ASTM D4157-02

(Test Method)Standard Test Method for Abrasion Resistance of Textile Fabrics (Oscillatory Cylinder Method)

Standard Test Method for Abrasion Resistance of Textile Fabrics (Oscillatory Cylinder Method)

SCOPE

1.1 This test method covers the determination of the abrasion resistance of woven textile fabrics using the oscillatory cylinder tester. This test method may not be usable for some fabric constructions.

Note 1—Other procedures for measuring the abrasion resistance of textile fabrics are given in: Test Methods D 3884, D 3885, D 3886, D 4158, and AATCC 93.

1.2 The values stated in SI units are to be regarded as standard; the values in English units are provided as information only and are not exact equivalents.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4157–02

Standard Test Method for

Abrasion Resistance of Textile Fabrics (Oscillatory Cylinder

Method)

This standard is issued under the fixed designation D 4157; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 5034 Test Method for Breaking Strength and Elongation

of Textile Fabrics (Grab Method)

1.1 This test method covers the determination of the abra-

D 5035 Test Method for Breaking Strength and Elongation

sion resistance of woven textile fabrics using the oscillatory

of Textile Fabrics (Strip Method)

cylinder tester. This test method may not be usable for some

2.2 Other Document:

fabric constructions.

AATCC 93 Abrasion Resistance of Fabrics: Accelerotor

NOTE 1—Other procedures for measuring the abrasion resistance of 3

Method

textile fabrics are given in: Test Methods D 3884, D 3885, D 3886,

D 4158, and AATCC 93.

3. Terminology

1.2 The values stated in SI units are to be regarded as

3.1 Definitions:

standard; the values in English units are provided as informa-

3.1.1 abrasion, n—the wearing away of any part of a

tion only and are not exact equivalents.

material by rubbing against another surface.

1.3 This standard does not purport to address all of the

3.1.2 abrasion cycle, n—in abrasion testing, one or more

safety concerns, if any, associated with its use. It is the

movements of the abrdant across a material surface, or the

responsibility of the user of this standard to establish appro-

material surface across the abradant, that permits a return to its

priate safety and health practices and determine the applica-

starting position.

bility of regulatory limitations prior to use.

3.1.2.1 Discussion—The abrasion cycle is dependent on the

programmed motions of the abrasion machine and the test

2. Referenced Documents

standard used. It may consist of one back-and-forth unidirec-

2.1 ASTM Standards:

tional movement such as for the flexing and abrasion test

D 123 Terminology Relating to Textiles

method; a circular movement such as for the rotary platform

D 1776 Practice for Conditioning and Testing Textiles

test method, or a combination of both such as for the inflated

D 3597 Specification for Woven Upholstery Fabrics—

diaphragm test method. For the oscillatory cylinder abrasion

Plain, Tufted, or Flocked

method, an abrasion cycle consists of one double-rub as

D 3884 Test Method for Abrasion Resistance of Textile

defined in 3.1.4.

Fabrics (Rotary Platform, Double Head Method)

3.1.3 breaking force, n—the maximum force applied to a

D 3885 Test Method for Abrasion Resistance of Textile

material carried to rupture (compare breaking point, breaking

Fabrics (Flexing and Abrasion Method)

strength).

D 3886 Test Method for Abrasion Resistance of Textile

3.1.4 double-rub, n—in oscillatory cylinder abrasion test-

Fabrics (Inflated Diaphragm Method)

ing, one forward and one backward motion required to com-

D 4158 Test Method for Abrasion Resistance of Textile

plete one cycle.

Fabrics (Uniform Abrasion Method)

3.2 For definitions of other textile terms used in this test

D 4966 Test Method for Abrasion Resistance of Textile

method, refer to Terminology D 123.

Fabrics (Martindale Abrasion Tester)

4. Summary of Test Method

4.1 Abrasion resistance is measured by subjecting the speci-

men to unidirectional rubbing action under known conditions

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

of pressure, tension, and abrasive action. Resistance to abra-

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

Specific. sion is evaluated by various means which are described in

Current edition approved Dec. 10, 2002. Published March 2003. Originally

Section 12.

published as D 4157 – 82. Last previous edition D 4157 – 92.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Association of Textile Chemists and Colorists, P.O.

the ASTM website. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4157–02

5. Significance and Use tories; however, they represent the methods now most widely

in use. This test method provides a comparative measurement

5.1 The measurement of the resistance to abrasion of textile

of the resistance of woven textile fabrics to abrasion, and may

and other materials is very complex.The resistance to abrasion

not necessarily predict the actyal performance of fabrics in

is affected by many factors, such as the inherent mechanical

actual use.

properties of the fibers; the dimensions of the fibers; the

5.7 If there are differences of practical significance between

structure of the yarns; the construction of the fabrics; and the

reported test results for two or more laboratories, comparative

type,kind,andamountoffinishingmaterialaddedtothefibers,

tests should be performed to determine if there is a statistical

yarns, or fabric.

bias between them, using competent statistical assistance.As a

5.2 The resistance to abrasion is also greatly affected by the

minimum, test samples that are as homogeneous as possible,

conditions of the tests, such as the nature of abradant; variable

drawn from the material from which the disparate test results

action of the abradant over the area of specimen abraded, the

were obtained, and randomly assigned in equal numbers to

tension of the specimen, the pressure between the specimen

each laboratory for testing. The test results from the two

and abradant, and the dimensional changes in the specimen.

laboratories should be compared using a statistical test for

5.3 Abrasion tests are all subject to variation due to changes

unpaired data, at a probability level chosen prior to the testing

in the abradant during specific tests. The abradant must

series. If bias is found, either its cause must be found and

accordingly be changed at frequent intervals or checked

corrected, or future test results must be adjusted in consider-

periodically against a standard. With disposable abradants, the

ation of the known bias.

abradant is used only once or changed after limited use. With

permanent abradants that use hardened metal or equivalent

6. Apparatus

surfaces, it is assumed that the abradant will not change

6.1 Oscillatory Cylinder Abrasive Machine, consisting of

appreciably in a specific series of tests, but obviously similar

the following

abradantsusedindifferentlaboratorieswillnotlikelychangeat

6.1.1 Oscillating Cylinder Section, equipped with edge

the same rate due to differences in usage. Permanent abradants

clamps to permit mounting of a sheet of abrasive material over

may also change due to pick up of finishing or other material

its surface, capable of oscillating through an arc of 76 62mm

from test fabrics and must accordingly be cleaned at frequent

(3 6 0.1 in.) at the rate of 90 6 1 cycles (double rub) per min.

intervals. The measurement of the relative amount of abrasion

6.1.2 Four Specimen Holding Arms, to permit testing of

may also be affected by the method of evaluation and may be

several specimens sumultaneously; each arm having a set of

influenced by the judgment of the operator.

controlled tension clamps with the forward clamp attached to a

5.4 The resistance of textile materials to abrasion as mea-

force scaled tension bar, and a controlled pressure pad attached

sured on a testing machine in the laboratory is generally only

to a force scaled pressure bar.

one of several factors contributing to wear performance or

6.1.3 Calibrated Mass (340 g), that slides on the tension bar

durability as experienced in the actual use of the material.

and attached on each arm forward clamp to adjust tension to

While “abrasion resistance” (often stated in terms of the

the specimen in increments of 4.45 N (1 lbf) up to a total of

number of cycles on a specified machine, using a specified

26.7 N (6 lbf).

technique to produce a specified degree or amount of abrasion)

6.1.4 Thumb Screw, that butts against the rear clamp of each

and “durability” (defined as the ability to withstand deteriora-

arm to provide slack take-up of the specimen.

tionorwearingoutinuse,includingtheeffectsofabrasion)are

6.1.5 Sponge Rubber Pressure Pad,50 350mm(2 32in.)

frequently related, the relationship varies with different end

with a tolerance of 6 1 mm (0.05 in.) shaped to the cylinder

uses, and different factors may be necessary in any calculation

surface and fitted to the pressure bar.

of predicted durability from specific abrasion data. Laboratory

6.1.6 Calibrated Mass (150 g), that slides on the pressure

tests may be reliable as an indication of relative end-use

bar and attached on each pressure pad to adjust and apply

performance in cases where the difference in abrasion resis-

pressure to the specimen in increments of 4.45 N (1 lbf) up to

tanceofvariousmaterialsislarge,buttheyshouldnotberelied

a total of 15.575 N (3.5 lbf).

upon where differences in laboratory test findings are small. In

6.1.7 Two Slotted Vacuum Pipes, suspended over the cylin-

general, they should not be relied upon for prediction of actual

der drum to remove lint and dust particles.

wear-life in specific end uses unless there are data showing the

6.1.8 Automatic Cycle Counter, with set and stop mecha-

specific relationship between laboratory abrasion tests and

nism to record the number of cycles (double rubs) and stop the

actual wear in the intended end-use.

machine at a predetermined number of cycles.

5.5 These general observations apply to all types of fabrics,

6.2 Abradant:

including woven, nonwoven, and knit apparel fabrics, house-

6.2.1 Cotton Duck # 10, with the following characteristics:

2 2

hold fabrics, industrial fabrics, and floor coverings. It is not

6.2.1.1 Mass/UnitArea—500 625g/m (14to15.8oz/yd ).

surprising, therefore, to find that there are many different types

6.2.1.2 Weave Type—plain weave.

of abrasion testing machines, abradants, testing conditions,

6.2.1.3 Fabric Count—41 6 1 end/in. 3 28 6 1 pick/in.

testing procedures, methods of evaluation of abrasion resis-

6.2.1.4 Yarn Size—7/2 cotton count 6 1 in both warp and

tance, and interpretation of results.

filling.

5.6 All the test methods and instruments so far developed 6.2.1.5 Air Permeability—less than 4 cfm.

forabrasionresistancemayshowahighdegreeofvariabilityin 6.2.1.6 Finish—loom state; no warp size.

results obtained by different operators and in different labora- 6.2.2 Wire Screen, specification information to follow.

D4157–02

6.2.3 Grit Sandpaper, to refurbish rubber pads. 10. Preparation, Maintenance, and Calibration of Test

6.2.4 Nylon Brush, medium brisstle, or equivalent. Apparatus

6.2.5 Mild Household Detergent Solution.

10.1 Prepare and verify calibration of the abrasion tester

6.2.6 Air Supply, with regulated nozzle.

using directions supplied by the manufacturer.

6.2.7 Digital Force Gage.

10.2 Verify that the rubber pads extend below their holders.

10.3 Verify that the entire lower surface of the rubber pad is

7. Sampling

in contact with the cylinder section, and that no space is

7.1 Take a lot sample as directed in the applicable material

observed. If space(s) are observed, reshape the lower pad

specification, or as agreed upon between the purchaser and

surface as directed. Pads should be changed at least once a

seller. In the absence of such a specification or other agree-

year.

ment, take a laboratory sample as directed in 7.2.

10.3.1 If wire screen abradant is used, remove and clean

7.2 Take a laboratory sample from each roll or piece of

with the nylon brush. Clean cylinder. Insert and clamp 50 grit

fabric in the lot sample. The laboratory sample should be full

sand paper to the cylinder. Remove all pressure from the pad

width and at least 50 cm (approximately 20 in.) long and

and lock the specimen holding arm in position. Run the tester

should not be taken any closer to the end of the roll or piece of

in 50 cycle increments. Inspect for spaces between the lower

fabric than1m(1 yd). Consider rolls or pieces of fabric to be

surface of the pad and the cylinder after each 50 cycles.

the primary sampling unit.

Continue until the entire surface of the pad conforms to the

7.3 Take a laboratory sampling unit from each roll or piece

shape of the cylinder section. The wear pattern on the sand

of fabric in the lot sample that is full width and at least 50 cm

paper can assist in determining conformance.

(20 in.) long and not taken any closer to the end of the roll or

10.4 At lease on a weekly schedule: clean surface of the

piece of fabric than1m(1 yd).

cylindersectionandthesteelscreenbybrushingandthenusing

7.4 Sample shipment of garments as agreed upon between

the mild detergent solution. Clean out vacuum system. Inspect

purchaser and seller.

the pads for wear and refurbish as directed in 10.3.1 as

required.

8. Number and Preparation of Test Specimens

10.5 After each test: brush the rubber pads to remove any

8.1 In the absence of any applicable material specifications,

loosefibers,etc.Usingthenylonbrush,cleanthesurfaceofthe

take 12 specimens, 6 warp (machine direction) and 6 filling,

cylinder section and the steel screen by brushing and wiping

(across machine direction) from each sample to be tested.

with a cloth. If disposible abradants are used, such as emery

8.2 Preparation of Specimens:

7 paper or cotton duck, replace after each test.

8.2.1 Cut the test specimens 73 mm (2 ⁄8 in.) by 245 mm

10.6 Calibration of the Oscillatory Cylinder machine should

(9 ⁄8 in.). Specimens should be cut with flares or wings. The

be performed as specified in the appendix of this method.

longdimensionsarecutparalleltothewarpyarnsforwarpwise

(machinedirection)abrasionandparalleltothefillingyarnsfor

11. Procedure

filling-wise (cross-machine direction) abrasion. For woven

fabrics do not cut two warp specimens from the same warp

11.1 Test the conditioned specimens in the standard atmo-

yarns or two filling specimens from the same filling yarns. If

sphere for testing textiles, which is 70 6 2°F (21 6 1°C) and

the fabric has a pattern, ensure that the specimens are repre-

65 6 2 % relative humidity.

sentative sampling of the pattern.

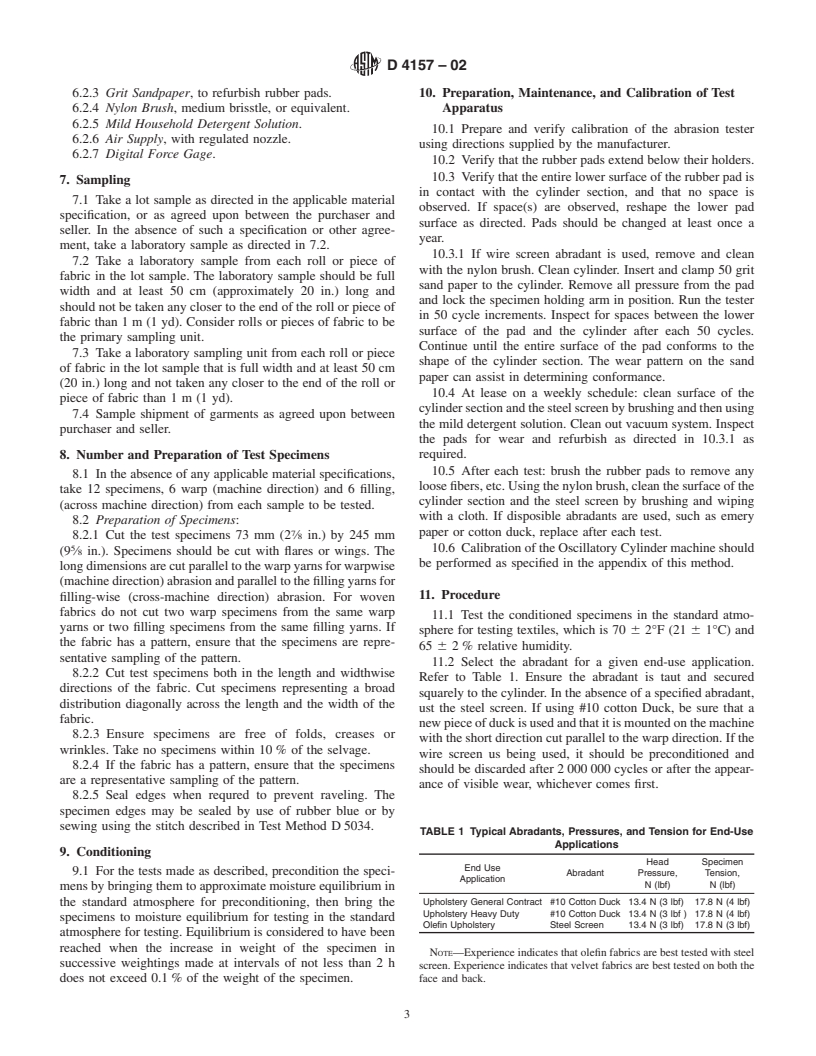

11.2 Select the abradant for a given end-use application.

8.2.2 Cut test specimens both in the length and widthwise

Refer to Table 1. Ensure the abradant is taut and secured

directions of the fabric. Cut speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.