ASTM E1781-98

(Practice)Standard Practice for Secondary Calibration of Acoustic Emission Sensors

Standard Practice for Secondary Calibration of Acoustic Emission Sensors

SCOPE

1.1 This practice covers requirements for the secondary calibration of acoustic emission (AE) sensors. The secondary calibration yields the frequency response of a sensor to waves of the type normally encountered in acoustic emission work. The source producing the signal used for the calibration is mounted on the same surface of the test block as the sensor under testing (SUT). Rayleigh waves are dominant under these conditions; the calibration results represent primarily the sensor's sensitivity to Rayleigh waves. The sensitivity of the sensor is determined for excitation within the range of 100 kHz to 1 MHz. Sensitivity values are usually determined at frequencies approximately 10 kHz apart. The units of the calibration are volts per unit of mechanical input (displacement, velocity, or acceleration).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1781 – 98

Standard Practice for

Secondary Calibration of Acoustic Emission Sensors

This standard is issued under the fixed designation E 1781; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 reference sensor (RS)—a sensor that has had its

response established by primary calibration (also called sec-

1.1 This practice covers requirements for the secondary

ondary standard transducer) (see Method E 1106).

calibration of acoustic emission (AE) sensors. The secondary

3.2.2 secondary calibration—a procedure for measuring the

calibration yields the frequency response of a sensor to waves

frequency or transient response of an AE sensor by comparison

of the type normally encountered in acoustic emission work.

with an RS.

The source producing the signal used for the calibration is

3.2.3 test block—a block of homogeneous, isotropic, elastic

mounted on the same surface of the test block as the sensor

material on which a source, an RS, and a SUT are placed for

under testing (SUT). Rayleigh waves are dominant under these

conducting secondary calibration.

conditions; the calibration results represent primarily the sen-

sor’s sensitivity to Rayleigh waves. The sensitivity of the

4. Significance and Use

sensor is determined for excitation within the range of 100 kHz

4.1 The purpose of this practice is to enable the transfer of

to 1 MHz. Sensitivity values are usually determined at frequen-

calibration from sensors that have been calibrated by primary

cies approximately 10 kHz apart. The units of the calibration

calibration to other sensors.

are volts per unit of mechanical input (displacement, velocity,

or acceleration).

5. General Requirements

1.2 The values stated in SI units are to be regarded as the

5.1 Units for Calibration—Secondary calibration produces

standard. The values given in parentheses are for information

the same type of information regarding a sensor as does

only.

primary calibration (Method E 1106). An AE sensor responds

1.3 This standard does not purport to address all of the

to motion at its front face. The actual stress and strain at the

safety concerns, if any, associated with its use. It is the

front face of a mounted sensor depends on the interaction

responsibility of the user of this standard to establish appro-

between the mechanical impedance of the sensor (load) and

priate safety and health practices and determine the applica-

that of the mounting block (driver); neither the stress nor the

bility of regulatory limitations prior to use.

strain is amenable to direct measurement at this location.

2. Referenced Documents However, the free displacement that would occur at the surface

of the block in the absence of the sensor can be inferred from

2.1 ASTM Standards:

measurements made elsewhere on the surface. Since AE

E 114 Practice for Ultrasonic Pulse-Echo Straight-Beam

2 sensors are used to monitor motion at a free surface of a

Examination by the Contact Method

structure and interactive effects between the sensor and the

E 494 Practice for Measuring Ultrasonic Velocity in Mate-

2 structure are generally of no interest, the free motion is the

rials

appropriate input variable. It is therefore required that the units

E 1106 Method for Primary Calibration of Acoustic Emis-

2 of calibration shall be volts per unit of free displacement or free

sion Sensors

velocity, that is, volts per metre or volt seconds per metre.

E 1316 Terminology for Nondestructive Examinations

5.2 The calibration results may be expressed, in the fre-

3. Terminology quency domain, as the steady-state magnitude and phase

response of the sensor to steady-state sinusoidal excitation or,

3.1 Definitions—Refer to Terminology E 1316, Section B,

in the time domain, as the transient response of the sensor to a

for terms used in this practice.

delta function of displacement.

3.2 Definitions of Terms Specific to This Standard:

5.3 Importance of the Test Block Material—The specific

acoustical impedance (rc) of the test block is an important

This practice is under the jurisdiction of ASTM Committee E-7 on Nonde- parameter that affects calibration results. Calibrations per-

structive Testing and is the direct responsibility of Subcommittee E07.04 on

formed on blocks of different materials yield sensor sensitivi-

Acoustic Emission Method.

ties that are very different. For example, a sensor that has been

Current edition approved Dec. 10, 1998. Published February 1999. Originally

calibrated on a steel block, if calibrated on a glass or aluminum

published as E 1781–96. Last previous edition E 1781–96.

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1781–98

block, may have an average sensitivity that is 50 % of the value sensors themselves, and calibration results are stated in terms

obtained on steel and, if calibrated on a polymethyl methacry- of the free displacement of the block surface.

late block, may have an average sensitivity that is 3 % of the

6.2 Qualification of The Test Block—The prototype second-

value obtained on steel.

ary calibration apparatus was designed for sensors intended for

5.3.1 For a sensor having a circular aperture (mounting

use on steel. The test block is therefore made of steel (hot

face) with uniform sensitivity over the face, there are frequen-

rolled steel A36 material). For a steel block, it is recommended

cies at which nulls in the frequency response occur. These nulls

that specification to the metal supplier require that the block be

occur at the zeroes of the first order Bessel function, J (ka),

stress relieved at 566°C (1050°F) or greater and that the stress

where k =2pf/c, f = frequency, c = the Rayleigh speed in the

relief be conducted subsequent to any flame cutting.

test block, and a = the radius of the sensor face. Therefore,

6.2.1 For a steel test block, there must be two parallel faces

calibration results depend on the Rayleigh wave speed in the

with a thickness, measured between the faces, of at least 18 cm.

material of the test block.

The volume of the block must contain a cylinder that is 40 cm

5.3.2 For the reasons outlined in 5.3 and 5.3.1, all secondary

in diameter by 18-cm long, and the two faces must be flat and

calibration results are specific to a particular material; a

parallel to within 0.12-mm overall (60.06 mm).

secondary calibration procedure must specify the material of

6.2.2 For a steel test block, the top surface of the block (the

the block.

working face) must have a rMS roughness value no greater

than 1 μm (40 μin.), as determined by at least three profilometer

6. Requirements of the Secondary Calibration Apparatus

traces taken in the central region of the block. The bottom

6.1 Basic Scheme—A prototype apparatus for secondary

surface of the block must have a rMS roughness value no

calibration is shown in Fig. 1. A glass-capillary-break device or

greater than 4 μm (160 μin.). The reason for having a

other suitable source device (A) is deployed on the upper face

specification on the bottom surface is to ensure reasonable

of the steel test block (B). The RS (C) and the SUT (D) are

ability to perform time-of-flight measurements of the speed of

placed at equal distances from the source and in opposite

sound in the block.

directions from it. Because of the symmetry of the sensor

6.2.3 For blocks of materials other than steel, minimum

placement, the free surface displacements at the locations of

dimensional requirements, dimensional accuracies, and the

the RS and SUT are the same. Voltage transients from the two

roughness limitation must be scaled in proportion to the

sensors are recorded simultaneously by digital waveform

longitudinal sound speed in the block material relative to that

recorders (E) and processed by a computer.

in steel.

6.1.1 Actual dynamic displacements of the surface of the

6.2.4 The top face of the block shall be the working face on

test block at the locations of the RS and SUT may be different

which the source, RS, and SUT are located. These locations

because the RS and SUT may present different load imped-

shall be chosen near the center so as to maximize the distances

ances to the test block. However, consistent with the definitions

of source and receivers to the nearest edge of the face. For a

used for primary and secondary calibration, the loading effects

test block of any material, the distance from the source to the

of both sensors are considered to be characteristics of the

RS and the distance from the source to the SUT must each be

100 6 2 mm (the same as that specified for primary calibra-

tion).

Breckenridge, F. R., Proctor, T. M., Hsu, N. N., and Eitzen, D. G.,“ Some

6.2.5 The block must undergo longitudinal ultrasonic in-

Notions Concerning the Behavior of Transducers,” Progress in Acoustic Emission

spection for flaws at some frequency between 2 and 5 MHz.

III, Japanese Society of Nondestructive Inspection, 1986, pp. 675–684.

The guidelines of Practice E 114 should be followed. The block

Although this practice addresses secondary calibrations on test blocks of

different materials, the only existing primary calibrations are performed on steel test

must contain no flaws that give a reflection greater than 12 %

blocks. To establish a secondary calibration on another material would also require

of the first back wall reflection.

the establishment of a primary calibration for the same material.

6.2.6 The material of the block must be highly uniform, as

determined by pulse-echo, time-of-flight measurements of both

longitudinal and shear waves. These measurements must be

made through the block at a minimum of seven locations

spaced regularly over the surface. The recommended method

of measurement is pulse-echo overlap using precisely con-

trolled delays between sweeps. See Practice E 494. It is

recommended that the pulse-echo sensors have their main

resonances in the range between 2 and 5 MHz. For the seven

(or more) longitudinal measurements, the maximum difference

between the individual values of the measurements must be no

more than 0.3 % of the average value. The shear measurements

must satisfy the same criterion.

6.3 Source—The source used in the prototype secondary

FIG. 1 Schematic of the Prototype Secondary Calibration

calibration system is a breaking glass capillary. Capillaries are

Apparatus: A = a Capillary-Break Source, B = a 41 by 41 by

prepared by drawing down 6-mm pyrex tubing to a diameter of

19-cm Steel Block, C = the RS, D = the SUT, and E = the Two-

Channel Waveform Recorder System 0.1 to 0.25 mm. Source events are generated by squeezing the

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1781–98

capillary tubing against the test block using pressure from the ferred hold-down force is 9.8 N. These conditions are all the

side of a 4-mm diameter glass rod held in the hand. same as for primary calibration.

6.6 Data Recording and Processing Equipment—For meth-

6.3.1 In general, a secondary calibration source may be any

ods using transient sources, the instrumentation would include

small aperture device that can provide sufficient energy to

a computer and two synchronized transient recorders, one for

make the calibration measurements conveniently at all frequen-

the RS channel and one for the SUT channel. The transient

cies within the range of 100 kHz to 1 MHz. Depending on the

recorders must be capable of at least eight-bit accuracy and a

technique of the calibration, the source could be a transient

sampling rate of 20 MHz, or at least ten-bit accuracy and a

device such as a glass-capillary-break apparatus, a spark

apparatus, a pulse-driven transducer, or a continuous wave sampling rate of 10 MHz. They must each be capable of storing

data for a time record of at least 55 μs. The data are transferred

device such as a National Institute for Standards and Technol-

ogy (NIST) Conical Transducer driven by a tone burst genera- to the computer for processing and also stored on a permanent

device, for example, floppy disc, as a permanent record.

tor. If the RS and SUT are to be tested on the block sequentially

instead of simultaneously, then it must be established that the

7. Calibration Data Processing

source is repeatable within 2 %.

7.1 Raw Data—In the prototype secondary calibration sys-

6.4 Reference Sensor—The RS in the prototype secondary

tem, the triggering event is the Rayleigh spike of the reference

calibration system is an NIST Conical Transducer.

channel. By means of pre-triggering, the data sequence in both

6.4.1 In general, the RS must have a frequency response, as

channels is made to begin 25 μs before the trigger event. The

determined by primary calibration, that is flat over the fre-

raw captured waveform record of one of the two channels

quency range of 100 kHz to 1 MHz within a total overall

comprises 2048 ten-bit data with a sampling interval t = 102.4

variation of 20 dB either as a velocity transducer or a

μs. Therefore, the total record has a length of T = 102.4 μs.

displacement transducer. It is preferred that the RS be of a type

Reflections from the bottom of the block appear approximately

that has a small aperture and that its frequency response be as

60 μs after the beginning of the record in both channels (see

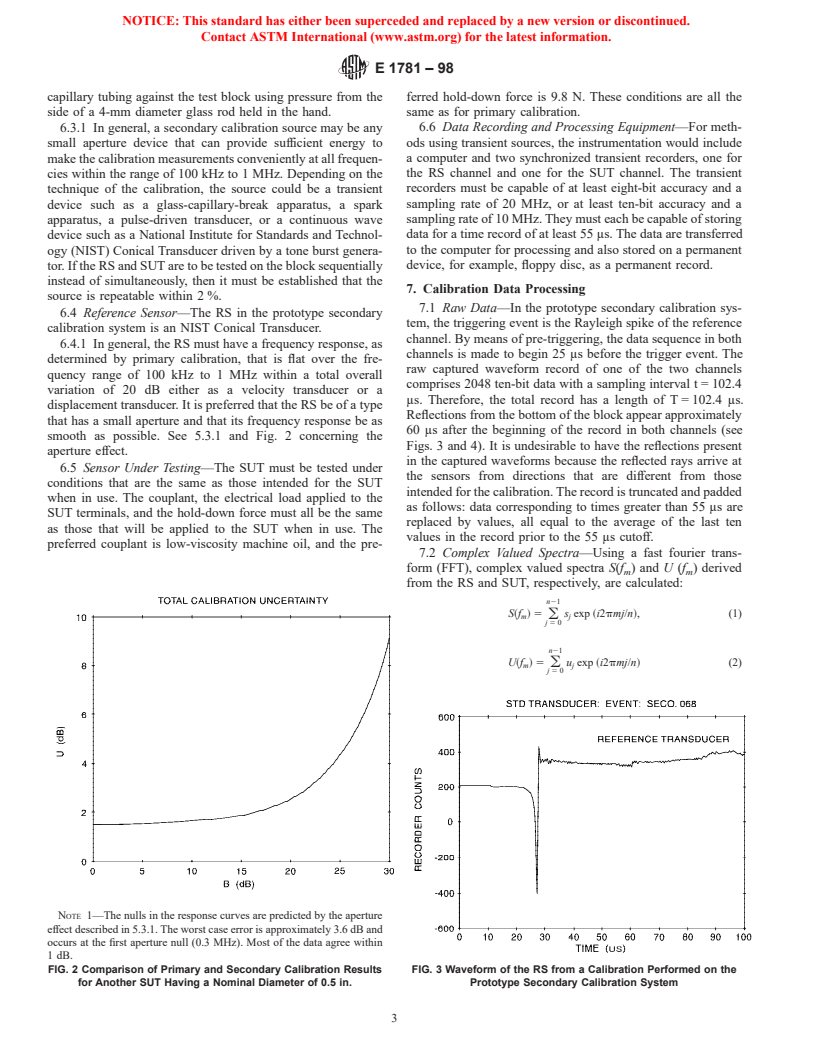

smooth as possible. See 5.3.1 and Fig. 2 concerning the

Figs. 3 and 4). It is undesirable to have the reflections present

aperture effect.

in the captured waveforms because the reflected rays arrive at

6.5 Sensor Under Testing—The SUT must be tested under

the sensors from directions that are different from those

conditions that are the same as those intended for the SUT

intended for the calibration. The record is truncated and padded

when in use. The couplant, the electrical load applied to the

as follows: data corresponding to times greater than 55 μs are

SUT terminals, and the hold-down force must all be the same

replaced by values, all equal to the average of the last ten

as those that will be applied to the SUT when in use. The

values in the record prior to the 55 μs cutoff.

preferred couplant is low-viscosity machine oil, and the pre-

7.2 Complex Valued Spectra—Using a fast fourie

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.