ASTM D6762-02a(2009)e1

(Test Method)Standard Test Method for Determining the Hiding Power of Paint by Visual Evaluation of Spray Applied Coatings

Standard Test Method for Determining the Hiding Power of Paint by Visual Evaluation of Spray Applied Coatings

SIGNIFICANCE AND USE

This test method determines hiding power of a test paint by visual evaluation of a spray applied coating.

Note 1—Test Method D 2805 describes an instrumental method for determining hiding power. The paint film is applied at a uniform thickness (for example with a doctor blade), the film thickness is measured rigorously, and the opacity is determined photometrically. Hiding power is thereby determined with a high degree of precision.

Test Method D 6762 is less precise than Test Method D 2805, but is commonly used since it is more closely related to the application characteristics of the paint and is simpler in concept and evaluation.

SCOPE

1.1 This test method provides for the quantitative visual determination of the film thickness required to achieve full hiding. This film thickness is considered to be the hiding power of a test paint.

1.2 This method applies only to spray applied coatings but its concepts are valid for other methods of application as well.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6762 − 02a (Reapproved 2009)

Standard Test Method for

Determining the Hiding Power of Paint by Visual Evaluation

of Spray Applied Coatings

This standard is issued under the fixed designation D6762; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement in 1.3 was added editorially in July 2009.

1. Scope a Ferrous Base (Withdrawn 2006)

D1400 TestMethodforNondestructiveMeasurementofDry

1.1 This test method provides for the quantitative visual

Film Thickness of Nonconductive Coatings Applied to a

determination of the film thickness required to achieve full

Nonferrous Metal Base (Withdrawn 2006)

hiding.Thisfilmthicknessisconsideredtobethehidingpower

D1729 Practice for Visual Appraisal of Colors and Color

of a test paint.

Differences of Diffusely-Illuminated Opaque Materials

1.2 This method applies only to spray applied coatings but

D1730 Practices for Preparation of Aluminum and

its concepts are valid for other methods of application as well.

Aluminum-Alloy Surfaces for Painting

1.3 The values stated in inch-pound units are to be regarded D2805 Test Method for Hiding Power of Paints by Reflec-

tometry

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

and are not considered standard.

1.4 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions—For definitions of terms used in this test

responsibility of the user of this standard to establish appro-

method, refer to Terminology D16 and the Paint/Coatings

priate safety and health practices and determine the applica-

Dictionary.

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 The test paint is applied by means of spray application

2.1 ASTM Standards:

in a wedge-shaped film over a black and white, black and gray

D16 TerminologyforPaint,RelatedCoatings,Materials,and

or red and gray pattern so that a thickness variation is obtained,

Applications

which provides excess hiding at one end of the pattern and

D609 Practice for Preparation of Cold-Rolled Steel Panels

partial hiding at the other end of the pattern.

for Testing Paint, Varnish, Conversion Coatings, and

Related Coating Products

4.2 The dry film is examined under standard illumination to

D1005 Test Method for Measurement of Dry-Film Thick-

select the point where the pattern just becomes obscured. The

ness of Organic Coatings Using Micrometers

thickness of the film at this point is designated the hiding

D1186 Test Methods for Nondestructive Measurement of

power of the paint.

Dry Film Thickness of Nonmagnetic Coatings Applied to

5. Significance and Use

5.1 This test method determines hiding power of a test paint

by visual evaluation of a spray applied coating.

NOTE 1—Test Method D2805 describes an instrumental method for

This test method is under the jurisdiction of ASTM Committee D01 on Paint

determining hiding power.The paint film is applied at a uniform thickness

and Related Coatings, Materials, andApplications and is the direct responsibility of

(for example with a doctor blade), the film thickness is measured

Subcommittee D01.26 on Optical Properties.

rigorously,andtheopacityisdeterminedphotometrically.Hidingpoweris

Current edition approved July 1, 2009. Published July 1, 2009. Originally

approved in 2002. Last previous edition approved in 2002 as D6762 – 02a. DOI:

10.1520/D6762-02AR09E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Published by the Federation of Societies for Coatings Technology, 492

the ASTM website. Norristown Rd., Blue Bell, PA 19422.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6762 − 02a (2009)

thereby determined with a high degree of precision.

5.2 Test Method D6762 is less precise than Test Method

D2805, but is commonly used since it is more closely related

to the application characteristics of the paint and is simpler in

concept and evaluation.

6. Apparatus

6.1 Test Surface, a smooth-surfaced paper chart, approxi-

mately2by11in.,withatestpatternhavingadjacentblackand

white, black and gray or red and gray areas and coated with a

suitable varnish or lacquer so as to render the surface imper-

vious to paint liquids.

NOTE 2—The red, gray, white and black areas should fall in the

following colorimetric range:

A A

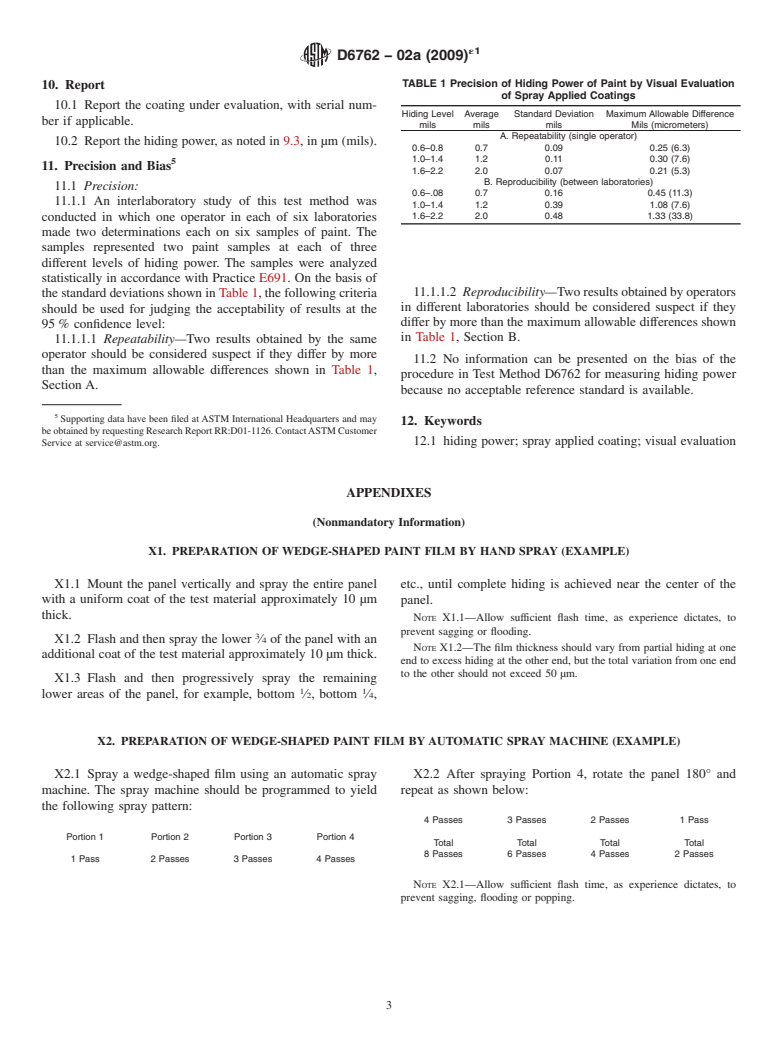

CIE-Y % C h

Red 4–7 10–18 26–38

Gray 28–34

White 80–83

Black 1 max

A 10 2

Valid for Illuminant D65 or C , with 0°/45° geometry.

6.2 Illumination, a light source providing diffuse light of

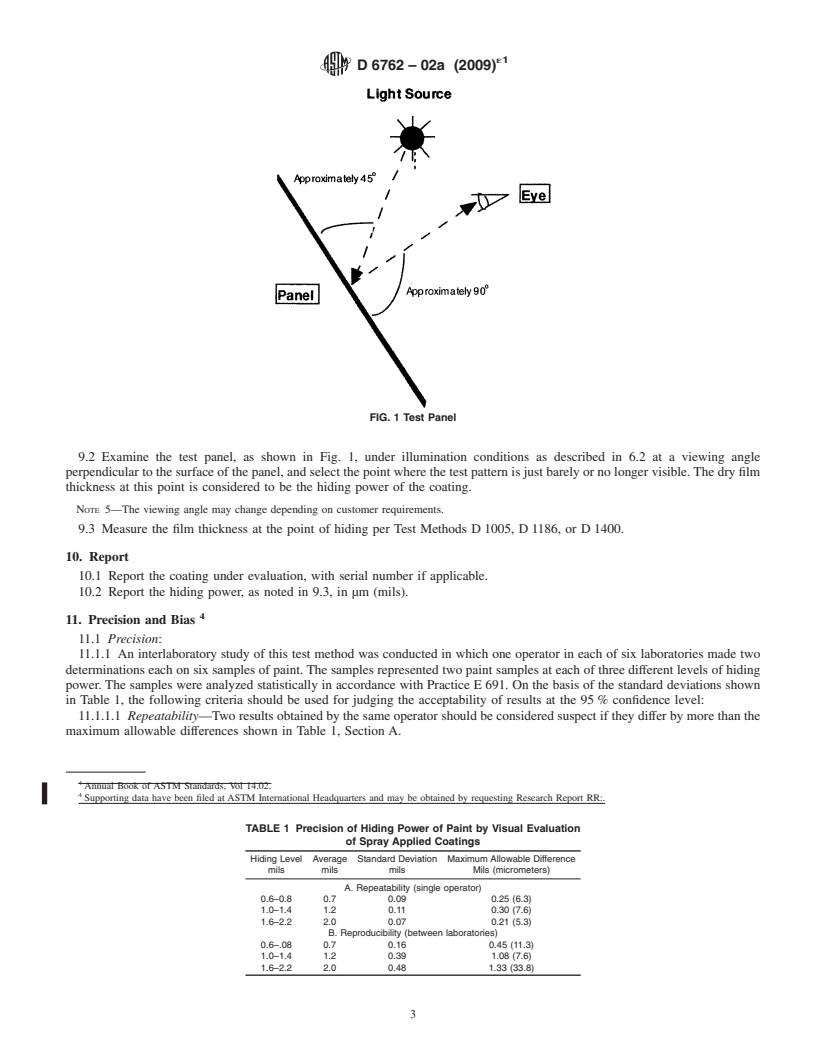

FIG. 1 Test Panel

reasonable intensity, preferably northern sky light or an ap-

proximation of the same (see Practice D1729).

6.3 Backer Panel, 4 by 12 in. steel or aluminum panel. A 8. Preparation of Wedge-shaped Paint Film (Automatic

Spray Machine)

larger panel may be used if desired.

6.4 Film Thickness Measuring Device, a film thickness 8.1 Prepare the backer panel in accordance with Practices

D609 or D1730.

measuring device in accordance with Test Methods D1005,

D1186, and D1400.

8.2 Attach the desired test pattern to the one side of the

backer panel with masking tape or adhesive tape.

6.5 Spray Equipment, either a hand spray gun or an auto-

matic spray machine.

8.3 Reduce the material being tested to spray viscosity.

6.6 Oven, capable of maintaining the bake schedule for the

8.4 Position the backer panel on the panel holder so that the

product being evaluated.

long side is horizontal or vertical depending on the type of

spray machine being used.

6.7 Tape, masking or adhesive.

8.5 Prepare a wedge-shaped film. An example of a proce-

7. Preparation of Wedge-shaped Paint Film (Hand

dure for preparing a wedge-shaped film by means of an

Spray)

automatic spray machine is shown in Appendix X2.

7.1 Prepare the backer panel in accordance with P

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D6762–02a Designation:D6762–02a(Reapproved2009)

Standard Test Method for

Determining the Hiding Power of Paint by Visual Evaluation

of Spray Applied Coatings

This standard is issued under the fixed designation D 6762; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Units statement in 1.3 was added editorially in July 2009.

1. Scope

1.1 This test method provides for the quantitative visual determination of the film thickness required to achieve full hiding.This

film thickness is considered to be the hiding power of a test paint.

1.2 This method applies only to spray applied coatings but its concepts are valid for other methods of application as well.

1.3

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D16 Terminology for Paint, Related Coatings, Materials, and Applications

D 609 Practice for Preparation of Cold-Rolled Steel Panels for Testing Paint, Varnish, Conversion Coatings, and Related

Coating Products

D 1005 Test Method for Measurement of Dry-Film Thickness of Organic Coatings Using Micrometers

D 1186 Test Methods for Nondestructive Measurement of Dry Film Thickness of Nonmagnetic Coatings Applied to a Ferrous

Base

D 1400 Test Method for Nondestructive Measurement of Dry Film Thickness of Nonconductive Coatings Applied to a

Nonferrous Metal Base

D 1729 Practice for Visual Appraisal of Colors and Color Differences of Diffusely-Illuminated Opaque Materials

D 1730 Practices for Preparation of Aluminum and Aluminum-Alloy Surfaces for Painting

D 2805 Test Method for Hiding Power of Paints by Reflectometry

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology D 16 and the Paint/Coatings

Dictionary.

4. Summary of Test Method

4.1 The test paint is applied by means of spray application in a wedge-shaped film over a black and white, black and gray or

red and gray pattern so that a thickness variation is obtained, which provides excess hiding at one end of the pattern and partial

hiding at the other end of the pattern.

4.2 The dry film is examined under standard illumination to select the point where the pattern just becomes obscured. The

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.26 on Optical Properties.

´1

Current edition approved Dec. 10, 2002. Published February 2003. Originally approved in 2002. Last previous edition approved in 2002 as D6762-02 .

Current edition approved July 1, 2009. Published July 1, 2009. Originally approved in 2002. Last previous edition approved in 2002 as D 6762 - 02a.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 06.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 02.05.

Published by the Federation of Societies for Coatings Technology, 492 Norristown Rd., Blue Bell, PA 19422.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D6762–02a (2009)

thickness of the film at this point is designated the hiding power of the paint.

5. Significance and Use

5.1 This test method determines hiding power of a test paint by visual evaluation of a spray applied coating.

NOTE 1—Test Method D 2805 describes an instrumental method for determining hiding power. The paint film is applied at a uniform thickness (for

example with a doctor blade), the film thickness is measured rigorously, and the opacity is determined photometrically. Hiding power is thereby

determined with a high degree of precision.

5.2 Test Method D 6762 is less precise than Test Method D 2805, but is commonly used since it is more closely related to the

application characteristics of the paint and is simpler in concept and evaluation.

6. Apparatus

6.1 Test Surface, a smooth-surfaced paper chart, approximately 2 by 11 in., with a test pattern having adjacent black and white,

black and gray or red and gray areas and coated with a suitable varnish or lacquer so as to render the surface impervious to paint

liquids.

NOTE 2—The red, gray, white and black areas should fall in the following colorimetric range:

A A

CIE-Y % C h

Red 4–7 10–18 26–38

Gray 28–34

White 80–83

Black 1 max

A 10 2

Valid for Illuminant D65 or C , with 0°/45° geometry.

6.2 Illumination, a light source providing diffuse light of reasonable intensity, preferably northern sky light or an approximation

of the same (see Practice D 1729).

6.3 Backer Panel, 4 by 12 in. steel or aluminum panel. A larger panel may be used if desired.

6.4 Film Thickness Measuring Device , a film thickness measuring device in accordance with Test Methods D 1005, D 1186,

and D 1400.

6.5 Spray Equipment, either a hand spray gun or an automatic spray machine.

6.6 Oven, capable of maintaining the bake schedule for the product being evaluated.

6.7 Tape, masking or adhesive.

7. Preparation of Wedge-shaped Paint Film (Hand Spray)

7.1 Prepare the backer panel in accordance with Practices D 609 or D 1730.

7.2 Attach the desired test pattern to one side of the backer panel with masking tape or adhesive tape.

7.3 Reduce the material being tested to spray viscosity.

7.4 Attach spray gun to a suitable compressed air supply line and adjust air pressure for consistent fan spray.

7.5 Position the backer panel so that the long side is vertical. The panel shou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.