ASTM F2608-07(2014)

(Test Method)Standard Test Method for Determining the Change in Room Air Particulate Counts as a Result of the Vacuum Cleaning Process

Standard Test Method for Determining the Change in Room Air Particulate Counts as a Result of the Vacuum Cleaning Process

SIGNIFICANCE AND USE

4.1 In this test method, the amount of particulate generated into the air by operating a vacuum cleaner over a specific floor covering that is contaminated with dust will be determined. Particles from the motor, floor covering, and the test dust will all be measured. The amount of dust generated in the laboratory practice will differ from that in residential/commercial installations because of variations in floor coverings, soil and other solid particulate compositions, the vacuuming process used by individual operators, the air exchange rate of heating, ventilation, and air conditioning (HVAC) systems, and other factors.

4.2 To provide a uniform basis for measuring the performance in 4.1, a standardized test chamber, equipment, floor covering material, and dust particulate are used in this test method.

SCOPE

1.1 This test method provides a laboratory test for the measurement of particulate generated as a direct result of the vacuuming process.

1.2 This test method is applicable to all residential/commercial uprights, canisters, stickvacs, central vacuum systems, and combination cleaners.

1.3 This test method applies to test dust removal from floor coverings not the removal of surface litter and debris.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2608 − 07(Reapproved 2014) An American National Standard

Standard Test Method for

Determining the Change in Room Air Particulate Counts as

a Result of the Vacuum Cleaning Process

This standard is issued under the fixed designation F2608; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F1038Test Method for Motor Life Evaluation of a Canister,

Hand-held, Stick, and UtilityTypeVacuum CleanerWith-

1.1 This test method provides a laboratory test for the

out a Driven Agitator

measurement of particulate generated as a direct result of the

F1334Test Method for Determining A-Weighted Sound

vacuuming process.

Power Level of Vacuum Cleaners

1.2 This test method is applicable to all residential/

F1409Test Method for Straight Line Movement of Vacuum

commercial uprights, canisters, stickvacs, central vacuum

Cleaners While Cleaning Carpets

systems, and combination cleaners.

2.2 AHAM Standard:

1.3 This test method applies to test dust removal from floor

ANSI/AHAM AC-1-2006Test Method for Performance of

coverings not the removal of surface litter and debris. Portable Household Electric Room Air Cleaners

2.3 Other References:

1.4 The values stated in SI units are to be regarded as

IEC 60312Vacuum Cleaners for Household Use—Methods

standard. The values given in parentheses are for information

for Measuring the Performance

only.

Standard LaboratoryPractice for Quantifying Respirable

1.5 This test method may involve hazardous materials,

Particulate Emissions Generated by Residential/

operations, and equipment. This standard does not purport to

Commercial Vacuums and Central Vacuum Systems, Car-

address all of the safety concerns, if any, associated with its

pet and Rug Institute, 12/4/02

use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

3.1 Definitions:

3.1.1 model, n—designation of a group of vacuum cleaners

2. Referenced Documents

having identical mechanical and electrical construction with

2.1 ASTM Standards:

only cosmetic or nonfunctional differences.

F555Test Method for Motor Life Evaluation of an Upright

3.1.2 population, n—total of all units of a particular model

Vacuum Cleaner

vacuum cleaner being tested.

F608Test Method for Evaluation of Carpet Embedded Dirt

Removal Effectiveness of Household/Commercial 3.1.3 repeatability limit, n—value below which the absolute

Vacuum Cleaners difference between two individual test results obtained under

F655Specification for Test Carpets and Pads for Vacuum the repeatability condition may be expected to occur with a

Cleaner Testing probability of approximately 0.95 (95%).

F884Test Method for Motor Life Evaluation of a Built-In

3.1.4 test run, n—definitive procedure that produces a sin-

(Central Vacuum) Vacuum Cleaner

gular measured result.

F922Test Method for Motor Life Evaluation of an Electric

3.1.5 unit, n—single vacuum cleaner of the model being

Motorized Nozzle

tested.

4. Significance and Use

ThistestmethodisunderthejurisdictionofASTMCommitteeF11onVacuum

Cleaners and is the direct responsibility of Subcommittee F11.23 on Filtration. 4.1 In this test method, the amount of particulate generated

Current edition approved Oct. 1, 2014. Published October 2014. Originally

into the air by operating a vacuum cleaner over a specific floor

approved in 2007. Last previous edition approved in 2007 as F2608–07. DOI:

covering that is contaminated with dust will be determined.

10.1520/F2608-07R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from the Association of Home Appliance Manufacturers, 19th St.

the ASTM website. NW, Suite 402, Washington, DC 20036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2608 − 07 (2014)

Particles from the motor, floor covering, and the test dust will 5.2.6 Motor and Blower for Conditioning Loop—0.35-m /s

all be measured. The amount of dust generated in the labora- (750-ft /min) fan.

tory practice will differ from that in residential/commercial

5.2.7 Relative Humidity—50 65%.

installations because of variations in floor coverings, soil and

5.2.8 Temperature—21 6 1.5°C (70 6 5°F).

other solid particulate compositions, the vacuuming process

5.2.9 Chamber Sealing—Chamber sealing shall be verified

used by individual operators, the air exchange rate of heating,

as follows: Particulate level in the sealed room shall not rise

ventilation, and air conditioning (HVAC) systems, and other

above 1000 particles/ft at≥0.3 µm after 20 min of HEPAoff,

factors.

with the room static.

4.2 To provide a uniform basis for measuring the perfor-

5.3 Real-time aerosol particle counter in the range of 0.3 to

mance in 4.1, a standardized test chamber, equipment, floor

5 µm. A laser photometer may be used, in addition to the

covering material, and dust particulate are used in this test

particle counter, with a range of 0.1 to 1000 µg/m .

method.

5.4 Particulatesamplingpickoffprobeshallbe152.4 612.7

cm (60 6 5 in.) above the test carpet, facing up, on centerline

5. Apparatus

of carpet.

5.1 An air-conditioned laboratory at 21 6 –1.5°C

5.5 Weighing Scale (for Weighing Test Dirt), accurate to

(70 65°F) and 50% relative humidity 65% is to be used for

0.01g(0.000353oz)andhavingaweighingcapacityofatleast

sample preparation.

100 g (3.53 oz) for weighing the dust for embedding.

5.2 Environmentally Controlled Test Chamber (per ANSI/

5.6 Dirt Embedment Tool—Roller may be locked or un-

AHAM AC-1-2006):

locked (see Fig. 1).

5.2.1 Chamber Size—Nominal dimensions of 3.2 by 3.7 by

2.4 m (10.5 by 12 by 8 ft) up to a 20% difference in volume

5.7 Dirt Dispenser—Dispensing system that provides the

is permitted.

operator with a method to distribute the test dirt uniformly on

5.2.2 Framework—Standard 5.1 by 10.2 cm (2 by 4 in.) or

the carpet test area.

equivalent construction sealed to the floor line with caulking

5.8 Voltmeter, to measure input volts to the vacuum cleaner,

compound.

to provide measurements accurate within 61%.

5.2.3 Walls—Anyhard,cleanablesurface,suchaswallboard

(sealed with a washable latex semi-gloss paint) or stainless

5.9 Voltage-Regulator System, to control the input voltage

steel. Seal with caulking compound. to the vacuum cleaner. The regulator shall be capable of

5.2.4 Flooring—Any hard, seamless cleanable surface such maintaining the vacuum cleaner’s rated voltage 61% and

asseamlessfull-widthvinyl,stainlesssteel,orsealedconcrete. rated frequency having a wave form that is essentially sinusoi-

5.2.5 Filtration—HEPA filtration (>99.97% at 0.3 µm, 0.5 dal with 3% maximum harmonic distortion for the duration of

3 3

m /s (1000 ft /min) minimum). the test.

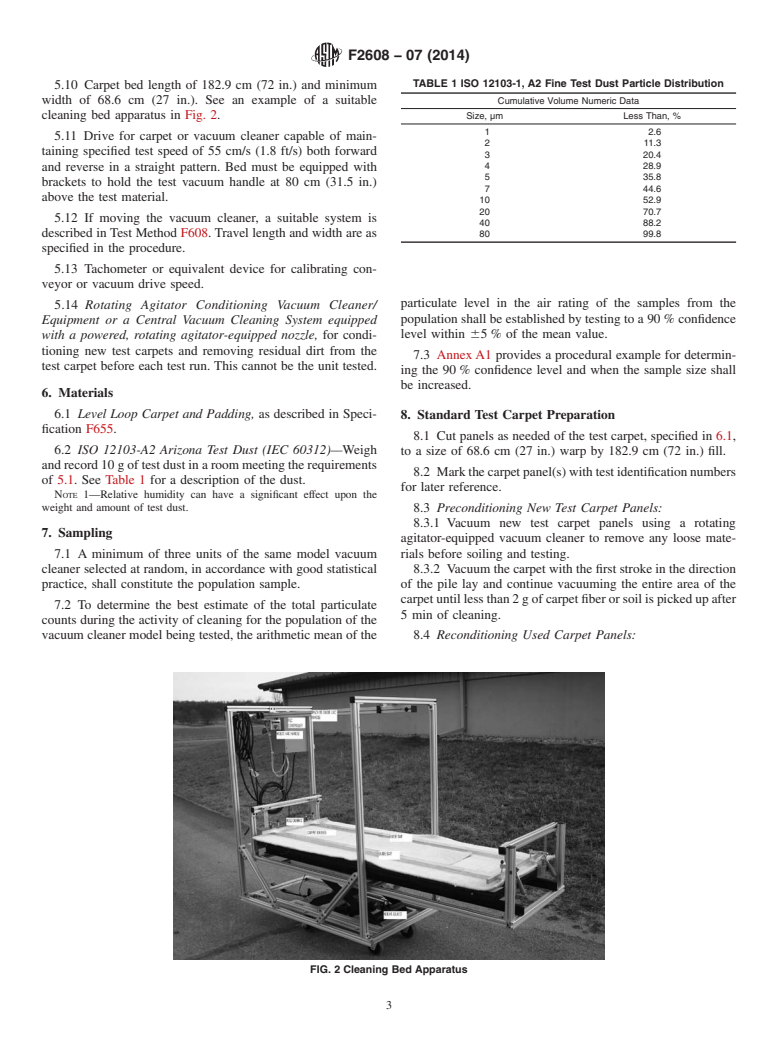

FIG. 1 Dirt Embedment Tool

F2608 − 07 (2014)

TABLE 1 ISO 12103-1, A2 Fine Test Dust Particle Distribution

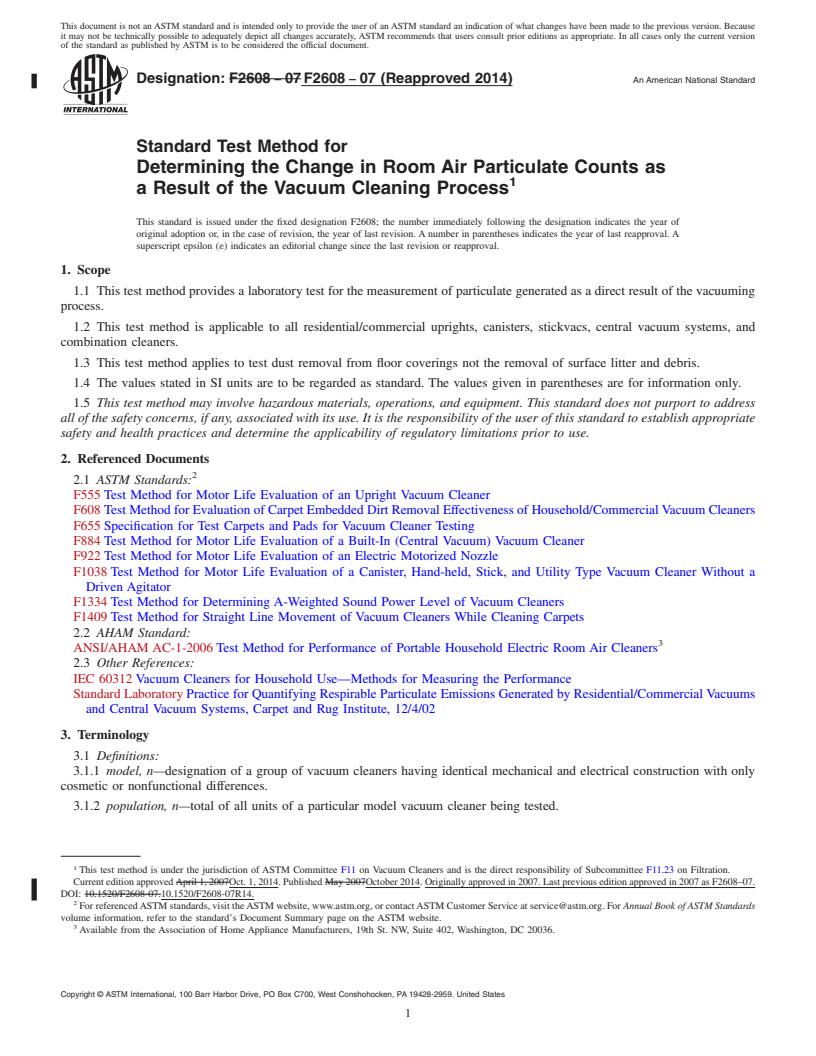

5.10 Carpet bed length of 182.9 cm (72 in.) and minimum

width of 68.6 cm (27 in.). See an example of a suitable Cumulative Volume Numeric Data

cleaning bed apparatus in Fig. 2. Size, µm Less Than, %

12.6

5.11 Drive for carpet or vacuum cleaner capable of main-

211.3

taining specified test speed of 55 cm/s (1.8 ft/s) both forward

3 20.4

4 28.9

and reverse in a straight pattern. Bed must be equipped with

5 35.8

brackets to hold the test vacuum handle at 80 cm (31.5 in.)

7 44.6

above the test material.

10 52.9

20 70.7

5.12 If moving the vacuum cleaner, a suitable system is

40 88.2

described inTest Method F608.Travel length and width are as 80 99.8

specified in the procedure.

5.13 Tachometer or equivalent device for calibrating con-

veyor or vacuum drive speed.

particulate level in the air rating of the samples from the

5.14 Rotating Agitator Conditioning Vacuum Cleaner/

populationshallbeestablishedbytestingtoa90%confidence

Equipment or a Central Vacuum Cleaning System equipped

level within 65% of the mean value.

with a powered, rotating agitator-equipped nozzle, for condi-

tioning new test carpets and removing residual dirt from the

7.3 AnnexA1 provides a procedural example for determin-

test carpet before each test run. This cannot be the unit tested.

ing the 90% confidence level and when the sample size shall

be increased.

6. Materials

6.1 Level Loop Carpet and Padding, as described in Speci-

8. Standard Test Carpet Preparation

fication F655.

8.1 Cut panels as needed of the test carpet, specified in 6.1,

6.2 ISO 12103-A2 Arizona Test Dust (IEC 60312)—Weigh

to a size of 68.6 cm (27 in.) warp by 182.9 cm (72 in.) fill.

andrecord10goftestdustinaroommeetingtherequirements

8.2 Markthecarpetpanel(s)withtestidentificationnumbers

of 5.1. See Table 1 for a description of the dust.

for later reference.

NOTE 1—Relative humidity can have a significant effect upon the

weight and amount of test dust.

8.3 Preconditioning New Test Carpet Panels:

8.3.1 Vacuum new test carpet panels using a rotating

7. Sampling

agitator-equipped vacuum cleaner to remove any loose mate-

7.1 A minimum of three units of the same model vacuum rials before soiling and testing.

cleaner selected at random, in accordance with good statistical 8.3.2 Vacuumthecarpetwiththefirststrokeinthedirection

practice, shall constitute the population sample. of the pile lay and continue vacuuming the entire area of the

carpetuntillessthan2gofcarpetfiberorsoilispickedupafter

7.2 To determine the best estimate of the total particulate

5 min of cleaning.

counts during the activity of cleaning for the population of the

vacuumcleanermodelbeingtested,thearithmeticmeanofthe 8.4 Reconditioning Used Carpet Panels:

FIG. 2 Cleaning Bed Apparatus

F2608 − 07 (2014)

8.4.1 Using the vacuum cleaner or a central vacuum clean- test system whenever the particle counts from reference and

ingsystemlistedin5.14,cleanthenentirecarpetareafor5min calibrationchecksoftestcarpetvaryfromthebaselinelevelby

using a stroke rate of 0.55 m/s (1.8 ft/s) in the direction of the 620%.

pile lay to ensure removal of all residual dust embedded in the

9. Test Chamber Setup and Conditioning

carpet. Clean the test chamber in accordance with 9.2.

9.1 All components involved in the test shall remain and be

8.5 Clean Carpet Particle Background Counts—Perform

exposed in the controlled environment for at least 16 h before

the following test to establish a baseline for clean carpet

the start of the test.

particle counts for use in referencing and calibration checks.

Thistestistobeperformedwhencarpetisnewandafterevery

9.2 Test Chamber Cleaning Procedure—Tobeperformedas

20 test runs. needed:

9.2.1 Using the vacuum cleaner or a central vacuum clean-

8.5.1 Position the test carpet on the supporting surface.

ing system listed in 5.14, clean all surfaces of the test chamber

8.5.2 Mark a baseline test area 40 by 102 cm (16 by 40 in.).

and equipment to remove all residual dust.

This area is based upon a standard nozzle width of 25 cm (10

9.2.2 Wipe down all surfaces of the test equipment with a

in.), plus an additional 7.6 cm (3 in.) per side. Nozzle width is

tack cloth or damp rag to remove any dust not removed by the

measured at the extreme outside dimension of the nozzle. For

vacuum cleaner.

nozzle widths exceeding 25 cm (10 in.), the test area width

shall be increased accordingly.

10. Vacuum Cleaners

8.5.3 Place the control vacuum cleaner with new bag and

10.1 New Test Vacuum Cleaners:

filters on the test carpet 10 to 15 cm (4 to 6 in.) in front of the

10.1.1 Preconditioning a New Test Vacuum Cleaner—Run

testarea.Setthedriveruntoincludecarpetanadditional10to

the vacuum cleaner in at rated voltage (61%) and frequency

15 cm (4 to 6 in.) after the test area as well.

(61 Hz) with filters in place for 1 h.

8.5.4 Exit the test chamber and initiate the particulate

10.1.1.1 Preconditioning Rotating Agitator-Type Vacuum

counter or photometer or both. Set the instrument(s) to take

Cleaner—In a stationary position, operate the vacuum cleaner

continuous readings throughout the duration of the test. The

for 1 h with the agitator bristles not engaged on any surface.

particle counter range sizes are 0.3, 0.5, and 1.0 µm (other

10.1.1.2 Preconditioning a Straight Air Canister Vacuum

particle size ranges are optional).

Cleaner—Operatethevacuumcleanerfor1hwithawide-open

8.5.5 Energize the chamber purge/room air purifier until the

inlet (without hose).

baseline particulate level is under 1000 particles/ft at 0.3 µm

and count variation is under 10% for 5 min at the 0.3-µm 10.2 Used Test Vacuum Cleaners:

10.2.1 Recondition a Used Vacuum Cleaner—Before each

range. For the photometer, the µg/m baseline should be less

than1µg/m ,withavariationoflessthan10%fromthemean. test run:

10.2.1.1 Thoroughly remove excess dirt from the vacuum

8.5.6 De-energize both the chamber purge/room air purifier

cleaner. Without using tools for disassembly, clean the entire

and room-conditioning equipment.

outersurface,brushes,nozzlechamber,ductwork,insideofthe

NOTE 2—Testing is to be conducted in a static environment.

chamber surrounding the primary filter, and inside hose and

wands.

8.5.7 Immediately energize vacuum and monitor particle

counts (and concentration if using photometer) for 10 min. A 10.2.1.2 For vacuum cleaners using disposable filters as the

primary filters, use a new disposable primary filter from the

hard surface or a method for raising the agitator off of the

carpet should be employed to protect the carpet during this manufacturer for each test.

10.2.1.3 For vacuum cleaners using non-disposable dirt

portion of the test. If a hard surface is employed it shall not be

receptacles, empty in accordance with the manufacturer’s

included in the test strokes.

instructions after each test run, clean the receptacle, and then

8.5.8 Set conveyor or vacuum stroke counter at the proper

installitasrecommendedbythevacuumcleanermanufacturer.

number of strokes to accomplish 10 min 6 5 s of back and

forth vacuuming at 55 cm/s (1.8 ft/s), then energize conveyor

NOTE4—Effectivenessofthiscleaningcanbeseenintheuniformityof

and continue to monitor particle counts (and concentration if the successive runs.

using photometer).

10.3 Test Vacuum Cleaner Settings—If various settings are

8.5.9 At the conclusion of 10 min of vacuuming, de-

provided, set the motor speed setting, suction regulator, nozzle

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2608 − 07 F2608 − 07 (Reapproved 2014) An American National Standard

Standard Test Method for

Determining the Change in Room Air Particulate Counts as

a Result of the Vacuum Cleaning Process

This standard is issued under the fixed designation F2608; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides a laboratory test for the measurement of particulate generated as a direct result of the vacuuming

process.

1.2 This test method is applicable to all residential/commercial uprights, canisters, stickvacs, central vacuum systems, and

combination cleaners.

1.3 This test method applies to test dust removal from floor coverings not the removal of surface litter and debris.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address

all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

F555 Test Method for Motor Life Evaluation of an Upright Vacuum Cleaner

F608 Test Method for Evaluation of Carpet Embedded Dirt Removal Effectiveness of Household/Commercial Vacuum Cleaners

F655 Specification for Test Carpets and Pads for Vacuum Cleaner Testing

F884 Test Method for Motor Life Evaluation of a Built-In (Central Vacuum) Vacuum Cleaner

F922 Test Method for Motor Life Evaluation of an Electric Motorized Nozzle

F1038 Test Method for Motor Life Evaluation of a Canister, Hand-held, Stick, and Utility Type Vacuum Cleaner Without a

Driven Agitator

F1334 Test Method for Determining A-Weighted Sound Power Level of Vacuum Cleaners

F1409 Test Method for Straight Line Movement of Vacuum Cleaners While Cleaning Carpets

2.2 AHAM Standard:

ANSI/AHAM AC-1-2006 Test Method for Performance of Portable Household Electric Room Air Cleaners

2.3 Other References:

IEC 60312 Vacuum Cleaners for Household Use—Methods for Measuring the Performance

Standard Laboratory Practice for Quantifying Respirable Particulate Emissions Generated by Residential/Commercial Vacuums

and Central Vacuum Systems, Carpet and Rug Institute, 12/4/02

3. Terminology

3.1 Definitions:

3.1.1 model, n—designation of a group of vacuum cleaners having identical mechanical and electrical construction with only

cosmetic or nonfunctional differences.

3.1.2 population, n—total of all units of a particular model vacuum cleaner being tested.

This test method is under the jurisdiction of ASTM Committee F11 on Vacuum Cleaners and is the direct responsibility of Subcommittee F11.23 on Filtration.

Current edition approved April 1, 2007Oct. 1, 2014. Published May 2007October 2014. Originally approved in 2007. Last previous edition approved in 2007 as F2608–07.

DOI: 10.1520/F2608-07.10.1520/F2608-07R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from the Association of Home Appliance Manufacturers, 19th St. NW, Suite 402, Washington, DC 20036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2608 − 07 (2014)

3.1.3 repeatability limit, n—value below which the absolute difference between two individual test results obtained under the

repeatability condition may be expected to occur with a probability of approximately 0.95 (95 %).

3.1.4 test run, n—definitive procedure that produces a singular measured result.

3.1.5 unit, n—single vacuum cleaner of the model being tested.

4. Significance and Use

4.1 In this test method, the amount of particulate generated into the air by operating a vacuum cleaner over a specific floor

covering that is contaminated with dust will be determined. Particles from the motor, floor covering, and the test dust will all be

measured. The amount of dust generated in the laboratory practice will differ from that in residential/commercial installations

because of variations in floor coverings, soil and other solid particulate compositions, the vacuuming process used by individual

operators, the air exchange rate of heating, ventilation, and air conditioning (HVAC) systems, and other factors.

4.2 To provide a uniform basis for measuring the performance in 4.1, a standardized test chamber, equipment, floor covering

material, and dust particulate are used in this test method.

5. Apparatus

5.1 An air-conditioned laboratory at 21 6 –1.5°C (70 6 5°F) and 50 % relative humidity 65 % is to be used for sample

preparation.

5.2 Environmentally Controlled Test Chamber (per ANSI/AHAM AC-1-2006):

5.2.1 Chamber Size—Nominal dimensions of 3.2 by 3.7 by 2.4 m (10.5 by 12 by 8 ft) up to a 20 % difference in volume is

permitted.

5.2.2 Framework—Standard 5.1 by 10.2 cm (2 by 4 in.) or equivalent construction sealed to the floor line with caulking

compound.

5.2.3 Walls—Any hard, cleanable surface, such as wallboard (sealed with a washable latex semi-gloss paint) or stainless steel.

Seal with caulking compound.

5.2.4 Flooring—Any hard, seamless cleanable surface such as seamless full-width vinyl, stainless steel, or sealed concrete.

3 3

5.2.5 Filtration—HEPA filtration (>99.97 % at 0.3 μm, 0.5 m /s (1000 ft /min) minimum).

3 3

5.2.6 Motor and Blower for Conditioning Loop—0.35-m /s (750-ft /min) fan.

5.2.7 Relative Humidity—50 6 5 %.

5.2.8 Temperature—21 6 1.5°C (70 6 5°F).

5.2.9 Chamber Sealing—Chamber sealing shall be verified as follows: Particulate level in the sealed room shall not rise above

1000 particles/ft at ≥0.3 μm after 20 min of HEPA off, with the room static.

5.3 Real-time aerosol particle counter in the range of 0.3 to 5 μm. A laser photometer may be used, in addition to the particle

counter, with a range of 0.1 to 1000 μg/m .

5.4 Particulate sampling pickoff probe shall be 152.4 6 12.7 cm (60 6 5 in.) above the test carpet, facing up, on centerline of

carpet.

5.5 Weighing Scale (for Weighing Test Dirt), accurate to 0.01 g (0.000353 oz) and having a weighing capacity of at least 100

g (3.53 oz) for weighing the dust for embedding.

5.6 Dirt Embedment Tool—Roller may be locked or unlocked (see Fig. 1).

5.7 Dirt Dispenser—Dispensing system that provides the operator with a method to distribute the test dirt uniformly on the

carpet test area.

5.8 Voltmeter, to measure input volts to the vacuum cleaner, to provide measurements accurate within 61 %.

5.9 Voltage-Regulator System, to control the input voltage to the vacuum cleaner. The regulator shall be capable of maintaining

the vacuum cleaner’s rated voltage 61 % and rated frequency having a wave form that is essentially sinusoidal with 3 % maximum

harmonic distortion for the duration of the test.

5.10 Carpet bed length of 182.9 cm (72 in.) and minimum width of 68.6 cm (27 in.). See an example of a suitable cleaning bed

apparatus in Fig. 2.

5.11 Drive for carpet or vacuum cleaner capable of maintaining specified test speed of 55 cm/s (1.8 ft/s) both forward and

reverse in a straight pattern. Bed must be equipped with brackets to hold the test vacuum handle at 80 cm (31.5 in.) above the test

material.

5.12 If moving the vacuum cleaner, a suitable system is described in Test Method F608. Travel length and width are as specified

in the procedure.

5.13 Tachometer or equivalent device for calibrating conveyor or vacuum drive speed.

F2608 − 07 (2014)

FIG. 1 Dirt Embedment Tool

FIG. 2 Cleaning Bed Apparatus

5.14 Rotating Agitator Conditioning Vacuum Cleaner/Equipment or a Central Vacuum Cleaning System equipped with a

powered, rotating agitator-equipped nozzle, for conditioning new test carpets and removing residual dirt from the test carpet before

each test run. This cannot be the unit tested.

6. Materials

6.1 Level Loop Carpet and Padding, as described in Specification F655.

6.2 ISO 12103-A2 Arizona Test Dust (IEC 60312)—Weigh and record 10 g of test dust in a room meeting the requirements of

5.1. See Table 1 for a description of the dust.

NOTE 1—Relative humidity can have a significant effect upon the weight and amount of test dust.

7. Sampling

7.1 A minimum of three units of the same model vacuum cleaner selected at random, in accordance with good statistical

practice, shall constitute the population sample.

F2608 − 07 (2014)

TABLE 1 ISO 12103-1, A2 Fine Test Dust Particle Distribution

Cumulative Volume Numeric Data

Size, μm Less Than, %

1 2.6

2 11.3

3 20.4

4 28.9

5 35.8

7 44.6

10 52.9

20 70.7

40 88.2

80 99.8

7.2 To determine the best estimate of the total particulate counts during the activity of cleaning for the population of the vacuum

cleaner model being tested, the arithmetic mean of the particulate level in the air rating of the samples from the population shall

be established by testing to a 90 % confidence level within 65 % of the mean value.

7.3 Annex A1 provides a procedural example for determining the 90 % confidence level and when the sample size shall be

increased.

8. Standard Test Carpet Preparation

8.1 Cut panels as needed of the test carpet, specified in 6.1, to a size of 68.6 cm (27 in.) warp by 182.9 cm (72 in.) fill.

8.2 Mark the carpet panel(s) with test identification numbers for later reference.

8.3 Preconditioning New Test Carpet Panels:

8.3.1 Vacuum new test carpet panels using a rotating agitator-equipped vacuum cleaner to remove any loose materials before

soiling and testing.

8.3.2 Vacuum the carpet with the first stroke in the direction of the pile lay and continue vacuuming the entire area of the carpet

until less than 2 g of carpet fiber or soil is picked up after 5 min of cleaning.

8.4 Reconditioning Used Carpet Panels:

8.4.1 Using the vacuum cleaner or a central vacuum cleaning system listed in 5.14, clean then entire carpet area for 5 min using

a stroke rate of 0.55 m/s (1.8 ft/s) in the direction of the pile lay to ensure removal of all residual dust embedded in the carpet.

Clean the test chamber in accordance with 9.2.

8.5 Clean Carpet Particle Background Counts—Perform the following test to establish a baseline for clean carpet particle

counts for use in referencing and calibration checks. This test is to be performed when carpet is new and after every 20 test runs.

8.5.1 Position the test carpet on the supporting surface.

8.5.2 Mark a baseline test area 40 by 102 cm (16 by 40 in.). This area is based upon a standard nozzle width of 25 cm (10 in.),

plus an additional 7.6 cm (3 in.) per side. Nozzle width is measured at the extreme outside dimension of the nozzle. For nozzle

widths exceeding 25 cm (10 in.), the test area width shall be increased accordingly.

8.5.3 Place the control vacuum cleaner with new bag and filters on the test carpet 10 to 15 cm (4 to 6 in.) in front of the test

area. Set the drive run to include carpet an additional 10 to 15 cm (4 to 6 in.) after the test area as well.

8.5.4 Exit the test chamber and initiate the particulate counter or photometer or both. Set the instrument(s) to take continuous

readings throughout the duration of the test. The particle counter range sizes are 0.3, 0.5, and 1.0 μm (other particle size ranges

are optional).

8.5.5 Energize the chamber purge/room air purifier until the baseline particulate level is under 1000 particles/ft at 0.3 μm and

3 3

count variation is under 10 % for 5 min at the 0.3-μm range. For the photometer, the μg/m baseline should be less than 1 μg/m ,

with a variation of less than 10 % from the mean.

8.5.6 De-energize both the chamber purge/room air purifier and room-conditioning equipment.

NOTE 2—Testing is to be conducted in a static environment.

8.5.7 Immediately energize vacuum and monitor particle counts (and concentration if using photometer) for 10 min. A hard

surface or a method for raising the agitator off of the carpet should be employed to protect the carpet during this portion of the

test. If a hard surface is employed it shall not be included in the test strokes.

8.5.8 Set conveyor or vacuum stroke counter at the proper number of strokes to accomplish 10 min 6 5 s of back and forth

vacuuming at 55 cm/s (1.8 ft/s), then energize conveyor and continue to monitor particle counts (and concentration if using

photometer).

8.5.9 At the conclusion of 10 min of vacuuming, de-energize the conveyor with the vacuum in its original position, then

de-energize the vacuum.

F2608 − 07 (2014)

NOTE 3—For products employing a soft dust bag, emissions generated due to bag collapse (“blow-back”) when powering down will be monitored and

captured during the settling period of this test.

8.5.10 Record the photometer readings (if used) and particle counts from step 8.5.7 for the 0.3, 0.5, and 1.0 μm particle size

ranges. This information will act as a baseline for reference and calibration checks after every 20 test runs performed on the test

carpet. Replace carpeting or evaluate potential problems with test system whenever the particle counts from reference and

calibration checks of test carpet vary from the baseline level by 620 %.

9. Test Chamber Setup and Conditioning

9.1 All components involved in the test shall remain and be exposed in the controlled environment for at least 16 h before the

start of the test.

9.2 Test Chamber Cleaning Procedure—To be performed as needed:

9.2.1 Using the vacuum cleaner or a central vacuum cleaning system listed in 5.14, clean all surfaces of the test chamber and

equipment to remove all residual dust.

9.2.2 Wipe down all surfaces of the test equipment with a tack cloth or damp rag to remove any dust not removed by the vacuum

cleaner.

10. Vacuum Cleaners

10.1 New Test Vacuum Cleaners:

10.1.1 Preconditioning a New Test Vacuum Cleaner—Run the vacuum cleaner in at rated voltage (61 %) and frequency (61

Hz) with filters in place for 1 h.

10.1.1.1 Preconditioning Rotating Agitator

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.