ASTM F1060-87(1993)e1

(Test Method)Standard Test Method for Thermal Protective Performance of Materials for Protective Clothing for Hot Surface Contact

Standard Test Method for Thermal Protective Performance of Materials for Protective Clothing for Hot Surface Contact

SCOPE

1.1 This test method is used to rate textile materials for thermal resistance and insulation when exposed for a short period of time to a hot surface with a temperature up to 600F (316C). This test method is applicable to woven fabrics, knit fabrics, battings, and sheet structures intended for use as clothing for protection against short exposure to hot surfaces. It is not intended for use in evaluating materials exposed to any other thermal exposure such as radiant energy or open flames. This test method is currently useful as a research and development tool.

1.2 This test method should be used to measure and describe the properties of materials, products, or assemblies in response to heat under controlled laboratory conditions and should not be used to describe or appraise the thermal hazard or fire risk of materials, products, or assemblies under actual exposure conditions.

1.3 The values as stated in SI units are to be regarded as the standard. The values in parentheses are given for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 1060 – 87 (Reapproved 1993) An American National Standard

Standard Test Method for

Thermal Protective Performance of Materials for Protective

Clothing for Hot Surface Contact

This standard is issued under the fixed designation F 1060; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 15 was added editorially in October 1993.

1. Scope terial, the response to hot surface contact is indicated by the

following descriptive terms:

1.1 This test method is used to rate textile materials for

3.1.1 charring—the formation of a carbonaceous residue as

thermal resistance and insulation when exposed for a short

the result of pyrolysis or incomplete combustion.

period of time to a hot surface with a temperature up to 600°F

3.1.2 embrittlement—the formation of a brittle residue as a

(300°C). This test method is applicable to woven fabrics, knit

result of pyrolysis or incomplete combustion.

fabrics, battings, and sheet structures intended for use as

3.2 Definitions of Terms Specific to This Standard:

clothing for protection against short exposure to hot surfaces. It

3.2.1 heat flux—the thermal intensity indicated by the

is not intended for use in evaluating materials exposed to any

amount of energy transmitted per unit area and per unit time

other thermal exposure such as radiant energy or open flames.

(cal/cm ·s) (watts/cm ).

This test method is currently useful as a research and devel-

3.2.2 human tissue heat tolerance—in the testing of thermal

opment tool.

protective materials, the amount of thermal energy predicted to

1.2 This test method should be used to measure and describe

cause a pain sensation or a second degree burn in human tissue.

the properties of materials, products, or assemblies in response

3.2.3 ignition—the initiation and continuation of combus-

to heat under controlled laboratory conditions and should not

tion.

be used to describe or appraise the thermal hazard or fire risk

3.2.4 melting—a response evidenced by softening of the

of materials, products, or assemblies under actual exposure

material, resulting in a nonreversible change.

conditions. However, results of this test method may be used as

3.2.5 shrinkage—a response evidenced by reduction in

elements of a thermal risk assessment which takes into account

specimen size.

all the factors which are pertinent to an assessment of the

3.2.6 sticking—a response evidenced by softening and ad-

thermal hazard of a particular end use.

herence of the material to the hot surface or other material.

1.3 The values as stated in inch–pound units are to be

3.2.7 thermal end point—in the testing of thermal protective

regarded as the standard. The values in parentheses are given

materials, the point at which the sensor response on the

for information only.

recorder chart intersects the human tissue burn tolerance

1.4 This standard does not purport to address all of the

criteria overlay.

safety concerns, if any, associated with its use. It is the

3.3 For definitions of other textile terms used in this test

responsibility of the user of this standard to establish appro-

method, refer to Terminology D 123.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents 4.1 This test method measures the performance of insulative

materials. A material is placed in contact with a standard hot

2.1 ASTM Standards:

2 surface. The amount of heat transmitted by the material is

D 123 Terminology Relating to Textiles

compared with the human tissue tolerance and the obvious

D 1776 Practice for Conditioning Textiles for Testing

effects of the heat on the material are noted.

3. Terminology

4.2 The temperature of the hot surface is measured/

controlled with a thermocouple and the heat transmitted by the

3.1 Definitions—In testing thermal protection clothing ma-

test specimen is measured with a copper calorimeter. The

calorimeter temperature increase is a direct measure of the heat

This test method is under the jurisdiction of ASTM Committee F–23 on energy received.

Protective Clothing and is the direct responsibility of Subcommittee F 23.80 on

4.3 A contact pressure of 0.5 psi (3 kPa) is used to compare

Molten Substances.

material performance under controlled conditions. A different

Current edition approved July 31, 1987. Published September 1987.

pressure may be chosen to represent a specific use condition,

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1060

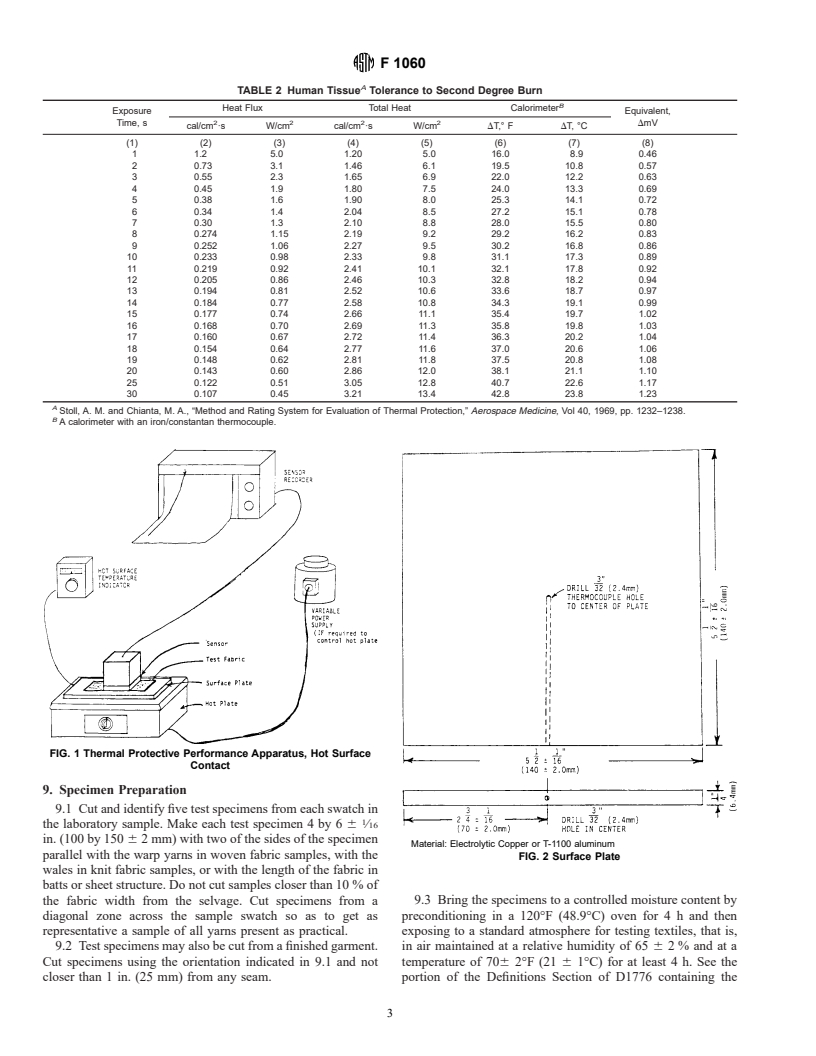

and where it is used should be noted under test conditions 6.3 Surface plate— The flat plate shall be ⁄4 in. (6.4 mm)

(13.1.2.3). thick, 5.5 by 5.5 in. (140 by 140 mm) wide, with a ⁄32-in.

4.4 The material performance is determined from the (2.4-mm) hole drilled from the edge to the center of the plate

amount of heat transferred by the specimen and the observed (Fig. 2). Either electrolytic copper or T-1100 aluminum surface

effect of the heat exposure on the specimen. The thermal plates may be used. The surface plate must be flat, smooth, and

protection is the exposure time required to cause the accumu- free from pits and cavities. (Flatness is indicated by negligible

lated heat received by the sensor to equal the heat that will light passing between a straight edge and the plate surface.)

result in a pain sensation (see Table 1) or cause a second degree Loss of the original mill finish (as judged with the naked eye)

burn in human tissue (see Table 2), as predicted from compari- or warping, or both, may result in failure to achieve calibration

son of heat transfer data with human tissue heat tolerance with the reference standard.

curves (see Table 1).

6.4 Sensor—A copper calorimeter mounted in an insulating

block with added weight and constructed as shown in Figs. 3

5. Significance and Use

and 4. The calorimeter must fit securely in the insulating block

5.1 This test method rates textile materials intended for use

and its surface must be flush with the face of the insulating

as protective clothing against exposure to hot surfaces, for their

block.

thermal insulating properties and their reaction to the test

NOTE 1—Caution: Surface variations may result in failure to achieve

conditions.

calibration with the reference standard.

5.2 The thermal protection time as determined by this test

method will relate to the actual end-use performance only to

6.5 Calibration Specimen—Six new, not previously tested

the degree that the end-use exposure is identical to the

sheets of ordinary newspaper with total thickness of 0.021 6

exposure used in this test method, that is, conductive energy

0.002 in. (0.53 6 0.05 mm).

from hot surfaces up to 600°F (300°C) and under a pressure of

6.6 Recorder—Any strip chart recorder with full-scale de-

0.5 psi (3 kPa).

flection of at least 300°F (150°C) or 10 mV and sufficient

5.3 The procedure maintains the specimen in a static,

sensitivity and scale divisions to read sensor response to 62°F

horizontal position under a standard pressure and does not

(1°C) or 60.05 mV. A chart speed to read exposure time to

involve movement.

60.1 s is required, 0.5 in./s (13 mm/s) is satisfactory.

5.4 This test method for materials for thermal protective

performance is intended for use in comparing the relative

7. Hazards

performance of various materials. Because information on the

7.1 Perform the test in a hood or a ventilated area to carry

possible biases that could exist between various laboratories

away degradation products, smoke, and fumes. Exercise care to

and their specific test fixtures is limited, this test method is not

prevent contact with hot surfaces. Use protective gloves when

recommended for direct comparison of results between labo-

handling hot objects. Have an appropriate portable fire extin-

ratories. If use of this test method is desired for acceptance

guisher nearby.

testing of commercial shipments, it is recommended that each

laboratory involved perform the test on a series of duplicate

8. Sampling

specimens drawn from the same material samples so that the

8.1 Lot Size—For acceptance sampling purposes, a lot is

statistical bias can be computed and any disagreements arising

defined as a single shipment of a single style of fabric. A lot

out of the differences can be resolved.

may constitute all or part of a single customer order.

6. Apparatus

8.2 Lot Sample—As a lot sample for acceptance testing,

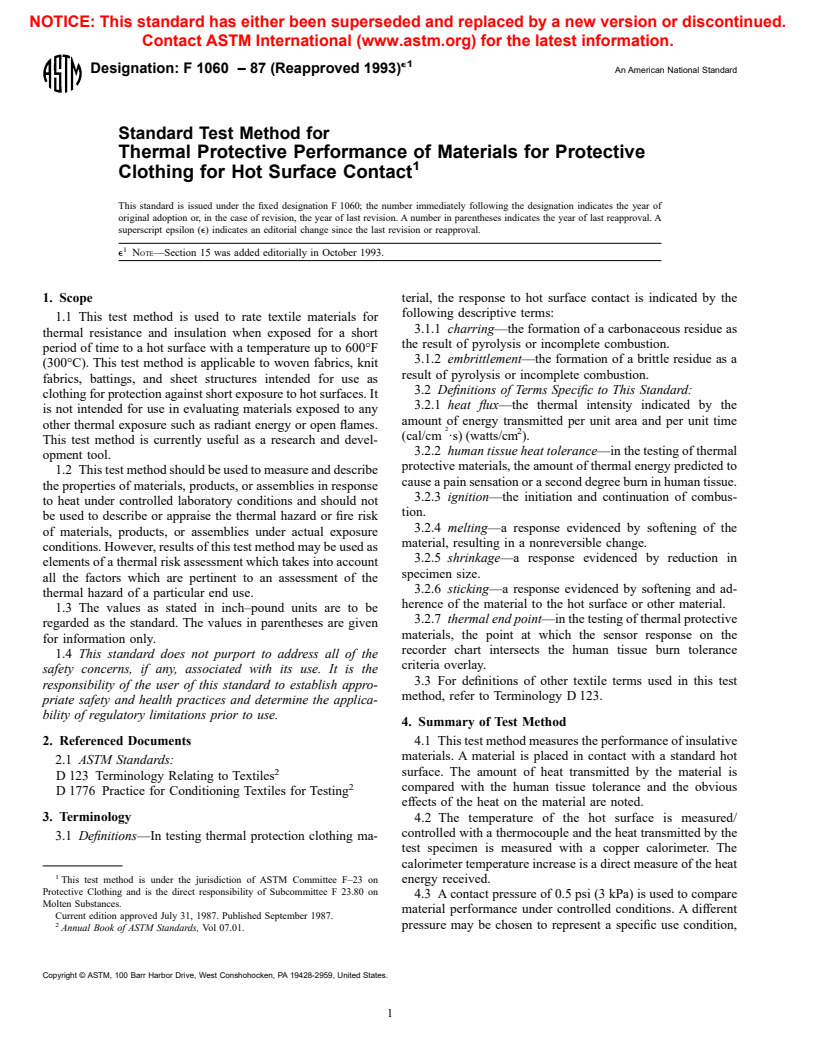

6.1 General Arrangement—The arrangement of the indi- take at random the number of rolls of fabric directed in an

applicable material specification or other agreement between

vidual components of the test apparatus is shown in Fig. 1.

6.2 Hot Plate—Shall have a flat heated surface with the the purchaser and the supplier.

smallest dimension, a minimum of at least 8 in. (200 mm) and 8.3 Laboratory Sample—As a laboratory sample, take from

have the ability to achieve a temperature of at least 700°F the outside of each roll in the lot sample a full width swatch of

(371°C) and to permit temperature control within 6 5°F fabric 1 yd (1 m) long after discarding a full width length of at

(2.8°C). least 1 yd (1 m) from the very outside of each roll.

TABLE 1 Human Tissue Tolerance to Pain Sensation

Heat Flux Total Heat Calorimeter Equivalent

Exposure

Time 2 2 2 2

cal/cm ·sec W/cm cal/cm ·s W sec/cm DT°, F DT°, C DmV

1.0 0.640 2.70 0.640 2.70 8.53 4.74 0.250

1.5 0.475 2.00 0.713 3.00 9.51 5.28 0.275

2.0 0.385 1.61 0.770 3.22 10.27 5.71 0.293

3.0 0.280 1.17 0.840 3.51 11.20 6.22 0.322

5.0 0.195 0.82 0.975 4.08 13.00 7.22 0.375

7.0 0.155 0.65 1.085 4.54 14.47 8.04 0.420

10.0 0.118 0.49 1.180 4.94 15.73 8.74 0.458

20.0 0.076 0.32 1.520 6.36 20.27 11.26 0.582

30.0 0.060 0.25 1.800 7.53 24.00 13.33 0.690

50.0 0.060 0.25 3.000 12.55 40.00 22.22 1.150

F 1060

A

TABLE 2 Human Tissue Tolerance to Second Degree Burn

B

Heat Flux Total Heat Calorimeter

Exposure Equivalent,

2 2 2 2

Time, s DmV

cal/cm ·s W/cm cal/cm ·s W/cm DT,° F DT, °C

(1) (2) (3) (4) (5) (6) (7) (8)

1 1.2 5.0 1.20 5.0 16.0 8.9 0.46

2 0.73 3.1 1.46 6.1 19.5 10.8 0.57

3 0.55 2.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.