Electrical equipment and its international standardization

Electrical equipment international standardization

In the process of industrialization, a large variety of technologies have emerged, automatically regulated. When forming the scientific and technological base of the organization, all aspects and parameters were taken into account, which were analyzed on the basis of empirical data. The tendency to build a well-functioning system based on analytical conclusions has remained popular to this day, but there has been a tendency for the globalization of production processes. One of the key issues in this context is the regulation and unification of the existing rules for the production and operation of equipment, not only to simplify the achievement of financial results, but also to increase the safety of the activities carried out. Regulation at the global as well as supranational level occurs thanks to the creation of CEN, ISO standards, with which we will introduce you today.

Machines for underground mines - Safety requirements for hydraulic powered roof supports - Part 1: Support units and general requirements

EN 1804-1:2020

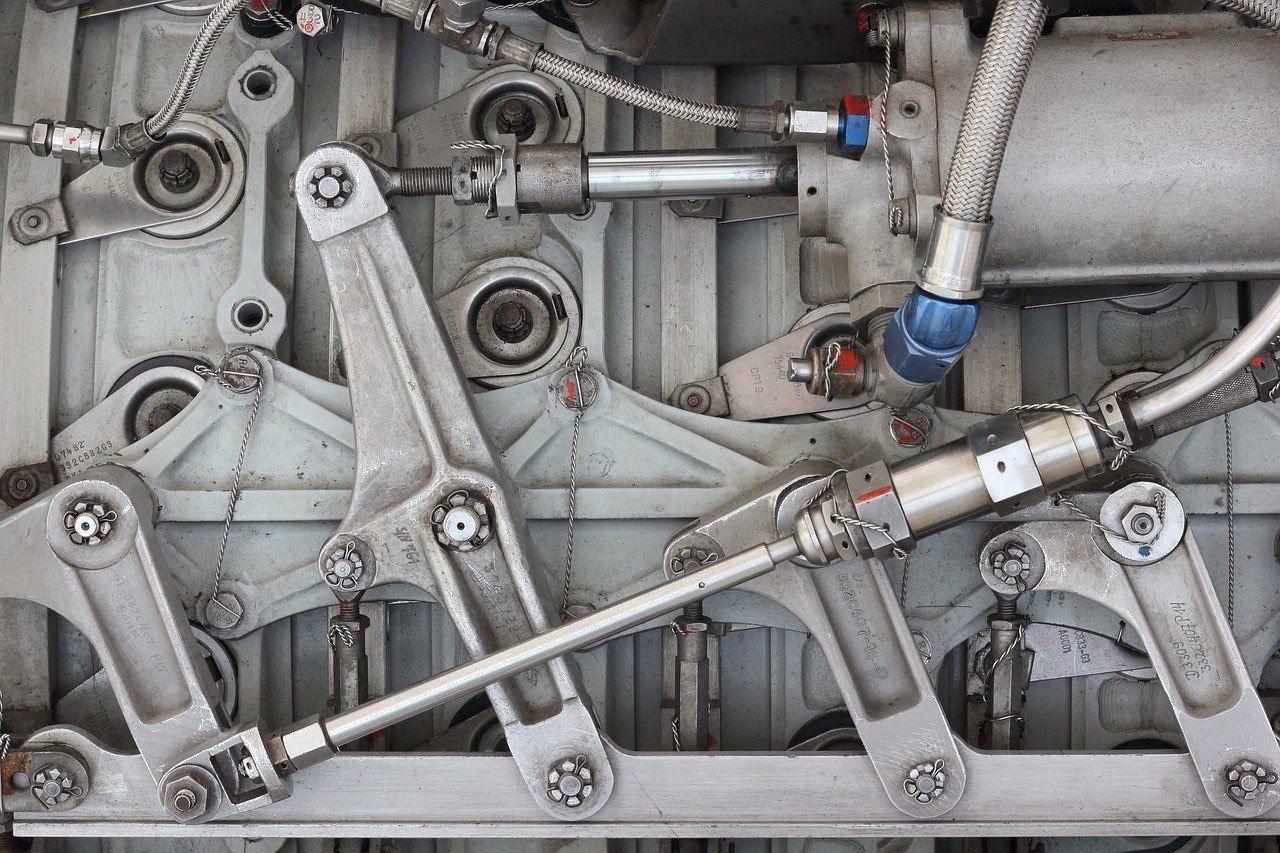

Equipment used in heavy industry not only has a set of subcategories that need to be regulated both locally and globally, but is responsible for the safety of each employee who uses it. That is why it is very important to adhere to the recommendations described in such international standards as EN 1804-1: 2020.

This document stipulates the safety requirements for the use of support units intended by the manufacturer. Examples of support units are: frame supports, chock supports, shield supports, paired frames and push-pull support systems including the components of advancing and anchoring devices which provide support functions. This document excludes fixing elements on the conveyor, coal-winning equipment, power set legs and rams, valves, hydraulic and electro-hydraulic control units, lighting and signalling facilities and other ancillary equipment.

Some components are discussed in other parts of this series of standards. This document applies for support units that are used at ambient temperatures between −10 °C and 60 °C.

This document also applies to support components and support accessories which are provided if the support unit is fitted with stowing equipment. This document identifies and takes account of:

- the hazards that can possibly be induced through operation of the support units;

- the hazardous areas and the operating conditions that can cause any type of hazard;

- the situations that can result in hazards that cause an injury or impair health;

- dangers that can be caused through mine gas and/or flammable dusts.

This document describes methods for reducing these hazards. Clause 4 contains a list of the hazards discussed.

This document does not specify any additional requirements for:

- a particularly corrosive environment;

- risks associated with manufacturing, transport and decommissioning;

- earthquake.

A complete hydraulic powered roof support consists of the support units (EN 1804-1:2020), legs and support rams (EN 1804-2:2020) and the hydraulic and electro hydraulic controls (EN 1804-3:2020). Each part of this multipart document addresses the safety requirements of the components mentioned in the scopes of the respective parts of this multipart series. This document is not applicable to all support units manufactured before the date of its publication.

The use of the above-mentioned equipment is quite narrow-profile, which is why the standard is created specifically for the methods and possibilities of its use. If the aforementioned technologies are applied in your field of activity, we recommend that you think about purchasing this standard and also check if its previous version was used in your production, to be sure that the activity is carried out in step with the times and the latest trends in international markets.

Machines for underground mines - Safety requirements for hydraulic powered roof supports - Part 3: Hydraulic and electro hydraulic control systems

EN 1804-3:2020

Any standard has a certain number of parts that tell about individual cases of their application. Sometimes these parts of the standard can be applied together, but the scope of some companies can get away with a separate document. One of the striking examples of such standards in the industry is EN 1804-3: 2020.

This document specifies the safety requirements for hydraulic and electro hydraulic control devices, including hydraulic valves and their control elements, valve combinations, control systems, pipes and hose assemblies, measuring devices, built-in pressure limiting and check valves in legs and rams and, as well emergency stop, start warning, blocking- and control unit when used as specified by the manufacturer or his authorized representative. Excluded are pressure generators, and internal valves of legs and rams (e.g. leg bottom valves, see EN 1804-2:2020). Some components are dealt with in other parts of this standard.

This document applies to hydraulic and electro hydraulic control devices at ambient temperatures from -10 °C to 60 °C.

This document identifies and takes into account:

- possible hazards which can be caused by the operation of hydraulic and electro hydraulic control devices;

- areas and operating conditions which can create such hazards;

- hazardous situations which can cause injury or can be damaging to health;

- hazards which can be caused by firedamp and/or combustible dusts.

This document describes methods for the reduction of these hazards. A list of significant hazards covered appears in Clause 4.

This document does not specify any additional requirements for:

- use in particularly corrosive environments;

- hazards occurring during construction, transportation, decommissioning;

- earthquakes.

A complete hydraulic powered roof support consists of the support units (EN 1804-1:2020), legs and support rams (EN 1804-2:2020) and the hydraulic and electro hydraulic controls (EN 1804-3:2020). Each part of this multipart document addresses the safety requirements of the components mentioned in the scopes of the respective parts of this multipart series. This document is not applicable to hydraulic and electro hydraulic control systems manufactured before the date of its publication.

Certain parameters of hydraulic technologies mentioned in this standard have a clear technical characteristic that you can check with the one that exists in your enterprise and make sure whether this standard will help you achieve the expected results and reach higher levels of activity.

Food processing machinery - Basic concepts - Part 2: Hygiene and cleanability requirements

EN 1672-2:2020

Hygiene issues have become some of the most popular and frequently discussed in the last two years. Since the issue of human health has undergone strict regulation both by most governments and by standardization institutions, a large list of regulatory documents regulating this area has been created. One of such international standard is EN 1672-2: 2020.

This document specifies common hygiene and cleanability requirements for machinery and machine components used in preparing and processing food for human (see informative Annex A) and, where relevant, animal feed processing to eliminate or minimize the risk of contagion, infection, illness or injury arising from this food to an acceptable level. It identifies the hazards which are significant to the use of such food processing machinery and describes design methods and information for use for the elimination or reduction of these risks.

Additional and/or deviant hygiene and cleanability requirements may be given in applicable C-standards for specific machines or categories of machinery.

Separate hygiene and cleanability requirements are contained in other EU-Directives or -Regulations (see Bibliography).

Examples of hygiene risks and acceptable solutions are given in the informative Annex B.

This document may also be used for machinery, components or other equipment used for other purposes than food preparing or processing, if cleanability is required.

Because of the high requirements on measurement conditions, grade 1 methods are normally not feasible for textile machinery.

Since the description of this document contains several possible areas of its application, we recommend that you familiarize yourself with their list in more detail by clicking on the link to our website. After all, it is possible that this document will become the beginning of a new way of development and achievement of the most productive results for your enterprise.

Machines for underground mines - Safety requirements for hydraulic powered roof supports - Part 2: Power set legs and rams

EN 1804-2:2020

When it comes to technology, mechanical systems and innovation, you should always pay attention to the fact that control of these technologies is somehow carried out by people. That is why a huge number of regulatory acts and documents are being created that not only allow you to master the technique in the fastest way, but also minimize all possible risks during their operation. One such international standard is EN 1804-2: 2020.

This document stipulates the safety requirements for use of legs and rams as intended by the manufacturer. These include legs, support rams and rams, including the mechanical extensions, the inner valves and safety devices, seals, the hydraulic connections (up to the 1st hose line or to the valve of design B, see EN 1804-3:2020) and their lifting points, but excluding protective pipes and gaiters, external valves and hydraulic and electrohydraulic control systems.

Some components are discussed in other parts of this standard series. This document applies for legs, support rams, and cylinders that are used at ambient temperatures between -10 °C and 60 °C. This document identifies and takes account of:

- possible hazards which may be caused by the operation of legs, support rams and rams;

- the hazardous areas and the operating conditions that can cause any type of hazard;

- the situations that can result in hazards that cause an injury or impair health;

- dangers that can be caused through mine gas and/or flammable dusts.

This document describes methods for reducing these hazards. Clause 4 contains a list of the hazards discussed.

This document does not specify any additional requirements for:

- specially corrosive environments;

- risks associated with manufacturing and decommissioning;

- earthquake.

A complete hydraulic powered roof support consists of the support units (EN 1804-1:2020), legs and support rams (EN 1804-2:2020) and the hydraulic and electro hydraulic controls (EN 1804-3:2020). Each part of this multipart document addresses the safety requirements of the components mentioned in the scopes of the respective parts of this multipart series. This document is not applicable to legs and rams manufactured before the date of its publication.

The above documents have clear technological characteristics in which cases and with what equipment it can be used. If you are interested in acquiring an international standard in a similar industry or with a similar type of technology, you can contact our team by clicking on the link to our website and get advice and selection of the international document you need.

Physical processes and their international standardization

Considering the physical processes carried out in manufacturing enterprises as well as in various types of technological organizations, it is necessary to pay attention to safety aspects. After all, security considered from the side of enterprises can be not only financial, but also technical. In the 21st century, the issue of introducing international standards is becoming especially key, since economic systems are more and more exposed to globalization, and therefore technological interaction between countries is becoming more active. If you want your company to develop not only locally, but also globally, the availability of international standards is not a recommendation, but a strict necessity that will enable you to develop at a fast pace with the most productive results.

Categories

- Latest News

- New Arrivals

- Generalities

- Services and Management

- Natural Sciences

- Health Care

- Environment

- Metrology and Measurement

- Testing

- Mechanical Systems

- Manufacturing

- Energy and Heat

- Electrical Engineering

- Electronics

- Telecommunications

- Information Technology

- Image Technology

- Road Vehicles

- Railway Engineering

- Shipbuilding

- Aircraft and Space

- Materials Handling

- Textile and Leather

- Clothing

- Agriculture

- Food technology

- Chemical Technology

- Petroleum

- Metallurgy

- Wood technology

- Rubber and Plastics

- Paint Industries

- Construction

- Civil Engineering

- Military Engineering

- Entertainment