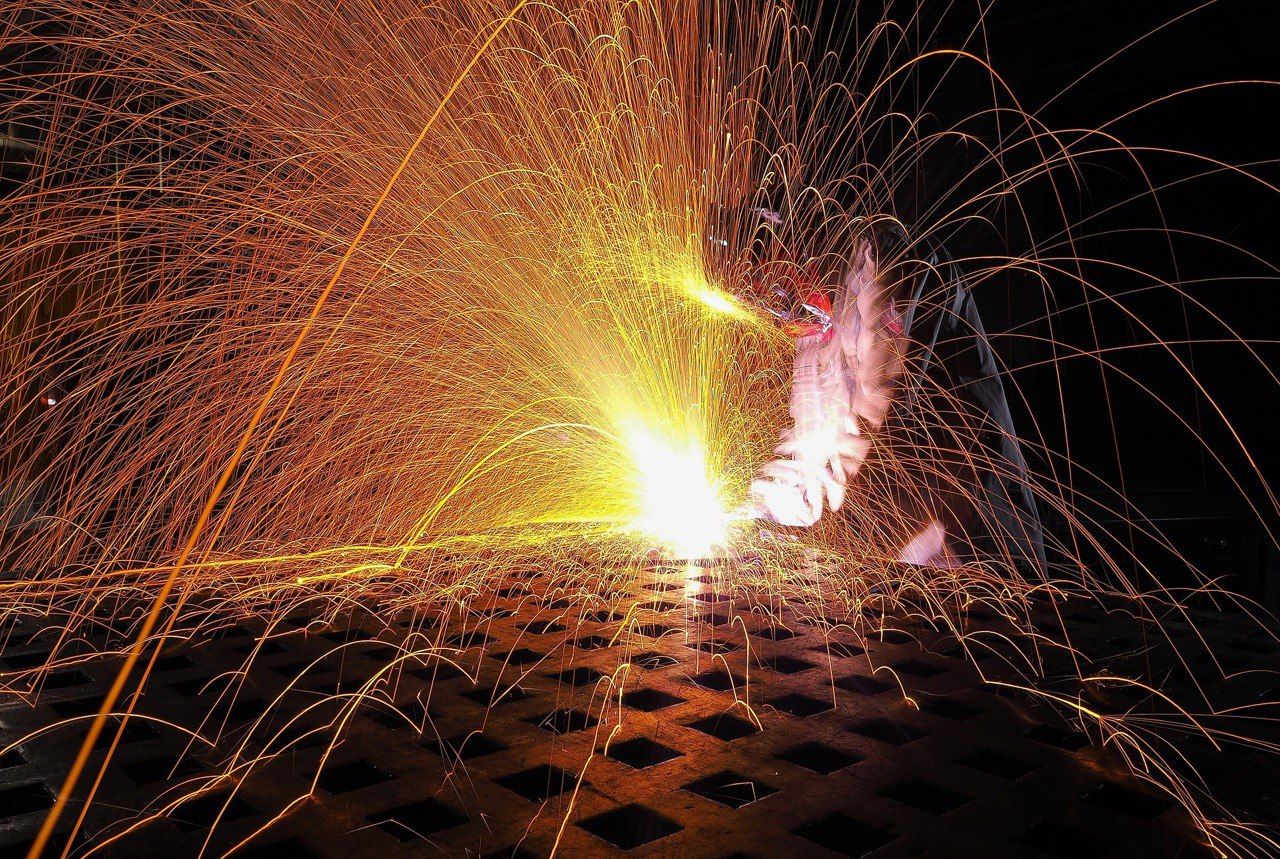

Standards for regulation welding processes and manufacturing engineering

Any technical and production process has a large scientific and technological base. As basically technical parameters are adapted under each production, in the course of realization of business activity at the international level formation of original discrepancies is possible. When it comes to welding processes and production engineering, it is necessary to take into account the fact that the exchange of technologies between countries is becoming more active every day. It is in order for this process to be the most structured that international standards are created. Today we will introduce you to the most popular documents in the field of production engineering and welding processes.

Welding consumables - Wire electrodes and weld deposits for gas shielded metal arc welding of non alloy and fine grain steels - Classification (ISO 14341:2020)

In each stage of production and any other activity there are separate materials and technologies. Separate standards are created for each of them, one of which is EN ISO 14341: 2020 for welding activities.

This document specifies requirements for classification of wire electrodes and weld deposits in the as-welded condition and in the post-weld heat-treated condition for gas shielded metal arc welding of non alloy and fine grain steels with a minimum yield strength of up to 500 MPa or a minimum tensile strength of up to 570 MPa. One wire electrode can be tested and classified with different shielding gases. This document constitutes a combined specification providing classification utilizing a system based upon the yield strength and the average impact energy of 47 J of all-weld metal, or utilizing a system based upon the tensile strength and the average impact energy of 27 J of all-weld metal. a) Clauses and tables which carry the suffix letter "A" are applicable only to wire electrodes classified to the system based on the yield strength and the average impact energy of 47 J of all-weld metal in accordance with this document. b) Clauses and tables which carry the suffix letter "B" are applicable only to wire electrodes classified to the system based on the tensile strength and the average impact energy of 27 J of all-weld metal in accordance with this document. c) Clauses and tables which have neither the suffix letter "A" nor the suffix letter "B" are applicable to all wire electrodes classified in accordance with this document.

This document has a large number of clear technical parameters that you should pay attention to to clarify the possibility of its application in your organization.

Welding consumables - Test methods - Part 2: Preparation of single-run and two-run technique test pieces and specimens in steel (ISO 15792-2:2020)

The quality of the material used in carrying out any activity affects not only the final result but also safety issues. That is why when welding it is very important to consider the quality of the metal that is used. One of the standards that regulates this issue is EN ISO 15792-2: 2020.

Since this document is quite specialized, we recommend that you delve in more detail into the study of its technical parameters, which you can find by clicking on the link above its description.

Welding consumables - Covered electrodes for manual metal arc welding of non-alloy and fine grain steels - Classification (ISO 2560:2020)

Classification of elements used in any activity is the key to the correct structuring of the processes. One of the documents that regulate this issue in welding is EN ISO 2560: 2020.

This document specifies the preparation of butt weld test pieces and specimens. The test pieces and specimens are used to determine the strength and impact properties of welded joints when testing welding consumables with single-run and two-run techniques. This document is applicable to welding consumables for arc welding of steel. This document is not suitable for electro-slag or electro-gas welding.

Since the standard has a certain number of amendments, we recommend clarifying the possibility of its application by a team of professionals.

Friction stir welding - Aluminium - Part 5: Quality and inspection requirements (ISO 25239-5:2020)

Since the key to the success of any product is first and foremost its quality, the standards that govern its inspection are basic in any production. One such document is EN ISO 25239-5: 2020.

This document specifies a method for determining the capability of a manufacturer to use the friction stir welding (FSW) process for the production of products of the specified quality. It specifies quality requirements, but does not assign those requirements to any specific product group. In this document, the term "aluminium" refers to aluminium and its alloys. This document does not apply to friction stir spot welding which is covered by the ISO 18785 series.

If you are interested in this document, you can clarify all the questions you are interested in on our website by contacting the team that will help you pick up all the necessary documents.

Welding consumables - Test methods - Part 1: Preparation of all-weld metal test pieces and specimens in steel, nickel and nickel alloys (ISO 15792-1:2020)

Test methods have always been and will be an important stage in the activities of the organization as they are responsible for the final result of the products. This stage is standardized at the international level by such document as EN ISO 15792-1: 2020.

This document specifies the preparation of test pieces and specimens for all-weld metal tests in steel, nickel and nickel alloys. The test pieces and specimens are used to determine the mechanical properties of all-weld metal where required by consumable classification standards or for other purposes, in arc welding of steel, nickel and nickel alloys. This document is not applicable to single- or two-run welding or fillet welding. For these cases, ISO 15792‑2 and ISO 15792‑3 apply.

So when a document may overlap with similar standards, we recommend that you refine in more detail the specifications that are used in your company to avoid further misapplication of incorrect standards.

Friction stir welding - Aluminium - Part 4: Specification and qualification of welding procedures (ISO 25239-4:2020)

The specification of any product is typical of the modern market, but sometimes it is very difficult to combine different types of products if they are not standardized by a single international system. One of the important documents that carries out this activity is EN ISO 25239-4: 2020.

This document specifies the requirements for the specification and qualification of welding procedures for the friction stir welding (FSW) of aluminium. In this document, the term "aluminium" refers to aluminium and its alloys. This document does not apply to friction stir spot welding which is covered by the ISO 18785 series. NOTE Service requirements, materials or manufacturing conditions can require more comprehensive testing than is specified in this document.

If you do not understand some points in the description of this standard, you can ask them to our team, which will greatly facilitate for you the selection of standards that structure the process of your business.

Production standards as a guarantee of high quality products

Standardization of production processes has always been a key aspect in the high quality of final products. As the number of goods and services in the modern global market increases significantly, so does competition. In order not only to survive in today's markets but also to be successful in terms of promoting their positions, you need to be aware of the latest updates of international standards in the field where you operate. If you want to take a leading position in the industry of your activity, stay with iTeh.

References:

Categories

- Latest News

- New Arrivals

- Generalities

- Services and Management

- Natural Sciences

- Health Care

- Environment

- Metrology and Measurement

- Testing

- Mechanical Systems

- Fluid Systems

- Manufacturing

- Energy and Heat

- Electrical Engineering

- Electronics

- Telecommunications

- Information Technology

- Image Technology

- Precision Mechanics

- Road Vehicles

- Railway Engineering

- Shipbuilding

- Aircraft and Space

- Materials Handling

- Packaging

- Textile and Leather

- Clothing

- Agriculture

- Food technology

- Chemical Technology

- Mining and Minerals

- Petroleum

- Metallurgy

- Wood technology

- Glass and Ceramics

- Rubber and Plastics

- Paper Technology

- Paint Industries

- Construction

- Civil Engineering

- Military Engineering

- Entertainment