ASTM B400-01

(Specification)Standard Specification for Compact Round Concentric-Lay-Stranded Aluminum 1350 Conductors

Standard Specification for Compact Round Concentric-Lay-Stranded Aluminum 1350 Conductors

SCOPE

1.1 This specification covers aluminum 1350-H19 (extra hard), 1350-H16 or -H26 ([n ]hard), 1350-H14 or -H24 (½ hard) and 1350-H142 or -H242 (½ hard) bare compact-round concentric-lay-stranded conductors made from round or shaped wires for use as uninsulated electrical conductors or in covered or insulated electrical conductors. These conductors shall be composed of a central core surrounded by one or more roller or die compacted layers of helically applied wires (Explanatory Note 1 and Note 2).

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification. For conductor sizes designated by AWG or kcmil sizes, the requirements in SI units are numerically converted from the corresponding requirements in inch-pound units. For conductor sizes designation by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

Note 1--Prior to 1975, aluminum 1350 was designated as EC aluminum.Note 2--The aluminum and temper designations conform to ANSI Standard H35.1. Aluminum 1350 corresponds to Unified Numbering System A91350 in accordance with Practice E527.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 400 – 01

Standard Specification for

Compact Round Concentric-Lay-Stranded Aluminum 1350

1

Conductors

This standard is issued under the fixed designation B 400; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 230 Specification for Aluminum 1350-H19 Wire for Elec-

2

trical Purposes

1.1 This specification covers aluminum 1350-H19 (extra

1 B 231 Specification for Concentric-Lay-Stranded Alumi-

hard), 1350-H16 or -H26 ([n ]hard), 1350-H14 or -H24 ( ⁄2

2

num 1350 Conductors

1

hard) and 1350-H142 or -H242 ( ⁄2 hard) bare compact-round

B 263 Test Method for Determination of Cross-Sectional

concentric-lay-stranded conductors made from round or shaped

2

Area of Stranded Conductors

wires for use as uninsulated electrical conductors or in covered

B 354 Terminology Relating to Uninsulated Metallic Elec-

or insulated electrical conductors. These conductors shall be

2

trical Conductors

composed of a central core surrounded by one or more roller or

B 609 Specification for Aluminum 1350 Round Wire, An-

die compacted layers of helically applied wires (Explanatory

2

nealed and Intermediate Tempers, for Electrical Purposes

Note 1 and Note 2).

E 29 Practice for Using Significant Digits in Test Data to

1.2 The values stated in inch-pound or SI units are to be

3

Determine Conformance with Specifications

regarded separately as standard. Each system shall be used

4

E 527 Practice for Numbering Metals and Alloys (UNS)

independently of the other. Combining values from the two

2.3 Other Documents:

systems may result in non-conformance with the specification.

ANSI H35.1 Alloy and Temper Designation Systems for

For conductor sizes designated by AWG or kcmil sizes, the

5

Aluminum

requirements in SI units are numerically converted from the

NBS Handbook 100-Copper Wire Tables, of the National

corresponding requirements in inch-pound units. For conductor

6

Bureau of Standards

sizes designation by AWG or kcmil, the requirements in SI

units have been numerically converted from corresponding

3. Classification

values stated or derived in inch-pound units. For conductor

3.1 For the purpose of this specification, conductors are

sizes designated by SI units only, the requirements are stated or

classified as follows:

derived in SI units.

3.1.1 Class AA—For bare conductors usually used in over-

1.2.1 For density, resistivity and temperature, the values

head lines.

stated in SI units are to be regarded as standard.

3.1.2 Class A—For conductors to be covered with weather-

NOTE 1—Prior to 1975, aluminum 1350 was designated as EC alumi-

resistant materials, and for bare conductors where greater

num.

flexibility than is afforded by Class AA is required. Conductors

NOTE 2—The aluminum and temper designations conform to ANSI

indicated for further fabrication into tree wire or to be insulated

Standard H35.1. Aluminum 1350 corresponds to Unified Numbering

and laid helically with or around aluminum or ACSR messen-

System A91350 in accordance with Practice E 527.

gers, shall be regarded as Class A conductors with respect to

2. Referenced Documents

direction of lay only (see 6.3).

3.1.3 Class B—For conductors to be insulated with various

2.1 The following documents of the issue in effect on date

materials such as rubber, paper, varnished cloth, etc., and for

of material purchase form a part of this specification to the

the conductors indicated under Class A where greater flexibility

extent referenced herein.

is required.

2.2 ASTM Standards:

2

Annual Book of ASTM Standards, Vol 02.03.

3

1

Annual Book of ASTM Standards, Vol 14.02.

This specification is under the jurisdiction of ASTM Committee B01 on

4

Annual Book of ASTM Standards, Vol 01.01.

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

5

Available from the American National Standards Institute, 11 West 42nd Street,

Conductors of Light Metals.

13th Floor, New York, NY 10036.

Current edition approved Apr. 10, 2001. Published April 2001. Originally

6

Available from the National Technical Information Service, 5285 Port Royal

published as B 400 – 63 T. Last previous edition B 400 – 94.

Rd., Springfield, VA 22161.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

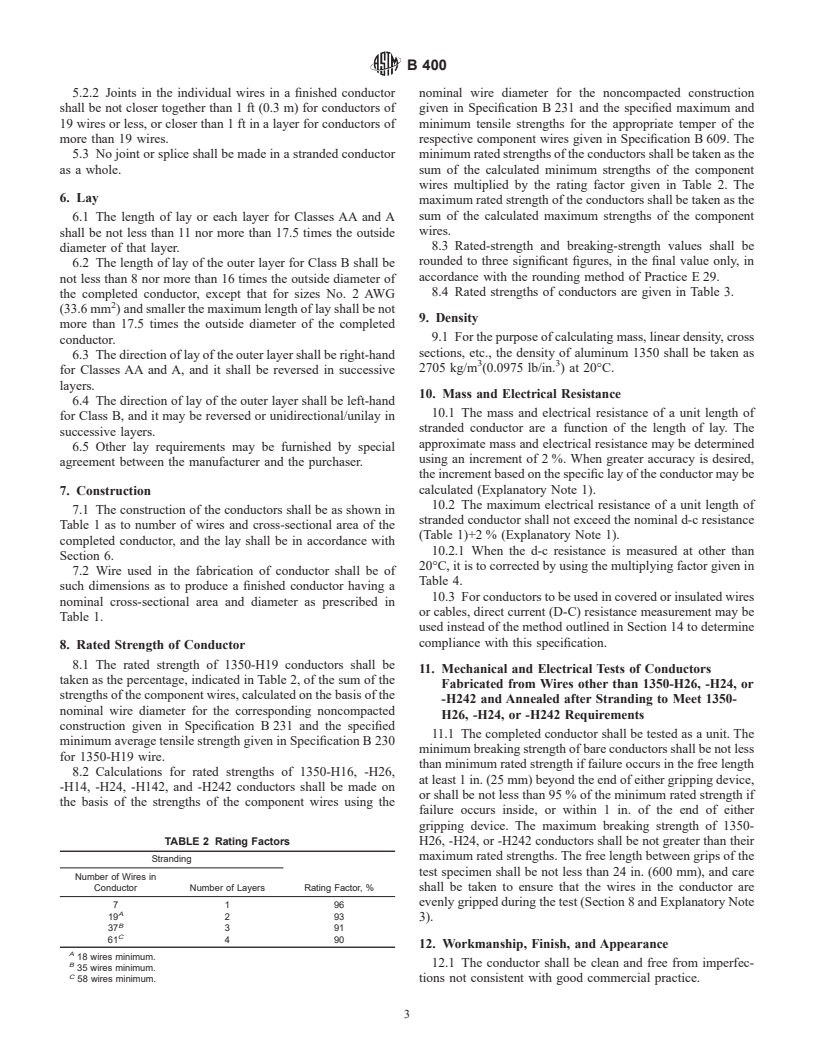

B 400

4. Ordering Information 5.1.1 Joints may be made in the six outer wires of seven-

strand conductors by cold-pressure welding or by electric-butt,

4.1 Orders for material under this specification shall include

cold-upset welding, but not by electric-butt welding. Joints are

the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.