ASTM D5031-96

(Practice)Standard Practice for Enclosed Carbon-Arc Exposure Tests of Paint and Related Coatings

Standard Practice for Enclosed Carbon-Arc Exposure Tests of Paint and Related Coatings

SCOPE

1.1 This practice covers the selection of test conditions for accelerated exposure testing of coatings and related products in enclosed carbon arc devices operated according to Practices G 151 and G 153. This practice also covers the preparation of test specimens, the test conditions suited for coatings, and the evaluation of test results. describes commonly used test conditions.Note 1--Previous versions of this practice referenced carbon arc devices described by Practice G 23, which described very specific equipment designs. Practice G 23 has been withdrawn and replaced by Practice G 151, which describes performance criteria for all exposure devices that use laboratory light sources, and by Practice G 153, which gives requirements for exposing nonmetallic materials in enclosed carbon-arc devices.

1.2 This practice does not cover filtered open-flame carbon-arc exposures of paints and related coatings, which is described in Practice D 822. Another procedure for exposing these products is covered by Practice D 3361, in which the specimens are subjected to radiation from an unfiltered open-flame carbon arc that produces shorter wavelengths and higher levels of short wavelength radiation than filtered open flame or enclosed carbon arcs.Note 2--Practice D 3361 requires use of open-flame carbon-arc apparatus with automatic humidity control.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5031 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Conducting Tests on Paint and Related Coatings and

Materials Using Enclosed Carbon-Arc Exposure Apparatus

This standard is issued under the fixed designation D 5031; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

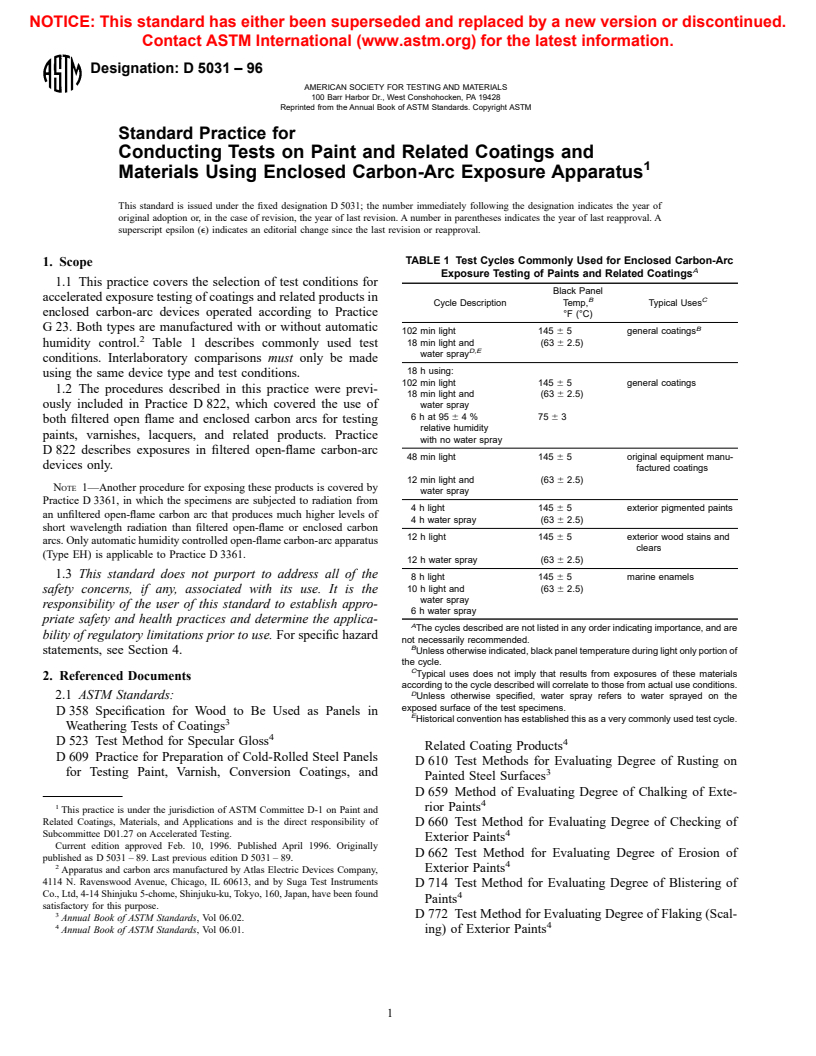

TABLE 1 Test Cycles Commonly Used for Enclosed Carbon-Arc

1. Scope

A

Exposure Testing of Paints and Related Coatings

1.1 This practice covers the selection of test conditions for

Black Panel

accelerated exposure testing of coatings and related products in

B C

Cycle Description Temp, Typical Uses

enclosed carbon-arc devices operated according to Practice °F (°C)

B

G 23. Both types are manufactured with or without automatic

102 min light 145 6 5 general coatings

18 min light and (63 6 2.5)

humidity control. Table 1 describes commonly used test

D,E

water spray

conditions. Interlaboratory comparisons must only be made

18 h using:

using the same device type and test conditions.

102 min light 145 6 5 general coatings

1.2 The procedures described in this practice were previ-

18 min light and (63 6 2.5)

ously included in Practice D 822, which covered the use of

water spray

6hat95 6 4% 75 6 3

both filtered open flame and enclosed carbon arcs for testing

relative humidity

paints, varnishes, lacquers, and related products. Practice

with no water spray

D 822 describes exposures in filtered open-flame carbon-arc

48 min light 145 6 5 original equipment manu-

devices only.

factured coatings

12 min light and (63 6 2.5)

NOTE 1—Another procedure for exposing these products is covered by

water spray

Practice D 3361, in which the specimens are subjected to radiation from

4 h light 145 6 5 exterior pigmented paints

an unfiltered open-flame carbon arc that produces much higher levels of

4 h water spray (63 6 2.5)

short wavelength radiation than filtered open-flame or enclosed carbon

12 h light 145 6 5 exterior wood stains and

arcs. Only automatic humidity controlled open-flame carbon-arc apparatus

clears

(Type EH) is applicable to Practice D 3361.

12 h water spray (63 6 2.5)

1.3 This standard does not purport to address all of the

8 h light 145 6 5 marine enamels

10 h light and (63 6 2.5)

safety concerns, if any, associated with its use. It is the

water spray

responsibility of the user of this standard to establish appro-

6 h water spray

priate safety and health practices and determine the applica-

A

The cycles described are not listed in any order indicating importance, and are

bility of regulatory limitations prior to use. For specific hazard

not necessarily recommended.

B

statements, see Section 4. Unless otherwise indicated, black panel temperature during light only portion of

the cycle.

C

Typical uses does not imply that results from exposures of these materials

2. Referenced Documents

according to the cycle described will correlate to those from actual use conditions.

D

2.1 ASTM Standards: Unless otherwise specified, water spray refers to water sprayed on the

exposed surface of the test specimens.

D 358 Specification for Wood to Be Used as Panels in

E

Historical convention has established this as a very commonly used test cycle.

Weathering Tests of Coatings

D 523 Test Method for Specular Gloss 4

Related Coating Products

D 609 Practice for Preparation of Cold-Rolled Steel Panels

D 610 Test Methods for Evaluating Degree of Rusting on

for Testing Paint, Varnish, Conversion Coatings, and 3

Painted Steel Surfaces

D 659 Method of Evaluating Degree of Chalking of Exte-

rior Paints

This practice is under the jurisdiction of ASTM Committee D-1 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of D 660 Test Method for Evaluating Degree of Checking of

Subcommittee D01.27 on Accelerated Testing.

Exterior Paints

Current edition approved Feb. 10, 1996. Published April 1996. Originally

D 662 Test Method for Evaluating Degree of Erosion of

published as D 5031 – 89. Last previous edition D 5031 – 89.

Exterior Paints

Apparatus and carbon arcs manufactured by Atlas Electric Devices Company,

4114 N. Ravenswood Avenue, Chicago, IL 60613, and by Suga Test Instruments

D 714 Test Method for Evaluating Degree of Blistering of

Co., Ltd, 4-14 Shinjuku 5-chome, Shinjuku-ku, Tokyo, 160, Japan, have been found

Paints

satisfactory for this purpose.

D 772 Test Method for Evaluating Degree of Flaking (Scal-

Annual Book of ASTM Standards, Vol 06.02.

4 4

Annual Book of ASTM Standards, Vol 06.01. ing) of Exterior Paints

D 5031

D 822 Practice for Conducting Tests on Paint and Related

Coatings and Materials using Filtered Open-Flame

Carbon-Arc Light and Water Exposure Apparatus

D 823 Practices for Producing Films of Uniform Thickness

of Paint, Varnish, and Related Products on Test Panels

D 1005 Test Methods for Measurement of Dry-Film Thick-

ness of Organic Coatings Using Micrometers

D 1186 Test Methods for Nondestructive Measurement of

Dry Film Thickness of Nonmagnetic Coatings Applied to

a Ferrous Base

D 1400 Test Method for Nondestructive Measurement of

Dry Film Thickness of Nonconductive Coatings Applied to

a Nonferrous Metal Base

D 1729 Practice for Visual Evaluation of Color Differences

of Opaque Materials

D 1730 Practices for Preparation of Aluminum and

Aluminum-Alloy Surfaces for Painting

NOTE 1—The enclosed carbon-arc irradiance was measured at the

D 2244 Test Method for Calculation of Color Differences

sample plane at a position centered between the two carbon arcs. Sunlight

from Instrumentally Measured Color Coordinates was measured in Phoenix, AZ, at the summer solstice with clear sky at

solor noon using a double grating monochromator (1-nm bandpass) with

D 2616 Test Method for Evaluation of Visual Color Differ-

a quartz cosine receptor on an equatorial follow-the-sun mount. Because

ence with a Gray Scale

of momentary fluctuations in intensity due to flickering of the carbon-arc

D 3361 Practice for Operating Light- and Water-Exposure

flame, the spectral power distribution shown in this figure is relative and

Apparatus (Unfiltered Open-Flame Carbon-Arc Type) for

is not to be used to calculate or estimate total radiant exposure for tests in

Testing Paint, Varnish, Lacquer, and Related Products

enclosed carbon-arc devices.

Using the Dew Cycle

FIG. 1 Representative Spectral Power Distributions (250–400 nm)

for Twin Enclosed Carbon Arcs and Terrestrial Sunlight

D 3980 Practice for Interlaboratory Testing of Paint and

Related Materials

D 4214 Test Methods for Evaluating Degree of Chalking of

Exterior Paint Films

E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of Test Methods

E 1347 Test Method for Color and Color Difference Mea-

sured by Tristimulus (filter) Colorimetry

G 23 Practice for Operating Light- and Water-Exposure

Apparatus (Carbon-Arc Type) With and Without Water for

Exposure of Nonmetallic Materials

G 113 Terminology Relating to Natural and Artificial

Weathering Tests of Nonmetallic Materials

3. Terminology

3.1 The definitions given in Terminology standard G113 are

applicable to this practice.

4. Significance and Use

NOTE 1—Measurements were made as described in Fig. 1. Because of

4.1 Organic coatings on exterior exposure are subjected to

momentary fluctuations in intensity due to flickering of the carbon-arc

attack by degrading elements of the weather, particularly

flame, the spectral power distribution shown in this figure is representative

ultraviolet light, oxygen, and water. This practice is intended to and is not meant to be used to calculate or estimate total radiant exposure

for tests in enclosed carbon-arc devices.

evaluate coating films for their stability in an apparatus that

FIG. 2 Representative Spectral Power Distributions (300–350 nm)

exposes specimens to ultraviolet (UV) light, heat, and mois-

for Twin Enclosed Carbon Arcs and Terrestrial Sunlight

ture. If the spectral power distribution of the light source used

for exposure tests does not adequately simulate that of terres-

4.1.1 Exposures in enclosed carbon-arc devices have been

trial solar radiation, it may produce a different type of

historically used to simulate the effects of terrestrial sunlight.

degradation and distort the ranking of materials obtained in

As shown in Fig. 1 and Fig. 2, the UV spectral power

outdoor exposures. Fig. 1 and Fig. 2 compare representative

distribution of the light from these devices is significantly

spectral power distributions of the enclosed carbon-arc with

different from that of terrestrial sunlight. The primary emission

that of terrestrial sunlight.

of the enclosed carbon-arc produces is in two relatively narrow

peaks between 350 and 400 nm. The intensity of the enclosed

carbon arc is less than that of terrestrial solar radiation at

Annual Book of ASTM Standards, Vol 02.05.

Annual Book of ASTM Standards, Vol 14.02. virtually all other wavelengths.

D 5031

4.1.2 The spectral power distribution of light from an tified so that statistically significant pass/fail judgments can be

enclosed carbon-arc is significantly different from that pro- made.

duced in light and water exposure devices using open-flame 4.5 It is strongly recommended that at least one control

carbon-arcs or other light sources. The rate and type of material be exposed with each test for the purpose of compar-

degradation produced in exposures to enclosed carbon-arcs can ing the performance of the test materials relative to that of the

be much different from that produced in exposures to other control. The control material should be of similar composition

types of laboratory light sources. and construction and be chosen so that its failure modes are the

4.2 No artificial exposure test can be specified as a complete same as that of the coating material being tested. It is

simulation of actual use conditions in outdoor environments. preferable to use two control materials, one with relatively

Results obtained from exposures conducted according to this good durability and one with relatively poor durability.

practice may be considered as representative of actual outdoor 4.6 All references to exposures in accordance with this

exposures only when the degree of rank correlation has been practice must include a complete description of the test cycle

established for the specific materials being tested. The relative used in addition to the type of device used.

durability of materials in actual outdoor service can be very

5. Apparatus

different in different locations because of differences in UV

radiation, time of wetness, temperature, pollutants, and other 5.1 Enclosed Carbon-Arc Device, that meets the require-

factors. Therefore, even if results from a specific artificial test

ments of Practice G 23.

conducted according to this practice are found to be useful for

6. Hazards

comparing the relative durability of materials exposed in a

particular exterior environment, it cannot be assumed that they

6.1 Precaution—In addition to other precautions, never

will be useful for determining relative durability for a different

look directly at the carbon arc because ultraviolet radiation can

environment.

damage the eye. Most carbon-arc machines are equipped with

4.3 Even though it is very tempting, calculation of an“

door safety switches, but users of old equipment must be

acceleration factor” relating “x” hours of exposures in a

certain to turn the OPERATE switch OFF before opening the

laboratory accelerated test to “y” months or years of exterior

test-chamber door.

exposure or actual use conditions is not recommended. Differ-

6.2 The burning carbon rods used in these devices become

ent materials and formulations of the same material can have

very hot during use. Make sure to allow at least 15 min for the

significantly different acceleration factors. The acceleration

arcs to cool after the device is turned off before attempting to

factor calculated also varies depending on the variability in rate

change the carbon rods.

of degradation in the laboratory accelerated test and in outdoor

6.3 Carbon residue and ash are known respiratory irritants.

or actual use exposures.

Wear an appropriate high efficiency dust respirator, gloves, and

4.3.1 Although the use of an acceleration factor is not

safety glasses when handling or changing carbon rods. Make

recommended, laboratories that calculate such a factor for a

sure to wash any carbon residue from hands or arms prior to

particular material shall base their findings on data from a

eating or drinking.

sufficient number of separate exterior and artificial exposures

so that results used to relate times to failure in each exposure 7. Test Specimens

can be analyzed using statistical methods. It must be noted

7.1 Apply the coating to flat (plane) panels with the sub-

that any acceleration factor is specific to the material and

strate, method of preparation, method of application, coating

formulation tested and cannot be extrapolated to other materi-

system, film thickness, and method of drying consistent with

als or formulations. In addition, use of an acceleration factor

the anticipated end use, or as mutually agreed upon between

assumes that the degradation mechanism is the same in both

the producer and user.

exterior and artificial exposures. It is important to note that

7.2 Panel specifications and methods of preparation include

exterior exposure and artificial exposure degradation mecha-

but are not limited to Practice D 609, Specification D 358, or

nisms can be different.

Practices D 1730. Select panel sizes suitable for use with the

4.4 This practice is best used to compare the relative

exposure apparatus.

performance of materials tested at the same time in the same

7.3 Coat test panels in accordance with Test Methods D 823

exposure device. Because of possible variability between the

and measure the film thickness in accordance with an appro-

same type of exposure devices, comparing the amount of

priate procedure selected from Test Methods D 1005, D 1186,

degradation in materials exposed for the same duration or

or D 1400. Nondestructive methods are preferred because

radiant energy at separate times, or in separate devices running

panels so measured need not be repaired.

the same test condition, is not recommended. This practice

7.4 Prior to exposing coated panels in the apparatus, condi-

should not be used to establish a “pass

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.