ASTM D7073-05

(Guide)Standard Guide for Application and Evaluation of Brush and Roller Applied Paint Films

Standard Guide for Application and Evaluation of Brush and Roller Applied Paint Films

SIGNIFICANCE AND USE

Laboratory measurement of application properties of architectural coatings generally employ a blade-type applicators that lay down films of highly uniform thickness. Applicators, such as brushes and rollers, typically apply films that lack uniformity due to variations in rheology, film build, flow and leveling properties resulting in the practical hiding of most paints being less than that measured on films applied with a blade-type applicator. This guide provides an indication of the actual application properties of the paint, as applied by a contractor or consumer.

SCOPE

1.1 This guide describes procedures for the application of brush or roller, or both, applied paint films to sealed wallboard for evaluating application properties.

1.2 Because both the application and panel evaluation are subjective, this guide should be used only for comparative testing within one laboratory using one operator for each set of applications, as the ratings assigned by different laboratories may not agree.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7073 − 05

StandardGuide for

Application and Evaluation of Brush and Roller Applied

Paint Films

This standard is issued under the fixed designation D7073; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D5301 Practice for Physical Characterization of Paint

Brushes

1.1 This guide describes procedures for the application of

D5913 Test Method for Evaluation of Cleanability of Paint

brush or roller, or both, applied paint films to sealed wallboard

Brushes

for evaluating application properties.

E1347 Test Method for Color and Color-Difference Mea-

1.2 Because both the application and panel evaluation are

surement by Tristimulus Colorimetry

subjective, this guide should be used only for comparative

2.2 Other Document:

testing within one laboratory using one operator for each set of

Pictorial Standards of Paint Roller Spatter, shown in the

applications, as the ratings assigned by different laboratories

Pictorials Standards of Coating Defects

may not agree.

1.3 The values stated in SI units are to be regarded as the

3. Summary of Guide

standard. The values given in parentheses are for information

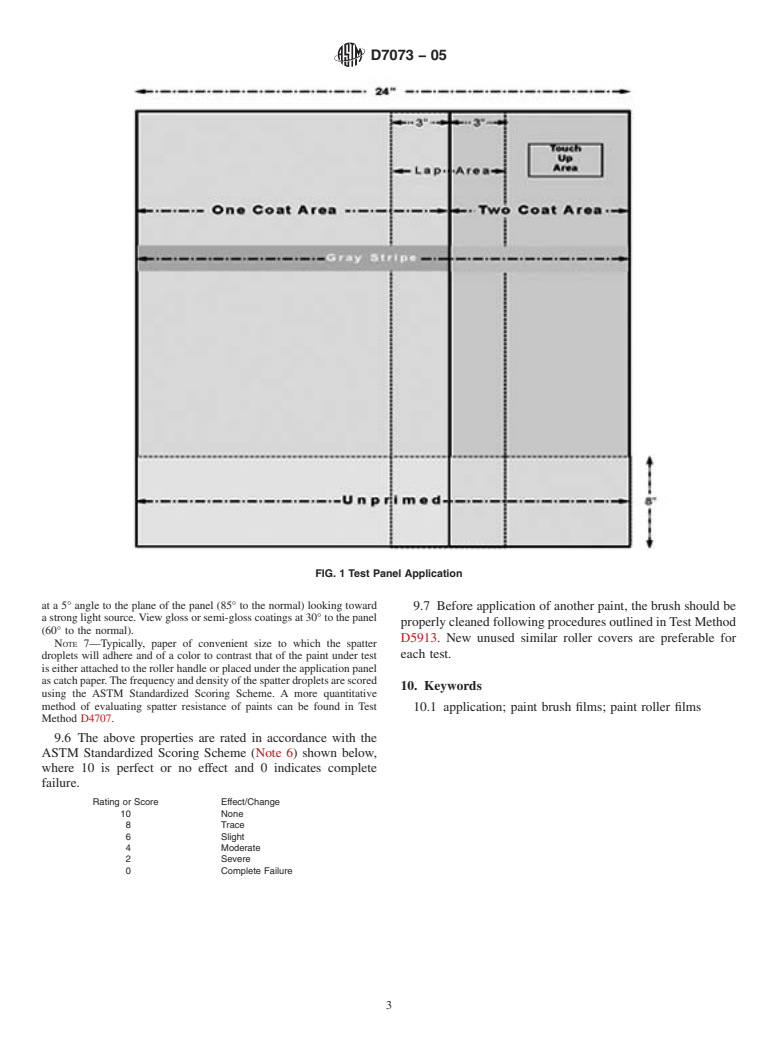

3.1 The test paints are applied with either a brush or a roller

only.

at an agreed upon spreading rate onto sealed test panels using

1.4 This standard does not purport to address all of the

both one and two coat applications and after drying, the panels

safety concerns, if any, associated with its use. It is the

are evaluated for various application properties.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use.

4.1 Laboratory measurement of application properties of

architectural coatings generally employ a blade-type applica-

2. Referenced Documents

tors that lay down films of highly uniform thickness. Applica-

2.1 ASTM Standards:

tors, such as brushes and rollers, typically apply films that lack

D1475 Test Method For Density of Liquid Coatings, Inks,

uniformity due to variations in rheology, film build, flow and

and Related Products

leveling properties resulting in the practical hiding of most

D3924 Specification for Environment for Conditioning and

paints being less than that measured on films applied with a

Testing Paint, Varnish, Lacquer, and Related Materials

blade-type applicator. This guide provides an indication of the

D3925 Practice for Sampling Liquid Paints and Related

actual application properties of the paint, as applied by a

Pigmented Coatings

contractor or consumer.

D4707 Test Method for Measuring Paint Spatter Resistance

During Roller Application

5. Apparatus

D5068 Practice for Preparation of Paint Brushes for Evalu-

5.1 Container, to hold paint, for example, a quart can.

ation

5.2 Good Quality Paint Brush, 50 to 100 mm (2 to 4 in.) in

D5069 Practice for Preparation of Paint-Roller Covers for

width with a chiseled tip.

Evaluation of Architectural Coatings

NOTE 1—The applicator should be aware that a brush can be a mixture

havingseveralchemicallydifferentfilamentsorbristles,orboth,inseveral

cross sections, with different thickness and length. Use the same type and

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

make of paint brush for all applications. See Practice D5301 for guidance.

Related Coatings, Materials, and Applications and is the direct responsibility of

5.3 Good Quality Paint Roller, typically 75 to 225 mm (3 to

Subcommittee D01.42 on Architectural Coatings.

Current edition approved Jan. 1, 2005. Published February 2005. DOI: 10.1520/

9 in.) in length.

D7073-05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Federation of Societies for Coatings Technology (FSCT), 492

the ASTM website. Norristown Rd., Blue Bell, PA 19422-2350, http://www.coatingstech.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7073 − 05

NOTE 2—Rollers constructed from woven fabric with a short nap 4.8 to

8.2 Air dry and examine the panel for uniformity of the

3 1

6.4 mm ( ⁄16 to ⁄4 in.) are used in typical laboratory testing of interior

primer application. If the appearance of the panel is satisfac-

paints.

tory, proceed with the application of the test paints.

NOTE 3—It is critical for proper performance to break-in the brush or

roller before application following procedures outlined in Practice D5068

8.3 Mount and secure the primed panel in a vertical position

or D5069. Until a brush or roller cover is broken-in (saturated with paint),

at a convenient height with the length of the panel horizontal to

only part of the paint loaded onto the applicator can be transferred to the

a surface that is vertical or within 5° of vertical (top sloping

surface being painted.

away from the operator).

5.4 Paint Tray.

5.5 Paint Roller Frame, of the same size as the paint-roller

9. Application of Paint Films

cover being used.

9.1 After the brush or roller has been properly broken-in

5.6 Balance, to weigh brush to the nearest 0.1 g.

(see Note 3), the test paint may be applied either following the

manufacturer’srecommendedspreadingrate,orusingthesame

5.7 Weight/Gallon Cup, or any other type of pycnometer

spreading rate for all paints under test or according to agree-

suitable for determining paint density to 0.1 lb/gal.

ment between purchaser and user. A spreading rate of 11.0

5.8 Spray Gun, any commercially available and typically

2 2

m /L (400 6 25 ft /gal) is suggested if there is no other

used to spray paint walls.

preference.

NOTE 5—Paints may also be applied freely until the gray stripe on the

6. Materials

test panel is visually covered (wet hide). Report the amount of paint

6.1 Test Paints.

needed to obtain wet hide and the spreading rate to obtain wet hiding as

shown below.

6.2 Paint-Out Panels, typically laminated fiberboard or

9.2 Apply the paint to the entire panel. Note the ease of

upson/universalboardaminimumof610by610mm(24by24

in.) or preferably larger, with at least one smooth side.The size application of the test paint. Also note any foaming and

spattering of the paint when using a roller. Determine the

and type of test panel to be used will be governed by the

brush/roller size and intended use of the paint. A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.