ASTM B593-21

(Test Method)Standard Test Method for Bending Fatigue Testing for Copper-Alloy Spring Materials

Standard Test Method for Bending Fatigue Testing for Copper-Alloy Spring Materials

SIGNIFICANCE AND USE

5.1 The bending fatigue test described in this test method provides information on the ability of a copper alloy flat sheet and strip of spring material to resist the development of cracks or general mechanical deterioration as a result of a relatively large number of cycles (generally in the range 105 to 108) under conditions of constant displacement.

5.2 This test method is primarily a research and development tool which may be used to determine the effect of variations in materials on fatigue strength and also to provide data for use in selecting copper alloy spring materials for service under conditions of repeated strain cycling.

5.3 The results are suitable for direct application in design only when all design factors such as loading, geometry of part, frequency of straining, and environmental conditions are known. The test method is generally unsuitable for an inspection test or a quality control test due to the amount of time and effort required to collect the data.

SCOPE

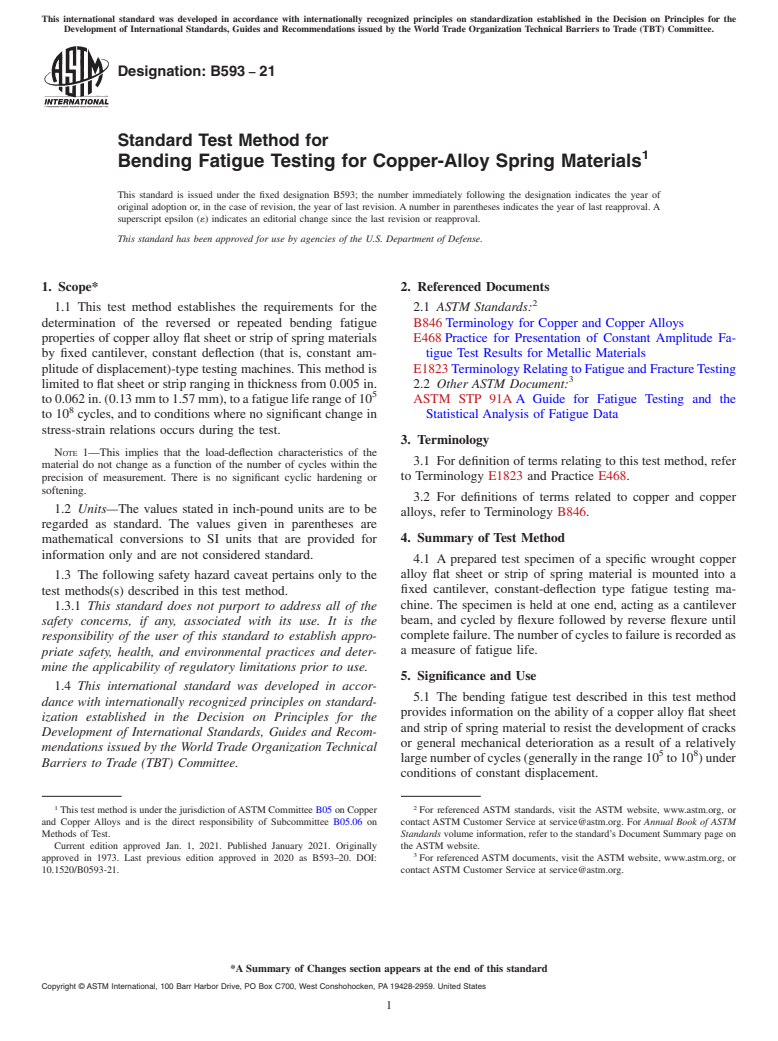

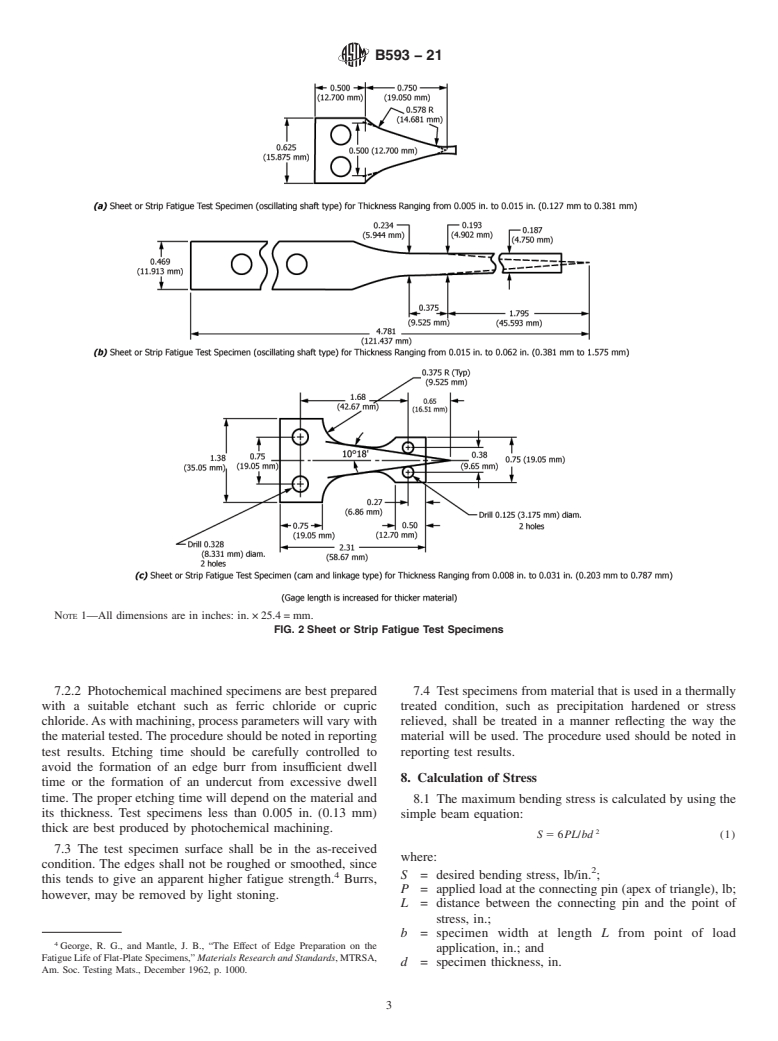

1.1 This test method establishes the requirements for the determination of the reversed or repeated bending fatigue properties of copper alloy flat sheet or strip of spring materials by fixed cantilever, constant deflection (that is, constant amplitude of displacement)-type testing machines. This method is limited to flat sheet or strip ranging in thickness from 0.005 in. to 0.062 in. (0.13 mm to 1.57 mm), to a fatigue life range of 105 to 108 cycles, and to conditions where no significant change in stress-strain relations occurs during the test.

Note 1: This implies that the load-deflection characteristics of the material do not change as a function of the number of cycles within the precision of measurement. There is no significant cyclic hardening or softening.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test methods(s) described in this test method.

1.3.1 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B593 − 21

Standard Test Method for

1

Bending Fatigue Testing for Copper-Alloy Spring Materials

This standard is issued under the fixed designation B593; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This test method establishes the requirements for the 2.1 ASTM Standards:

determination of the reversed or repeated bending fatigue B846Terminology for Copper and Copper Alloys

properties of copper alloy flat sheet or strip of spring materials E468Practice for Presentation of Constant Amplitude Fa-

by fixed cantilever, constant deflection (that is, constant am- tigue Test Results for Metallic Materials

plitudeofdisplacement)-typetestingmachines.Thismethodis E1823TerminologyRelatingtoFatigueandFractureTesting

3

limited to flat sheet or strip ranging in thickness from 0.005 in. 2.2 Other ASTM Document:

5

to0.062in.(0.13mmto1.57mm),toafatigueliferangeof10 ASTM STP 91AA Guide for Fatigue Testing and the

8

to 10 cycles, and to conditions where no significant change in Statistical Analysis of Fatigue Data

stress-strain relations occurs during the test.

3. Terminology

NOTE 1—This implies that the load-deflection characteristics of the

3.1 For definition of terms relating to this test method, refer

material do not change as a function of the number of cycles within the

to Terminology E1823 and Practice E468.

precision of measurement. There is no significant cyclic hardening or

softening.

3.2 For definitions of terms related to copper and copper

1.2 Units—The values stated in inch-pound units are to be

alloys, refer to Terminology B846.

regarded as standard. The values given in parentheses are

4. Summary of Test Method

mathematical conversions to SI units that are provided for

information only and are not considered standard.

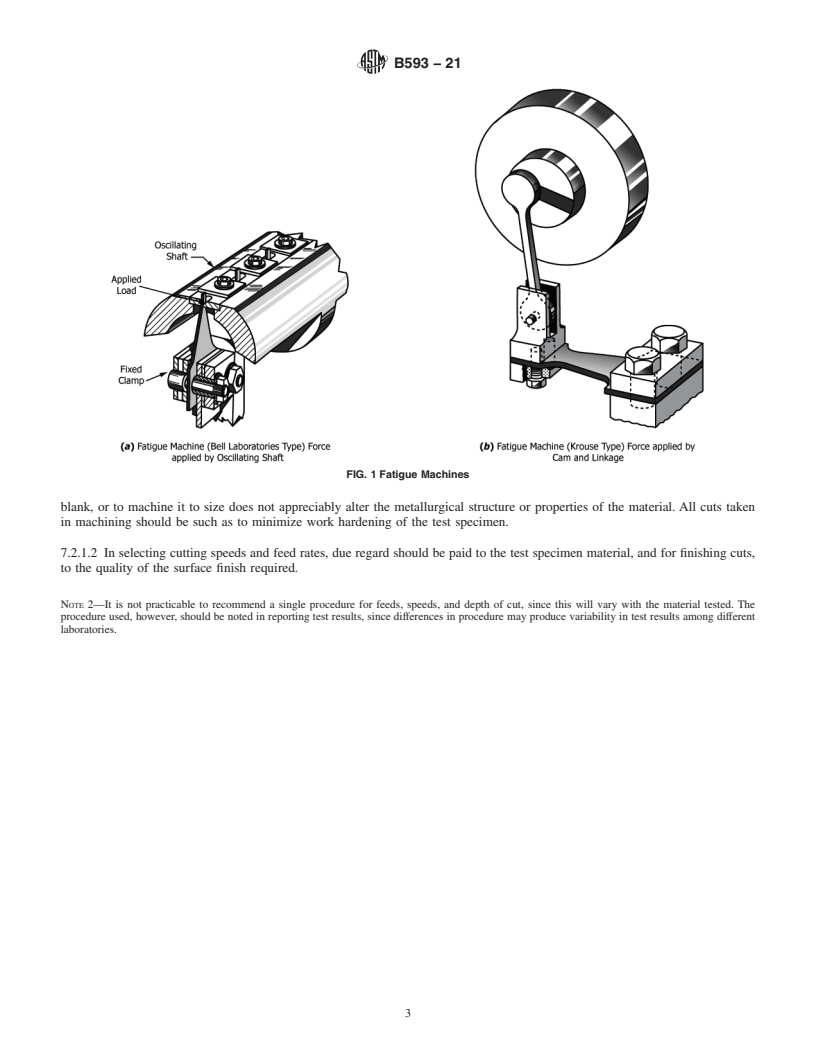

4.1 A prepared test specimen of a specific wrought copper

alloy flat sheet or strip of spring material is mounted into a

1.3 The following safety hazard caveat pertains only to the

fixed cantilever, constant-deflection type fatigue testing ma-

test methods(s) described in this test method.

chine. The specimen is held at one end, acting as a cantilever

1.3.1 This standard does not purport to address all of the

beam, and cycled by flexure followed by reverse flexure until

safety concerns, if any, associated with its use. It is the

completefailure.Thenumberofcyclestofailureisrecordedas

responsibility of the user of this standard to establish appro-

a measure of fatigue life.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5. Significance and Use

1.4 This international standard was developed in accor-

5.1 The bending fatigue test described in this test method

dance with internationally recognized principles on standard-

provides information on the ability of a copper alloy flat sheet

ization established in the Decision on Principles for the

and strip of spring material to resist the development of cracks

Development of International Standards, Guides and Recom-

or general mechanical deterioration as a result of a relatively

mendations issued by the World Trade Organization Technical

5 8

largenumberofcycles(generallyintherange10 to10 )under

Barriers to Trade (TBT) Committee.

conditions of constant displacement.

1 2

This test method is under the jurisdiction ofASTM Committee B05 on Copper For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Methods of Test. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2021. Published January 2021. Originally the ASTM website.

3

approved in 1973. Last previous edition approved in 2020 as B593–20. DOI: For referenced ASTM documents, visit the ASTM website, www.astm.org, or

10.1520/B0593-21. contact ASTM Customer Service at service@astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B593 − 21

5.2 This test method is primarily a research and develop- 7. Test Specimen

ment tool which may b

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B593 − 20 B593 − 21

Standard Test Method for

1

Bending Fatigue Testing for Copper-Alloy Spring Materials

This standard is issued under the fixed designation B593; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method establishes the requirements for the determination of the reversed or repeated bending fatigue properties of

copper alloy flat sheet,sheet or strip of spring materials by fixed cantilever, constant deflection (that is, constant amplitude of

displacement)-type testing machines. This method is limited to flat sheet or strip ranging in thickness from 0.005 in. to 0.062 in.

5 8

(0.13 mm to 1.57 mm), to a fatigue life range of 10 to 10 cycles, and to conditions where no significant change in stress-strain

relations occurs during the test.

NOTE 1—This implies that the load-deflection characteristics of the material do not change as a function of the number of cycles within the precision of

measurement. There is no significant cyclic hardening or softening.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test methods(s) described in this test method.

1.3.1 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B846 Terminology for Copper and Copper Alloys

B950 Guide for Editorial Procedures and Form of Product Specifications for Copper and Copper Alloys

E468 Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials

E1823 Terminology Relating to Fatigue and Fracture Testing

1

This test method is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.06 on Methods

of Test.

Current edition approved April 1, 2020Jan. 1, 2021. Published April 2020January 2021. Originally approved in 1973. Last previous edition approved in 20142020 as

ε1

B593–96 (2014)–20. . DOI: 10.1520/B0593–20.10.1520/B0593-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B593 − 21

3

2.2 Other ASTM Document:

ASTM STP 91-A91A A Guide for Fatigue Testing and the Statistical Analysis of Fatigue Data

3. Terminology

3.1 For definition of terms relating to this test method, refer to Terminology E1823 and Practice E468.

3.2 For definitions of terms related to copper and copper alloys, refer to Terminology B846.

4. Summary of Test Method

4.1 A prepared test specimen of a specific wrought copper alloy flat sheet or strip of spring material is mounted into a fixed

cantilever, constant-deflection type fatigue testing machine. The specimen is held at one end, acting as a cantilever beam, and

cycled by flexure followed by reverse flexure until complete failure. The number of cycles to failure is recorded as a measure of

fatigue life.

5. Significance and Use

5.1 The bending fatigue test described in this test method provides information on the ability of a copper alloy flat sheet and strip

of spring material to resist the development of cracks or general mechanical deterioration as a result of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.