ASTM D2829/D2829M-07(2023)

(Practice)Standard Practice for Sampling and Analysis of Existing Built-Up Roof Systems

Standard Practice for Sampling and Analysis of Existing Built-Up Roof Systems

SIGNIFICANCE AND USE

5.1 This practice is for the sampling and analysis of existing built-up roof systems. For roofs under construction, use Practice D3617/D3617M.

SCOPE

1.1 This practice is a guide for removing test specimens from existing built-up roofing systems in the field and for determining the approximate quantities of the components of that specimen (Note 1). Components determined may be:

1.1.1 Insulation components when they are part of the roof membrane system,

1.1.2 Plies of roofing felt,

1.1.3 Interply layers of bituminous material,

1.1.4 Top coating, and

1.1.5 Surfacing.

Note 1: This procedure is for the investigation of existing roofs and is not intended for new construction inspection.

1.2 This practice is applicable to both 914 mm [36 in.] and 1000 mm [393/8 in.] wide felt rolls.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary information, see 6.3.2.1.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2829/D2829M − 07 (Reapproved 2023)

Standard Practice for

Sampling and Analysis of Existing Built-Up Roof Systems

This standard is issued under the fixed designation D2829/D2829M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice is a guide for removing test specimens

D226/D226M Specification for Asphalt-Saturated Organic

from existing built-up roofing systems in the field and for

Felt Used in Roofing and Waterproofing

determining the approximate quantities of the components of

D227/D227M Specification for Coal-Tar-Saturated Organic

that specimen (Note 1). Components determined may be:

Felt Used in Roofing and Waterproofing

1.1.1 Insulation components when they are part of the roof

D249 Specification for Asphalt Roll Roofing (Organic Felt)

membrane system,

Surfaced with Mineral Granules (Withdrawn 2002)

1.1.2 Plies of roofing felt,

D250 Standard Specification for Asphalt-Saturated Asbestos

1.1.3 Interply layers of bituminous material,

Felt Used in Roofing and Waterproofing (Withdrawn

1991)

1.1.4 Top coating, and

D371 Specification for Asphalt Roll Roofing (Organic Felt)

1.1.5 Surfacing.

Surfaced with Mineral Granules; Wide Selvage (With-

NOTE 1—This procedure is for the investigation of existing roofs and is

drawn 2002)

not intended for new construction inspection.

D1079 Terminology Relating to Roofing and Waterproofing

D2178/D2178M Specification for Asphalt Glass Felt Used in

1.2 This practice is applicable to both 914 mm [36 in.] and

3 Roofing and Waterproofing

1000 mm [39 ⁄8 in.] wide felt rolls.

D2626/D2626M Specification for Asphalt-Saturated and

1.3 The values stated in either SI units or inch-pound units

Coated Organic Felt Base Sheet Used in Roofing

are to be regarded separately as standard. The values stated in

D3158 Specification for Asphalt Saturated and Coated Or-

each system are not necessarily exact equivalents; therefore, to

ganic Felt Used in Roofing (Withdrawn 1983)

ensure conformance with the standard, each system shall be

D3617/D3617M Practice for Sampling and Analysis of

used independently of the other, and values from the two

Built-Up Roof Systems During Application

systems shall not be combined.

D3672 Standard Specification for Venting Asphalt-Saturated

and Coated Inorganic Felt Base Sheet Used in Roofing

1.4 This standard does not purport to address all of the

(Withdrawn 1990)

safety concerns, if any, associated with its use. It is the

D3909/D3909M Specification for Asphalt Roll Roofing

responsibility of the user this standard to establish appropriate

(Glass Felt) Surfaced with Mineral Granules

safety, health, and environmental practices and determine the

D4601/D4601M Specification for Asphalt-Coated Glass Fi-

applicability of regulatory limitations prior to use. For specific

ber Base Sheet Used in Roofing

precautionary information, see 6.3.2.1.

D4897/D4897M Specification for Asphalt-Coated Glass-

1.5 This international standard was developed in accor-

Fiber Venting Base Sheet Used in Roofing

dance with internationally recognized principles on standard-

D4990 Specification for Coal-Tar Glass Felt Used in Roof-

ization established in the Decision on Principles for the

ing and Waterproofing

Development of International Standards, Guides and Recom-

3. Terminology

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.1 Definitions—For definitions of terms used in this

practice, refer to Terminology D1079.

1 2

This practice is under the jurisdiction of ASTM Committee D08 on Roofing and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Waterproofing and is the direct responsibility of Subcommittee D08.20 on Roofing contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Membrane Systems. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 1, 2023. Published September 2023. Originally the ASTM website.

approved in 1969. Last previous edition approved in 2019 as D2829/D2829M – 07 The last approved version of this historical standard is referenced on

ɛ1

(2019) . DOI: 10.1520/D2829_D2829M-07R23. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2829/D2829M − 07 (2023)

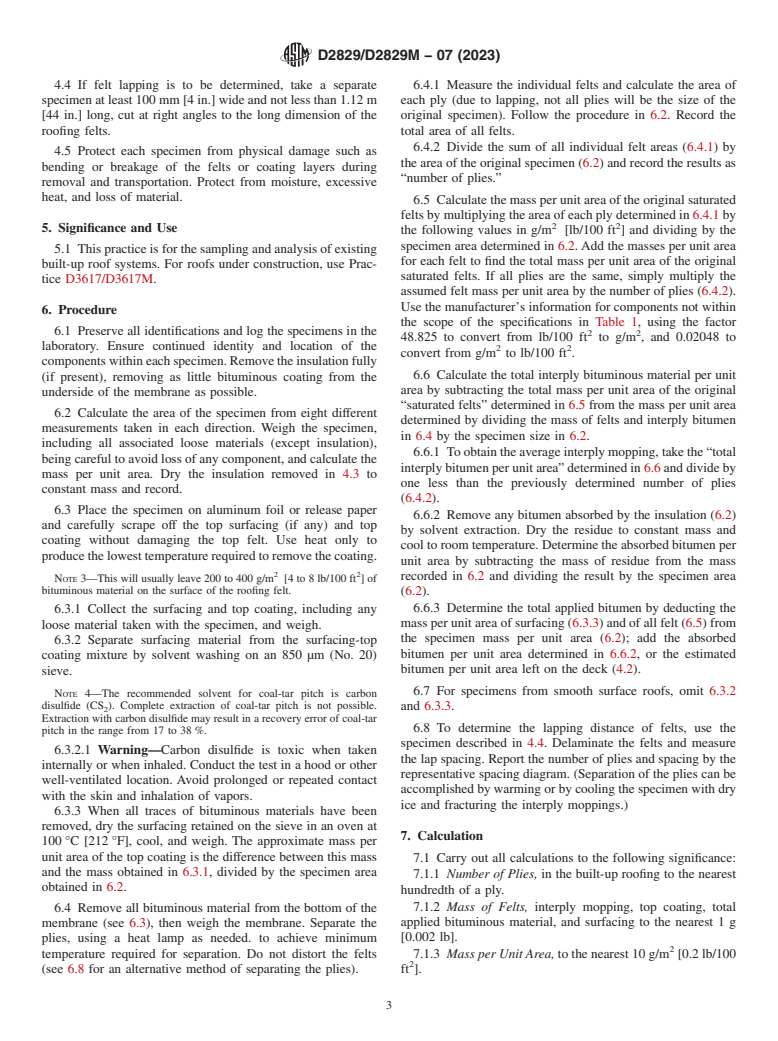

4. Securing of Specimens in the Field the sample. (The application of dry ice at the areas to be

spudded will ease the removal of the top coating during hot

4.1 Do not disturb any surfacing in the area from which a

weather. A large propane torch can also be used as an alternate

specimen is to be taken. Cut each specimen at least 300 by

to the dry ice method, to melt the top coating so that it can be

300 mm [12 by 12 in.] and use the total specimen taken in the

easily removed with a scraper and facilitate cutting.) Record

field for laboratory analysis.

the length and width of the sample. If the quantities of

4.2 The recommended practice is to use a cutting template

unadhered surfacing or total surfacing are desired, collect and

(Fig. 1) consisting of a 300 by 300 mm [12 by 12 in.] metal box

package the unadhered surfacing from the sample area.

with an open bottom. Place the box over the roof area that is to

4.2.1.3 Cut through the roofing membrane with a razor knife

be removed, and while the template is held firmly in position,

or sharp power cutting tool, taking care not to damage the edge

remove the surfacing around the perimeter and then cut

through the roof membrane around the perimeter of the box. of the sample. Do not pound on the sample, as this might cause

Lift the specimen, including all associated loose materials, interply delamination. Carefully loosen and remove the roofing

from the roof and place it in a plastic bag. Fully identify the

membrane including all adhered insulation. Observe and re-

specimen. Note if the insulation is adhered to the specimen or,

cord the kind and degree of attachment between the roofing

where insulation is not used, if bitumen is left on the deck, and

membrane and the insulation or deck.

the type of deck. Estimate bitumen mass per unit area left on

4.2.1.4 Cut through the roof insulation with a blade long

the deck.

enough to penetrate all of the insulation layers. Observe and

4.2.1 Alternate Method:

record the type and thickness of each insulation layer, and the

4.2.1.1 Mark each sample as at least a square 356 mm

percent of the sample area adhered between the layers and

[14 in.] on a side. Try to include a seam in each membrane

between the insulation and the deck and vapor retarder.

sample. During cold weather, use a square 457 mm [18 in.] on

4.2.1.5 Cut and remove a small specimen of the vapor

a side, since cold weather cutting may inadvertently break,

retarder, if it is present, to observe its attachment to the deck

distort, or delaminate the sample. If the roofing membrane is

and to obtain a specimen for moisture content and analysis.

mechanically fastened, mark rectangular 864 by 457 mm [34

by 18 in.] sample, with the longer dimension perpendicular to

NOTE 2—This procedure will not provide as accurate a measure of total

the length of the ply felts. Half of these large samples can be

aggregate as the procedure described in 4.2.

shipped to the laboratory for analysis after the number of

4.3 If bituminous material has been absorbed by the insu-

fasteners in the larger area is recorded.

lation (4.2), remove sufficient insulation to allow laboratory

4.2.1.2 Carefully broom off the loose aggregate, and spud

off the adhered aggregate and flood coating at the perimeter of analysis of absorbed bitumen mass (weight).

Dimensions

Square (3.2) Rectangular (3.4)

Dimension

mm in. mm in.

A 300 12 100 4

B 300 12 1000 40

C 150 6 150 6

D 40 1.5 40 1.5

E 40 1.5 40 1.5

1 1

F 3 ⁄8 3 ⁄8

FIG. 1 Cutting Template

D2829/D2829M − 07 (2023)

4.4 If felt lapping is to be determined, take a separate 6.4.1 Measure the individual felts and calculate the area of

specimen at least 100 mm [4 in.] wide and not less than 1.12 m each ply (due to lapping, not all plies will be the size of the

[44 in.] long, cut at right angles to the long dimension of the original specimen). Follow the procedure in 6.2. Record the

roofing felts. total area of all felts.

6.4.2 Divide the sum of all individual felt areas (6.4.1) by

4.5 Protect each specimen from physical damage such as

the area of the original specimen (6.2) and record the results as

bending or breakage of the felts or coating layers during

“number of plies.”

removal and transportation. Protect from moisture, excessive

heat, and loss of material.

6.5 Calculate the mass per unit area of the original saturated

felts by multiplying the area of each ply determined in 6.4.1 by

2 2

5. Significance and Use

the following values in g/m [lb/100 ft ] and dividing by the

specimen area determined in 6.2. Add the masses per unit area

5.1 This practice is for the sampling and analysis of existing

for each felt to find the total mass per unit area of the original

built-up roof systems. For roofs under construction, use Prac-

saturated felts. If all plies are the same, simply multiply the

tice D3617/D3617M.

assumed felt mass per unit area by the number of plies (6.4.2).

Use the manufacturer’s information for components not within

6. Procedure

the scope of the specifications in Table 1, using the factor

6.1 Preserve all identifications and log the specimens in the

2 2

48.825 to convert from lb/100 ft to g/m , and 0.02048 to

laboratory. Ensure continued identity and location of the 2 2

convert from g/m to lb/100 ft .

components within each specimen. Remove the insulation fully

6.6 Calculate the total interply bituminous material per unit

(if present), removing as little bituminous coating from the

area by subtracting the total mass per unit area of the original

underside of the membrane as possible.

“saturated felts” determined in 6.5 from the mass per unit area

6.2 Calculate the area of the specimen from eight different

determined by dividing the mass of felts and interply bitumen

measurements taken in each direction. Weigh the specimen,

in 6.4 by the specimen size in 6.2.

including all associated loose materials (except insulation),

6.6.1 To obtain the average interply mopping, t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.