ASTM F940-99(2005)

(Practice)Standard Practice for Quality Control Receipt Inspection Procedures for Protective Coatings (Paint), Used in Marine Construction and Shipbuilding

Standard Practice for Quality Control Receipt Inspection Procedures for Protective Coatings (Paint), Used in Marine Construction and Shipbuilding

SIGNIFICANCE AND USE

This practice provides a means of assuring that products supplied during ship construction and maintenance are substantially the same as the materials on which the original selection was based. The selection of a paint for shipboard use frequently involves laboratory and field evaluations of candidate materials as part of the specification process. When a paint is selected, it shall have the same composition and characteristics throughout the delivery period as the materials originally evaluated.

5.1.1 When significant changes in composition or paint characteristics are observed, it is necessary to determine the cause of the change (production error or formulation change) and its impact on coating performance. Actions to take if a formulation change is required are specified in 6.5.

This practice is not meant to cover all possible chemical or physical tests that may be used to identify a coating. Additional tests may be needed to meet specific user needs.

This practice does not recommend specific tolerance limits for the tests indicated. Tolerance values need to be agreed upon by the coating supplier, the shipbuilder, and the ship’owner.

This practice does not establish critical attributes that must be controlled. These attributes are selected by the shipbuilder and the ship’owner based on specific needs (for example, colors).

SCOPE

1.1 This practice provides the quality control receipt inspection procedures for protective coatings (paints) procured for end item use on ships and other marine structures. The practice includes methods and procedures for verifying that coating materials received are within the range of physical and chemical characteristics as those originally specified and tested.

1.2This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F 940–99 (Reapproved 2005)

Standard Practice for

Quality Control Receipt Inspection Procedures for

Protective Coatings (Paint), Used in Marine Construction

and Shipbuilding

This standard is issued under the fixed designation F 940; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 1309 Test Method for Settling Properties ofTraffic Paints

During Storage

1.1 Thispracticeprovidesthequalitycontrolreceiptinspec-

D 1475 Test Method for Density of Liquid Coatings, Inks,

tion procedures for protective coatings (paints) procured for

and Related Products

end item use on ships and other marine structures.The practice

D 1640 Test Methods for Drying, Curing, or Film Forma-

includes methods and procedures for verifying that coating

tion of Organic Coatings at Room Temperature

materials received are within the range of physical and

D 1729 Practice for Visual Appraisal of Colors and Color

chemical characteristics as those originally specified and

Differences of Diffusely-Illuminated Opaque Materials

tested.

D 2196 Test Methods for Rheological Properties of Non-

1.2 This standard does not purport to address the safety

Newtonian Materials by Rotational (Brookfield-Type)Vis-

concerns associated with its use. It is the responsibility of the

cometer

user of this standard to consult and establish appropriate

D 2244 Practice for Calculation of Color Tolerances and

safety and health practices and determine the applicability of

Color Differences from Instrumentally Measured Color

regulatory limitations prior to use.

Coordinates

2. Referenced Documents

D 2369 Test Method for Volatile Content of Coatings

D 2621 Test Method for Infrared Identification of Vehicle

2.1 ASTM Standards:

Solids From Solvent-Reducible Paints

D 185 Test Methods for Coarse Particles in Pigments,

D 2697 Test Method for Volume Nonvolatile Matter in

Pastes, and Paints

Clear or Pigmented Coatings

D 523 Test Method for Specular Gloss

D 2698 Test Method for Determination of the Pigment

D 562 Test Method for Consistency of Paints Measuring

Content of Solvent-Reducible Paints by High-Speed Cen-

Krebs Unit (KU)Viscosity Using a Stormer-TypeViscom-

trifuging

eter

D 2805 Test Method for Hiding Power of Paints by Reflec-

D 1200 Test Method for Viscosity by Ford Viscosity Cup

tometry

D 1210 TestMethodforFinenessofDispersionofPigment-

D 2832 Guide for Determining Volatile and Nonvolatile

Vehicle Systems by Hegman-Type Gage

Content of Paint and Related Coatings

D 1308 Test Method for Effect of Household Chemicals on

D 3278 Test Methods for Flash Point of Liquids by Small-

Clear and Pigmented Organic Finishes

Scale Closed-Cup Apparatus

D 3925 Practice for Sampling Liquid Paints and Related

This practice is under the jurisdiction of ASTM Committee F25 on Ships and

Pigmented Coatings

Marine Technology and is the direct responsibility of Subcommittee F25.01 on

Structures.

3. Terminology

Current edition approved May 1, 2005. Published May 2005. Originally

3.1 batch—a manufacturing run. The industrial unit or

approved in 1985. Last previous edition approved in 1999 as F 940 – 99.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

quantity of production made in one complete operation. The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

volume or mass that constitutes a batch is flexible and varies

Standards volume information, refer to the standard’s Document Summary page on

with the size of the plant and its facilities for converting the

the ASTM website.

Withdrawn. raw materials into the finished product.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 940–99 (2005)

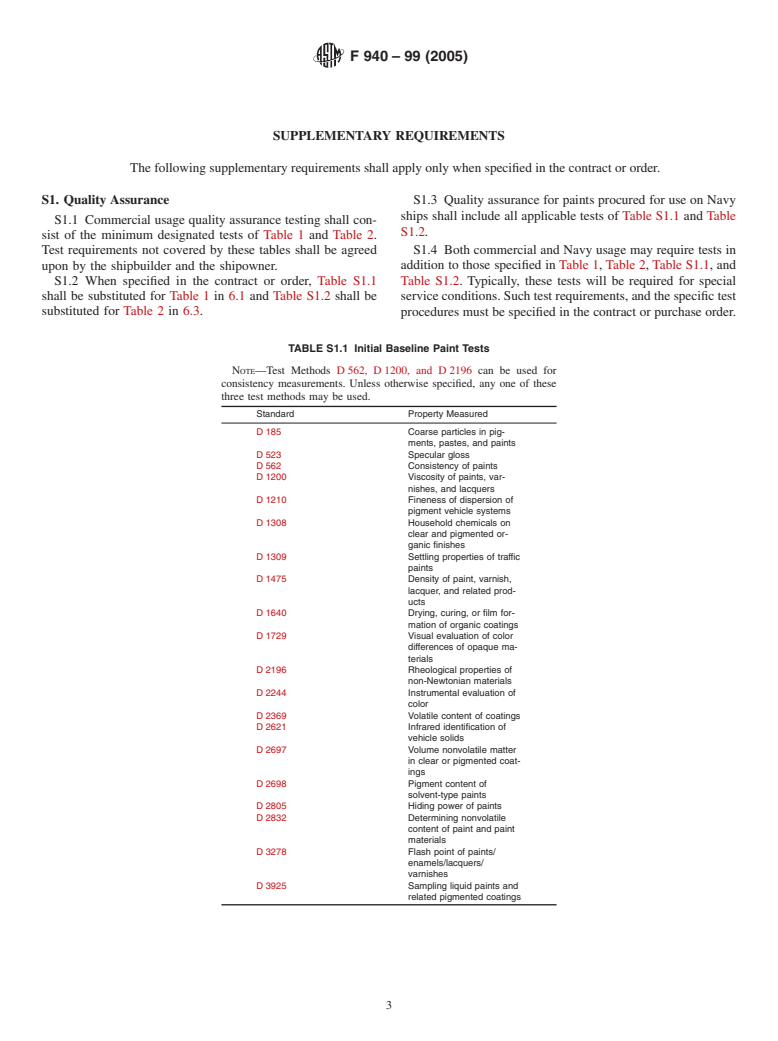

TABLE 1 Initial Baseline Paint Tests

4. Summary of Practice

4.1 Test requirements for identifying characteristics (physi- NOTE—Test Methods D 562, D 1200, and D 2196 can be used for

consistency measurements. Unless otherwise specified, any one of these

cal and chemical) of marine coatings are established. Receipt

three test methods may be used.

inspection tests are provided to assure that procured paints do

Test Method Property Measured

not differ significantly from the paints initially evaluated.

D 562 Consistency of paints

D 1200 Viscosity of paints, var-

5. Significance and Use

nishes, and lacquers

5.1 This practice provides a means of assuring that products D 1210 Fineness of dispersion of

pigment vehicle systems

suppliedduringshipconstructionandmaintenancearesubstan-

D 1475 Density of paint, varnish,

tially the same as the materials on which the original selection

lacquer, and related prod-

wasbased.Theselectionofapaintforshipboardusefrequently ucts

D 1640 Drying, curing, or film for-

involveslaboratoryandfieldevaluationsofcandidatematerials

mation of organic coatings

as part of the specification process. When a paint is selected, it

D 2196 Rheological properties of

non-Newtonian materials

shallhavethesamecompositionandcharacteristicsthroughout

D 2697 Volume nonvolatile matter

the delivery period as the materials originally evaluated.

in clear or pigmented

5.1.1 When significant changes in composition or paint

coatings

characteristics are observed, it is necessary to determine the D 2832 Nonvolatile content of

paint and paint materials

cause of the change (production error or formulation change)

and its impact on coating performance. Actions to take if a

formulation change is required are specified in 6.5.

TABLE 2 Routine Receipt Inspection Tests

5.2 This practice is not meant to cover all possible chemical

NOTE—Test Methods D 562, D 1200, and D 2196 can be used for

or physical tests that may be used to identify a coating.

consistency measurements. Unless otherwise specified, any one of these

Additional tests may be needed to meet specific user needs.

three test methods may be used.

5.3 This practice does not recommend specific tolerance

Test Method Property Measured

limits for the tests indicated. Tolerance values need to be

D 562 Consistency of paints

agreed upon by the coating supplier, the shipbuilder, and the

D 1200 Viscosity of paints, var-

ship’s owner.

nishes, and lacquers

5.4 This practice does not establish critical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.