ASTM D3270-00(2006)

(Test Method)Standard Test Methods for Analysis for Fluoride Content of the Atmosphere and Plant Tissues (Semiautomated Method)

Standard Test Methods for Analysis for Fluoride Content of the Atmosphere and Plant Tissues (Semiautomated Method)

SIGNIFICANCE AND USE

These test methods may be used for determining the fluoride content of particulate matter and gases collected from the atmosphere by passive and active means, including plant tissues. The user is warned that the fluoride content of passive collectors (including plants) give only qualitative or semiquantitative measurement of atmospheric fluoride content.

SCOPE

1.1 These test methods describe the semiautomated procedure for the analyses of various types of samples for the purpose of determining total fluoride. Since the test methods incorporate microdistillation of the sample, they may be applied to any fluoride-containing solution where standards of identical composition have been carried through the same sample preparation procedures and have proven to provide quantitative recovery when analyzed by the semiautomated system. Conversely, the methods shall not be applied for analyses until the applicability has been demonstrated.

1.2 In normal use, the procedure can detect 0.1 g/mL of F. The normal range of analysis is from 0.1 to 1.6 g/mL of F. Higher concentrations can be analyzed by careful dilution of samples with reagent water. If digested samples routinely exceed 1.6 g/mL of F, the analytical portion of the pump manifold can be modified to reduce sensitivity. However, the best procedure is to analyze a smaller aliquot of the sample. Most accurate results are obtained when the fluoride concentration falls in the middle or upper part of the calibration curve.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 8.3, 10.2.4, and 10.2.5 for additional precautions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3270 − 00(Reapproved 2006)

Standard Test Methods for

Analysis for Fluoride Content of the Atmosphere and Plant

Tissues (Semiautomated Method)

This standard is issued under the fixed designation D3270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1356Terminology Relating to Sampling and Analysis of

Atmospheres

1.1 These test methods describe the semiautomated proce-

D3266Test Method for Automated Separation and Collec-

dure for the analyses of various types of samples for the

tion of Particulate and Acidic Gaseous Fluoride in the

purpose of determining total fluoride. Since the test methods

Atmosphere (Double Paper Tape Sampler Method)

incorporate microdistillation of the sample, they may be

D3267Test Method for Separation and Collection of Par-

applied to any fluoride-containing solution where standards of

ticulate and Water-Soluble Gaseous Fluorides in the At-

identical composition have been carried through the same

mosphere (Filter and Impinger Method)

sample preparation procedures and have proven to provide

D3268Test Method for Separation and Collection of Par-

quantitative recovery when analyzed by the semiautomated

ticulate and Gaseous Fluorides in the Atmosphere (So-

system. Conversely, the methods shall not be applied for

dium Bicarbonate-Coated Glass Tube and Particulate

analyses until the applicability has been demonstrated.

Filter Method)

1.2 In normal use, the procedure can detect 0.1 µg/mLof F.

D3269Test Methods for Analysis for Fluoride Content of

The normal range of analysis is from 0.1 to 1.6 µg/mL of F.

the Atmosphere and Plant Tissues (Manual Procedures)

Higher concentrations can be analyzed by careful dilution of 3

(Withdrawn 2010)

samples with reagent water. If digested samples routinely

D3614Guide for Laboratories Engaged in Sampling and

exceed 1.6 µg/mL of F, the analytical portion of the pump

Analysis of Atmospheres and Emissions

manifold can be modified to reduce sensitivity. However, the

best procedure is to analyze a smaller aliquot of the sample.

3. Terminology

Most accurate results are obtained when the fluoride concen-

3.1 Definitions—For definitions of terms used in these

trationfallsinthemiddleorupperpartofthecalibrationcurve.

methods, see Terminology D1356.

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

4. Summary of Test Methods

only.

4.1 These semiautomated methods are based on the distil-

1.4 This standard does not purport to address all of the

lation of hydrogen fluoride (HF) from the sample and subse-

safety concerns, if any, associated with its use. It is the

quent reaction of the distillate with alizarin fluorine blue-

responsibility of the user of this standard to establish appro-

lanthanum nitrate reagent, to form a blue complex which is

priate safety and health practices and determine the applica-

measured colorimetrically at 624 nm (1) , or the subsequent

bility of regulatory limitations prior to use.See8.3,10.2.4,and

measurement with a specific ion probe.

10.2.5 for additional precautions.

4.2 General, Plant Material:

2. Referenced Documents

4.2.1 The plant material including leaf samples, washed or

2.1 ASTM Standards:

unwashed, is dried, and ground, then dissolved with perchloric

D1193Specification for Reagent Water

acid and diluted to 50 mL with water. In the case of leaf

samples, an appreciable amount of fluoride may be deposited

These test methods are under the jurisdiction ofASTM Committee D22 on Air

on the external leaf surfaces. This fluoride behaves differently

Quality and are the direct responsibility of Subcommittee D22.03 on Ambient

physiologically from fluoride absorbed into the leaf and it is

Atmospheres and Source Emissions.

Current edition approved April 1, 2006. Published May 2006. Originally

approved in 1991. Last previous edition approved in 2000 as D3270-00. DOI:

10.1520/D3270-00R06.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the references at the end of this

the ASTM website. method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3270 − 00 (2006)

oftendesirabletowashitfromthesurfaceasapreliminarystep 4.5.4 Temperaturecontrolismaintainedwithin 62°Cbythe

in the analysis. Details of a leaf-washing process are described thermoregulator and by efficient stirring of the oil bath. Acid

in 9.1. concentration during distillation is regulated by taking plant

samples in the range from 0.1 to 2.0 g and by using 100 6 10

4.3 General, Atmospheric Samples:

mg of CaO and 3.0 6 0.1 g of NaOH for ashing and fusion of

4.3.1 Test Methods D3269 contains acceptable procedures

each sample. Vacuum in the system is controlled with flow-

and also techniques for the proper preparation of atmospheric

meters and a vacuum gage. Any marked change in vacuum

samples. Test Methods D3266, D3267, and D3268 are sam-

(greater than 0.7 kPa or 0.2 in. Hg) over a short time period

pling procedures for ambient air and each method contains

indicates either a leak or a block in the system. Distillation

specificinstructionsforsamplepreparationpriortoanalysesby

should take place at the same vacuum each day unless some

the semiautomated method.

other change in the system has been made. It is also essential

4.4 General, System Operation:

to maintain the proper ratio between air flow on the line

drawing liquid and solid wastes from the distillation coil and

4.4.1 The dissolved digest is pumped into the polytetrafluo-

roethylene coil of a microdistillation device maintained at on the line drawing HF and water vapor (Fig. 1) from the

170°C (2-6). A stream of air carries the acidified sample distillation unit. Occasional adjustments on the two flow-

meters should be made to keep this ratio constant and to

through a coil of TFE-fluorocarbon tubing to a fractionation

column.Thefluorideandwatervapordistilledfromthesample maintain higher vacuum on the line drawing HF vapor so that

little or no HF is diverted into the liquid and solid waste line.

aresweptupthefractionationcolumnintoacondenser,andthe

condensate passed into a small collector. Acid and solid (See 10.3.4 for description of air flow system.)

material pass through the bottom of the fractionation column

5. Significance and Use

and are collected for disposal. Acid and solid material pass

through the bottom of the fractionation column and are 5.1 These test methods may be used for determining the

collectedfordisposal.Inthecolorimetricmethod,thedistillate

fluoride content of particulate matter and gases collected from

is mixed continuously with alizarin fluorine blue-lanthanum the atmosphere by passive and active means, including plant

reagent, the colored stream passes through a 15-mm tubular

tissues. The user is warned that the fluoride content of passive

flow cell of a colorimeter, and the absorbance measured at 624 collectors(includingplants)giveonlyqualitativeorsemiquan-

nm. In the potentiometric method, the distillate is mixed

titative measurement of atmospheric fluoride content.

continually with a buffer, the mixed streams pass through a

6. Interferences

flow-through fluoride ion electrode, and the differential milli-

voltage is measured with an electrometer. The impulse is

6.1 Since the air that is swept through the microdistillation

transmitted to a recorder.

unit is taken from the ambient atmosphere, airborne contami-

4.4.2 All pieces of apparatus are commercially available, or nants in the laboratory may contaminate samples. If this is a

may be adapted from commercially available equipment. The problem, a small drying bulb filled with calcium carbonate

test method can also be run on most commercially available

granules can be attached to the air inlet tube of the microdis-

robot chemical analyzers. Details of construction of the micro- tillation unit.

distillationdevicearedescribedin7.10.Earlierversionsofthis

6.2 If the polytetrafluoroethylene distillation coil is not

test method have been published (3,5,6).

cleaned periodically, particulate matter will accumulate and

4.5 Principle of Operation: will reduce sensitivity.

4.5.1 Colorimetric System—The absorbance of an alizarin

6.3 Silicate, chloride, nitrate, and sulfate ions in high

fluorine blue-lanthanum reagent is changed by very small

concentration can be distilled with fluoride ion and will

amounts of inorganic fluoride.

interfere with the analysis by bleaching the alizarin fluorine

4.5.2 Potentiometric System—Since the sample system is

the same for this procedure as for the colorimetric procedure,

the distillation step removes all of the interfering cations. The

volatile acids that remain can be buffered by mixing with the

Total Ionic Strength Adjustment Buffer (TISAB).

4.5.3 Distillation System—Since HF has a high vapor

pressure, it is more efficiently distilled than the other acids

previously mentioned (4.5). The factors controlling efficiency

of distillation are temperature, concentration of acid in the

distillation coil, and vacuum in the system. Large amounts of

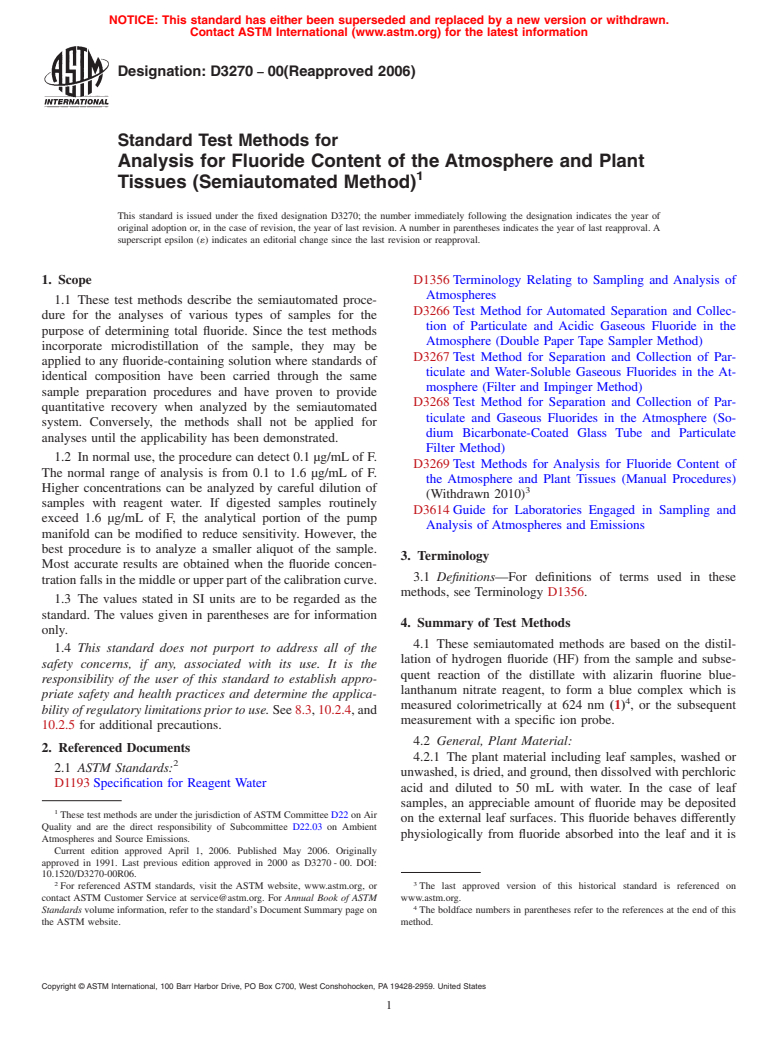

a Air Inlet g Waste Bottle with H SO

solid matter, particularly silicates, will also retard distillation. 2 4

b Microdistillation Coil h Gas-Drying Tower

Accordingly, the smallest sample of vegetation consistent with

c Fractionation Column i T-Tube

obtaining a suitable amount of fluoride should be analyzed.

d Water-Jacketed Condenser j Vacuum Gauge

e Sample Trap k Flowmeter

The aforementioned conditions must be carefully controlled,

f Waste Bottle l Vacuum Pump

since accurate results depend on obtaining the same degree of

efficiency of distillation from samples as from the standard

FIG. 1 Schematic Drawing of Air Flow System for Semiauto-

fluoride solutions used for calibration. mated Analysis of Fluorides

D3270 − 00 (2006)

blue-lanthanum reagent. Phosphate ion is not distilled, and 7.8 Recorder.

therefore does not interfere. Metals such as iron and aluminum

7.9 Range Expander.

are not distilled and will not interfere with the analysis (most

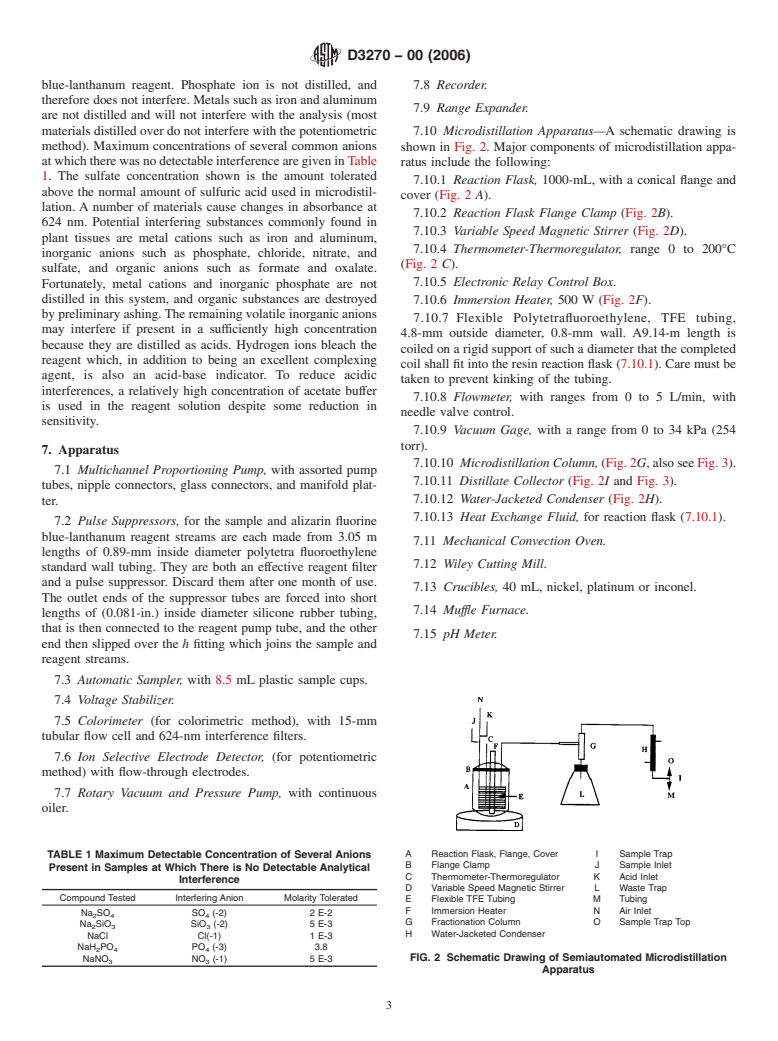

materialsdistilledoverdonotinterferewiththepotentiometric 7.10 Microdistillation Apparatus—A schematic drawing is

method). Maximum concentrations of several common anions

shown in Fig. 2. Major components of microdistillation appa-

atwhichtherewasnodetectableinterferencearegiveninTable ratus include the following:

1. The sulfate concentration shown is the amount tolerated

7.10.1 Reaction Flask, 1000-mL, with a conical flange and

above the normal amount of sulfuric acid used in microdistil-

cover (Fig. 2 A).

lation. A number of materials cause changes in absorbance at

7.10.2 Reaction Flask Flange Clamp (Fig. 2B).

624 nm. Potential interfering substances commonly found in

7.10.3 Variable Speed Magnetic Stirrer (Fig. 2D).

plant tissues are metal cations such as iron and aluminum,

7.10.4 Thermometer-Thermoregulator, range 0 to 200°C

inorganic anions such as phosphate, chloride, nitrate, and

(Fig. 2 C).

sulfate, and organic anions such as formate and oxalate.

7.10.5 Electronic Relay Control Box.

Fortunately, metal cations and inorganic phosphate are not

distilled in this system, and organic substances are destroyed

7.10.6 Immersion Heater,500W(Fig. 2F).

bypreliminaryashing.Theremainingvolatileinorganicanions

7.10.7 Flexible Polytetrafluoroethylene, TFE tubing,

may interfere if present in a sufficiently high concentration

4.8-mm outside diameter, 0.8-mm wall. A9.14-m length is

because they are distilled as acids. Hydrogen ions bleach the

coiled on a rigid support of such a diameter that the completed

reagent which, in addition to being an excellent complexing

coil shall fit into the resin reaction flask (7.10.1). Care must be

agent, is also an acid-base indicator. To reduce acidic

taken to prevent kinking of the tubing.

interferences, a relatively high concentration of acetate buffer

7.10.8 Flowmeter, with ranges from 0 to 5 L/min, with

is used in the reagent solution despite some reduction in

needle valve control.

sensitivity.

7.10.9 Vacuum Gage, with a range from 0 to 34 kPa (254

torr).

7. Apparatus

7.10.10 Microdistillation Column,(Fig.2G,alsoseeFig.3).

7.1 Multichannel Proportioning Pump, with assorted pump

7.10.11 Distillate Collector (Fig. 2I and Fig. 3).

tubes, nipple connectors, glass connectors, and manifold plat-

7.10.12 Water-Jacketed Condenser (Fig. 2H).

ter.

7.10.13 Heat Exchange Fluid, for reaction flask (7.10.1).

7.2 Pulse Suppressors, for the sample and alizarin fluorine

blue-lanthanum reagent streams are each made from 3.05 m

7.11 Mechanical Convection Oven.

lengths of 0.89-mm inside diameter polytetra fluoroethylene

7.12 Wiley Cutting Mill.

standard wall tubing. They are both an effective reagent filter

and a pulse suppressor. Discard them after one month of use.

7.13 Crucibles, 40 mL, nickel, platinum or inconel.

The outlet ends of the suppressor tubes are forced into short

7.14 Muffle Furnace.

lengths of (0.081-in.) inside diameter silicone rubber tubing,

that is then connected to the reagent pump tube, and the other

7.15 pH Meter.

end then slipped over the h fitting which joins the sample and

reagent streams.

7.3 Automatic Sampler, with 8.5 mL plastic sample cups.

7.4 Voltage Stabilizer.

7.5 Colorimeter (for colorimetric method), with 15-mm

tubular flow cell and 624-nm interference filters.

7.6 Ion Selective Electrode Detector, (for potentiometric

method) with flow-through electrodes.

7.7 Rotary Vacuum and Pressure Pump, with continuous

oiler.

A Reaction Flask, Flange, Cover I Sample Trap

TABLE 1 Maximum Detectable Concentration of Several Anions

B Flange Clamp J Sample Inlet

Present in Samples at Which There is No Detectable Analytical

C Thermometer-Thermoregulator K Acid Inlet

Interference

D Variable Speed Magnetic Stirrer L Waste Trap

Compound Tested Interfering Anion Molarity Tolerated

E Flexible TFE Tubing M Tubing

F Immersion Heater N Air Inlet

Na SO SO (-2) 2 E-2

2 4 4

G Fractionation Column O Sample Trap Top

Na SiO SiO (-2) 5 E-3

2 3 3

H Water-Jacketed Condenser

NaCl Cl(-1) 1 E-3

NaH PO PO (-3) 3.8

2 4 4

NaNO NO (-1) 5 E-3 FIG. 2 Schematic Drawing of Semiautomated Microdistillation

3 3

Apparatus

D3270 − 00 (2006)

8.3.8 CDTA, (1,2-cyclohe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.