ASTM D7981-20

(Practice)Standard Practice for Compaction of Prismatic Asphalt Specimens by Means of the Shear Box Compactor

Standard Practice for Compaction of Prismatic Asphalt Specimens by Means of the Shear Box Compactor

SIGNIFICANCE AND USE

5.1 Asphalt prisms compacted with the shear box compactor can be used to obtain specimens for further testing, including bulk specific gravity following Test Methods D6752/D6752M and D2726/D2726M; dynamic modulus following AASHTO T 342; dynamic modulus, flow number, and flow time following AASHTO T 378; and fatigue performance characteristics following AASHTO T 321.

5.2 Specimens to perform other standard tests could also be obtained, as long as their volume is contained within the volume of a prism having maximum width, length, and height (W × L × H) of 150 mm, 450 mm, and 185 mm, respectively. The maximum prism height depends on the mix type, the target air voids, and the equipment limitations.

Note 1: The aggregate orientation in the samples produced by this method may be different from samples produced by other laboratory compaction methods. This should be considered when comparing mechanical test results from different compaction methods.

Note 2: The quality of the results produced by this standard are dependent on the competence of the personnel performing the procedure and the capability, calibration, and maintenance of the equipment used. Agencies that meet the criteria of Specification D3666 are generally considered capable of competent and objective testing, sampling, inspection, etc. Users of this standard are cautioned that compliance with Specification D3666 alone does not completely ensure reliable results. Reliable results depend on many factors. Following the suggestions of Specification D3666 or some similar acceptable guideline provides a means of evaluating and controlling some of those factors.

SCOPE

1.1 This practice covers the fabrication of prismatic specimens of asphalt mixture using the shear box compactor (SBC). Compacted specimens are suitable for volumetric and physical property testing. This standard practice should not be used for acceptance or rejection of a material or for purchasing purposes.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard with exception of degrees (°) where angle is specified.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7981 − 20

Standard Practice for

Compaction of Prismatic Asphalt Specimens by Means of

1

the Shear Box Compactor

This standard is issued under the fixed designation D7981; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3666Specification for Minimum Requirements for Agen-

cies Testing and Inspecting Road and Paving Materials

1.1 This practice covers the fabrication of prismatic speci-

D6752/D6752MTest Method for Bulk Specific Gravity and

mensofasphaltmixtureusingtheshearboxcompactor(SBC).

Density of CompactedAsphalt Mixtures UsingAutomatic

Compacted specimens are suitable for volumetric and physical

Vacuum Sealing Method

property testing. This standard practice should not be used for

D6857/D6857MTest Method for Maximum Specific Grav-

acceptance or rejection of a material or for purchasing pur-

ity and Density of Asphalt Mixtures Using Automatic

poses.

Vacuum Sealing Method

1.2 Units—The values stated in SI units are to be regarded

E644Test Methods for Testing Industrial Resistance Ther-

asstandard.Nootherunitsofmeasurementareincludedinthis

mometers

standardwithexceptionofdegrees(°)whereangleisspecified.

3

2.2 AASHTO Standards:

1.3 The text of this standard references notes and footnotes AASHTO T 378Standard Method of Test for Determining

whichprovideexplanatorymaterial.Thesenotesandfootnotes

the Dynamic Modulus and Flow Number for Asphalt

(excluding those in tables and figures) shall not be considered Mixtures Using the Asphalt Mixture Performance Tester

as requirements of the standard.

(AMPT)

AASHTO T 321Standard Method of Test for Determining

1.4 This standard does not purport to address all of the

the Fatigue Life of Compacted Asphalt Mixtures Sub-

safety concerns, if any, associated with its use. It is the

jected to Repeated Flexural Bending

responsibility of the user of this standard to establish appro-

AASHTO T 342Standard Method of Test for Determining

priate safety, health, and environmental practices and deter-

DynamicModulusofHot-MixAsphaltConcreteMixtures

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

3.1 Definitions:

ization established in the Decision on Principles for the

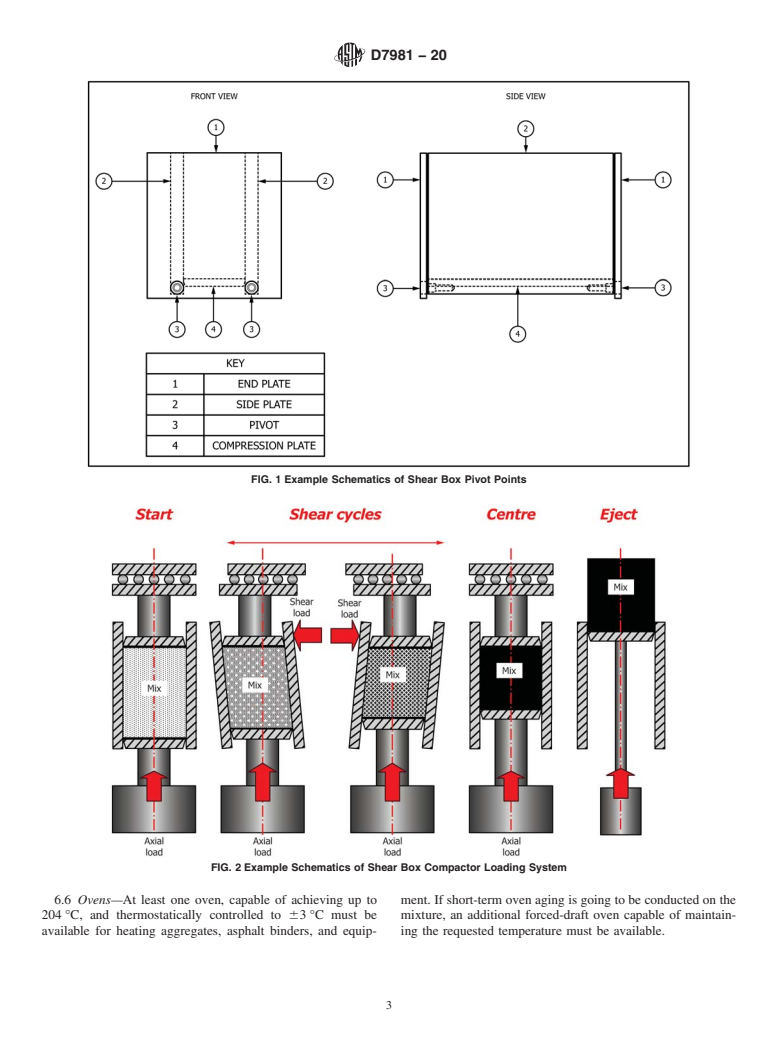

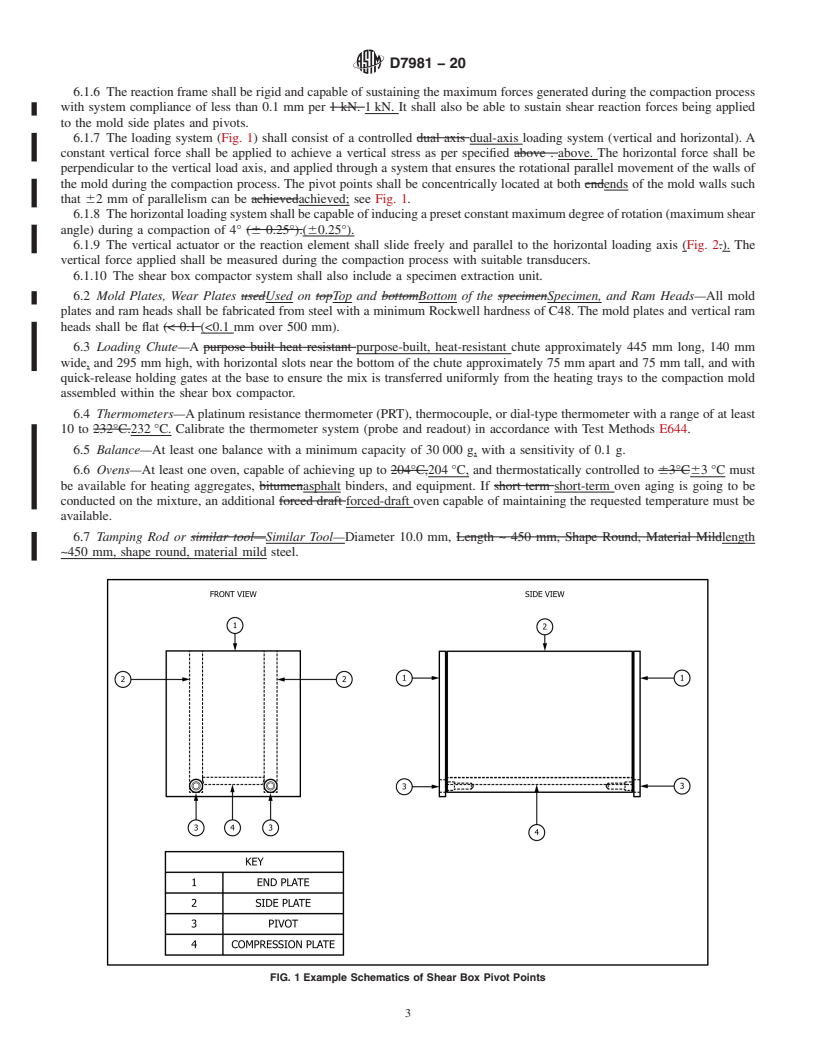

Development of International Standards, Guides and Recom- 3.1.1 load cycle—the angular movement of the shearing

platensinthecompactorgoingfromtheverticalpositiontothe

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. positionofmaximumshearangleatoneside,thengoingtothe

maximum shear angle at the other side and back to the vertical

2. Referenced Documents

position (90 6 0.25° with reference to the horizontal plane).

2

2.1 ASTM Standards:

3.1.2 shear angle—the external angle measured between a

D2041/D2041MTest Method for Theoretical Maximum

vertical plane (angle of 90° with respect to a horizontal plane)

Specific Gravity and Density of Asphalt Mixtures

and the plane formed by a shearing plate in the compactor

D2726/D2726MTest Method for Bulk Specific Gravity and

when it has reached its maximum travel. Set at 4°.

Density of Non-Absorptive Compacted Asphalt Mixtures

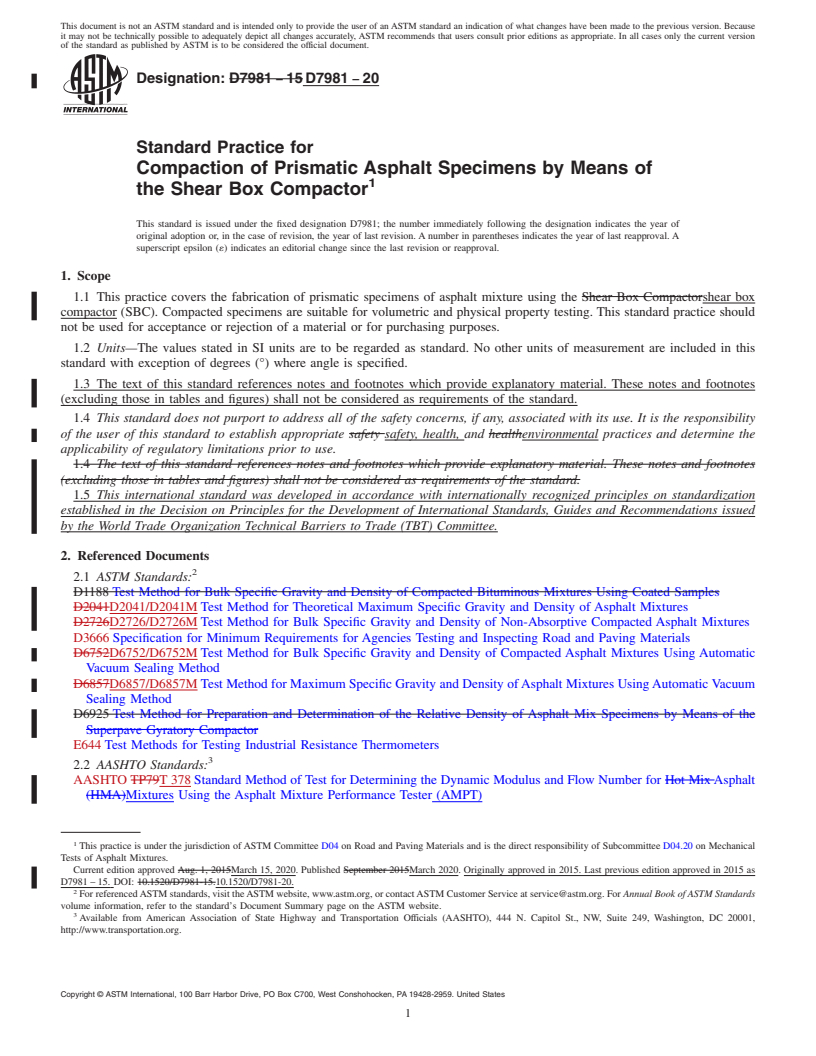

4. Summary of Practice

1 4.1 A sample of loose asphalt mixture is compacted in a

This practice is under the jurisdiction ofASTM Committee D04 on Road and

Paving Materials and is the direct responsibility of Subcommittee D04.20 on fully automatic apparatus by the combination of a static

Mechanical Tests of Asphalt Mixtures.

vertical force and a horizontal cyclic shear force applied to

Current edition approved March 15, 2020. Published March 2020. Originally

twin vertical parallel platens up to a fixed maximum shear

approved in 2015. Last previous edition approved in 2015 as D7981–15. DOI:

10.1520/D7981-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Association of State Highway and Transportation

Standards volume information, refer to the standard’s Document Summary page on Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

the ASTM website. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7981 −

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7981 − 15 D7981 − 20

Standard Practice for

Compaction of Prismatic Asphalt Specimens by Means of

1

the Shear Box Compactor

This standard is issued under the fixed designation D7981; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the fabrication of prismatic specimens of asphalt mixture using the Shear Box Compactorshear box

compactor (SBC). Compacted specimens are suitable for volumetric and physical property testing. This standard practice should

not be used for acceptance or rejection of a material or for purchasing purposes.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard with exception of degrees (°) where angle is specified.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1188 Test Method for Bulk Specific Gravity and Density of Compacted Bituminous Mixtures Using Coated Samples

D2041D2041/D2041M Test Method for Theoretical Maximum Specific Gravity and Density of Asphalt Mixtures

D2726D2726/D2726M Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Asphalt Mixtures

D3666 Specification for Minimum Requirements for Agencies Testing and Inspecting Road and Paving Materials

D6752D6752/D6752M Test Method for Bulk Specific Gravity and Density of Compacted Asphalt Mixtures Using Automatic

Vacuum Sealing Method

D6857D6857/D6857M Test Method for Maximum Specific Gravity and Density of Asphalt Mixtures Using Automatic Vacuum

Sealing Method

D6925 Test Method for Preparation and Determination of the Relative Density of Asphalt Mix Specimens by Means of the

Superpave Gyratory Compactor

E644 Test Methods for Testing Industrial Resistance Thermometers

3

2.2 AASHTO Standards:

AASHTO TP79T 378 Standard Method of Test for Determining the Dynamic Modulus and Flow Number for Hot Mix Asphalt

(HMA)Mixtures Using the Asphalt Mixture Performance Tester (AMPT)

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.20 on Mechanical

Tests of Asphalt Mixtures.

Current edition approved Aug. 1, 2015March 15, 2020. Published September 2015March 2020. Originally approved in 2015. Last previous edition approved in 2015 as

D7981 – 15. DOI: 10.1520/D7981-15.10.1520/D7981-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7981 − 20

AASHTO T321T 321 Standard Method of Test for Determining the Fatigue Life of Compacted Hot Mix Asphalt

(HMA)Mixtures Subjected to Repeated Flexural Bending

AASHTO T342T 342 Standard Method of Test for Determining Dynamic Modulus of Hot Mix Hot-Mix Asphalt Concrete

Mixtures

3. Terminology

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.