ASTM D3882-99(2006)

(Test Method)Standard Test Method for Bow and Skew in Woven and Knitted Fabrics

Standard Test Method for Bow and Skew in Woven and Knitted Fabrics

SIGNIFICANCE AND USE

This test method is considered satisfactory for acceptance testing of commercial shipments.

5.1.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, the test samples to be used are as homogeneous as possible, are drawn from the material from which the disparate test results were obtained, and are randomly assigned in equal numbers to each laboratory for testing. Other fabrics with established test values may be used for this purpose. The test results from the two laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

Individual rolls are normally accepted or rejected on the basis of the maximum amount of bow or skew in a specific roll of fabric. The average bow or skew in a roll or lot or the range of bow or skew in a roll may be determined but are not normally used in the trade for acceptance or rejection.

Bow or skew can be induced during fabric manufacturing, dyeing, tentering, finishing, or other operations where a potential exists for uneven distribution of tensions across the fabric width. Bow and skew are more visually displeasing in colored, patterned fabrics such as plaids and horizontal stripes rather than in solid colors because the contrast makes the distortion more prominent. These defects may cause sewing problems in such fabrics and draping problems in finished products. In some cases, a specified amount of skew is needed, for example, to prevent trouser leg twisting. Matching plaids from distorted patterns may create serious problems for the garment manufacturer or home sewer. Wavy or sharp breaks in the bow line are ...

SCOPE

1.1 This test method covers the determination of bow and skew of filling yarns in woven fabrics and the courses in knitted fabrics.

1.2 This test method can also be used to measure the bow and skew of printed geometric designs such as plaids.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this test method.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3882–99 (Reapproved 2006)

Standard Test Method for

Bow and Skew in Woven and Knitted Fabrics

This standard is issued under the fixed designation D 3882; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

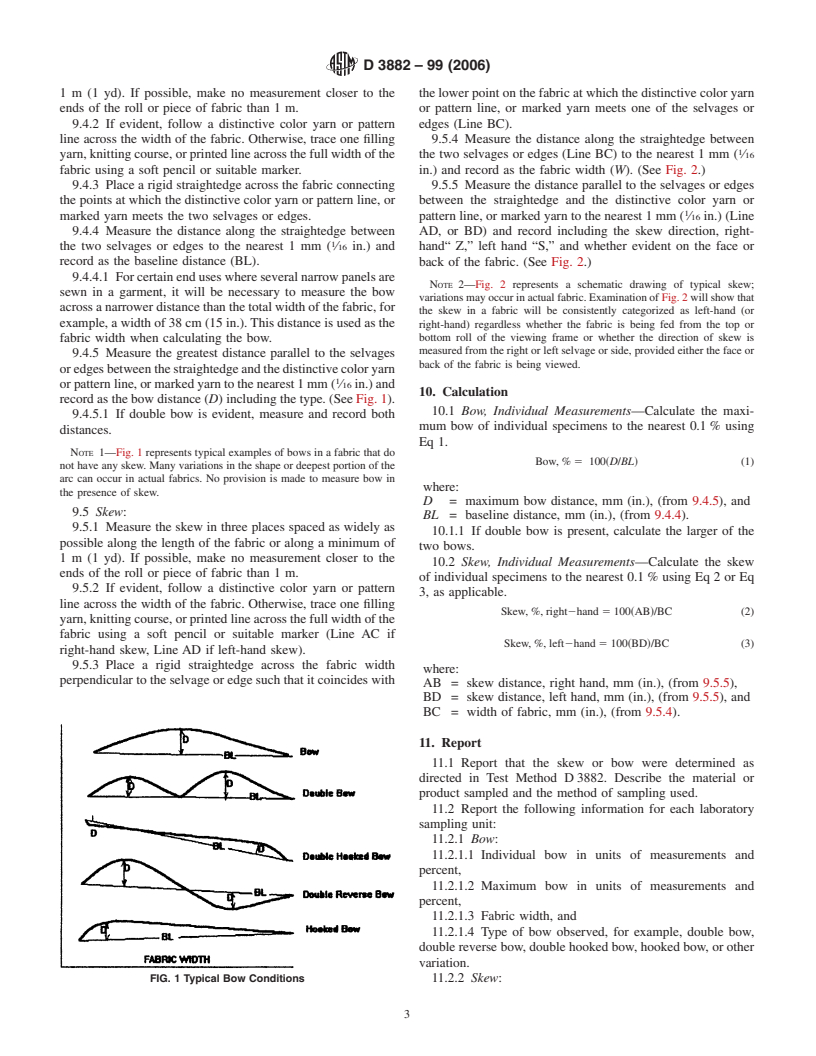

1. Scope the selvages and form one or more arcs across the width of the

fabric. (See alsodouble bow .)

1.1 This test method covers the determination of bow and

3.1.2 double bow, n—two fabric bows, arcing in the same

skew of filling yarns in woven fabrics and the courses in

direction, as in a flattened M or W depending on the viewing

knitted fabrics.

angle. (See alsodouble bow .) (Compare double reverse bow.)

1.2 This test method can also be used to measure the bow

3.1.2.1 Discussion—In tubular knits, there may be differen-

and skew of printed geometric designs such as plaids.

tial bowing between the top and bottom of the tube.

1.3 The values stated in either SI units or inch-pound units

3.1.3 double hooked bow, n—one hooked bow at each side

are to be regarded separately as the standard. Within the text,

of the fabric that arc in opposite directions. (See alsohooked

the inch-pound units are shown in parentheses. The values

bow .)

stated in each system may not be exact equivalents; therefore,

3.1.4 double reverse bow, n—two fabric bows arcing in

each system shall be used independently of the other. Combin-

opposite directions. (See also bowdouble bow.) (Compare .)

ingvaluesfromthetwosystemsmayresultinnonconformance

3.1.5 hooked bow, n—a fabric condition in which the filling

with this test method.

yarns or knitted courses are in the proper position for most of

1.4 This standard does not purport to address all of the

the fabric width but are pulled out of alignment at one side of

safety concerns, if any, associated with its use. It is the

the fabric. (See also double hooked bow.)

responsibility of the user of this standard to establish appro-

3.1.6 knitted fabric, n—astructureproducedbyinterlooping

priate safety and health practices and determine the applica-

one or more ends of yarn or comparable materials.

bility of regulatory limitations prior to use.

3.1.7 skew, n—a fabric condition resulting when filling

2. Referenced Documents yarns or knitted courses are angularly displaced from a line

perpendicular to the edge or side of the fabric.

2.1 ASTM Standards:

3.1.7.1 Discussion—Knitted courses or filling yarns usually

D 123 Terminology Relating to Textiles

appear as straight line at right angles to the edge or side of the

D 1776 Practice for Conditioning and Testing Textiles

fabric.Whentubularknittedfabricisfinished,differentialskew

D 2904 Practice for Interlaboratory Testing of a Textile Test

may occur on the top and bottom part of the tube.

Method that Produces Normally Distributed Data

3.1.8 standard atmosphere for testing textiles,

D 2906 Practice for Statements on Precision and Bias for

n—laboratoryconditionsfortestingfibers,yarns,andfabricsin

Textiles

which air temperature and relative humidity are maintained at

D 3990 Terminology Relating to Fabric Defects

specific levels with established tolerances.

3. Terminology

3.1.8.1 Discussion—Textile materials are used in a number

ofspecificend-useapplicationsthatfrequentlyrequiredifferent

3.1 Definitions:

testing temperatures and relative humidities. Specific condi-

3.1.1 bow, n—afabricconditionresultingwhenfillingyarns

tioning and testing of textiles for end-product requirements can

or knitting courses are displaced from a line perpendicular to

be carried out using Table 1 in Practice D 1776.

3.1.9 For definitions of fabric defect terms, refer to Termi-

nology D 3990. For definitions of other textile terms used in

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

this test method, refer to Terminology D 123.

and is the direct responsibility of Subcommittee D13.60 on Fabrics, Specific.

Current edition approved Jan. 1, 2006. Published February 2006. Originally

4. Summary of Test Method

approved in 1980. Last previous edition approved in 1999 as D 3882 – 99.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 Bow—A straightedge is placed across the fabric be-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tween two points at which a marked filling yarn, knitting

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. course, designated printed line, or designated design meets the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3882–99 (2006)

TABLE 1 Critical Differences, 95% Probability Level, for Bow

products. In some cases, a specified amount of skew is needed,

and Skew for the Conditions Noted

for example, to prevent trouser leg twisting. Matching plaids

A

Property Number of Critical Differences for the Conditions Noted ,%

from distorted patterns may create serious problems for the

Observations in

Repeatability Reproducibility

garment manufacturer or home sewer. Wavy or sharp breaks in

Each Average

the bow line are more detrimental to the appearance of small

(Within- (Between-

(Single-Operator)

Laboratory) Laboratory)

parts of a garment (such as collars, pockets, and so forth) than

Precision

Precision Precision

a gradual slope from a straight line.

Bow 1 0.80 0.80 0.80

3 0.46 0.46 0.46

6. Apparatus

6 0.33 0.33 0.33

12 0.23 0.23 0.23 6.1 Measuring Stick or Steel Tape, graduated in 1-mm

24 0.16 0.16 0.16 1

( ⁄16-in.) divisions and longer than the width of the fabric that

is to be measured.

Skew 1 2.99 2.99 3.18

3 1.73 1.73 2.04

6.2 Rigid Straightedge, longer than the width of the fabric

6 1.22 1.22 1.63

that is to be measured.

12 0.86 0.86 1.38

6.3 Flat Surface, of sufficient length to unroll or unfold the

24 0.61 0.61 1.24

fabric (see 6.4).

A

The critical differences for Table 1 were calculated using t = 1.960, which is

6.4 Fabric Inspection Table (Optional), to unroll and roll

based on infinite degrees of freedom.

fabric rolls or unfold and fold fabric bolts with sufficient

lighting that provides transmitted light from underneath the

two selvages or edges. The greatest distance between the

fabric to make the defect more clearly visible.

straightedge and the marked filling line, knitting course,

7. Sampling and Test Specimens

designated printed line, or designated design is measured

parallel to the selvage.

7.1 Primary Sampling Unit—Consider rolls or bolts of

4.2 Skew—The straight-line distortion of a marked filling

fabric or fabric components of fabricated systems to be the

yarn, knitting course, designated printed line, or designated

primary sampling unit, as applicable.

design is measured from its normal perpendicular to the

7.2 Laboratory Sampling Unit—As a laboratory sampling

selvage or edge.

unit take the entire roll or bolt after removing a first 1-mm

(1-yd)length.Forfabriccomponentsoffabricatedsystems,use

5. Significance and Use

the entire system.

5.1 This test method is considered satisfactory for accep-

7.3 Test Specimens—As test specimens, select 3 test areas

tance testing of commercial shipments.

from each laboratory sampling unit. Exclude the first and last

5.1.1 If there are differences of practical significance be-

fifth of the roll or bolt or piece length. Select test areas at

tween reported test results for two laboratories (or more),

random but no closer to one another than one fifth of the roll

comparative tests should be performed to determine if there is

or bolt or piece length.

a statistical bias between them, using competent statistical

8. Conditioning

assistance. As a minimum, the test samples to be used are as

homogeneous as possible, are drawn from the material from 8.1 Conditionthetestspecimenstomoistureequilibriumfor

which the disparate test results were obtained, and are ran-

testing in the standard atmosphere for testing textiles in

domlyassignedinequalnumberstoeachlaboratoryfortesting. accordance with Practice D 1776 or, if applicable, in the

Other fabrics with established test values may be used for this specified atmosphere in which the testing is to be performed.

purpose. The test results from the two laboratories should be 8.1.1 When full rolls or bolts of fabric cannot be properly

compared using a statistical test for unpaired data, at a conditioned in a reasonable time with available facilities,

probability level chosen prior to the testing series. If a bias is

perform the test without conditioning and report the actual

found, either its cause must be found and corrected, or future condition prevailing at the time of the test. Such results may

test results must be adjusted in consideration of the known

not correspond with the results obtained when testing condi-

bias. tioned specimens at the standard atmosphere for testing tex-

5.2 Individual rolls are normally accepted or rejected on the

tiles.

basis of the maximum amount of bow or skew in a specific roll

9. Procedure

of fabric. The average bow or skew in a roll or lot or the range

of bow or skew in a roll may be determined but are not 9.1 Test the test specimens in the standard atmosphere for

normally used in the trade for acceptance or rejection. testing textiles in accordance with Section 8.

5.3 Bow or skew can be induced during fabric manufactur- 9.2 Handle the test specimens carefully to avoid altering the

ing, dyeing, tentering, finishing, or other operations where a natural state of the material.

potential exists for uneven distribution of tensions across the 9.3 Lay the fabric on a smooth, horizontal surface without

fabric width. Bow and skew are more visually displeasing in tension in any direction or use the optional fabric inspection

colored, patterned fabrics such as plaids and horizontal stripe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.