ASTM F2191-02(2008)

(Specification)Standard Specification for Packing Material, Graphitic or Carbon Braided Yarn

Standard Specification for Packing Material, Graphitic or Carbon Braided Yarn

ABSTRACT

This specification covers staple or continuous filament carbon/graphite yarn valve stem compression packing, suitable for use as end-rings on packing systems for valves. Intended services include steam, hydrocarbons, water and non-oxidizing chemicals. The material shall be of the following types, classes, and grades: Type I, type II, and Type III; Class 1; Class 2; and Class 3; and Grade A and Grade B. The following tests shall be performed: size; mass; carbon assay; ash content; specific gravity; moisture content; detrimental materials tests; analysis of PTFE coating; compression recovery; and braid geometry retention.

SCOPE

1.1 This specification covers staple or continuous filament carbon/graphite yarn valve stem compression packing, suitable for use as end-rings on packing systems for valves. Intended services include steam, hydrocarbons, water and non-oxidizing chemicals. Where this specification is invoked as ASTM F 2191, Sections 1-18 apply. Where this specification is invoked as ASTM/DoD F 2191, Sections 1-18 and the Supplementary Requirements are applicable.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2191 −02(Reapproved 2008) An American National Standard

Standard Specification for

Packing Material, Graphitic or Carbon Braided Yarn

This standard is issued under the fixed designation F2191; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3178Test Methods for Carbon and Hydrogen in the

Analysis Sample of Coal and Coke (Withdrawn 2007)

1.1 This specification covers staple or continuous filament

D3684Test Method for Total Mercury in Coal by the

carbon/graphiteyarnvalvestemcompressionpacking,suitable

Oxygen BombCombustion/Atomic Absorption Method

for use as end-rings on packing systems for valves. Intended

D3761Test Method for Total Fluorine in Coal by the

servicesincludesteam,hydrocarbons,waterandnon-oxidizing

Oxygen Bomb Combustion/Ion Selective Electrode

chemicals. Where this specification is invoked as ASTM

Method

F2191, Sections 1-18 apply. Where this specification is in-

D3951Practice for Commercial Packaging

voked as ASTM/DoD F2191, Sections 1-18 and the Supple-

D4239Test Method for Sulfur in the Analysis Sample of

mentary Requirements are applicable.

Coal and Coke Using High-Temperature Tube Furnace

1.2 The values stated in SI units are to be regarded as the

Combustion

standard.

2.2 Military Standards:

1.3 This standard does not purport to address all of the 4

MIL-STD-129 Marking for Shipment and Storage

safety concerns, if any, associated with its use. It is the

MIL-P-24583 Packing Material, Graphitic or Carbon

responsibility of the user of this standard to establish appro- 4

Braided Yarn

priate safety and health practices and determine the applica-

MIL-P-24503Packing Material, Graphitic, Corrugated Rib-

bility of regulatory limitations prior to use.

bon or Textured Tape and Preformed Ring

2.3 Fluid Sealing Association Handbook:

2. Referenced Documents

Guidelines for the Use of Compression Packings, Copyright

2.1 ASTM Standards:

C135Test Method for True Specific Gravity of Refractory

Materials by Water Immersion

3. Terminology

C561Test Method for Ash in a Graphite Sample

3.1 base fiber density—bulk density of the base fiber before

C562Test Method for Moisture in a Graphite Sample

being coated or impregnated and braided into packing; ex-

C816Test Method for Sulfur in Graphite by Combustion-

pressed as lb/ft .

Iodometric Titration Method

3.2 braided flexible graphite—a braid constructed of con-

C889Test Methods for Chemical and Mass Spectrometric

tinuous strands or strips of expanded flexible graphite tape or

Analysis of Nuclear-Grade Gadolinium Oxide (Gd O )

2 3

ribbons which may have been overwrapped or have imbedded

Powder

reinforcing fibers.

D129Test Method for Sulfur in Petroleum Products (Gen-

eral High Pressure Decomposition Device Method)

3.3 carbon fibers—fibers used in braided packing are pro-

D512Test Methods for Chloride Ion In Water duced from viscose rayon, pitch, or polyacrylonitrile (PAN)

D1179Test Methods for Fluoride Ion in Water andaredefinedasayarnwithacarbonassayoflessthan99%.

D1246Test Method for Bromide Ion in Water

3.4 carbon yarns—manufactured from continuous or staple

carbon fibers that are twisted or plied into continuous indi-

vidual strands of between 6 and 18 µm in diameter.

This specification is under the jurisdiction ofASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.02 on

Insulation/Processes.

CurrenteditionapprovedMay1,2008.PublishedJuly2008.Originallyapproved The last approved version of this historical standard is referenced on

in 2002. Last previous edition approved in 2002 as F2191-02. DOI: 10.1520/ www.astm.org.

F2191-02R08. Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.dodssp.daps.mil.

Standards volume information, refer to the standard’s Document Summary page on Available from the Fluid Sealing Association, 994 Old Eagle School Road,

the ASTM website. Suite 1019, Wayne, PA 19087-1866.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2191−02 (2008)

TABLE 2 Detrimental Materials (Class 2 only (see 13.8))

3.5 carbon/graphite fibers—carbon/graphite fibers used in

braided packing are produced from viscose rayon, pitch, or Maximum Allowable

Total

polyacrylonitrile (PAN).

Element Impurity Levels in

parts per million

3.6 center or corner filler strands—strandsoffiber/yarnthat

(ppm)

run parallel to the longitudinal axis of the braid in the corners

Mercury (Hg) 10

or center to control the internal density and dimensional

Sulfur (S) 750

stability of the braid.

Total halogens (chlorine, bromine, and fluorine) 500

Chlorine (Cl) 250

3.7 continuous—individual fibers are almost infinite in

Bromine (Br) 250

length.

Fluorine (F) 250

3.8 continuous or staple carbon/graphite—continuous or

staple defines the length of the individual fibers in the

carbonaceous yarn. Continuous means the fibers are infinite in

3.18 specific gravity—the ratio of the mass of a unit volume

lengthandstaplemeanstheindividualfibersareatleast75mm

of a material at a stated temperature to the mass of the same

(3 in.) long and preferably 150 to 200 mm (6 to 8 in.) long.All

volume of distilled water at the same temperature.

of the fibers are between 6 to 18 µm in diameter and are

3.19 square plait braid—the strands in this type of braid

twisted/plied into continuous strands called yarns.

interlock in a single plane and do not interlock through the

3.9 corrosion inhibitors—additives to the yarn or braid to

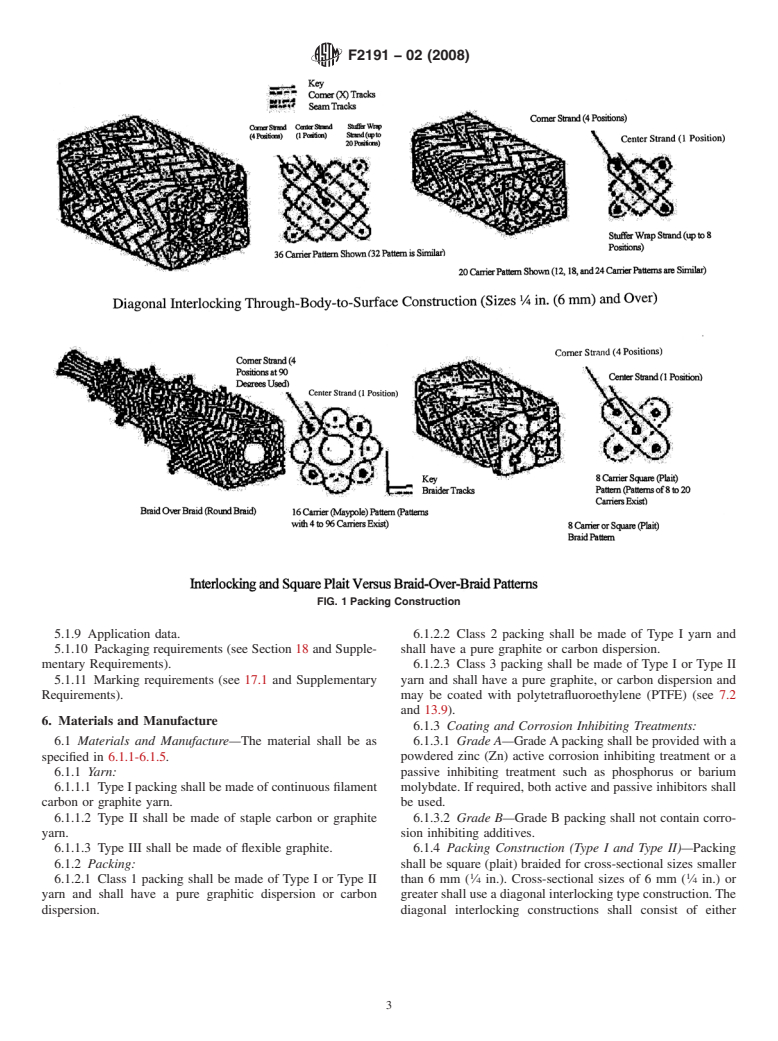

body of the braid (see Fig. 1).

function in a passive or sacrificial manner to reduce galvanic

3.20 staple carbon/graphite—individual fibers are at least

corrosion such as embedded zinc powder, phosphorus, or

75 mm (3 in.) long and preferably 150 to 200 mm (6 to 8 in.)

barium molybdate.

long.

3.10 detrimental materials—abrasive or chemically active

3.21 unraveling—a loss of the original braiding shape or

constituents such as abrasive ash particles (in high ash content

dimensionsofthecutendextendingfromthecutforadistance

foils) or elemental materials as in Table 2.

greater than that specified along the axis of the packing.

3.11 diagonal interlocking braid—these strands criss-cross

4. Classification

fromthesurfaceofthebraiddiagonallythroughthebodyofthe

braid and each strand is strongly locked by other strands to

4.1 Classification—The material shall be of the following

form an integral structure (see Fig. 1).

types, classes, and grades, as specified (see 5.1):

4.1.1 Type I—Continuous carbon or graphite yarn.

3.12 dispersion—various coatings or impregnants added to

4.1.2 Type II—Staple carbon or graphite yarn.

the base fibers or braid to facilitate handling, lubricate the

4.1.3 Type III—Braided flexible graphite.

fibers,acceleratebreak-in,oractasblockingagentsduringuse.

4.1.3.1 Class 1—For use where detrimental material and

3.13 graphite fibers—fibers used in braided packing are

lubricant content of the packing need not be controlled beyond

producedfromviscoserayon,pitch,orpolyacrylonitrile(PAN)

normal manufacturing limits.

andaredefinedasayarnwithacarbonassayof99%orhigher.

4.1.3.2 Class 2—For use where detrimental materials con-

3.14 graphite yarns—manufactured from continuous or

tent must be controlled to limits specified herein.

staple graphite fibers that are twisted or plied into continuous

4.1.3.3 Class 3—For use where detrimental materials con-

individual strands between 6 to 18 µm in diameter.

tent need not be controlled beyond normal manufacturing

3.15 lot—all finished packing of one size, type, class, and

limits, and media temperatures do not exceed 500°F (260°C).

grade produced in a continuous run or at the same time and

(1) Grade A—Treated with corrosion inhibitor.

under essentially the same conditions.

(2) Grade B—No corrosion inhibitor.

3.16 PAN—polyacrylonitrile fibers used as precursors to

5. Ordering Information

manufacture carbon/graphite for braided packing.

5.1 Acquisition Requirements—Acquisition documents

3.17 PTFE—polytetrafluoroethylene.(Warning—Graphitic

must specify the following:

valve packing containing PTFE has been associated with

5.1.1 Title, number, and date of this specification.

accelerated valve stem corrosion.)

5.1.2 Type, Class and Grade required (see Section 4).

5.1.3 Carbon or graphite.

5.1.4 Type of corrosion inhibitor.

TABLE 1 Chemical and Physical Properties

5.1.5 Chemical properties (see 7.1).

Property Value Test

5.1.6 Inspection, testing, and certification of the material

Carbon Assay

shallbeagreeduponbetweenthepurchaserandthesupplieras

Graphitic 99 % by mass, min. 13.4

Carbon 95 % by mass, min. 13.4

part of the purchase contract.

Ash 1 % by mass, max. 13.5

5.1.7 Size required (see 9.1). When pre-cut rings are de-

Finished Packing (in as-

supplied state): sired, specify the braid cross-section, inside diameter, outside

Specific gravity 1.38 g/cc, min. 13.6

diameter, and number of rings required.

Moisture content 3 %, max. 13.7

5.1.8 Put-up, if other than required by Table S4.1 (see

Compression recovery 25 %, min. 13.10

Supplementary Requirements).

F2191−02 (2008)

FIG. 1Packing Construction

5.1.9 Application data. 6.1.2.2 Class 2 packing shall be made of Type I yarn and

5.1.10 Packaging requirements (see Section 18 and Supple- shall have a pure graphite or carbon dispersion.

mentary Requirements). 6.1.2.3 Class 3 packing shall be made of Type I or Type II

5.1.11 Marking requirements (see 17.1 and Supplementary yarn and shall have a pure graphite, or carbon dispersion and

Requirements). may be coated with polytetrafluoroethylene (PTFE) (see 7.2

and 13.9).

6. Materials and Manufacture

6.1.3 Coating and Corrosion Inhibiting Treatments:

6.1 Materials and Manufacture—The material shall be as 6.1.3.1 Grade A—GradeApacking shall be provided with a

powdered zinc (Zn) active corrosion inhibiting treatment or a

specified in 6.1.1-6.1.5.

6.1.1 Yarn: passive inhibiting treatment such as phosphorus or barium

molybdate. If required, both active and passive inhibitors shall

6.1.1.1 TypeIpackingshallbemadeofcontinuousfilament

carbon or graphite yarn. be used.

6.1.1.2 Type II shall be made of staple carbon or graphite 6.1.3.2 Grade B—Grade B packing shall not contain corro-

yarn. sion inhibiting additives.

6.1.1.3 Type III shall be made of flexible graphite. 6.1.4 Packing Construction (Type I and Type II)—Packing

6.1.2 Packing: shall be square (plait) braided for cross-sectional sizes smaller

1 1

6.1.2.1 Class 1 packing shall be made of Type I or Type II than6mm( ⁄4 in.). Cross-sectional sizes of 6 mm ( ⁄4 in.) or

yarn and shall have a pure graphitic dispersion or carbon greatershalluseadiagonalinterlockingtypeconstruction.The

dispersion. diagonal interlocking constructions shall consist of either

F2191−02 (2008)

singleorpliedyarnsbraidedon12,18,20,24,32,or36carrier sured using a ground dimensional plug gauge and the outside

braidingmachines.Additionalaxialcenter,corner,and(stuffer) diameter is measured by the above (caliper) while the plug is

warp yarn(s) can be added within the braid as necessary to inserted. Information regarding tolerance and measurement is

produceadensesquarecross-sectionpackingprofilewithgood available in the Guidelines for the Use of Compression

dimensional stability. Packings published by the FSA.

6.1.5 Mercury Exclusion—During manufacturing, fabrica-

10. Workmanship, Finish, and Appearance

tion, handling, packaging, and packing, the packing material

shall not come in contact with mercury or mercury containing

10.1 Workmanship—The packing shall be free of defects

compounds.

that have the potential to affect its serviceability as defined in

Table 5.

7. Properties

10.2 Construction—The sample shall be visually examined

7.1 Chemical and Physical Properties—Unless otherwise

and confirmed to be of the correct braid construction (square

specified, the properties of the finished packing shall conform

plait braid or diagonal interlocking braid) for the ordered size

to the requirements of Table 1. Class 2 also requires compli-

(see 5.1 and 6.1.4).

ance with Table 2.

7.2 PTFE Coating (Class 3 only)—If PTFE is used, it shall

11. Quality Assurance

not exceed 10% by mass of the packing (see 13.9) unless

11.1 Quality Systems—Manufacturers shall be prepared to

otherwise agreed to by the purchaser. (Warning—Graphitic

document use of a quality system such as compliance with an

valve packing containing PTFE has been associated with

ISO 9000 series program or similar program.

accelerated valve stem corrosion.)

7.3 Prohibited Additions—There shall be no intentional 12. Specimen Preparation

additionsofanyofthedetrimentalmaterialslistedinTable2or

12.1 SpecimenPreparation—Buyerandsellershallagreeon

any antimony (Sb), arsenic (As), bismuth (Bi), cadmium (Cd),

specimen preparation.

gallium(Ga),indium(In),lead(Pb),mercury(Hg),silver(Ag),

or tin (Sn), or, in the case of Grade B packing, zinc (Zn).

13. Test Methods

13.1 Tests—In the event that tests are required as part of the

8. Other Requirements

purchasingrequirements5.1,testsshallbemadeinaccordance

8.1 Braid Geometry Retention—Untaped, cut ends shall not

with the following tests or by way of alternate methods of

unravel more than 3 mm ( ⁄8 in.) with the packing dry or wet

analysiswithequaltoorimprovedaccuracyandprecision.The

(see 13.11). For example, packing 12 mm ( ⁄2-in.) in cross

use of an alternate analytical method requires the prior written

section shall not unravel more than 3 mm ( ⁄8 in.) at either end

consent of the purchasing party before acceptance will be

of the packing.

allowed.

9. Dimensions, Mass, and Permissible Variations 13.2 Size—Before unbraiding, the size shall be determined

bymeasuringeachsampleselectedforvisualexamination(see

9.1 Sizes and Mass—Packing shall be furnished in the sizes

Table 3).Asteel rule with 1 mm ( ⁄32 in.) divisions accurate to

showninTable3,orothersize(s)asisorderedbythecustomer,

1 1

1mm( ⁄32 in.) or a steel slide caliper with 1 mm ( ⁄32 in.) and

(see Section 5 and 6.1.4). Packing shall be formed approxi-

0.5 mm ( ⁄64 in.) divisions shall be used (see 9.1).

mately square or rectangular in cross-section (either when

straight or when placed about a shaft) within the dimensional

13.3 Mass—Themassshallbedeterminedusingaspecimen

tolerances of Table 3. When specifie

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.