ASTM B701/B701M-00

(Specification)Standard Specification for Concentric-Lay-Stranded Self-Damping Aluminum Conductors, Steel Reinforced (ACSR/SD)

Standard Specification for Concentric-Lay-Stranded Self-Damping Aluminum Conductors, Steel Reinforced (ACSR/SD)

SCOPE

1.1 This specification covers concentric-lay-stranded self-damping aluminum conductor, steel-reinforced (ACSR/SD) and its component wires for use as overhead electrical conductors (Explanatory Note 1 and Note 2).

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification. For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

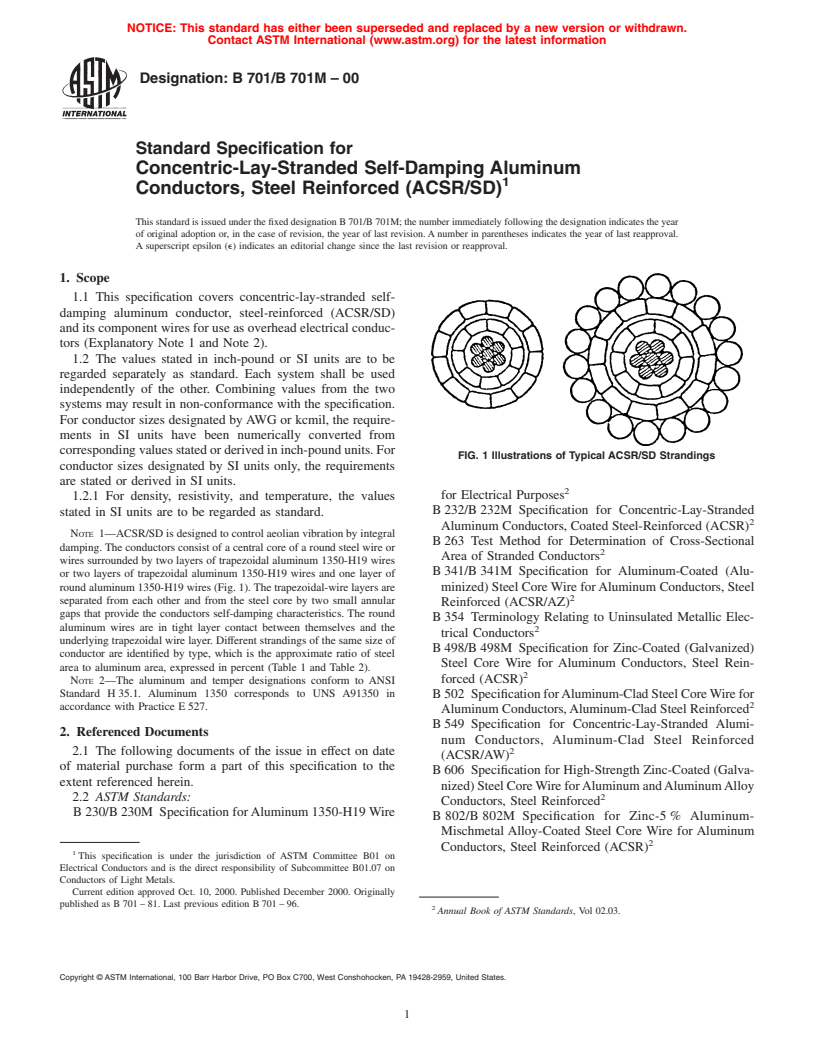

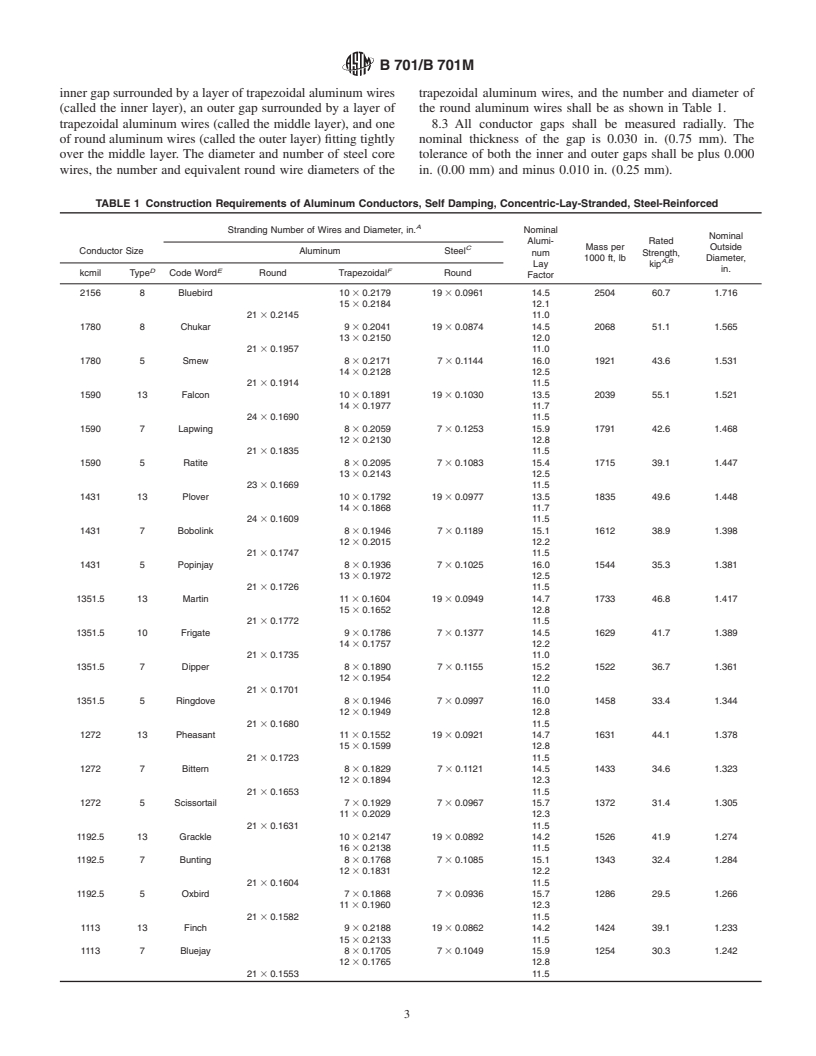

Note 1--ACSR/SD is designed to control aeolian vibration by integral damping. The conductors consist of a central core of a round steel wire or wires surrounded by two layers of trapezoidal aluminum 1350-H19 wires or two layers of trapezoidal aluminum 1350-H19 wires and one layer of round aluminum 1350-H19 wires (Fig. 1). The trapezoidal-wire layers are separated from each other and from the steel core by two small annular gaps that provide the conductors self-damping characteristics. The round aluminum wires are in tight layer contact between themselves and the underlying trapezoidal wire layer. Different strandings of the same size of conductor are identified by type, which is the approximate ratio of steel area to aluminum area, expressed in percent ( Table 1and Table 2).

Note 2--The aluminum and temper designations conform to ANSI Standard H 35.1. Aluminum 1350 corresponds to UNS A91350 in accordance with Practice E527.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 701/B 701M – 00

Standard Specification for

Concentric-Lay-Stranded Self-Damping Aluminum

Conductors, Steel Reinforced (ACSR/SD)

This standard is issued under the fixed designation B 701/B 701M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers concentric-lay-stranded self-

damping aluminum conductor, steel-reinforced (ACSR/SD)

and its component wires for use as overhead electrical conduc-

tors (Explanatory Note 1 and Note 2).

1.2 The values stated in inch-pound or SI units are to be

regarded separately as standard. Each system shall be used

independently of the other. Combining values from the two

systems may result in non-conformance with the specification.

For conductor sizes designated byAWG or kcmil, the require-

ments in SI units have been numerically converted from

correspondingvaluesstatedorderivedininch-poundunits.For

FIG. 1 Illustrations of Typical ACSR/SD Strandings

conductor sizes designated by SI units only, the requirements

are stated or derived in SI units.

for Electrical Purposes

1.2.1 For density, resistivity, and temperature, the values

B 232/B 232M Specification for Concentric-Lay-Stranded

stated in SI units are to be regarded as standard.

Aluminum Conductors, Coated Steel-Reinforced (ACSR)

NOTE 1—ACSR/SD is designed to control aeolian vibration by integral

B 263 Test Method for Determination of Cross-Sectional

damping. The conductors consist of a central core of a round steel wire or

Area of Stranded Conductors

wires surrounded by two layers of trapezoidal aluminum 1350-H19 wires

B 341/B 341M Specification for Aluminum-Coated (Alu-

or two layers of trapezoidal aluminum 1350-H19 wires and one layer of

round aluminum 1350-H19 wires (Fig. 1). The trapezoidal-wire layers are minized) Steel CoreWire forAluminum Conductors, Steel

separated from each other and from the steel core by two small annular

Reinforced (ACSR/AZ)

gaps that provide the conductors self-damping characteristics. The round

B 354 Terminology Relating to Uninsulated Metallic Elec-

aluminum wires are in tight layer contact between themselves and the

trical Conductors

underlying trapezoidal wire layer. Different strandings of the same size of

B 498/B 498M Specification for Zinc-Coated (Galvanized)

conductor are identified by type, which is the approximate ratio of steel

Steel Core Wire for Aluminum Conductors, Steel Rein-

area to aluminum area, expressed in percent (Table 1 and Table 2).

forced (ACSR)

NOTE 2—The aluminum and temper designations conform to ANSI

Standard H 35.1. Aluminum 1350 corresponds to UNS A91350 in

B 502 SpecificationforAluminum-CladSteelCoreWirefor

accordance with Practice E 527.

Aluminum Conductors,Aluminum-Clad Steel Reinforced

B 549 Specification for Concentric-Lay-Stranded Alumi-

2. Referenced Documents

num Conductors, Aluminum-Clad Steel Reinforced

2.1 The following documents of the issue in effect on date

(ACSR/AW)

of material purchase form a part of this specification to the

B 606 Specification for High-Strength Zinc-Coated (Galva-

extent referenced herein.

nized)SteelCoreWireforAluminumandAluminumAlloy

2.2 ASTM Standards:

Conductors, Steel Reinforced

B 230/B 230M Specification forAluminum 1350-H19 Wire

B 802/B 802M Specification for Zinc-5 % Aluminum-

Mischmetal Alloy-Coated Steel Core Wire for Aluminum

Conductors, Steel Reinforced (ACSR)

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

Conductors of Light Metals.

Current edition approved Oct. 10, 2000. Published December 2000. Originally

published as B 701 – 81. Last previous edition B 701 – 96.

Annual Book of ASTM Standards, Vol 02.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 701/B 701M

B 803 Specification for High-Strength Zinc-5 % 4.1.1 Quantity of each size and type (Note 1),

Aluminum-Mischmetal Alloy-Coated Steel Core Wire for 4.1.2 Conductor size: kcmil area,

Aluminum and Aluminum-Alloy Conductors, Steel Rein- 4.1.3 Conductor type and number of wires, aluminum and

forced steel (Table 1),

E 29 Practice for Using Significant Digits in Test Data to 4.1.4 Type of steel core wire and if zinc or Zn-5 % Al-MM

Determine Conformance with Specifications alloy coated, area density (ClassesA, B, and C) of coating (see

E 527 Practice for Numbering Metals and Alloys (UNS) 5.2),

2.3 ANSI Documents: 4.1.5 Special tension test, if required (see 9.2),

ANSI H35.1 American National Standard Alloy and Tem- 4.1.6 Place of inspection (Section 15),

per Designation Systems for Aluminum 4.1.7 Package size (see 16.1),

2.4 NIST Documents: 4.1.8 Specialpackagemarking,ifrequired(Section17),and

NBS Handbook 100 —Copper Wire Tables of the National 4.1.9 Heavy wood lagging, if required (see 16.3).

Bureau of Standards

5. Requirement For Wires

2.5 Aluminum Association Documents:

5.1 Before stranding, the round and trapezoidal aluminum

Publication 50, Code Words for Overhead Aluminum Elec-

trical Conductors wires shall conform to the requirements of Specification B 230

except for shape and diameter tolerance of the trapezoidal

3. Terminology

wires. The tensile strength and elongation requirements of

3.1 Definitions of Terms Specific to This Standard: trapezoidal wires shall be the same as for round wires of equal

3.1.1 ACSR/SD covered by this specification has five types

area. The area tolerances shall be such that the finished

of coated core wire and one type of aluminum-clad core wire conductor conforms to Section 12.

which are designated by abbreviations as follows (Explanatory

5.2 Before stranding, the steel core wire shall meet the

Note 2): requirements of Specifications B 341/B 341M, B 498/B 498M,

3.1.1.1 ACSR/SD/AW—ACSR/SD using aluminum-clad

B 502, B 606, B 802/B 802M, or B 803, whichever is appli-

steel wire (Specification B 502). cable.

3.1.1.2 ACSR/SD/AZ—ACSR/SD using aluminum-coated

6. Joints

(aluminized) steel wire (Specification B 341/B 341M).

3.1.1.3 ACSR/SD/GA—ACSR/SD using Class A zinc- 6.1 Electric-butt welds, electric-butt, cold-upset welds, or

coated steel wire (Specification B 498/B 498M). cold-pressure welds may be made in the individual aluminum

3.1.1.4 ACSR/SD/GB—ACSR/SD using Class B zinc- wires during the stranding process. No weld shall occur within

coated steel wire (Specification B 498/B 498M).

50 ft. (15 m) of any other weld in the completed conductor

3.1.1.5 ACSR/SD/GC—ACSR/SD using Class C zinc- (Explanatory Note 2).

coated steel wire (Specification B 498/B 498M).

6.2 There shall be no joints made in the finished steel wires.

3.1.1.6 ACSR/SD/HS—ACSR/SD using extra highstrength

7. Lay

steel wire (Specification B 606).

3.1.1.7 ACSR/SD/MA—ACSR/SD using Class A zinc-5 % 7.1 The nominal lay factors for the trapezoidal aluminum

aluminum-mischmetal alloy-coated steel core wire (Specifica- wires are shown in Table 1 (Explanatory Note 1).

tion B 802/B 802M). 7.2 Thelayfactorfortheroundaluminumwiresshallbenot

3.1.1.8 ACSR/SD/MB—ACSR/SD using Class B zinc-5 % less than 10 nor more than 13.

7.3 The lay factor for the 6-wire layer of 7 and 19-wire steel

aluminum-mischmetal alloy-coated steel core wire (Specifica-

tion B 802/B 802M). cores shall be not less than 18 nor more than 30.

7.4 The lay factor for the 12-wire layer of 19-wire steel

3.1.1.9 ACSR/SD/MC—ACSR/SD using Class V zinc-5 %

aluminum-mischmetal alloy-coated steel core wire (Specifica- cores shall be no less than 16 nor more than 24.

7.5 The direction of lay of the outside layer of aluminum

tion B 802/B 802M).

3.1.1.10 ACSR/SD/MS—ACSR/SD using high-strength wires shall be right-hand.

7.6 The direction of lay of the aluminum and steel wires

zinc-5 % Aluminum-mischmetal alloy-coated steel core wire

(Specification B 803). shall be reversed in successive layers.

7.7 For the purpose of this specification the lay factor is the

4. Ordering Information

length of lay of a given layer divided by its outside diameter.

4.1 Orders for material under this specification shall include

8. Construction

the following information:

8.1 The nominal aluminum cross-sectional area, type,

stranding, and equivalent wire diameters shall be as shown in

Annual Book of ASTM Standards, Vol 14.02.

4 Table 1 (Explanatory Note 1).

Annual Book of ASTM Standards, Vol 01.01.

8.2 ThesmallersizesofACSR/SDconsistofasteelcore,an

Available from American National Standards Institute, 11 West 42nd St., 13th

Floor, New York, NY 10036.

inner gap surrounded by a layer of trapezoidal aluminum wires

Available from National Institute of Standards and Technology (NIST),

(called the inner layer), and an outer gap surrounded by a

Gaithersburg, MD 20899.

7 th

second layer of trapezoidal aluminum wire (called the outer

Available from Aluminum Association Inc., 900 19 Street, NW, Suite 300,

Washington, DC 20006. layer). The larger sizes ofACSR/SD consist of a steel core, an

B 701/B 701M

inner gap surrounded by a layer of trapezoidal aluminum wires trapezoidal aluminum wires, and the number and diameter of

(called the inner layer), an outer gap surrounded by a layer of the round aluminum wires shall be as shown in Table 1.

trapezoidal aluminum wires (called the middle layer), and one 8.3 All conductor gaps shall be measured radially. The

of round aluminum wires (called the outer layer) fitting tightly nominal thickness of the gap is 0.030 in. (0.75 mm). The

over the middle layer. The diameter and number of steel core tolerance of both the inner and outer gaps shall be plus 0.000

wires, the number and equivalent round wire diameters of the in. (0.00 mm) and minus 0.010 in. (0.25 mm).

TABLE 1 Construction Requirements of Aluminum Conductors, Self Damping, Concentric-Lay-Stranded, Steel-Reinforced

A

Stranding Number of Wires and Diameter, in. Nominal

Nominal

Alumi- Rated

C Mass per Outside

Conductor Size Aluminum Steel

num Strength,

1000 ft, lb Diameter,

A,B

Lay kip

D E F in.

kcmil Type Code Word Round Trapezoidal Round

Factor

2156 8 Bluebird 10 3 0.2179 19 3 0.0961 14.5 2504 60.7 1.716

15 3 0.2184 12.1

21 3 0.2145 11.0

1780 8 Chukar 9 3 0.2041 19 3 0.0874 14.5 2068 51.1 1.565

13 3 0.2150 12.0

21 3 0.1957 11.0

1780 5 Smew 8 3 0.2171 7 3 0.1144 16.0 1921 43.6 1.531

14 3 0.2128 12.5

21 3 0.1914 11.5

1590 13 Falcon 10 3 0.1891 19 3 0.1030 13.5 2039 55.1 1.521

14 3 0.1977 11.7

24 3 0.1690 11.5

1590 7 Lapwing 8 3 0.2059 7 3 0.1253 15.9 1791 42.6 1.468

12 3 0.2130 12.8

21 3 0.1835 11.5

1590 5 Ratite 8 3 0.2095 7 3 0.1083 15.4 1715 39.1 1.447

13 3 0.2143 12.5

23 3 0.1669 11.5

1431 13 Plover 10 3 0.1792 19 3 0.0977 13.5 1835 49.6 1.448

14 3 0.1868 11.7

24 3 0.1609 11.5

1431 7 Bobolink 8 3 0.1946 7 3 0.1189 15.1 1612 38.9 1.398

12 3 0.2015 12.2

21 3 0.1747 11.5

1431 5 Popinjay 8 3 0.1936 7 3 0.1025 16.0 1544 35.3 1.381

13 3 0.1972 12.5

21 3 0.1726 11.5

1351.5 13 Martin 11 3 0.1604 19 3 0.0949 14.7 1733 46.8 1.417

15 3 0.1652 12.8

21 3 0.1772 11.5

1351.5 10 Frigate 9 3 0.1786 7 3 0.1377 14.5 1629 41.7 1.389

14 3 0.1757 12.2

21 3 0.1735 11.0

1351.5 7 Dipper 8 3 0.1890 7 3 0.1155 15.2 1522 36.7 1.361

12 3 0.1954 12.2

21 3 0.1701 11.0

1351.5 5 Ringdove 8 3 0.1946 7 3 0.0997 16.0 1458 33.4 1.344

12 3 0.1949 12.8

21 3 0.1680 11.5

1272 13 Pheasant 11 3 0.1552 19 3 0.0921 14.7 1631 44.1 1.378

15 3 0.1599 12.8

21 3 0.1723 11.5

1272 7 Bittern 8 3 0.1829 7 3 0.1121 14.5 1433 34.6 1.323

12 3 0.1894 12.3

21 3 0.1653 11.5

1272 5 Scissortail 7 3 0.1929 7 3 0.0967 15.7 1372 31.4 1.305

11 3 0.2029 12.3

21 3 0.1631 11.5

1192.5 13 Grackle 10 3 0.2147 19 3 0.0892 14.2 1526 41.9 1.274

16 3 0.2138 11.5

1192.5 7 Bunting 8 3 0.1768 7 3 0.1085 15.1 1343 32.4 1.284

12 3 0.1831 12.2

21 3 0.1604 11.5

1192.5 5 Oxbird 7 3 0.1868 7 3 0.0936 15.7 1286 29.5 1.266

11 3 0.1960 12.3

21 3 0.1582 11.5

1113 13 Finch 9 3 0.2188 19 3 0.0862 14.2 1424 39.1 1.233

15 3 0.2133 11.5

1113 7 Bluejay 8 3 0.1705 7 3 0.1049 15.9 1254 30.3 1.242

12 3 0.1765 12.8

21 3 0.1553 11.5

B 701/B 701M

TABLE 1 Continued

A

Stranding Number of Wires and Diameter, in. Nominal

Nominal

Alumi- Rated

C Mass per Outside

Conductor Size Aluminum Steel

num Strength,

1000 ft, lb Diameter,

A,B

Lay kip

D E F in.

kcmil Type Code Word Round Trapezoidal Round

Factor

1113 5 Avocet 7 3 0.1818 7 3 0.0904 16.0 1200 27.5 1.226

12 3 0.1798 12.4

21 3 0.1533 11.5

1033.5 13 Curlew 9 3 0.2106 7 3 0.1383 14.2 1329 36.3 1.191

14 3 0.2129 11.5

1033.5 7 Ortolan 8 3 0.2168 7 3 0.1010 15.2 1161 28.1 1.145

14 3 0.2167 11.5

1033.5 5 Snowbird 7 3 0.1746 7 3 0.871 16.0 1115 25.9 1.185

12 3 0.1731 12.4

21 3 0.1481 11.5

954 13 Cardinal 8 3 0.2147 7 3 0.1329 14.2 1227 33.5 1.147

13 3 0.2122 11.5

954 7 Rail 8 3 0.2080 7 3 0.0971 15.2 1073 26.1 1.103

13 3 0.2163 11.5

954 5 Phoenix 7 3 0.2196 7 3 0.0836 15.6 1027 23.7 1.088

13 3 0.2178 11.5

795 16 Drake 9 3 0.1865 7 3 0.1360 13.9 1093 31.8 1.077

13 3 0.1926 11.5

795 13 Condor 8 3 0.1957 7 3 0.1213 14.2 1023 28.2 1.055

12 3 0.2018 11.5

795 10 Puffin 7 3 0.2067 7 3 0.1056 14.7 956 25.1 1.034

12 3 0.2033 11.5

795 7 Tern 7 3 0.2034 7 3 0.0886 15.2 893 21.9 1.013

11 3 0.2144 11.5

795 5 Macaw 6 3 0.2167 7 3 0.0764 15.6 856 19.8 0.999

11 3 0.2160 11.5

636 16 Grosbeak 9 3 0.1666 7 3 0.1216 13.9 874 25.4 0.975

13 3 0.1723 11.5

636 13 Rook 8 3 0.1749 7 3 0.1085 14.3 818 22.9 0.955

12 3 0.1806 11.5

636 10 Goldfinch 7 3 0.1848 7 3 0.0945 14.7 765 20.1 0.935

12 3 0.1819 11.5

636 7 Killdeer 7 3 0.1815 7 3 0.0793 15.2 715 17.7 0.917

12 3 0.1838 11.5

636 5 Pipit 6 3 0.1938 7 3 0.0684 15.8 684 16.1 0.903

11 3 0.1932 11.5

556.5 16 Dove 9 3 0.1557 7 3 0.1138 14.0 765 22.6 0.919

13 3 0.1613 11.5

556.5 13 Parakeet 8 3 0.1637 7 3 0.1015 14.3 716 20.0 0.901

13 3 0.1662 11.5

556.5 10 Sapsucker 7 3 0.1728 7 3 0.0884 14.7 669 17.8 0.882

12 3 0.1702 11.5

556.5 7 Sunbird 7 3 0.1707 7 3 0.0741 15.2 625 15.5 0.863

11 3 0.1790 11.5

556.5 5 Blackbird 6 3 0.1820 1 3 0.1692 15.8 599 13.6 0.843

10 3 0.1892 11.5

477 16 Hawk 9 3 0.1438 7 3 0.1053 14.0 655.8 19.5 0.860

13 3 0.1496 11.5

477 13 Flicker 8 3 0.1515 7 3 0.0940 14.4 613.5 17.2 0.843

13 3 0.1502 11.5

477 10 Toucan 7 3 0.1599 7 3 0.0818 14.8 573.4 15.3 0.824

12 3 0.1576 11.5

477 7 Jackdaw 7 3 0.1577 7 3 0.0686 15.2 535.8 13.3 0.808

12 3 0.1589 11.5

477 5 Kestrel 6 3 0.1656 1 3 0.1566 16.0 513.3 11.7 0.787

10 3 0.1768 11.5

397.5 16 Ibis 9 3 0.1278 7 3 0.0961 14.2 546.5 16.4 0.771

14 3 0.1338 11.5

397.5 10 Stork 7 3 0.1424 7 3 0.0747 15.0 477.9 12.9 0.750

12 3 0.1459 11.5

397.5 7 Longspu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.