conveniently using

usedinalltests.Allreagentsshallconformtothespecifications

the PbO candles or sulfation plates.

2 of the Committee on Analytical Reagents of the American

5.4 Atmospheric corrosion of metallic materials is a func-

Chemical Society, except where such reagents are not avail-

tion of many weather and atmospheric variables. The effect of

able.

specific corrodants, such as SO , can accelerate the atmo-

7.2 Purity of Water—References to water shall be under-

spheric corrosion of metals or structures significantly. The

stood to mean reagent water as defined by Type II of Specifi-

PbO candle and sulfation plate test methods provide simple

cation D1193.

techniques to monitor SO levels in the atmosphere indepen-

7.3 Acetone—Reagent grade.

dently to yield a weighted average result.

7.4 Barium Chloride Solution (50 g/L)—Dissolve 59 g of

5.5 The results of these test methods are useful for charac- bariumchloridedihydrate(BaCl 32H O)inwateranddilute

2 2

terizingatmosphericcorrosiontestsitesregardingtheeffective

to1L.

average concentrations of SO in the atmosphere at these 7.5 Ethyl Alcohol (95%).

locations.

7.6 Gum Tragacanth, powdered.

5.6 These test methods are useful for determining microcli-

7.7 Hydrochloric Acid (sp gr 1.19)—Concentrated hydro-

matic seasonal and long-term variations in effective average chloric acid (HCl).

SO concentrations.

7.8 Hydrochloric Acid (2 N)—Dilute 171 mL of concen-

5.7 The results of these test methods may be used in trated HCl to 1 L.

correlations of atmospheric corrosion rates with atmosphere 7.9 Hydrochloric Acid (0.05 N)—Dilute 25 mL of 2 N HCl

datatodeterminethesensitivityofthecorrosionratetotheSO to1L.

level. 7.10 Lead Dioxide (Powdered)—PbO ofthehighestpurity.

7.11 Sodium Carbonate Solution (83.3 g/L)—Dissolve 83.3

5.8 These test methods may also be used with other test

methods to characterize the atmosphere at sites at which gofanhydroussodiumcarbonate(Na CO )inwateranddilute

2 3

to1L.

buildings or other construction are planned in order to deter-

mine the extent of protective measures required for the 7.12 Methyl Orange Indicator (0.1 %)—Dissolve100mgin

water and dilute to 100 mL.

materials of construction.

6. Apparatus

6.1 Test Method A:

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

6.1.1 Lead Dioxide Candle—An inert cylinder with a sur-

2 listed by the American Chemical Society, see Analar Standards for Laboratory

face area of approximately 100 cm , covered with a fabric and

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

coated with PbO paste. See Appendix X1 for preparation of

2 and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

the candle. MD.

D2010/D2010M–98 (2004)

FIG. 1 Sulfation Plate Holder

8. Precautions at random on a uniform network grid over the area to be

studied. The density of the sampling stations shall not be less

8.1 Safety Precautions—Since lead is a toxic material,

2 2

than 1/km [2/mile ].

prepare and analyze the PbO candles and sulfation plates

9.3 Location of Sampling Device—Locate the box or

under a fume hood, or with a respirator approved for use with

bracketinamannerthatwillensureprotectionfromtampering

toxic dusts.

andsecurityfromfalling.Theheightfromgroundlevelshallbe

8.2 PbO , which is a strong oxidizing agent, can permeate

the same at all stations. The minimum height above the

and contaminate any laboratory area, making it impossible for

supporting surface shall be 1 m [3 ft].The sulfation plate shall

use in conducting analysis of environmental samples for lead.

behorizontalandplacedsothatitisnotprotectedfromnormal

Therefore, use a dedicated room that is well ventilated to the

winds and air currents.

outside for the PbO candle or sulfation plate work.

9.4 The sampling period may be 1 month or long enough to

9. Sampling

provide a convenient minimum of total sulfate for analysis.

9.1 Refer to Practice D1357 for guidance in planning The work of Keagy (5), which is used as the criterion for the

sampling programs. sampling procedure for candles, shows a range from 5 to 2000

9.2 WhenthesetestmethodsareusedforestimatingtheSO mg of barium sulfate (BaSO ) per candle. The sampling

2 4

concentration over a designated area, select sampling stations frequencyshallbeuniformanddeterminedbytherequirements

D2010/D2010M–98 (2004)

of the survey. Monthly, bimonthly, and seasonal sampling 12.1.1.1 The standard deviation, S , for the reproducibility

b

periods have been shown to provide consistent and reliable of total sulfation activity measurements by different laborato-

data (5). ries ranging from 0.00178 to 0.01371 mg/cm 3day may be

expressed by the following equation:

10. Analytical Procedure

½

S 50.0136 M (2)

b

10.1 Return the candles or plates to containers that can be

sealed from contamination at the end of the sampling period.

where:

10.2 Test Method A, Treatment of Candles—Measure the S and M = mg/cm 3day.

b

surface area of the candle. Separate the impregnated cloth

12.1.1.2 The standard deviation, S , for replicate measure-

w

surface from the cylinder, using a spatula or knife point, if ments of total sulfation activity ranging from 0.00178 to

necessary. The fabric may be cut into smaller pieces. Transfer

0.01371 mg/cm 3day by the same laboratory (repeatability)

thePbO -coveredfabrictoa250-mLbeakercontaining60mL may be expressed by the following equation:

of 83.3-g/L solution of Na CO (7.11). Soak the immersed

2 3 ½

S 50.00504 M (3)

w

pieces for 3 h, with occasional stirring. Cover the beakers, and

simmer the mixtures gently on a water bath plate for 30 min,

where:

taking care to minimize water evaporation in order to maintain S and M = mg/cm 3day.

w

an approximately constant volume. Filter the beaker contents

12.1.2 Theaverageresultsoftheanalysisofspikedsamples

through a fast filter paper, with appropriate washings, and (8) indicates that the determination of sulfate by Test Method

adjustthefiltratewith2NHCl(7.8)toapHrangeof3.0to4.0,

D516 can be performed with a recovery of 98%.

using methyl orange as the indicator (7.12). Exercise care to 12.1.2.1 The standard deviation of the percent of sulfate

prevent any loss of sample by foaming, particularly when the

spikerecoveryofthesulfateanalysisstepis10%forbetween-

point of neutralization is approached. laboratory measurements and 21% for within-laboratory mea-

10.3 Test Method B—Remove the contents of the sulfation

surements.

plate to a 250-mLbeaker, and add 12 mLof 83.3 g/LNa CO

12.2 Test Method B (9):

2 3

solution (7.11). Cover the beaker, and proceed as described in

12.2.1 The standard deviation of replicate plates run under

10.2.

the same exposure conditions for a single laboratory has been

10.4 Determination of Sulfate as Barium Sulfate—

found to be related to the mean sulfation level by the equation

Determine the sulfate ion in accordance with the gravimetric

given below:

test method (Test MethodA) in Test Method D516. The rapid

s50.0790 m (4)

avg

addition of a boiling solution of BaCl (7.4) to a gently boiling

where:

solution of the sulfate in 0.05 N HCl (7.9) will yield a granular

s = standard deviation in mg SO /m 3day, and

and easily filterable BaSO precipitate.

m = mean net SO capture rate in mg SO /m 3day

10.5 Determine the sulfate in the unexposed (blank) candle avg 2 2

based on 10 runs with six or more plates per run.

or p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.