ASTM D1006-01(2006)

(Practice)Standard Practice for Conducting Exterior Exposure Tests of Paints on Wood

Standard Practice for Conducting Exterior Exposure Tests of Paints on Wood

SIGNIFICANCE AND USE

The procedure described in this practice is intended to aid in evaluating the performance of house and trim paints to new, previously unpainted wood.

The relative durability of paints in outdoor exposures can be very different depending on the location of the exposure because of differences in solar radiation, time of wetness, temperature, pollutants, and other factors. Therefore, it cannot be assumed that results from one exposure in a single location will be useful for determining relative durability in a different location. Exposures in several locations with different climates which represent a broad range of anticipated service conditions are recommended.

4.2.1 Because of year-to-year climatological variations, results from a single exposure test cannot be used to predict the absolute rate at which a material degrades. Several years of repeat exposures are needed to get an “average” test result for a given location.

4.2.2 Solar radiation varies considerably as function of time of year. This can cause large differences in the apparent rate of degradation in many polymers. Comparing results for materials exposed for short periods (less than one year) is not recommended unless materials are exposed at the same time in the same location.

The Significance and Use section in Practice G 7 addresses many variables to be considered in exterior exposure tests.

SCOPE

1.1 This practice covers procedures to be followed for direct exposure of house and trim paints on new, previously unpainted wood materials to the environment. When originators of a weathering test have the actual exposure conducted by a separate agency, the specific conditions for the exposure of test and control specimens should be clearly defined and mutually agreed upon between all parties.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1006 − 01 (Reapproved2006)

Standard Practice for

Conducting Exterior Exposure Tests of Paints on Wood

This standard is issued under the fixed designation D1006; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 U.S. Federal Standard:

TT-W-571b Federal Specification for Wood-Preservative,

1.1 Thispracticecoversprocedurestobefollowedfordirect

Recommended Treating Practice

exposure of house and trim paints on new, previously un-

painted wood materials to the environment. When originators

3. Terminology

of a weathering test have the actual exposure conducted by a

3.1 Definitions—The definitions given in Terminologies

separate agency, the specific conditions for the exposure of test

E41 and G113 are applicable to this practice.

and control specimens should be clearly defined and mutually

agreed upon between all parties.

4. Significance and Use

1.2 The values stated in SI units are to be regarded as the

4.1 The procedure described in this practice is intended to

standard. The values given in parentheses are for information

aid in evaluating the performance of house and trim paints to

only.

new, previously unpainted wood.

1.3 This standard does not purport to address all of the

4.2 The relative durability of paints in outdoor exposures

safety concerns, if any, associated with its use. It is the

can be very different depending on the location of the exposure

responsibility of the user of this standard to establish appro-

because of differences in solar radiation, time of wetness,

priate safety and health practices and determine the applica-

temperature, pollutants, and other factors. Therefore, it cannot

bility of regulatory limitations prior to use.

be assumed that results from one exposure in a single location

will be useful for determining relative durability in a different

2. Referenced Documents

location. Exposures in several locations with different climates

which represent a broad range of anticipated service conditions

2.1 ASTM Standards:

D358 Specification for Wood to Be Used as Panels in are recommended.

4.2.1 Because of year-to-year climatological variations, re-

Weathering Tests of Coatings

E41 Terminology Relating To Conditioning sults from a single exposure test cannot be used to predict the

absolute rate at which a material degrades. Several years of

G7 Practice for Atmospheric Environmental Exposure Test-

ing of Nonmetallic Materials repeat exposures are needed to get an “average” test result for

a given location.

G113 Terminology Relating to Natural andArtificial Weath-

ering Tests of Nonmetallic Materials 4.2.2 Solar radiation varies considerably as function of time

of year. This can cause large differences in the apparent rate of

G147 Practice for Conditioning and Handling of Nonmetal-

lic Materials for Natural and Artificial Weathering Tests degradationinmanypolymers.Comparingresultsformaterials

exposed for short periods (less than one year) is not recom-

mended unless materials are exposed at the same time in the

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

same location.

Related Coatings, Materials, and Applications and is the direct responsibility of

4.3 The Significance and Use section in Practice G7 ad-

Subcommittee D01.27 on Accelerated Testing.

Current edition approved Nov. 1, 2006. Published November 2006. Originally

dresses many variables to be considered in exterior exposure

approved in 1951. Last previous edition approved in 2001 as D1006 – 01. DOI:

tests.

10.1520/D1006-01R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1006 − 01 (2006)

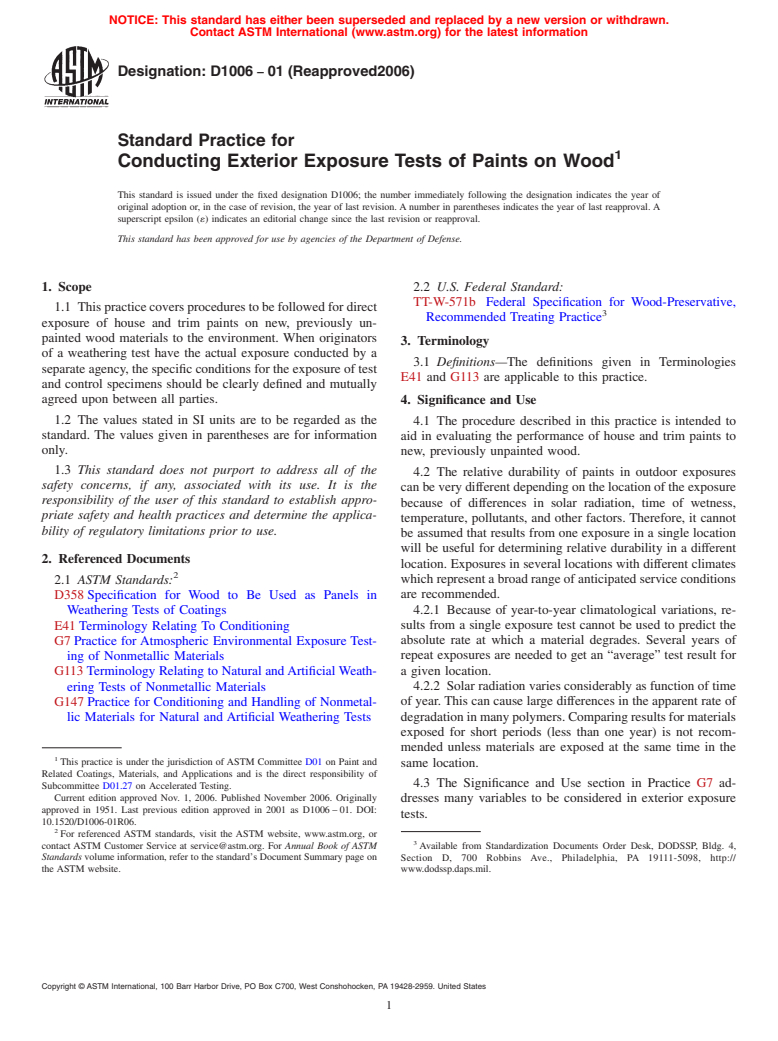

5. Location of Test Sites and Exposure Orientation exposures, are presented fully in AnnexA1. Test racks that are

commonly used for the exposure of wood siding boards,

5.1 Test Sites—The climatic conditions of the test sites

primarily for the evaluation of mildew growth, dirt

shouldberepresentativeofthoseoftheareainwhichthepaints

accumulation, and color change are shown in Fig. 1. These

are to be used. The type and rate of failure of a paint film will

racks can be configured to hold specimens or specimen holders

vary when exposed to different combinations of climatic and

of any convenient width and length. Adjustable racks can be

atmospheric conditions. For reliable results, exposure sites

used to accommodate specimens of different lengths.An offset

should be selected that are representative geographically,

design (notched cutouts) in the mounting hardware shall be

climatically, and in atmospheric contaminations with those of

used in order to avoid contamination from specimens mounted

the locality in which the paint will be used. To obtain

above other specimens. Offsets shall be of the proper size to

conclusions that are valid for paints with national distribution

accommodatethewidthofthesidingboard.Typically,152-mm

requires exposure at several sites, selected to cover a wide

(6-in.) or 230-mm (9-in.) sized offsets are used. Other sizes are

range in climatic conditions. Suggested sites include south

available. An example of an offset mounting hardware is

Florida, the Great Lakes region, the hot desert southwest, the

shown in Fig. 2.

northeast, and extreme southern Louisiana.

5.2 Exposure Orientation—Unless otherwise specified,

7. Construction of Test Specimens

specimensfortestinghousepaintshouldbeexposedonvertical

7.1 Choose a wood substrate in accordance with Specifica-

test fixtures facing both north or south, or both. In comparisons

tion D358. Prior to use, test lumber and panels shall be stored

where dirt collection and mildew resistance are not pertinent,

under such conditions that the moisture content of the wood

north vertical exposures may be omitted. Test fixtures shall be

will be maintained within the normal range for exterior

placedinalocationsothatthereisnoshadowonanyspecimen

woodwork in the region in which the tests are conducted.

when the sun’s angle of elevation is greater than 20°. Speci-

Exposures on wood substrates should be performed on three

mens can be exposed at north or south orientations or other “

panels to allow for variations in wood.

exposure angles” in order to focus on the degradation mode

7.2 For house paints, unless the pattern of siding requires

desired. Typical exposure angles are as follows:

some other choice, test panels should be made of one or the

5.2.1 Vertical North (Northern Hemisphere)—Exposure

other of two patterns of siding, namely 127-mm (0.5-in.) or

rackispositionedsothattheexposedsurfacesofspecimensare

190-mm (0.75-in.) bevel siding or 5-mm (1-in.) by 152-mm

vertical (90°) facing north, away from the equator. This

(6-in.) drop siding.Atest panel may be subdivided into two or

orientation allows for the accelerated growth of biological

more test areas. A subdivided panel is one complete panel in

organisms since the amount of direct sunlight reaching the

which multiple paint specimens are applied to sections of the

specimens is reduced or completely eliminated depending on

panel. If the panels in the house paint test are not subdivided,

latitude.

one914-mm(3-ft)lengthof152-mmsidingwillbeacceptable.

5.2.2 Vertical South (Northern Hemisphere)—Exposure

If the panels are subdivided, each test area shall be a minimum

rackispositionedsothattheexposedsurfacesofthespecimens

of 152-mm in length.

are vertical (90°) facing south, toward the equator. This

orientation allows direct sunlight to reach the specimens and

7.3 For trim paints, the test panel may have 25-mm (1-in.)

results in degradation commonly associated with ultraviolet

by 102-mm (4-in.) pieces of lumber at each end (see Annex

exposure.

A1).

NOTE 1—Other Exposure Orientations—If desired, exposures may also

7.4 For exposures of paints on test fixtures described in 6.2

be conducted to provide faster results. See Practice G7 for more

and Fig. 1, a test panel should be a 914-mm (36-in.) length of

information on other exposure options.

152-mm (6-in.) siding substrate unless otherwise agreed upon.

5.3 In the case where it is desirable to expose coated panels

in a sheltered area, such as under eaves, a suitable test fence

with a sheltered or eave arrangement can be used (see Annex

A1).

6. Construction of Test Fixtures (Exposed Racks)

6.1 Test fixtures should be durable and rigid enough to

withstand the effects of weather. All materials used for test

fixtures shall be either treated wood or noncorrodible metal

without surface treatment. Aluminum Alloys 6061T6 or

6063T6 have been found suitable for use in most locations.

Properly primed and coated steel is suitable for use in desert

areas.

6.2 Test Fixture Design—Test racks of several different

designs are currently used for the exposure testing of paints on

wood.Test racks for the exposure of paints and trims that more

closely simulate end-use applications, including under eave FIG. 1 Typical Exposure Rack

D1006 − 01 (2006)

commercial paints, it may be appropriate to let the painter

apply them at their natural spreading rates. When the purpose

is to study variation in the paint composition, application

shouldusuallybeatsuitablepredeterminedspreadingratesthat

can be controlled by applying a given weight or volume of

coating to a measured area.

10. Procedure

10.1 After the panels have been prepared, identify each

specimen with a unique mark that will not be destroyed or

become illegible during the exposure. Practice G147 provides

guidance for this procedure.

10.2 Measure the desired properties on all test and reference

control specimens prior to exposure.

10.3 Mount the specimens on the correctly oriented expo-

sure rack that accommodates the dimensions of the specimens

being exposed.

FIG. 2 Offset Mounting Hardware

10.4 Perform the exposure test in accordance with the

guidelines in Practices G7 and G147.

Each area shall be a minimum of 152 mm in length. Each test

10.5 Select one of the methods for defining the duration of

area can be painted with a different paint thus providing a

the exposure in accordance with Practice G7.

side-by-side comparison for performance.

NOTE 2—It is important to remember that up to 75 mm (3 in.) of each

11. Inspection and Records

end of the test will be masked by the exposure rack.

11.1 After the panels have been exposed to the weather,

8. Use of Control or Reference Materials

inspections should be made after not more than one month, at

three months, and at intervals of three months during the first

8.1 When several paints are being compared, one paint

two years, and every six months thereafter. Midwinter

should be selected as a “control.” The control paint should be

inspections, however, may be omitted in northern latitudes.

applied to one area of each test panel. Variations caused by

Inspections may be made more frequently if desired. Usually

wooddifferencesarerevealedintheperformanceofthecontrol

the exposures should be continued for a considerable length of

paint, and can be used to adjust the ratings of other paints to a

time after deterioration has reached the point at which best

common basis. For best results there should be two controls,

practice calls for repainting.

one known to perform well and one known to perform poorly.

11.2 Records should be kept on report forms agreed upon

9. Application of Paints

between the purchaser and the seller.

9.1 All materials being compared in a single study shall be

preparedandexposedwithinathirty-dayperiod.Forverylarge

12. Report

studies where all specimens cannot be prepared and exposed

12.1 The report section shall contain the following informa-

within the thirty-day period, prepare duplicate coatings of at

tion when applicable and available. In most cases, commercial

least 30 % of the materials or prepare and expose specimens of

testing agencies used to perform exposures may not have

a control paint at the beginning and at the end of the period

specific information about the materials used or preparation of

needed for completion.

the test specimens and, therefore, cannot be reported.

9.2 It is best in theory and practice to do the painting

12.1.1 Complete description of the test specimens and any

outdoors in proper weather for painting; however, indoor

control and weathering materials used, including:

painting is permissible provided no more than one week (72 h

12.1.1.1 Composition, including description of substrate to

isthepreferredmaximumtime)elapsesbetweenthesuccessive

which the paint is applied and

coats and between applying the last coat and exposing on the

12.1.1.2 Method of preparation (reference applicable stan-

test fence. Furthermore, all painting must be performed under

dards here).

essentially the same drying conditions. It is necessary to allow

12.1.2 Location of exposure (including whether specimens

each coat to cure sufficiently before top coating.

were exposed at ground level, on a rooftop, and so forth).

9.3 The preferred procedure is to apply paints with the test

12.1.3 Ground cover in area of test racks.

panel in a vertical position and kept vertical until the paint has

12.1.4 Angle at which exposure was conducted.

set. If paint is spread on horizontal panels, the panels should be

12.1.5 Type of exposure (unbacked or backed). If backed

placed vertically immediately thereafter.

exposure is used, include thickness and type of backing and, if

painted, the color of paint used.

9.4 Records should be kept of the spreading rates at which

paints are applied. When the purpose of the tests is to compare 12.1.6 Date exposure started and date exposure completed.

D1006 − 01 (2006)

12.1.7 If required, solar radiant energy for all exposures 13.1.1 Repeatability and reproducibility of results obtained

oriented towards the equator including the wavelength band- by this practice will vary depending on the materials being

pass in which radiant energy is measured. All solar radiant tested, the material property being measured, the climate in

energy reported should be meas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.