Standardization of electrical equipment

Electrical equipment standardization

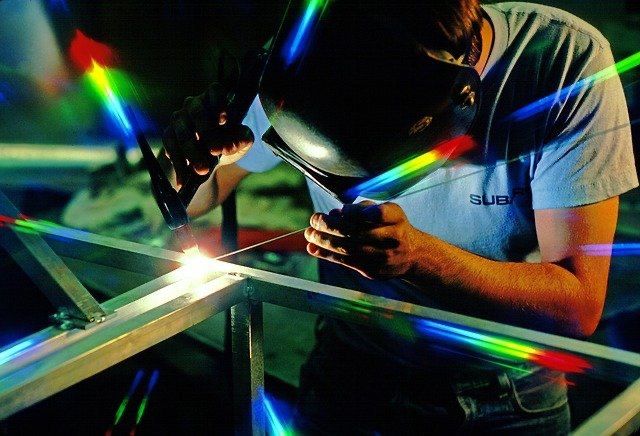

The post-industrial stage of the development of society has led to a huge number of innovations that both complement each other and neutralize the actions of the previous ones. Nevertheless, technologies created in the industrial stage are used to this day in large-scale industries as well as in small and medium-sized businesses. When it comes to production processes, it is necessary to understand that despite a large number of innovative technologies, human labor has not been completely replaced, which is why safety issues remain relevant to this day. To regulate industrial systems as well as the technologies used in them, such as, for example, welding processes, special international standards have been created that determine the norms and rules for interaction with technologies, as well as the correct step-by-step recommendations for establishing the entire process. Today we will introduce you to some of the most significant international standards in this area.

Quality requirements for fusion welding of metallic materials - Part 3: Standard quality requirements (ISO 3834-3:2021)

EN ISO 3834-3:2021

The use of metal material processing is one of the main subjects for regulation by international standards. Since this activity directly involves the intervention of human labor and is responsible for safety issues, it is necessary to pay attention to the availability of an appropriate scientific and technological base, namely standards such as EN ISO 3834-3: 2021.

ISO 3834-3:2021 defines standard quality requirements for fusion welding of metallic materials both in workshops and at field installation sites.

Since the number of companies in this industry is increasing every year, therefore, the competitiveness is increasing. If initially, when the issue of quality was still relative, now its minimum chapels are regulated by international documents. If you want to take the leading positions in your field of activity, we recommend adhering to international standards and their recommendations.

Quality requirements for fusion welding of metallic materials - Part 2: Comprehensive quality requirements (ISO 3834-2:2021)

EN ISO 3834-2:2021

Each international document has several parts that regulate the stage-by-stage processing of a certain material. In this case, we are talking about metal. The next part to the previous standard, which can be a great addition to expand the possibilities of your operations, is EN ISO 3834-2: 2021.

ISO 3834-2:2021 defines comprehensive quality requirements for fusion welding of metallic materials both in workshops and at field installation sites.

These international documents are quite similar. If you decide to choose one of them for your enterprise, we strongly recommend consulting with specialists in the field of selection in international documents in order to choose the most suitable standard specifically for your business.

Quality requirements for fusion welding of metallic materials - Part 4: Elementary quality requirements (ISO 3834-4:2021)

EN ISO 3834-4:2021

For any activity today, a huge variation of technologies and mechanisms is used, which is why standards are created not only for global systems, but also for individual details of the technologies used. One of these standards for equipment implemented in welding activities is EN ISO 3834-4: 2021.

This document defines elementary quality requirements for fusion welding of metallic materials both in workshops and at field installation sites.

Since this document is suitable for a large number of organic electrical systems, it can be widely used in various types of production, both large and medium. It is if your field of activity comes into contact with the aforementioned technologies and equipment, we recommend that you familiarize yourself with this document in more detail by clicking on the link to our website attached to the standard in the description.

Forestry and gardening machinery - Noise test code for portable hand-held machines with internal combustion engine - Engineering method (Grade 2 accuracy) (ISO 22868:2021)

EN ISO 22868:2021

Despite the fact that at first glance, garden equipment is not associated with an object for regulation by international regulatory legal acts, nevertheless, the various types of technology on the basis of which the equipment was created give the right to prescribe recommendations for its operation in order to avoid mechanical damage during its use. One of such international standard is EN ISO 22868: 2021.

2020-12-02 JF: ISO/CS confirmed that the changes addressing HAS assessment will be incorporated in the final ISO draft (editorial changes).

2020-11-18 JF: information on the resolution of LoC HAS assessment has been provided to ISO/CS. 2020-10-09 Lack of compliance assessment at 2nd FV has been resolved by CEN/TC 144.

This international standard has been subjected to many changes and additions, which is why if you used previous versions, we strongly recommend that you stay up to date with updates in order for new recommendations and technological amendments to minimize possible risks.

Non-destructive testing - Characteristics of focal spots in industrial X-ray systems for use in non-destructive testing - Part 2: Pinhole camera radiographic method

EN 12543-2:2021

Radiation as well as a large number of side effects from applied innovations increases every day, thereby exerting a certain dose of influence on human lives. Since in a post-industrial society the influence of technology is less and less subject to control, a large number of international standards are being created to correct this situation, one of which is EN 12543-2: 2021.

This document specifies a method for the measurement of effective focal spot dimensions above 0,1 mm of X-ray systems up to and including 1000 kV tube voltage by means of the pinhole camera method with digital evaluation. The tube voltage applied for this measurement is restricted to 200 kV for visual film evaluation and may be selected higher than 200 kV if digital detectors are used.

The imaging quality and the resolution of X-ray images depend highly on the characteristics of the effective focal spot, in particular the size and the two dimensional intensity distribution as seen from the detector plane. This method compared to the others in the EN 12543 series allows to obtain an image of the focal spot and to see the state of it (e.g. cratering of the anode).

This test method provides instructions for determining the effective size (dimensions) of standard (macro focal spots) and mini focal spots of industrial X-ray tubes. This determination is based on the measurement of an image of a focal spot that has been radiographically recorded with a "pinhole" technique and evaluated with a digital method. For the characterization of commercial X-ray tube types (i.e. for advertising or trade) it is advised that the specific FS (Focal spot) values of Annex A are used.

Technical characteristics give possibility to clarify the area of usage of the document. It is very important to pay attention to such a kind of parameters in order to increase the productivity of your activity in the most appropriate and profitable way.

International standards for achieving new goals

Each of the annotations to the documents mentioned gives a rough understanding of a specific subcategory of the whole area in which it can be applied. In order to select an international standard that will be useful specifically for your organization, you need to check the technological parameters in the annotations and technological parameters of the equipment used in your production. If you have additional questions, you can follow the link to our website and contact a team of specialists who will be happy to advise you on the selection of the required standard.

Categories

- Latest News

- New Arrivals

- Generalities

- Services and Management

- Health Care

- Environment

- Metrology and Measurement

- Testing

- Mechanical Systems

- Manufacturing

- Electrical Engineering

- Electronics

- Telecommunications

- Information Technology

- Road Vehicles

- Railway Engineering

- Materials Handling

- Agriculture

- Food technology

- Petroleum

- Metallurgy

- Wood technology

- Construction

- Entertainment