ASTM D2369-07

(Test Method)Standard Test Method for Volatile Content of Coatings

Standard Test Method for Volatile Content of Coatings

SIGNIFICANCE AND USE

This test method is the procedure of choice for determining volatiles in coatings for the purpose of calculating the volatile organic content in coatings under specified test conditions. The weight percent solids content (nonvolatile matter) may be determined by difference. This information is useful to the paint producer and user and to environmental interests for determining the volatiles emitted by coatings.

SCOPE

1.1 This test method describes a procedure for the determination of the weight percent volatile content of solventborne and waterborne coatings. Test specimens are heated at 110 ±5°C for 60 min.

Note 1 - The coatings used in these round-robin studies represented air-dried, air-dried oxidizing, heat-cured baking systems, and also included multicomponent paint systems.

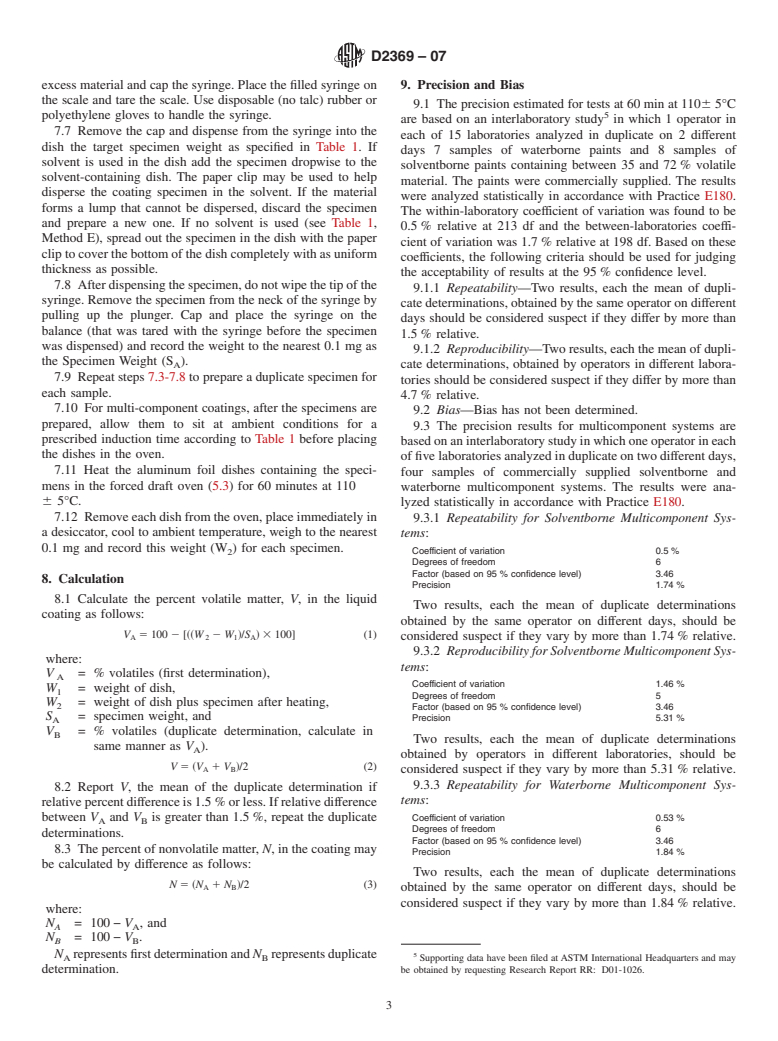

1.2 Sixty minutes at 110 ±5°C is a general purpose test method based on the precision obtained with both solventborne and waterborne coatings (see Section 9).

1.3 This test method is viable for coatings wherein one or more parts may, at ambient conditions, contain liquid coreactants that are volatile until a chemical reaction has occurred with another component of the multi-package system.

Note 2 - Committee D01 has run round-robin studies on volatiles of multicomponent paint systems. The only change in procedure is to premix the weighed components in the correct proportions and allow the specimens to stand at room temperature for 1 h prior to placing them into the oven.

1.4 Test Method D 5095 for Determination of the Nonvolatile Content in Silanes, Siloxanes and Silane-Siloxane Blends Used in Masonry Water Repellent Treatments is the standard method for nonvolatile content of these types of materials.

1.5 Test Methods D 5403 for Volatile Content of Radiation Curable Materials is the standard method for determining nonvolatile content of radiation curable coatings, inks and adhesives.

1.6 Test Method D 6419 for Volatile Content of Sheet-Fed and Coldset Web Offset Printing Inks is the method of choice for these types of printing inks.

1.7 This test method may not be applicable to all types of coatings. Other procedures may be substituted with mutual agreement between the producer and the user.

Note 3 - If unusual decomposition or degradation of the specimen occurs during heating, the actual time and temperature used to cure the coating in practice may be substituted for the time and temperature specified in this test method, subject to mutual agreement between the producer and the user. The U.S. EPA Reference Method 24 specifies 110 ±5°C for 1 h for coatings.

Note 4 - Practice D 3960 for Determining Volatile Organic Compound (VOC) Content of Paints and Related Coatings describes procedures and calculations and provides guidance on selecting test methods to determine VOC content of solventborne and waterborne coatings.

1.8 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2369–07

Standard Test Method for

1

Volatile Content of Coatings

This standard is issued under the fixed designation D2369; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

NOTE 3—If unusual decomposition or degradation of the specimen

1. Scope

occurs during heating, the actual time and temperature used to cure the

1.1 This test method describes a procedure for the determi-

coating in practice may be substituted for the time and temperature

nation of the weight percent volatile content of solventborne

specified in this test method, subject to mutual agreement between the

and waterborne coatings. Test specimens are heated at 110 6

producer and the user. The U.S. EPA Reference Method24 specifies 110

5°C for 60 min. 6 5°C for 1 h for coatings.

NOTE 4—Practice D3960 for Determining Volatile Organic Compound

NOTE 1—The coatings used in these round-robin studies represented

(VOC) Content of Paints and Related Coatings describes procedures and

air-dried, air-dried oxidizing, heat-cured baking systems, and also in-

calculationsandprovidesguidanceonselectingtestmethodstodetermine

cluded multicomponent paint systems.

VOC content of solventborne and waterborne coatings.

1.2 Sixty minutes at 110 6 5°C is a general purpose test

1.8 The values stated in SI units are to be regarded as the

methodbasedontheprecisionobtainedwithbothsolventborne

standard. The values given in parentheses are for information

and waterborne coatings (see Section 9).

only.

1.3 This test method is viable for coatings wherein one or

1.9 This standard does not purport to address all of the

more parts may, at ambient conditions, contain liquid coreac-

safety concerns, if any, associated with its use. It is the

tants that are volatile until a chemical reaction has occurred

responsibility of the user of this standard to establish appro-

with another component of the multi-package system.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

NOTE 2—Committee D01 has run round-robin studies on volatiles of

multicomponentpaintsystems.Theonlychangeinprocedureistopremix

2. Referenced Documents

the weighed components in the correct proportions and allow the

2

specimens to stand at room temperature for 1 h prior to placing them into

2.1 ASTM Standards:

the oven.

D1193 Specification for Reagent Water

1.4 Test Method D5095 for Determination of the Nonvola-

D3925 Practice for Sampling Liquid Paints and Related

tile Content in Silanes, Siloxanes and Silane-Siloxane Blends Pigmented Coatings

Used in Masonry Water Repellent Treatments is the standard

D3960 Practice for Determining Volatile Organic Com-

method for nonvolatile content of these types of materials. pound (VOC) Content of Paints and Related Coatings

1.5 Test Methods D5403 for Volatile Content of Radiation

D5095 Test Method for Determination of the Nonvolatile

Curable Materials is the standard method for determining Content in Silanes, Siloxanes and Silane-Siloxane Blends

nonvolatile content of radiation curable coatings, inks and

Used in Masonry Water Repellent Treatments

adhesives. D5403 Test Methods for Volatile Content of Radiation

1.6 Test Method D6419 for Volatile Content of Sheet-Fed

Curable Materials

and Coldset Web Offset Printing Inks is the method of choice D6419 Test Method for Volatile Content of Sheet-Fed and

for these types of printing inks.

Coldset Web Offset Printing Inks

1.7 This test method may not be applicable to all types of E145 Specification for Gravity-Convection and Forced-

coatings. Other procedures may be substituted with mutual

Ventilation Ovens

agreement between the producer and the user. E180 Practice for Determining the Precision of ASTM

Methods for Analysis and Testing of Industrial and Spe-

cialty Chemicals

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

2

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2007. Published August 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1965. Last previous edition approved in 2004 as D2369–04. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2369-07. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.