ASTM B1-13

(Specification)Standard Specification for Hard-Drawn Copper Wire

Standard Specification for Hard-Drawn Copper Wire

ABSTRACT

This specification covers hard-drawn round copper wire for electrical purposes. The wire shall be tested and shall conform to the requirements as to tensile strength, elongation, and electrical resistivity. No joints shall be made in the completed wire. Joints in the wire and rod made prior to final drawing shall be in accordance with the best commercial practice.

SCOPE

1.1 This specification covers hard-drawn round copper wire for electrical purposes.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception—For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B1 −13

Standard Specification for

1

Hard-Drawn Copper Wire

This standard is issued under the fixed designation B1; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.1.3 Type of copper, if special (Section 4),

3.1.4 Package size (10.1),

1.1 This specification covers hard-drawn round copper wire

3.1.5 Special package marking, if required, and

for electrical purposes.

3.1.6 Place of inspection (7.1).

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4. Materials

conversions to SI units that are provided for information only

4.1 The material shall be copper of such quality and purity

and are not considered standard.

that the finished product shall have the properties and charac-

1.2.1 Exception—For density, resistivity and temperature,

teristics prescribed in this specification.

the values stated in SI units are to be regarded as standard.

NOTE 1—Specification B49 defines the materials suitable for use.

2. Referenced Documents

2.1 The following documents of the issue in effect at the

5. General Requirements (see Section 8)

time of reference form a part of this specification to the extent

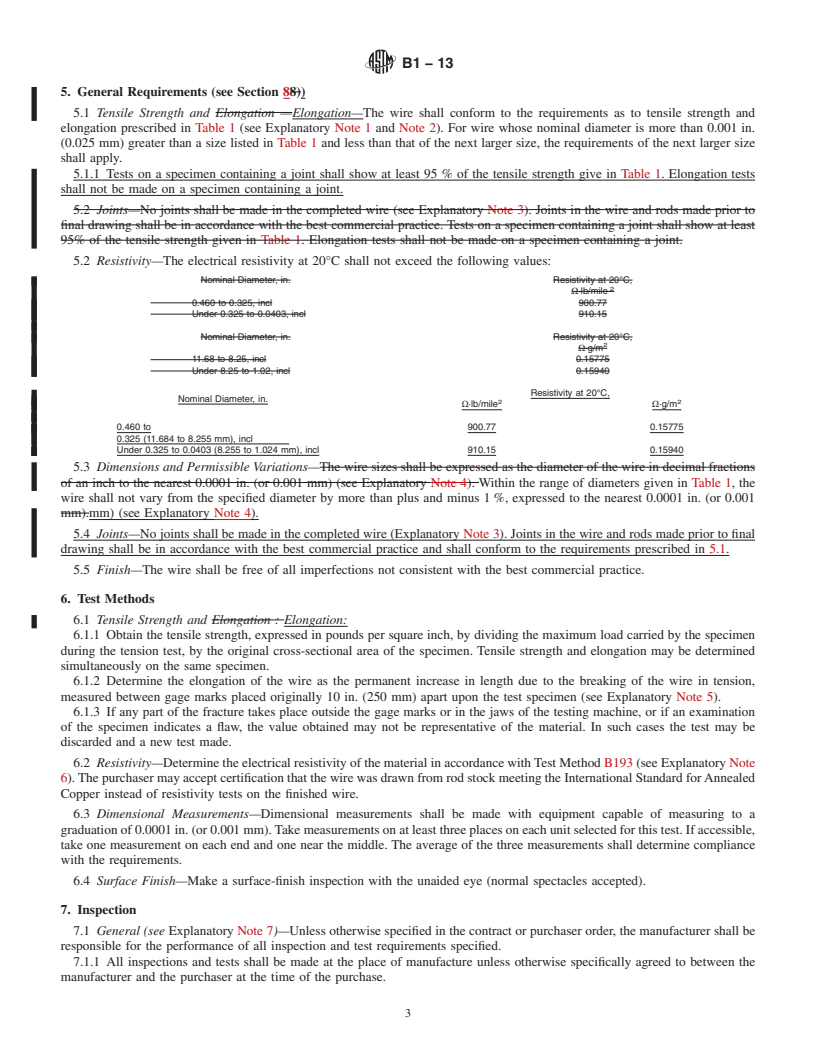

5.1 Tensile Strength and Elongation—The wire shall con-

referenced herein:

form to the requirements as to tensile strength and elongation

2

2.2 ASTM Standards:

prescribed in Table 1 (see Explanatory Note 1 and Note 2). For

B49 Specification for Copper Rod Drawing Stock for Elec-

wire whose nominal diameter is more than 0.001 in. (0.025

trical Purposes

mm) greater than a size listed in Table 1 and less than that of

B193 Test Method for Resistivity of Electrical Conductor

the next larger size, the requirements of the next larger size

Materials

shall apply.

B258 Specification for Nominal Diameters and Cross-

5.1.1 Tests on a specimen containing a joint shall show at

SectionalAreasofAWGSizesofSolidRoundWiresUsed

least 95 % of the tensile strength give in Table 1. Elongation

as Electrical Conductors

tests shall not be made on a specimen containing a joint.

2.3 Other Documents:

5.2 Resistivity—The electrical resistivity at 20°C shall not

3

NBS Handbook 100 — Copper Wire Tables

exceed the following values:

Resistivity at 20°C,

3. Ordering Information

Nominal Diameter, in.

2 2

Ω·lb/mile Ω·g/m

3.1 Orders for material under this specification shall include

0.460 to 0.325 (11.684 to 8.255 mm), incl 900.77 0.15775

the following information:

Under 0.325 to 0.0403 (8.255 to 1.024 mm), incl 910.15 0.15940

3.1.1 Quantity of each size,

5.3 Dimensions and Permissible Variations—Within the

3.1.2 Wire size: diameter in inches (5.3 and Table 1),

range of diameters given in Table 1, the wire shall not vary

from the specified diameter by more than plus and minus 1 %,

1 expressed to the nearest 0.0001 in. (or 0.001 mm) (see

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Explanatory Note 4).

Conductors of Copper and Copper Alloys.

5.4 Joints—No joints shall be made in the completed wire

Current edition approved Oct. 1, 2013. Published October 2013. Originally

approved in 1909. Last previous edition approved in 2012 as B1 – 12. DOI:

(Explanatory Note 3). Joints in the wire and rods made prior to

10.1520/B0001-13.

final drawing shall be in accordance with the best commercial

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

practice and shall conform to the requirements prescribed in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 5.1.

the ASTM website.

3

5.5 Finish—The wire shall be free of all imperfections not

Available from National Technical Information Service (NTIS), 5301 Shawnee

Rd., Alexandria, VA 22312, http://www.ntis.gov. consistent with the best commercial practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

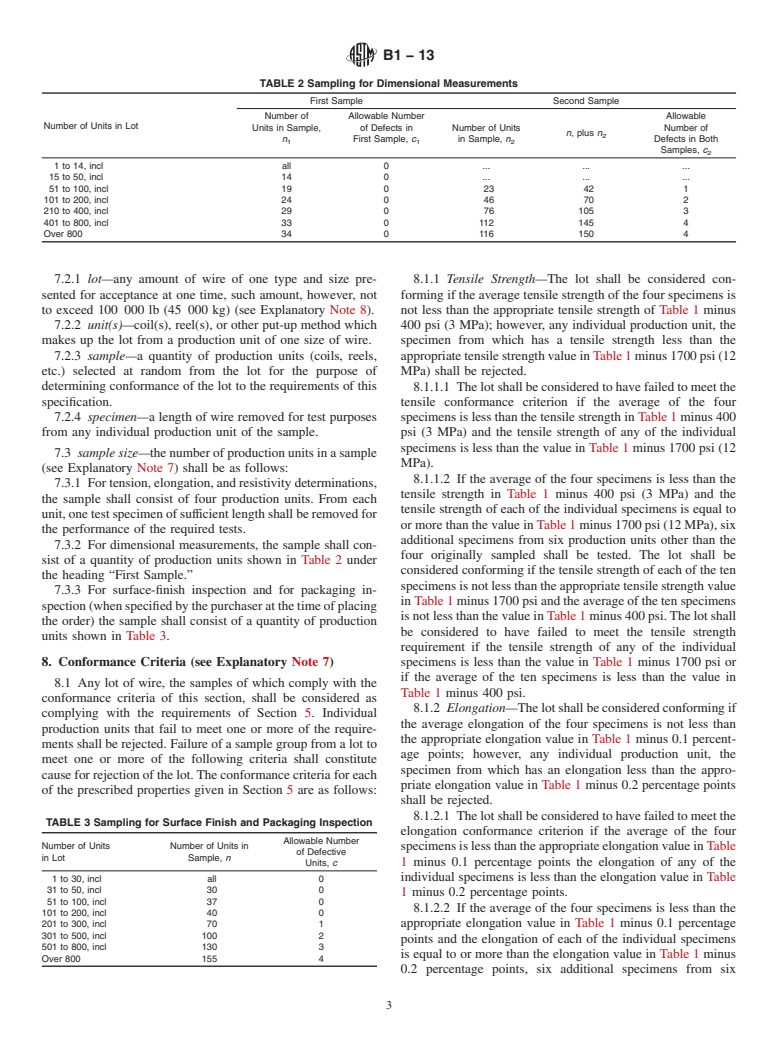

B1−13

TABLE 1 Tensile Properties

Nominal Tensile

Nominal

A

B

Diameter Area at 20°C Strength (see Explanatory

B

Elongation,%

Note 2)

2 2

in. mm cmil in. mm psi MPa in 10 in. (250 mm)

0.4600 11.684 211 600 0.1662 107.0 49 000 340 3.8

0.4096 10.464 167 800 0.1318 85.0 51 000 350 3.3

0.3648 9.266 133 100 0.1045 67.4 52 800 365 2.8

0.3249 8.252 105 600 0.08291 53.5 54 500 375 2.4

0.2893 7.348 83 690 0.06573 42.4

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B1 − 12 B1 − 13

Standard Specification for

1

Hard-Drawn Copper Wire

This standard is issued under the fixed designation B1; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers hard-drawn round copper wire for electrical purposes.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception—For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

2. Referenced Documents

2.1 The following documents of the issue in effect at the time of reference form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B49 Specification for Copper Rod Drawing Stock for Electrical Purposes

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical

Conductors

2.3 National Institute of Standards and Technology:Other Documents:

3

NBS Handbook 100 —Copper — Copper Wire Tables

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size,

3.1.2 Wire size: diameter in inches (5.45.3 and Table 1),

3.1.3 Type of copper, if special (Section 4),

3.1.4 Whether certification of resistivity of rod stock is acceptable instead of resistivity tests on the finished wire (6.2),

3.1.4 Package size (8.110.1),

3.1.5 Special package marking, if required, and

3.1.6 Place of inspection (7.1).

4. Materials and Manufacture

4.1 The material shall be copper of such quality and purity that the finished product shall have the properties and characteristics

prescribed in this specification.

NOTE 1—Specification B49 defines the materials suitable for use.

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved Nov. 15, 2012Oct. 1, 2013. Published November 2012October 2013. Originally approved in 1909. Last previous edition approved in 20072012

as B1 – 01 (2007).B1 – 12. DOI: 10.1520/B0001-12.10.1520/B0001-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the National Technical Information Service, 5285 Port Royal Road, Springfield, VA 22161.Service (NTIS), 5301 Shawnee Rd., Alexandria, VA 22312,

http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B1 − 13

TABLE 1 Tensile Properties

Nominal Tensile

Nominal

A

B

Diameter Area at 20°C Strength (see Explanatory

B

Elongation,%

Note 2)

2 2

in. mm cmil in. mm psi MPa in 10 in. (250 mm)

0.4600 11.684 211 600 0.1662 107.0 49 000 340 3.8

0.4096 10.464 167 800 0.1318 85.0 51 000 350 3.3

0.3648 9.266 133 100 0.1045 67.4 52 800 365 2.8

0.3249 8.252 105 600 0.08291 53.5 54 500 375 2.4

0.2893 7.348 83 690 0.06573 42.4 56 100 385 2.2

0.2576 6.543 66 360 0.05213 33.6 57 600 395 2.0

0.2294 5.827 52 620 0.04133 26.7 59 000 405 1.8

0.2043 5.189 41 740 0.03278 21.2 60 100 415 1.7

0.1819 4.620 33 090 0.02599 16.8 61 200 420 1.6

0.1650* 4.191 27 220 0.02138 13.8 62 000 425 1.5

0.1620 4.115 26 240 0.02061 13.3 62 100 430 1.4

0.1443 3.665 20 820 0.01635 10.5 63 000 435 1.3

0.1340* 3.404 17 960 0.01410 9.10 63 400 435 1.3

0.1285 3.264 16 510 0.01297 8.37 63 700 440 1.3

0.1144 2.906 13 090 0.01028 6.63 64 300 445 1.2

0.1040* 2.642 10 820 0.008495 5.48 64 800 445 1.2

0.1019 2.588 10 380 0.008155 5.26 64 900 445 1.2

0.0920* 2.387 8 460 0.00665 4.29 65 400 450 1.1

0.0907 2.304 8 230 0.00646 4.17 65 400 450 1.1

0.0808 2.052 6 530 0.00513 3.31 65 700 455 1.1

0.0800* 2.032 6 400 0.00503 3.24 65 700 455 1.1

0.0720 1.829 5 180 0.00407 2.63 65 900 455 1.1

0.0650* 1.651 4 220 0.00

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.