ASTM C696-99

(Test Method)Standard Test Methods for Chemical, Mass Spectrometric, and Spectrochemical Analysis of Nuclear-Grade Uranium Dioxide Powders and Pellets

Standard Test Methods for Chemical, Mass Spectrometric, and Spectrochemical Analysis of Nuclear-Grade Uranium Dioxide Powders and Pellets

SCOPE

1.1 These test methods cover procedures for the chemical, mass spectrometric, and spectrochemical analysis of nuclear-grade uranium dioxide powders and pellets to determine compliance with specifications.

1.2 The analytical procedures appear in the following order: Sections Uranium by Ferrous Sulfate Reduction in Phosphoric Acid and 7 to 15 Dichromate Titration Method Uranium and Oxygen Uranium Atomic Ratio by the Ignition 16 to 22 (Gravimetric) Impurity Correction Method Carbon (Total) by Direct Combustion-Thermal Conductivity 23 to 32 Method Total Chlorine and Fluorine by Pyrohydrolysis Ion-Selective 33 to 39 Electrode Method Moisture by the Coulometric, Electrolytic Moisture Analyzer 40 to 47 Method Nitrogen by the Kjeldahl Method 48 to 55 Isotopic Uranium Composition by Multiple-Filament Surface- Ionization Mass Spectrometric Method Spectrochemical Determination of Trace Elements in High-Purity 56 to 63 Uranium Dioxide Silver, Spectrochemical Determination of, by Gallium Oxide 64 to 65 Carrier D-C Arc Technique Rare Earths by Copper Spark-Spectrochemical Method 66 to 75 Impurity Elements by a Spark-Source Mass Spectrographic 76 to 82 Method Surface Area by Nitrogen Absorption Method 83 to 89 Total Gas in Reactor-Grade Uranium Dioxide Pellets 90 to 97 Thorium and Rare Earth Elements by Spectroscopy 98 to 105 Hydrogen by Inert Gas Fusion 106 to 115 Uranium Isotopic Analysis by Mass Spectrometry 116 to 124

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C696–99

Standard Test Methods for

Chemical, Mass Spectrometric, and Spectrochemical

Analysis of Nuclear-Grade Uranium Dioxide Powders and

Pellets

This standard is issued under the fixed designation C696; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Sections

1.1 These test methods cover procedures for the chemical,

C 1413 Test Method for Isotopic Analysis of Hydroly-

mass spectrometric, and spectrochemical analysis of nuclear-

sed Uranium Hexafluoride and Uranyl Nitrate So-

lutions By Thermal Ionization Mass Spectrometry

grade uranium dioxide powders and pellets to determine

compliance with specifications.

2. Referenced Documents

1.2 Theanalyticalproceduresappearinthefollowingorder:

2.1 ASTM Standards:

Sections

C753 Specification for Nuclear-Grade, Sinterable Uranium

Uranium by Ferrous Sulfate Reduction in Phosphoric Dioxide Powder

Acid and Dichromate Titration Method

C761 Test Method for Chemical, Mass Spectrometric,

C 1267 Test Method for Uranium By Iron (II) Reduc-

Spectrochemical, Nuclear, and RadiochemicalAnalysis of

tion In Phosphoric Acid Followed By Chromium

(VI) Titration In The Presence of Vanadium

Uranium Hexafluoride

Uranium and Oxygen Uranium Atomic Ratio by the 7-13 3

C776 Specification for Sintered Uranium Dioxide Pellets

Ignition (Gravimetric) Impurity Correction Method

2 C1267 Test Method for Uranium By Iron (II) Reduction In

Carbon (Total) by Direct Combustion-Thermal Con-

ductivity Method

PhosphoricAcid Followed By Chromium (VI)Titration In

C 1408 Test Method for Carbon (Total) in Uranium 3

The Presence of Vanadium

Oxide Powders and Pellets By Direct Combustion-

C1287 Test Method for Determination of Impurities In

Infrared Detection Method

Total Chlorine and Fluorine by Pyrohydrolysis Ion- 14-20

Uranium Dioxide By Inductively Coupled Plasma Mass

Selective Electrode Method 3

Spectrometry

Moisture by the Coulometric, Electrolytic Moisture 21-28

C1347 PracticeforPreparationandDissolutionofUranium

Analyzer Method

Nitrogen by the Kjeldahl Method 29-36

Materials for Analysis

Isotopic Uranium Composition by Multiple-Filament

C1408 Test Method for Carbon (Total) in Uranium Oxide

Surface Ionization Mass Spectrometric Method

Powders and Pellets By Direct Combustion-Infrared De-

Spectrochemical Determination of Trace Elements in 37-44

High-Purity Uranium Dioxide

tection Method

Silver, Spectrochemical Determination of, by Gallium 45 to 46

C1413 Test Method for Isotopic Analysis of Hydrolysed

OxideCarrier D-C Arc Technique

Uranium Hexafluoride and Uranyl Nitrate Solutions By

Rare Earths by Copper Spark-Spectrochemical

Method

Thermal Ionization Mass Spectrometry

Impurity Elements by a Spark-Source Mass Spectro-

D1193 Specification for Reagent Water

graphic Method

C 761 Test Method for Chemical, Mass Spectromet- E 115 Practice for Photographic Processing in Optical

ric, Spectrochemical, Nuclear, and Radiochemical

Emission Spectrographic Analysis

Analysis of Uranium Hexafluoride

3 E116 Practice for Photographic Photometry by Spectro-

C 1287 Test Method for Determination of Impurities

In Uranium Dioxide By Inductively Coupled chemical Analysis

Plasma Mass Spectrometry

E130 Practice for Designation of Shapes and Sizes of

Surface Area by Nitrogen Absorption Method 47-53

2 Graphite Electrodes

Total Gas in Reactor-Grade Uranium Dioxide Pellets

Thorium and Rare Earth Elements by Spectroscopy E217 Test Method for Uranium by Controlled-Potential

Hydrogen by Inert Gas Fusion 54-63

Coulometry

Uranium Isotopic Analysis by Mass Spectrometry

Discontinued January 1999. See C696–80.

1 3

These test methods are under the jurisdiction of ASTM Committee C-26 on Annual Book of ASTM Standards, Vol 12.01.

Nuclear Fuel Cycle. Discontinued as of May 30, 1980.

Current edition approved Jan. 10, 1999. Published March 1999. Originally Annual Book of ASTM Standards, Vol 11.01.

{1 6

published as C696 – 72. Last previous edition C696 – 93 . Annual Book of ASTM Standards, Vol 03.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C696

E305 Practice for Establishing and Controlling Spectro- URANIUM BY FERROUS SULFATE REDUCTION IN

chemical Analytical Curves PHOSPHORIC ACID AND DICHROMATE

E402 TestMethodforSpectrographicAnalysisofUranium TITRATION METHOD

Oxide (U O ) by Gallium Oxide-Carrier Technique This Test method was discontinued in January 1999 and

3 8

replaced by Test method C1267.

3. Significance and Use

URANIUM AND OXYGEN TO URANIUM ATOMIC

3.1 Uranium dioxide is used as a nuclear-reactor fuel. In

RATIO BY THE IGNITION (GRAVIMETRIC)

order to be suitable for this purpose, the material must meet

IMPURITY CORRECTION METHOD

certain criteria for uranium content, stoichiometry, isotopic

composition, and impurity content. These test methods are

7. Scope

designed to show whether or not a given material meets the

specifications for these items as described in Specifications 7.1 This test method covers the determination of uranium

and the oxygen to uranium atomic ratio in nuclear-grade

C753 and C776.

3.1.1 An assay is performed to determine whether the uranium dioxide powder and pellets.

material has the minimum uranium content specified on a dry

8. Summary of Test Method

weight basis.

3.1.2 The stoichiometry of the oxide is useful for predicting

8.1 A weighed portion of UO is dried under reduced

its sintering behavior in the pellet production process.

pressure in a nitrogen atmosphere, desiccated, and weighed.

3.1.3 Determination of the isotopic content of the uranium

ThedriedoxideisthenconvertedtoU O byignitionat900°C

3 8

intheuraniumdioxidepowderismadetoestablishwhetherthe

(8, 9).

effective fissile content is in compliance with the purchaser’s

specifications. 9. Interferences

3.1.4 Impurity content is determined to ensure that the

9.1 The weight of U O is corrected for the nonvolatile

3 8

maximum concentration limit of certain impurity elements is

impurities present as determined by spectrographic analysis.

not exceeded. Determination of impurities is also required for

An extended ignition time may be required if significant

calculation of the equivalent boron content (EBC).

amounts of anions that are difficult to decompose are present.

4. Reagents

10. Apparatus

4.1 Purity of Reagents—Reagent grade chemicals shall be

10.1 Vacuum Oven, capable of maintaining and controlling

used in all tests. Unless otherwise indicated, it is intended that

temperatures to 180°C and equipped with double stopcocks

all reagents shall conform to the specifications of the Commit-

and a vacuum gage (range from 0 to 102 kPa (0 to 30 in. Hg)).

tee onAnalytical Reagents of theAmerican Chemical Society,

10.2 Drying Tower— Prepare a U-tube filled with a carbon

where such specifications are available. Other grades may be 9

dioxide absorbent and a suitable moisture absorbent, that is,

used, provided it is first ascertained that the reagent is of

anhydrous magnesium perchlorate Mg(ClO ) .

4 2

sufficiently high purity to permit its use without lessening the

10.3 MuffleFurnace,capableofmaintainingandcontrolling

accuracy of the determination.

temperatures to 1000°C.

4.2 Purity of Water— Unless otherwise indicated, refer-

ences to water shall be understood to mean reagent water

11. Procedure

conforming to Specification D1193.

11.1 Transfer approximately 5 to 10 g of UO powder or up

to 50 g of pellets to a tared platinum crucible and weigh to

5. Safety Precautions

within 0.1 mg.

5.1 Proper precautions should be taken to prevent inhala-

11.2 Place the crucible in a vacuum oven set at room

tion, or ingestion of uranium dioxide powders or dust during

temperature, seal the oven, and reduce the pressure to approxi-

grinding or handling operations.

mately 95 to 102 kPa (28 to 30 in. Hg).

11.3 Closethevacuumvalveandslowlyflushtheovenwith

6. Sampling

dry nitrogen.

6.1 Criteria for sampling this material are given in Specifi-

11.4 Close the nitrogen inlet and reduce the pressure to 95

cation C753 and Specification C776.

to 102 kPa (28 to 30 in. Hg). Repeat the nitrogen flush as in

6.2 Samples can be dissolved using the appropriate disso-

step 11.3 to give a total of three flushes.

lution techniques described in Practice C1347, but final

11.5 Closethenitrogeninletvalve,reducethepressureto95

determination of applicability must be made by the user.

to 102 kPa (28 to 30 in. Hg), set the temperature at 45°C for

powder samples or 160°C for pellets, and maintain these

conditions for 4 h. After 4 h of heating turn off the heat and

Annual Book of ASTM Standards, Vol 03.06.

allow the oven to cool to room temperature while under

Reagent Chemicals, American Chemical Society Specifications, American

reduced pressure.

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

MD. Ascarite has been found satisfactory for this purpose.

C696

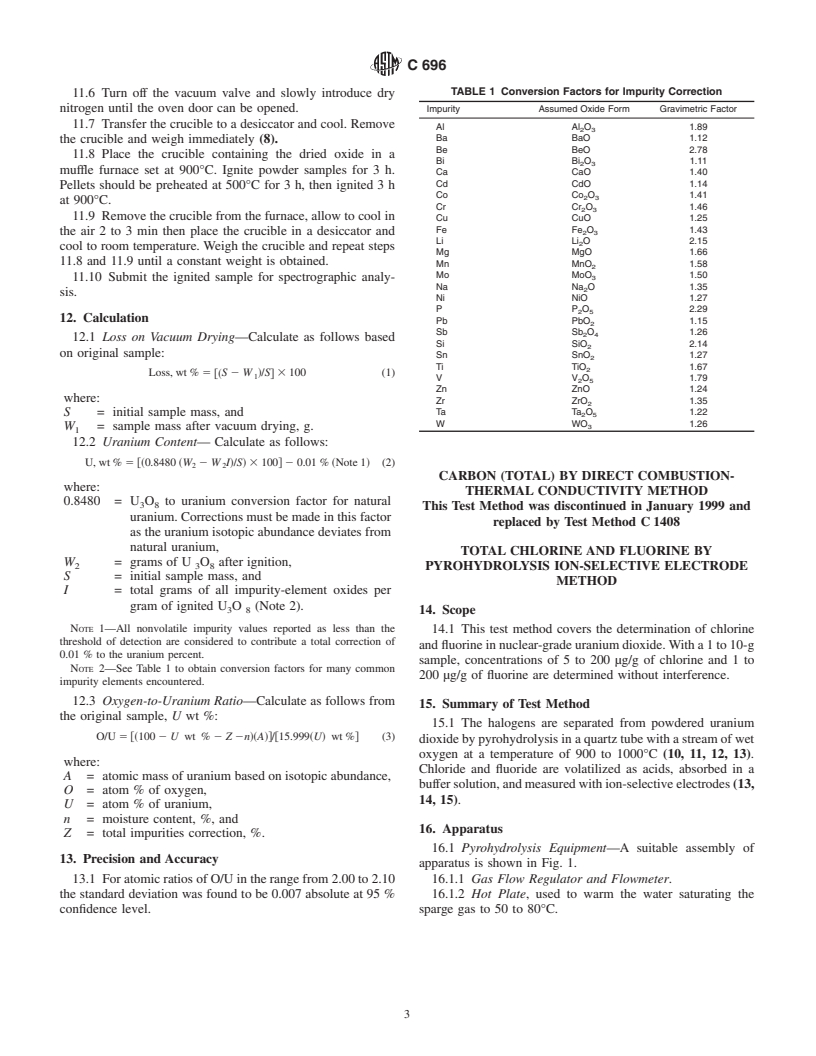

TABLE 1 Conversion Factors for Impurity Correction

11.6 Turn off the vacuum valve and slowly introduce dry

nitrogen until the oven door can be opened. Impurity Assumed Oxide Form Gravimetric Factor

11.7 Transfer the crucible to a desiccator and cool. Remove

Al Al O 1.89

2 3

Ba BaO 1.12

the crucible and weigh immediately (8).

Be BeO 2.78

11.8 Place the crucible containing the dried oxide in a

Bi Bi O 1.11

2 3

muffle furnace set at 900°C. Ignite powder samples for 3 h.

Ca CaO 1.40

Cd CdO 1.14

Pellets should be preheated at 500°C for 3 h, then ignited 3 h

Co Co O 1.41

2 3

at 900°C.

Cr Cr O 1.46

2 3

11.9 Remove the crucible from the furnace, allow to cool in

Cu CuO 1.25

Fe Fe O 1.43

2 3

the air 2 to 3 min then place the crucible in a desiccator and

Li Li O 2.15

cool to room temperature. Weigh the crucible and repeat steps

Mg MgO 1.66

11.8 and 11.9 until a constant weight is obtained.

Mn MnO 1.58

Mo MoO 1.50

11.10 Submit the ignited sample for spectrographic analy- 3

Na Na O 1.35

sis.

Ni NiO 1.27

PP O 2.29

2 5

12. Calculation

Pb PbO 1.15

Sb Sb O 1.26

2 4

12.1 Loss on Vacuum Drying—Calculate as follows based

Si SiO 2.14

on original sample:

Sn SnO 1.27

Ti TiO 1.67

Loss,wt% 5 @~S 2 W !/S# 3100 (1)

VV O 1.79

2 5

Zn ZnO 1.24

where:

Zr ZrO 1.35

Ta Ta O 1.22

S = initial sample mass, and 2 5

WWO 1.26

W = sample mass after vacuum drying, g.

12.2 Uranium Content— Calculate as follows:

U,wt% 5 @~0.8480 ~W 2 W I!/S! 3100# 20.01% ~Note1! (2)

2 2

CARBON (TOTAL) BY DIRECT COMBUSTION-

where:

THERMAL CONDUCTIVITY METHOD

0.8480 = U O to uranium conversion factor for natural

3 8

This Test Method was discontinued in January 1999 and

uranium.Correctionsmustbemadeinthisfactor

replaced by Test Method C1408

as the uranium isotopic abundance deviates from

natural uranium,

TOTAL CHLORINE AND FLUORINE BY

W = grams of U O after ignition,

2 3 8

PYROHYDROLYSIS ION-SELECTIVE ELECTRODE

S = initial sample mass, and

METHOD

I = total grams of all impurity-element oxides per

gram of ignited U O (Note 2).

3 8

14. Scope

NOTE 1—All nonvolatile impurity values reported as less than the

14.1 This test method covers the determination of chlorine

threshold of detection are considered to contribute a total correction of

andfluorineinnuclear-gradeuraniumdioxide.Witha1to10-g

0.01 % to the uranium percent.

sample, concentrations of 5 to 200 µg/g of chlorine and 1 to

NOTE 2—See Table 1 to obtain conversion factors for many common

200 µg/g of fluorine are determined without interference.

impurity elements encountered.

12.3 Oxygen-to-Uranium Ratio—Calculate as follows from

15. Summary of Test Method

the original sample, U wt %:

15.1 The halogens are separated from powdered uranium

O/U 5 @~100 2 U wt % 2 Z 2n!~A!#/@15.999~U! wt%# (3)

dioxidebypyrohydrolysisinaquartztubewithastreamofwet

oxygen at a temperature of 900 to 1000°C (10, 11, 12, 13).

where:

Chloride and fluoride are volatilized as acids, absorbed in a

A = atomic mass of uranium based on isotopic abundance,

buffersolution,andmeasuredwithion-selectiveelectrodes(13,

O = atom % of oxygen,

14, 15).

U = atom % of uranium,

n = moisture content, %, and

16. Apparatus

Z = total impurities correction, %.

16.1 Pyrohydrolysis Equipment—A suitable assembly of

13. Precision and Accuracy

apparatus is shown in Fig. 1.

13.1 ForatomicratiosofO/Uintherangefrom2.00to2.10 16.1.1 Gas Flow Regulator and Flowmeter.

the standard deviation was found to be 0.007 absolute at 95 % 16.1.2 Hot Plate, used to warm the water saturating the

confidence level. sparge gas to 50 to 80°C.

C696

FIG. 1 Pyrohydrolysis Apparatus

NOTE 3—Dehydrate 165 g of Na WO in a large platinum dish.

16.1.3 CombustionTubeFurnace,havingaboreofabout32

2 4

1 Transfer the dried material to a mortar, add 116 g of WO , and grind the

mm (1 ⁄4in.), a length of about 305 mm (12 in.), and the 3

mixture to ensure good mixing. Transfer the mixture into a platinum dish

capability of maintaining a temperature of 1000°C.

and heat with a burner for 2 h. Cool the melt, transfer the flux to a mortar

16.1.4 Quartz Reaction Tube (Fig. 2)—The exit end

andgrindtoacoarsepowder.Storethefluxinanairtightbottle.Mixabout

should not extend over 51 mm (2 in.) beyond the furnace with

8 g of flux with each portion of sample to be pyrohydrolyzed.

a ground joint connecting to the delivery tube. The delivery

17.2 Buffer Solution— Dissolve 0.1 g potassium acetate

tube extends into a polyethylene absorption vessel with a tip

(KC H O ) in water, add 0.050 mL of acetic acid (CH CO H,

2 3 2 3 2

capable of giving a stream of fine bubbles.

sp gr 1.05), and dilute to 1 litre.

16.1.5 Combustion Boat—Aplatinum or quartz boat with a

17.3 Chloride, Standard Solution (1 mL = 100 µg Cl)—

10-ml capacity (89 to 102 mm (3 ⁄2to 4 in.) long, 12.7 mm

Dissolve 165 mg of dry sodium chloride (NaCl) in water and

1 3

( ⁄2in.) wide, and 9.53 mm ( ⁄8 in.) high).

dilute to 1 litre.

16.1.6 Absorption Vessel—A 50-mL polyethylene graduate

17.4 Distilled Water— The water must be free of all

or tube is satisfactory.

chlorides and fluorides.

16.2 Ion-Specific Electrodes—A fluoride-specific activity

17.5 Fluoride, Standard Solution (1mL=50µgF)—

10 11

electrode ; chloride-specific electrode.

Dissolve 111 mg of sodium fluoride (NaF) in water and dilute

16.3 pH Meter and Double-Junction Reference Electrode,

to 1 lit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.