ASTM C938-02

(Practice)Standard Practice for Proportioning Grout Mixtures for Preplaced-Aggregate Concrete

Standard Practice for Proportioning Grout Mixtures for Preplaced-Aggregate Concrete

SIGNIFICANCE AND USE

This practice provides a standard procedure for selecting proportions for mixtures of grout to be used at fluid consistency in the production of PA concrete meeting applicable criteria for strength, density, and other properties.

This practice is also useful for determining the composition of grout mixed at fluid consistency and meeting specified requirements for filling voids, cavities, and spaces in rock, foundations, and concrete structures.

SCOPE

1.1 This practice describes the laboratory procedure for selecting proportions for grout mixtures required in the production of preplaced-aggregate (PA) concrete.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C938–02

Standard Practice for

Proportioning Grout Mixtures for Preplaced-Aggregate

1

Concrete

This standard is issued under the fixed designation C938; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C939 Test Method for Flow of Grout for Preplaced-

Aggregate Concrete (Flow Cone Method)

1.1 This practice describes the laboratory procedure for

C940 Test Method for Expansion and Bleeding of Freshly

selecting proportions for grout mixtures required in the pro-

Mixed Grouts for Preplaced-Aggregate Concrete in the

duction of preplaced-aggregate (PA) concrete.

Laboratory

1.2 The values stated in SI units are to be regarded as the

C941 Test Method for Water Retentivity of Grout Mixtures

standard. The values given in parentheses are provided for

for Preplaced-Aggregate Concrete in the Laboratory

information purposes only.

C942 Test Method for Compressive Strength of Grouts for

1.3 This standard does not purport to address all of the

Preplaced-Aggregate Concrete in the Laboratory

safety concerns, if any, associated with its use. It is the

C943 Practice for Making Test Cylinders and Prisms for

responsibility of the user of this standard to establish appro-

Determining Strength and Density of Preplaced-Aggregate

priate safety and health practices and determine the applica-

Concrete in the Laboratory

bility of regulatory limitations prior to use.

3. Summary of Practice

2. Referenced Documents

2

3.1 Grouts at fluid consistency are prepared from one or

2.1 ASTM Standards:

more mixtures of cement, pozzolan, fine aggregate, grout

C39/C39M Test Method for Compressive Strength of Cy-

fluidifier, with or without other chemical admixtures, and

lindrical Concrete Specimens

water, and tested to determine:

C109/C109M Test Method for Compressive Strength of

3.1.1 The properties of the grout, and

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

3.1.2 The properties of PA concrete made with the grout

Specimens)

when the grout is intended for such use.

C150 Specification for Portland Cement

3.2 The procedure and equipment required for mixing this

C185 Test Method for Air Content of Hydraulic Cement

grout are prescribed in this practice.

Mortar

C192/C192M Practice for Making and Curing Concrete

4. Significance and Use

Test Specimens in the Laboratory

4.1 Thispracticeprovidesastandardprocedureforselecting

C618 Specification for Coal Fly Ash and Raw or Calcined

proportionsformixturesofgrouttobeusedatfluidconsistency

Natural Pozzolan for Use in Concrete

in the production of PAconcrete meeting applicable criteria for

C637 Specification for Aggregates for Radiation-Shielding

strength, density, and other properties.

Concrete

4.2 This practice is also useful for determining the compo-

C937 Specification for Grout Fluidifier for Preplaced-

sition of grout mixed at fluid consistency and meeting specified

Aggregate Concrete

requirements for filling voids, cavities, and spaces in rock,

foundations, and concrete structures.

1

This practice is under the jurisdiction of ASTM Committee C09 on Concrete

and Concrete Aggregates and is the direct responsibility of Subcommittee C09.41

5. Apparatus

on Concrete for Radiation Shielding.

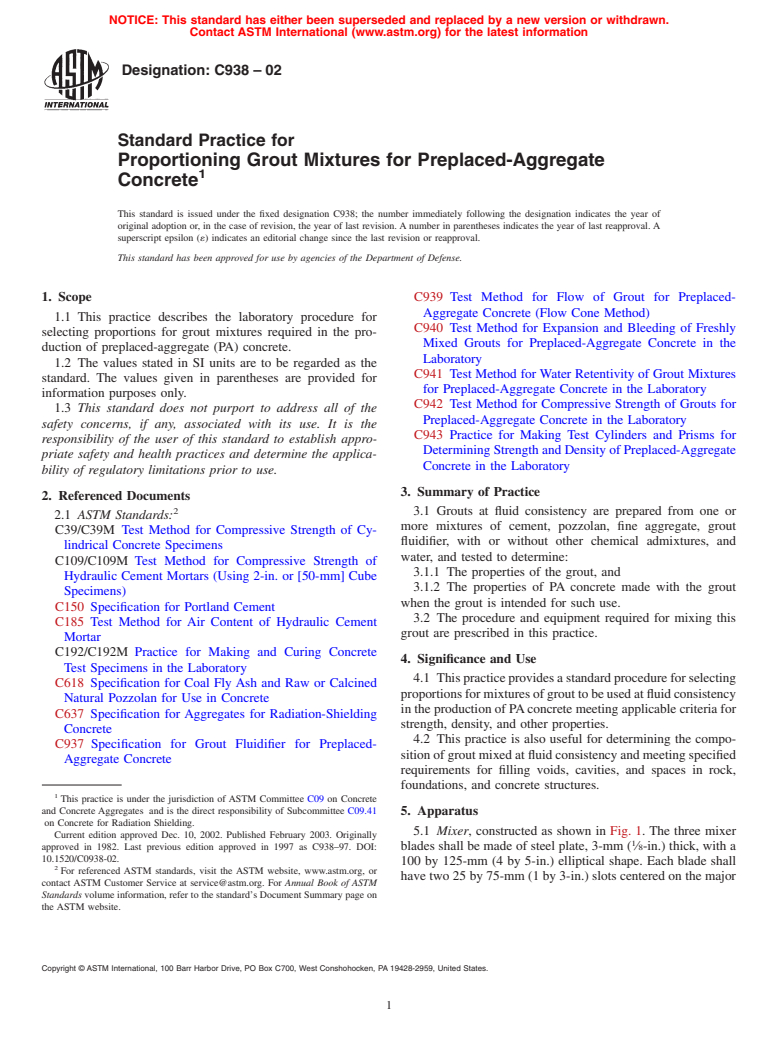

5.1 Mixer, constructed as shown in Fig. 1. The three mixer

Current edition approved Dec. 10, 2002. Published February 2003. Originally

1

approved in 1982. Last previous edition approved in 1997 as C938–97. DOI: blades shall be made of steel plate, 3-mm ( ⁄8-in.) thick, with a

10.1520/C0938-02.

100 by 125-mm (4 by 5-in.) elliptical shape. Each blade shall

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

have two 25 by 75-mm (1 by 3-in.) slots centered on the major

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C938–02

FIG. 1 Grout Mixer

axis, and shall be welded to the shaft at an angle of approxi- 7.2 Agitation of the batch shall be continuous until all

mately 23° with the horizontal in such a way as to force grout samples required from that batch have been drawn.

to the bottom of the mixer during rotation. The mixer blades 7.3 Grout in the mixer shall not be retempered by the

shall be powered to rotate at approximately 275 r/min under addition of water. If mixing water is added in increments to

load. a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.